Process method for automobile bottom plate powder coating

A technology of powder coating and process method, which is applied in the direction of powder coating, device for coating liquid on the surface, coating, etc. It can solve the problems of complex curing conditions, low spraying quality, long spraying cycle, etc., and achieve short curing time , low preparation cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

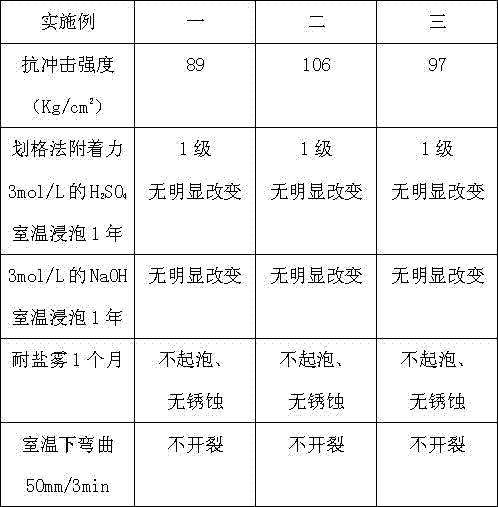

Examples

Embodiment 1

[0017] A kind of technological method of powder coating of automobile floor that the present invention proposes, comprises the following steps:

[0018] S1, prepare raw materials, including novolak epoxy resin 26wt%, carboxyl polyester resin 22wt%, epoxy acrylate 25wt%, pigment 5wt%, cast stone powder 12wt%, graphene oxide 5wt% and the processing aid of the remainder, wherein Processing aids include curing agent, accelerator, degassing agent, anti-wear agent, leveling agent, antioxidant and dispersant. After mixing the above raw materials evenly, they are melted and extruded by a twin-screw extruder, and finally pulverized and ground Finely made powder coating with a particle size of 300μm;

[0019] S2. After sandblasting and roughening the car floor, place it at a temperature of 95°C, then perform spray degreasing and hot water washing in sequence, each time for 25 minutes, and after cleaning, place it at a temperature of 123°C and dry for 15 minutes , to pre-treat the car f...

Embodiment 2

[0023] A kind of technological method of powder coating of automobile floor that the present invention proposes, comprises the following steps:

[0024] S1, prepare raw materials, including novolak epoxy resin 24wt%, carboxyl polyester resin 20wt%, epoxy acrylate 21wt%, pigment 3wt%, cast stone powder 10wt%, graphene oxide 3wt% and the processing aid of the remainder, wherein Processing aids include curing agent, accelerator, degassing agent, anti-wear agent, leveling agent, antioxidant and dispersant. After mixing the above raw materials evenly, they are melted and extruded by a twin-screw extruder, and finally pulverized and ground Fine powder coating with a particle size of 100 μm;

[0025] S2. After sandblasting and roughening the car floor, place it at a temperature of 88°C, then perform spray degreasing and hot water washing in sequence, each time for 22 minutes, and after cleaning, place it at a temperature of 115°C and dry for 12 minutes , to pre-treat the car floor; ...

Embodiment 3

[0029] A kind of technological method of powder coating of automobile floor that the present invention proposes, comprises the following steps:

[0030] S1, prepare raw materials, including novolac epoxy resin 22wt%, carboxyl polyester resin 17wt%, epoxy acrylate 19wt%, pigment 1wt%, cast stone powder 8wt%, graphene oxide 1wt% and the rest of the processing aid, wherein Processing aids include curing agent, accelerator, degassing agent, anti-wear agent, leveling agent, antioxidant and dispersant. After mixing the above raw materials evenly, they are melted and extruded by a twin-screw extruder, and finally pulverized and ground Finely made powder coating with a particle size of 1 μm;

[0031] S2. After sandblasting and roughening the car floor, place it at a temperature of 80°C, then perform spray degreasing and hot water washing in sequence, each time for 18 minutes, and after cleaning, place it at a temperature of 108°C and dry for 8 minutes , to pre-treat the car floor;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com