Method for preparing concrete water-reducing agent by grafting compound side chain of polycarboxylic acid modified acid halide

A technology of concrete water reducing agent and polycarboxylic acid, which is applied in the field of composite side chain type concrete water reducing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

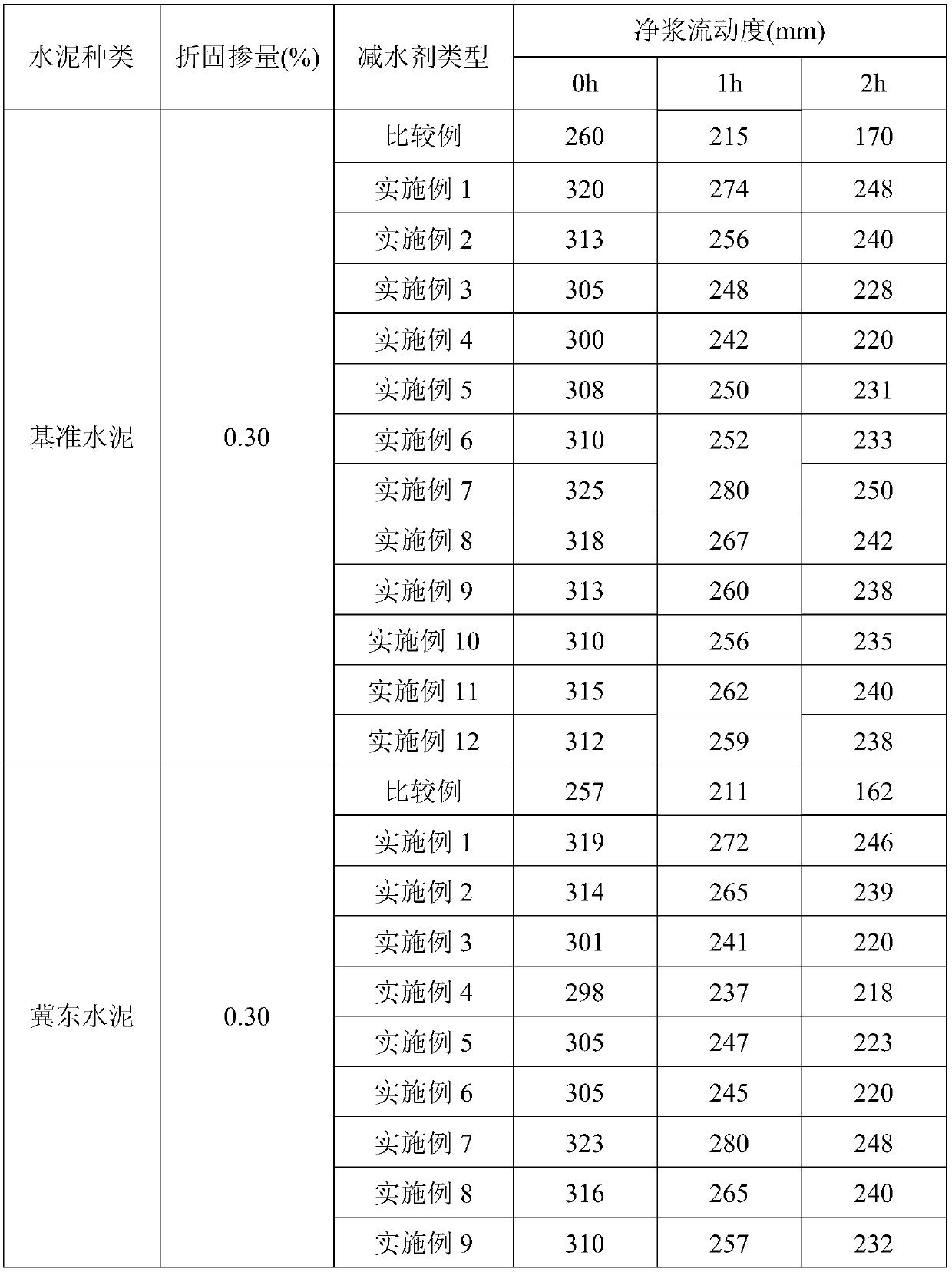

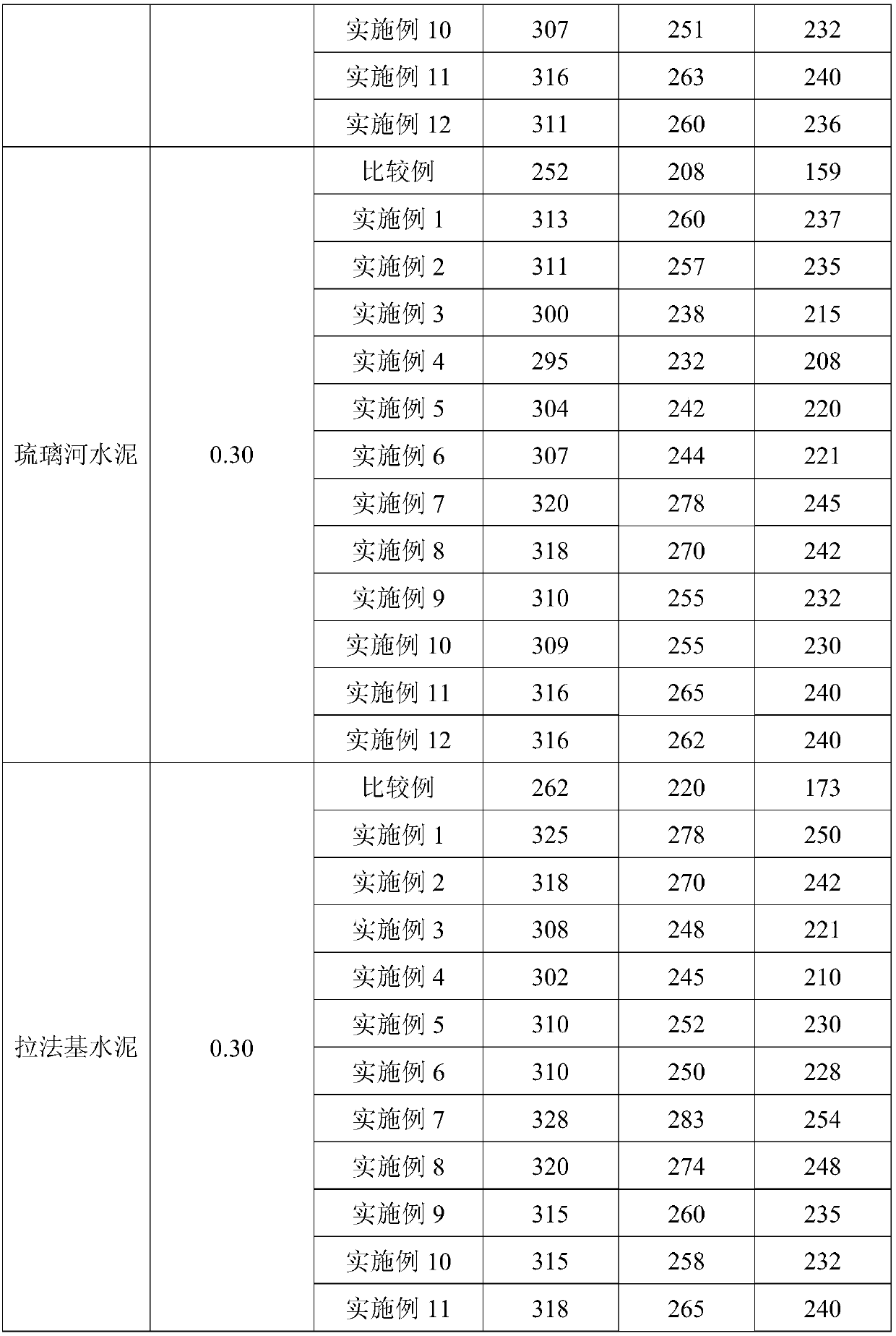

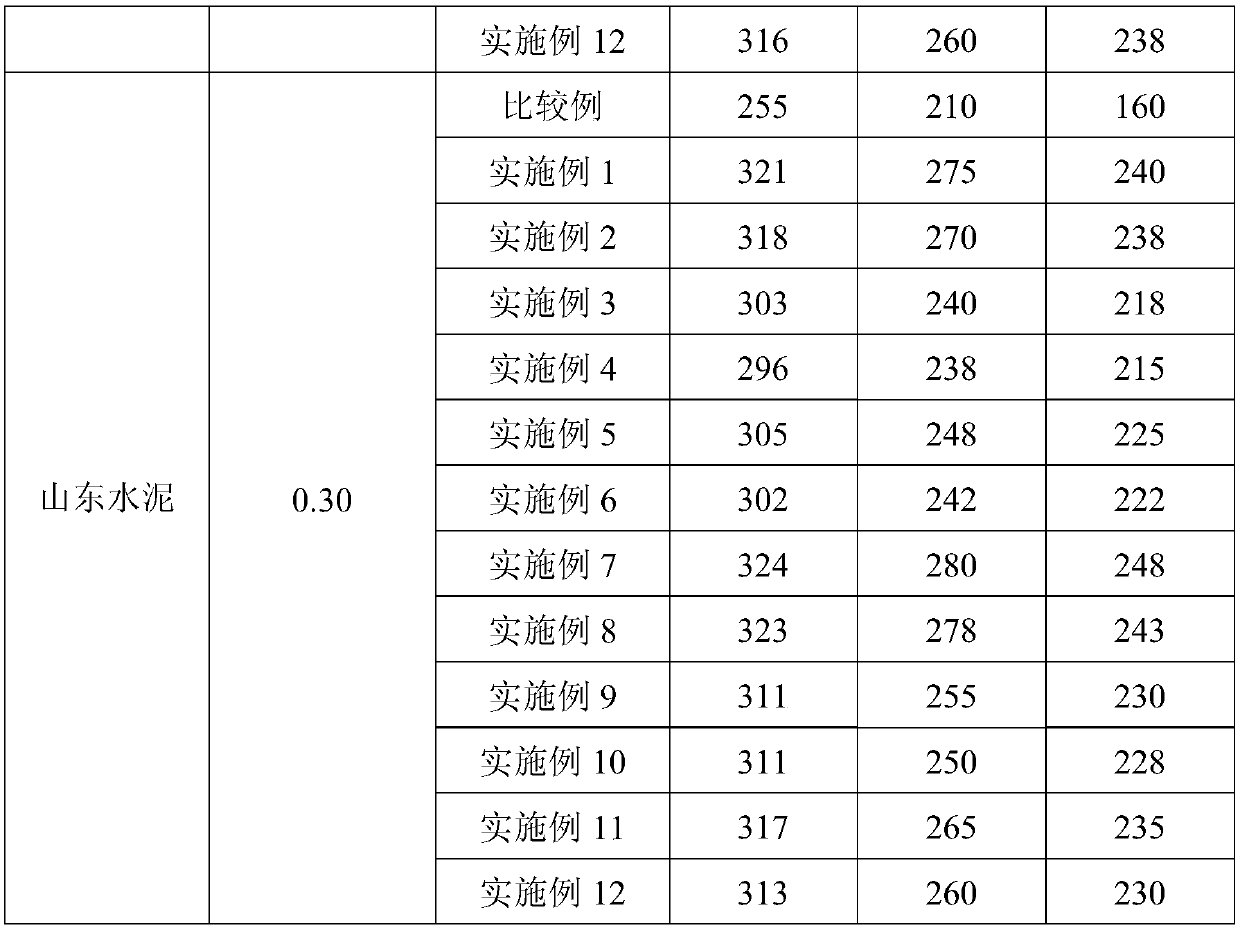

Examples

Embodiment 1

[0029] First, add 7.21g of acrylic acid, 10.81g of water, 0.96g of mercaptopropionic acid, and 7.94g of a 12% sodium persulfate aqueous solution to the reactor in sequence, and the stirring time between each addition is 11 minutes, and the temperature is raised to 68°C. Polymerization reaction, reacted for 6 hours, and obtained the aqueous solution of the polycarboxylic acid main chain; vacuumized the obtained aqueous solution of the polycarboxylic acid main chain to remove the moisture in the system, added 45.45g of 1,4-dioxane, stirred for 11 minutes, and cooled in an ice-water bath. Add 4.16g of thionyl bromide dropwise to the reactor within 0.9 hours, continue to heat up to 50°C and react at a constant temperature for 4 hours, and simultaneously use 20.2g of potassium hydroxide solution with a mass fraction of 25% to absorb the gas produced by the reaction, to obtain Polycarboxylic acid-acyl bromide solution; 29.91g methacryloyloxyethyltrimethylammonium chloride and 0.48g i...

Embodiment 2

[0031] After storing the 30% concrete water reducer solution obtained in Example 1 at 6° C. for 30 days, its implementation effect was measured.

Embodiment 3

[0033] First add 4.8g acrylic acid, 3.87g fumaric acid, 8.67g water, 2.16g sodium allyl sulfonate, 8.56g mass fraction in the reactor successively and be the ammonium persulfate aqueous solution of 8%, and every feeding interval stirring time After 8 minutes, the temperature was raised to 55°C for polymerization reaction, and the reaction was carried out for 7 hours to obtain an aqueous solution of polycarboxylic acid main chain; the obtained aqueous solution of polycarboxylic acid main chain was evacuated to remove moisture in the system, and 16.99 g of dimethylformamide was added, and stirred In 18 minutes, add 8.31g of thionyl bromide dropwise to the reactor within 0.5 hours under ice-water bath conditions, continue to heat up to 40°C and react at a constant temperature for 4.5 hours. The gas generated by the reaction is the polycarboxylic acid-acyl bromide solution; 48.8g of acryloyloxyethyltrimethylammonium chloride and 0.84g of cyclohexanol are added to another reactor, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com