Method for synthesizing polycarboxylate high-performance water reducer by copolymerization reaction of benzenesulfonate ester active macromonomer

A technology of active macromonomer and benzene sulfonate, which is applied in the field of polycarboxylate high-performance water reducer and benzenesulfonate polycarboxylate high-performance water reducer for concrete to reduce activation energy and broaden research ideas and development direction, the effect of mild and stable polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

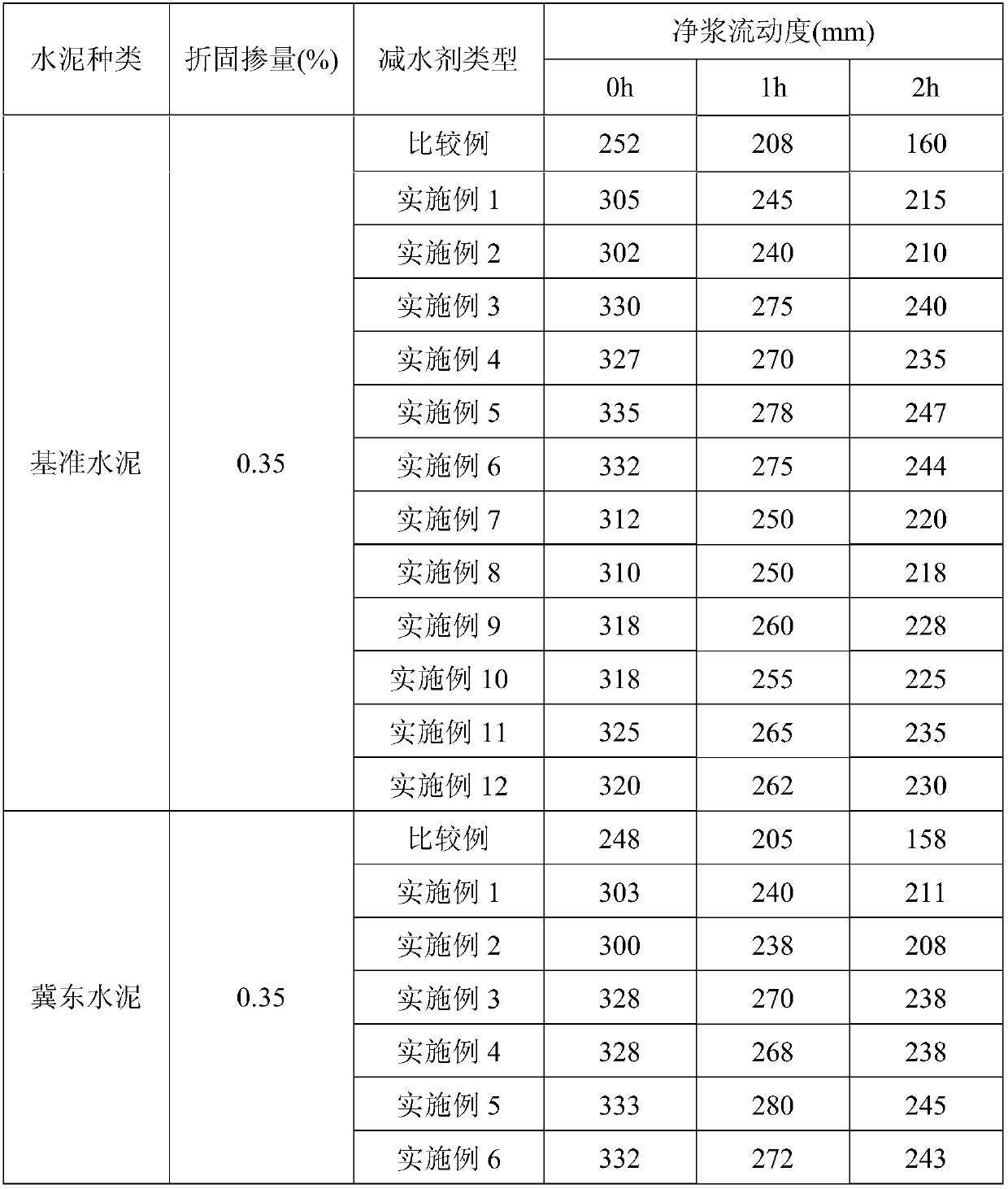

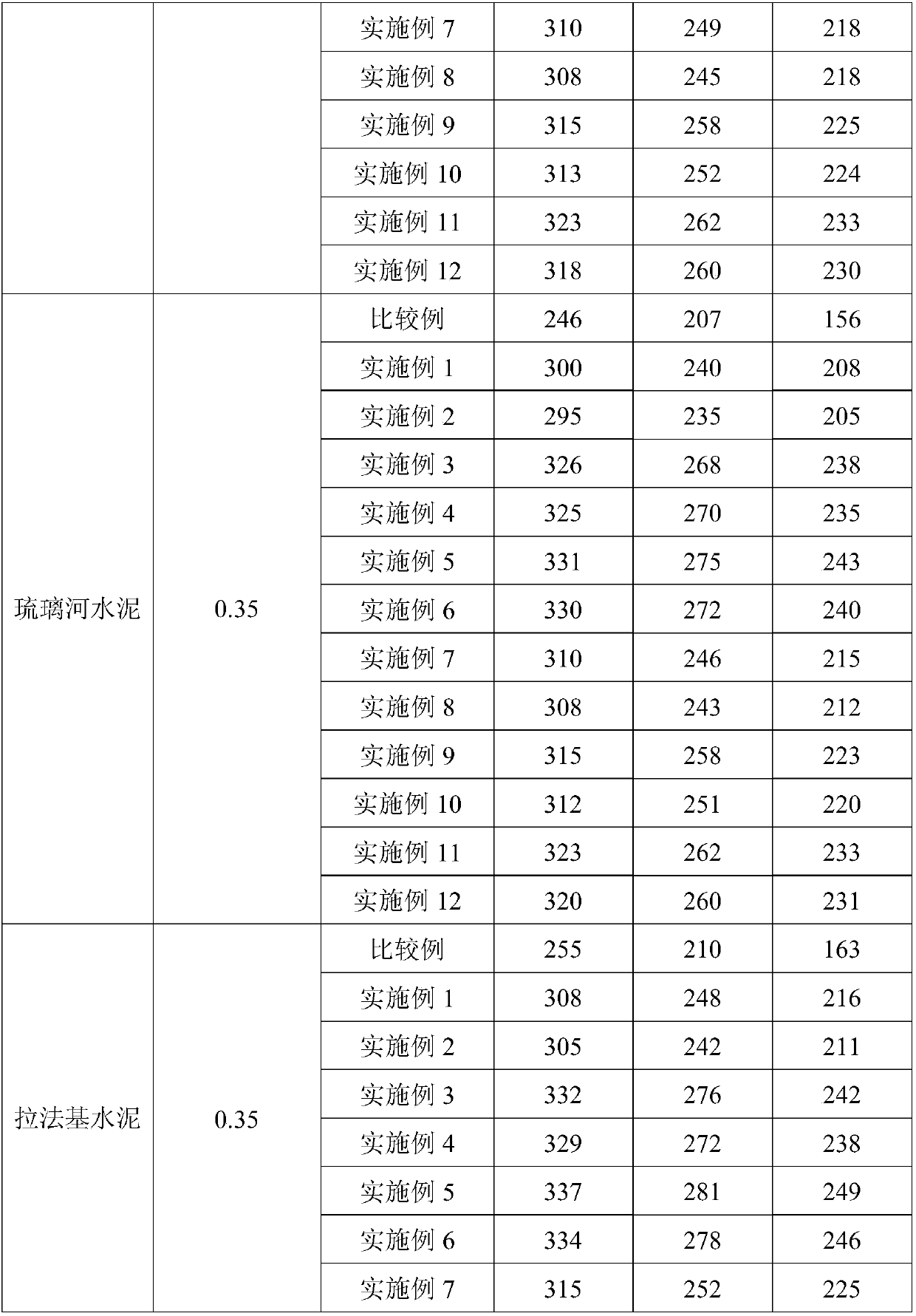

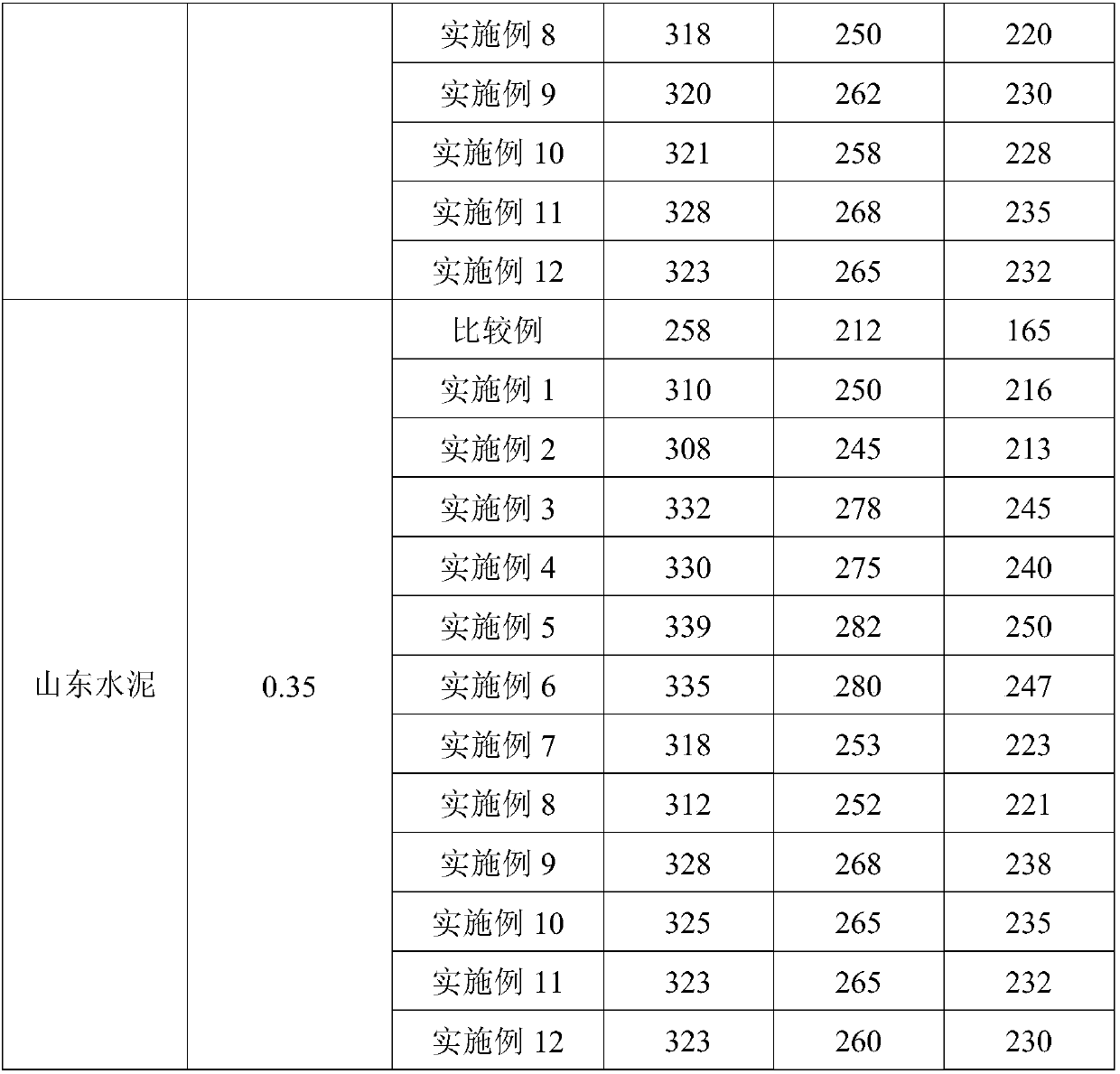

Examples

Embodiment 1

[0029] First, add 4.45g potassium p-styrenesulfonate and 32.06g 1,4-dioxane to the reactor successively, stir for 8 minutes, add 3.57g thionyl chloride dropwise to the reactor within 1 hour under ice-water bath conditions, and control After constant temperature reaction at 2°C for 16 hours, add 3.78g of ice water and 40.08g of toluene in sequence, vacuum-dry the extracted organic phase at 80°C to constant weight to obtain p-styrenesulfonyl chloride; Add dimethyl diallyl ammonium chloride and 1g cyclohexanol into another reactor, then add 775.54g water to prepare an aqueous solution with a mass concentration of 6%. The reactor is filled with nitrogen and repeatedly deoxygenated 4 times and then sealed for 18 minutes. , add 0.16g of cerium ammonium nitrate, stir for 28 minutes until it is evenly mixed, continue to heat up to 10°C for polymerization reaction, and react for 16 hours to obtain a long-chain hydroxyl-terminated cation aqueous solution; vacuumize the obtained long-chai...

Embodiment 2

[0031] The polycarboxylate superplasticizer solution with a mass fraction of 30% obtained in Example 1 was stored at 7° C. for 30 days, and its implementation effect was measured.

Embodiment 3

[0033] First, add 4.12g sodium p-styrene sulfonate, 14.43g dimethyl sulfoxide successively in the reactor, stir for 15 minutes, add 3.09g thionyl chloride dropwise to the reactor in 0.6 hours under ice-water bath conditions, control the temperature at After 13 hours of constant temperature reaction at 3.5°C, 2.81g of ice water and 25.26g of toluene were added in sequence, and the extracted organic phase was vacuum-dried at 60°C to constant weight to obtain p-styrenesulfonyl chloride; 40.69g of trimethyl Allyl ammonium chloride and 0.37g n-butanol are added in another reactor, then add 472.22g water and be mixed with the aqueous solution that mass concentration is 8%, the reactor is filled with nitrogen repeatedly 4 times and deoxygenated and sealed after 20 minutes, add 0.89g ammonium cerium sulfate, stir for 10 minutes until it is mixed evenly, continue to heat up to 35°C for polymerization reaction, and react for 13 hours to obtain an aqueous solution of long-chain hydroxyl-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com