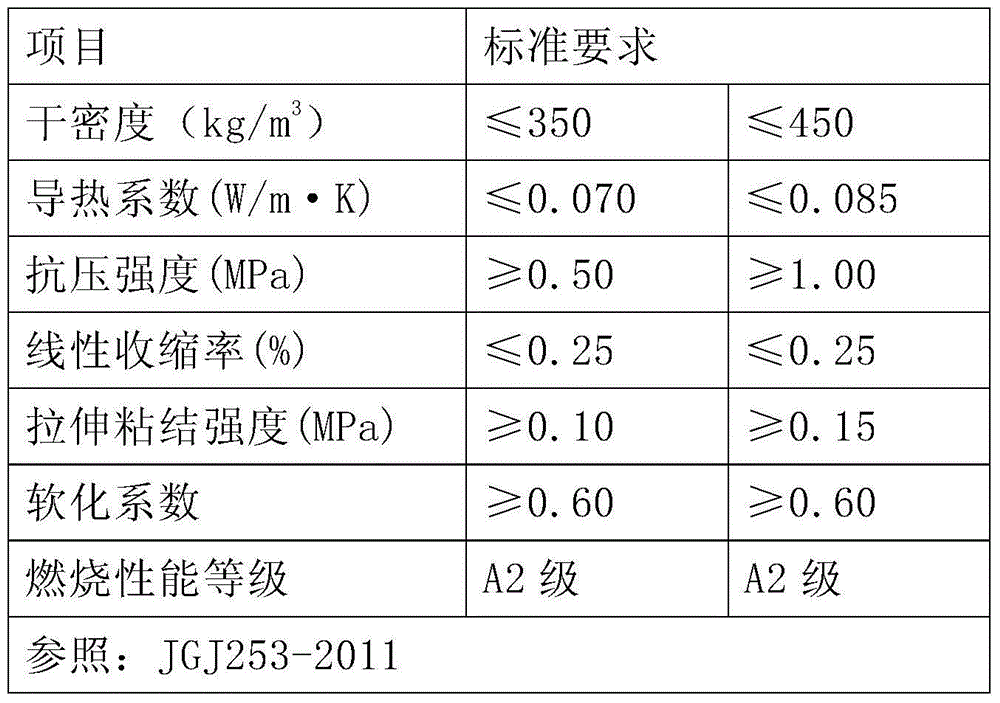

A1-grade fireproof insulation mortar and preparation method thereof

A technology of fire-proof and heat-insulating mortar and fiber, which is applied in the field of building energy-saving materials, can solve problems such as poor fire performance, and achieve the effect of improving comprehensive performance and construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

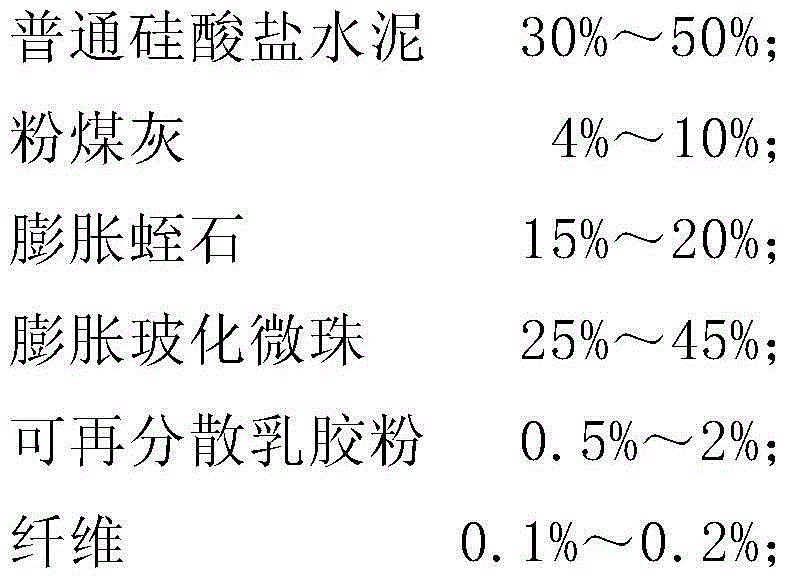

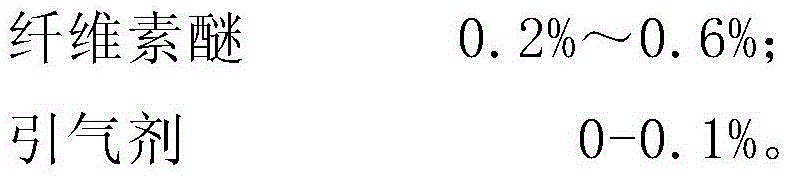

Method used

Image

Examples

Embodiment 1

[0034] Ordinary Portland cement 33.5%, fly ash 5.2%, expanded vermiculite 17.38%, expanded vitrified microbeads 41.5%, fiber 0.18%, redispersible latex powder 1.6%, cellulose ether 0.56%, air-entraining agent 0.08 %.

[0035] The label of ordinary Portland cement is P.O42.5, and the bulk density of expanded vermiculite is 100kg / m 3 , the bulk density of expanded vitrified microbeads is 80kg / m 3 , The thermal conductivity is 0.042W / m·K. The fiber is wood fiber with a length of 10 mm, and the air-entraining agent is a fatty acid salt air-entraining agent.

[0036] Its preparation method is as follows:

[0037] After weighing according to the weight ratio, mix ordinary Portland cement, fly ash, expanded vermiculite with pre-mixed redispersible latex powder, cellulose ether, fiber, air-entraining agent, etc. through a gravity-free mixer, and then Add expanded vitrified microspheres and mix until uniform to obtain the desired product.

[0038] The performance results obtained ...

Embodiment 2

[0040] Ordinary Portland cement 38.2%, fly ash 7.2%, expanded vermiculite 15.62%, expanded vitrified microbeads 37.1%, fiber 0.16%, redispersible latex powder 1.2%, cellulose ether 0.46%, air-entraining agent 0.06 %.

[0041] The label of ordinary Portland cement is P.O42.5, and the bulk density of expanded vermiculite is 100kg / m 3 , the bulk density of expanded vitrified microbeads is 80kg / m 3 , The thermal conductivity is 0.042W / m·K. The fiber is wood fiber with a length of 10 mm, and the air-entraining agent is a fatty acid salt air-entraining agent.

[0042] Its preparation method is as follows:

[0043] After weighing according to the weight ratio, mix ordinary Portland cement, fly ash, expanded vermiculite with pre-mixed redispersible latex powder, cellulose ether, fiber, air-entraining agent, etc. through a gravity-free mixer, and then Add expanded vitrified microspheres and mix until uniform to obtain the desired product.

[0044] The performance results obtained ...

Embodiment 3

[0046] Ordinary Portland cement 41.1%, fly ash 8.2%, expanded vermiculite 19.06%, expanded vitrified microbeads 30.2%, fiber 0.14%, redispersible latex powder 0.9%, cellulose ether 0.36%, air-entraining agent: 0.04%.

[0047] The label of ordinary Portland cement is P.O42.5, and the bulk density of expanded vermiculite is 100kg / m 3 , the bulk density of expanded vitrified microbeads is 80kg / m 3, The thermal conductivity is 0.042W / m·K. The fiber is wood fiber with a length of 10 mm, and the air-entraining agent is a fatty acid salt air-entraining agent.

[0048] Its preparation method is as follows:

[0049] After weighing according to the weight ratio, mix ordinary salt cement, fly ash, expanded vermiculite with pre-mixed redispersible latex powder, cellulose ether, fiber, air-entraining agent, etc. through a gravity-free mixer, and then add The expanded vitrified microbeads are mixed until uniform to obtain the desired product.

[0050] The performance results obtained f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com