Preparation method of resistive screen hardening liquid

A technology of adding hard liquid and resistive screen, applied in the direction of coating, can solve the problem of short life and achieve the effect of prolonging the service life, less environmental pollution and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

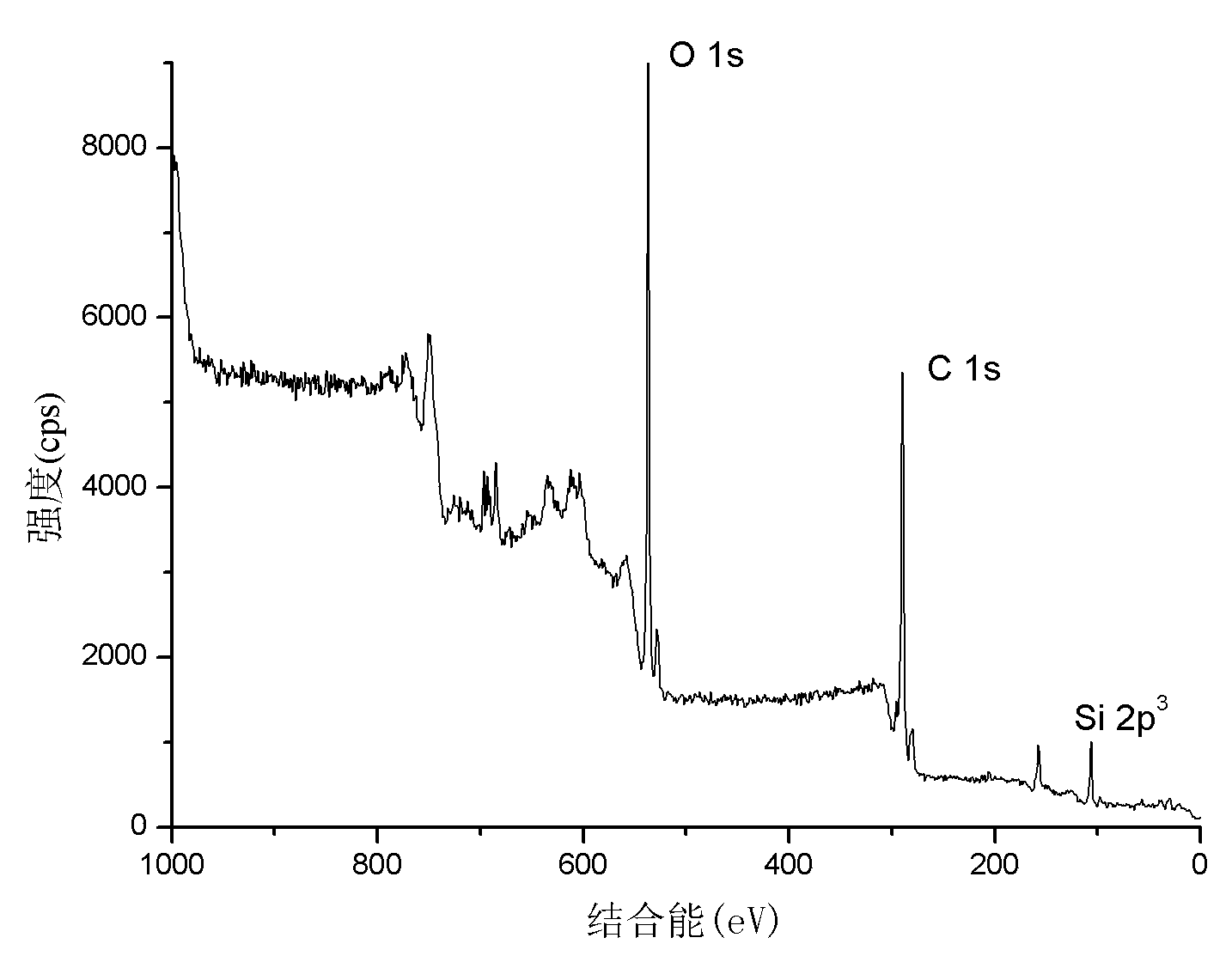

[0033] Take 50g of methyltrimethoxysilane, 50g of γ-glycidoxypropyltrimethoxysilane (KH-560), and 10g of phenyltriethoxysilane and mix them evenly. Mix 30g of methanol, 2g of acetylacetone and 50g of water, add the resulting mixed solution into the uniformly mixed silane coupling agent, and at the same time add 20g of ethylene glycol diglycidyl ether, and hydrolyze at a constant temperature of 30°C for 24h. Take 40g of ethylene glycol methyl ether, 66.7g of ethylene glycol butyl ether, 200g of isopropanol, 13.3g of n-butanol, and 40g of acetone, and mix them evenly. Filter the hydrolyzed product to remove impurities, mix 200g of the hydrolyzed product with 300g of solvent, add 2.5g of leveling agent BYK-320, 2.5g of defoamer FS-31, and mix well to obtain the resistance screen hardened liquid. The hardening solution was dip-coated on the surface of the PET film and cured at 70°C for 30 minutes. The resulting film was observed by SEM, as figure 1 As shown, the surface particle...

Embodiment 2

[0035] Take 20g of methyltriethoxysilane, 20g of 3-glycidyloxypropylmethyldiethoxysilane, and 4g of diphenyldimethoxysilane and mix them uniformly. Mix 12g of methanol, 0.8g of acetylacetone and 20g of water, add the resulting mixed solution into the well-mixed silane coupling agent, add 8g of ethylene glycol diglycidyl ether at the same time, and hydrolyze at a constant temperature of 30°C for 24h. Take 20 g of ethylene glycol methyl ether, 33.3 g of ethylene glycol butyl ether, 100 g of isopropanol, 6.67 g of n-butanol, and 20 g of acetone, and mix them evenly. Filter the hydrolyzed product to remove impurities, mix 70g of the hydrolyzed product with 105g of solvent, add 2.5g of leveling agent BYK-320, 2.5g of defoamer FSO-100, and mix well to obtain the resistance screen hardened liquid. Using a Samsung i900 resistive screen mobile phone, remove the outer screen film of the resistive screen, apply the hardened liquid evenly on the outer screen by rolling coating, cure at 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com