Material with negative thermal expansion performance and preparation method thereof

A negative thermal expansion and mold technology, applied in the field of negative thermal expansion materials, can solve the problems of insufficient negative thermal expansion performance and weakened NTE effect, and achieve the effects of enhanced negative thermal expansion, widened negative thermal expansion temperature zone, and enhanced ferroelectricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a material with strong negative thermal expansion and a preparation method thereof. The chemical formula of the material with strong negative thermal expansion described in this embodiment is (1-x)PbTiO 3 -xBiCoO 3 (0.0≤x≤1.0); the specific steps of the preparation method are:

[0042] Step 1: According to PbO:TiO 2 : Bi 2 o 3 :Co 3 o 4 The ratio of the amount of the substance of the sample is 6(1-x): 6(1-x): 3x: 2x batching, mixing, followed by pretreatment, and heat preservation at a temperature of 300-800°C for 0.5-10h;

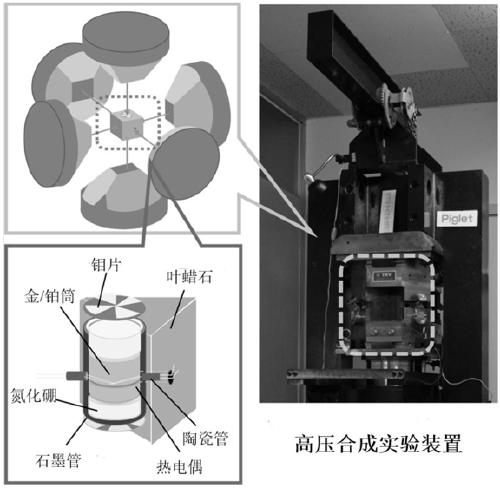

[0043] The second step: put the mixed sample into an Au or Pt cylinder crucible with a diameter of Φ (2-10mm) and a height of h (2-10mm), and add KClO 4 As an oxidant, the Au / Pt cylinder crucible containing the mixed sample was then placed into a closed mold including pyrophyllite, BN, graphite, Mo flakes, ceramic tubes, and thermocouples;

[0044] Step 3: Place the mold in such as figure 1 In the high-pressure synt...

Embodiment 2

[0051] This embodiment provides a material with strong negative thermal expansion and a preparation method thereof. The chemical formula of the material with strong negative thermal expansion described in this embodiment is (1-x)PbTiO 3 -xBiCoO 3 (0.0≤x≤1.0); the specific steps of the preparation method are:

[0052] Step 1: According to PbO:TiO 2 : Bi 2 o 3 :Co 3 o 4 The ratio of the amount of the substance of the sample is 6(1-x): 6(1-x): 3x: 2x batching, mixing, followed by pretreatment, and heat preservation at a temperature of 300-800°C for 0.5-10h;

[0053] The second step: put the mixed sample into an Au or Pt cylinder crucible with a diameter of Φ (2-10mm) and a height of h (2-10mm), and add KClO 4 As an oxidant, the Au / Pt cylinder crucible containing the mixed sample was then placed into a closed mold including pyrophyllite, BN, graphite, Mo flakes, ceramic tubes, and thermocouples;

[0054] Step 3: Place the mold in such as figure 1 In the high-pressure synt...

Embodiment 3

[0061] This embodiment provides a material with strong negative thermal expansion and a preparation method thereof. The chemical formula of the material with strong negative thermal expansion described in this embodiment is (1-x)PbTiO 3 -xBiCoO 3 (0.0≤x≤1.0); the specific steps of the preparation method are:

[0062] Step 1: According to PbO:TiO 2 : Bi 2 o 3 :Co 3 o 4 The ratio of the amount of the substance of the sample is 6(1-x): 6(1-x): 3x: 2x batching, mixing, followed by pretreatment, and heat preservation at a temperature of 300-800°C for 0.5-10h;

[0063] The second step: put the mixed sample into an Au or Pt cylinder crucible with a diameter of Φ (2-10mm) and a height of h (2-10mm), and add KClO 4 As an oxidant, the Au / Pt cylinder crucible containing the mixed sample was then placed into a closed mold including pyrophyllite, BN, graphite, Mo flakes, ceramic tubes, and thermocouples;

[0064] Step 3: Put the mold in the high-pressure synthesis equipment, and at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com