UV-cured silica gel for lead sealing

A wire sealing and silicone gel technology, which is applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as wire sealing problems, reduced bonding strength, and product failure

- Summary

- Abstract

- Description

- Claims

- Application Information

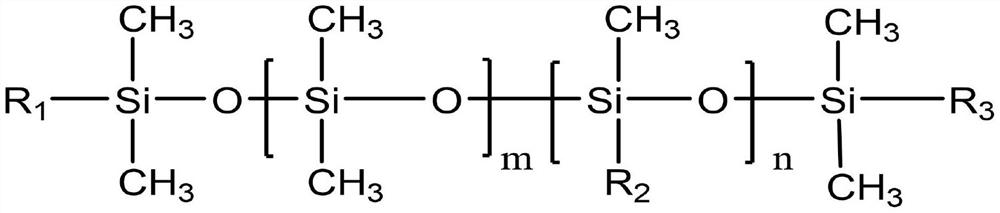

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

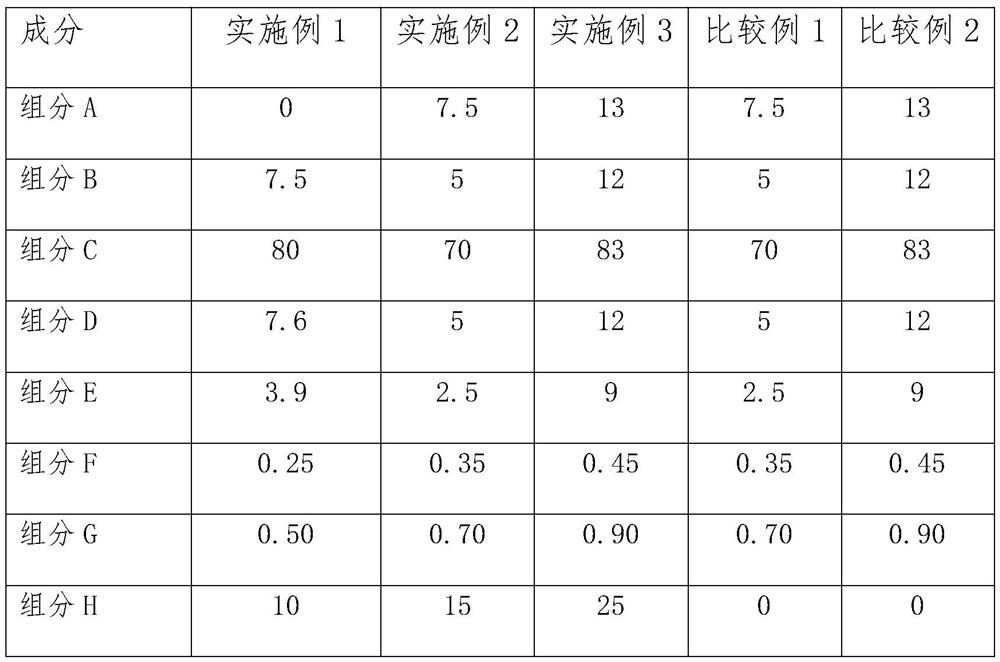

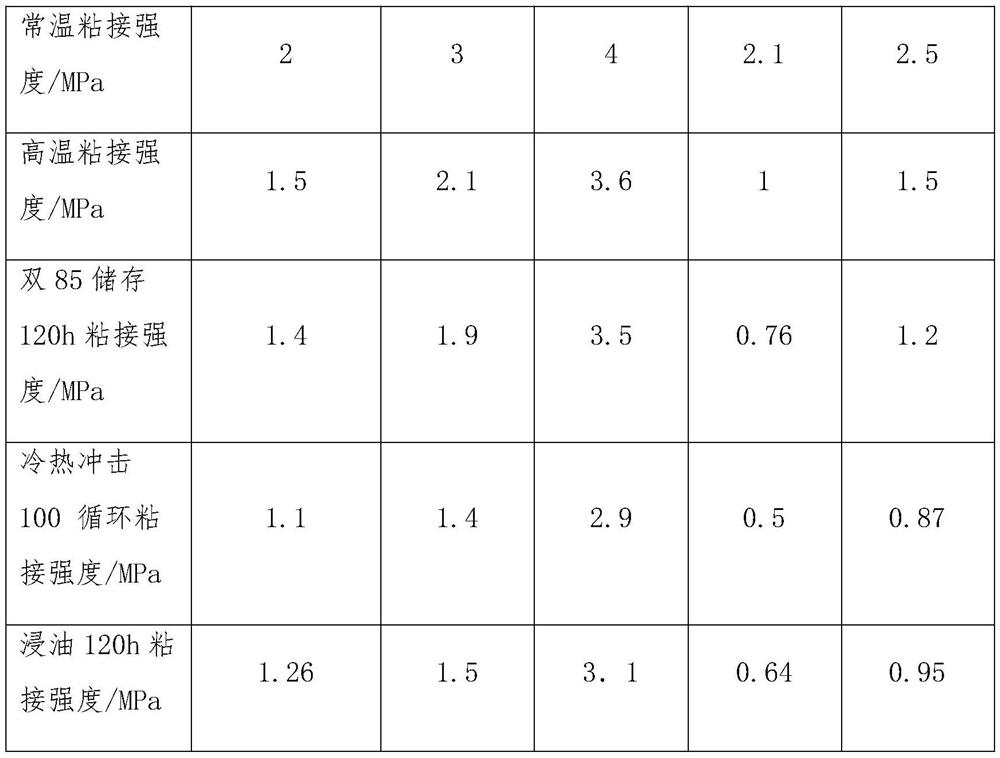

Embodiment 1

[0033] Example 1: Get 7.5 parts of component B, 80 parts of component C, 7.6 parts of component D, 3.9 parts of component E, and 0.50 part of component G into a double planetary mixer, then divide 10 parts of component H into 3 times Add, keep the stirring speed at 40rpm, the dispersion speed at 1200rpm, stir and mix for 20min to form the base material, add 0.25 parts of component F into the double planetary mixer under the condition of avoiding light, then keep the stirring speed at 25rpm, the dispersion speed at 1800rpm, and stir and mix for 15min , keep the vacuum degree in the double planetary mixer at -0.1Mpa, perform 10min defoaming treatment, and package and store the defoamed glue under dark conditions.

Embodiment 2

[0034] Example 2: Add 7.5 parts of component A, 5 parts of component B, 70 parts of component C, 5 parts of component D, 2.5 parts of component E, and 0.70 parts of component G into a double planetary mixer, and then add 15 parts of Add component H in 3 times, keep the stirring speed at 40rpm, disperse at 1200rpm, stir and mix for 20min to form the base material, add 0.35 parts of component F into the double planetary mixer under the condition of avoiding light, then keep the stirring speed at 25rpm, and disperse at 25rpm. Stir and mix at 1800rpm for 15min, keep the vacuum degree in the double planetary mixer at -0.1Mpa, perform defoaming treatment for 10min, and package and store the defoamed glue under dark conditions.

Embodiment 3

[0035] Example three: get 13 parts of component A, 12 parts of component B, 83 parts of component C, 12 parts of component D, 9 parts of component E, and 0.90 part of component G into a double planetary mixer, and then add 25 parts of Add component H in 3 times, keep stirring speed at 40rpm, disperse at 1200rpm, stir and mix for 20min to form the base material, add 0.45 parts of component F into the double planetary mixer under light-proof conditions, then keep stirring at 25rpm, disperse at Stir and mix at 1800rpm for 15min, keep the vacuum degree in the double planetary mixer at -0.1Mpa, perform defoaming treatment for 10min, and package and store the defoamed glue under dark conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com