Low density heat conduction pouring sealant and preparation method thereof

A thermally conductive potting, low-density technology, applied in the field of potting glue, can solve the problems of limiting wide application and increasing battery weight, and achieve the effect of reducing battery weight, low density, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

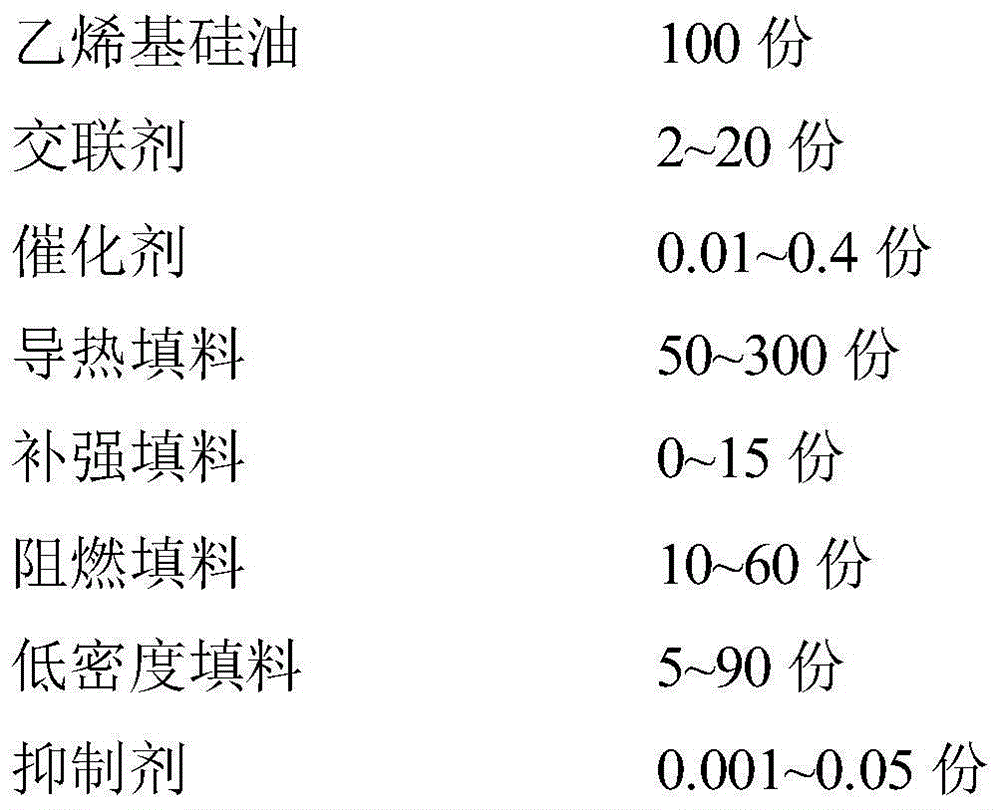

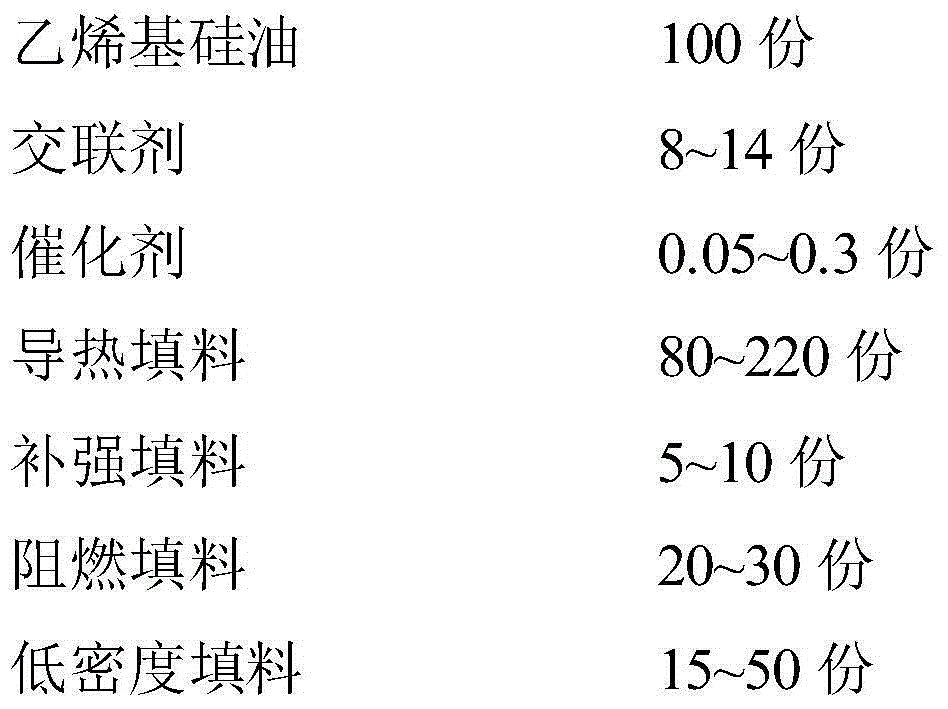

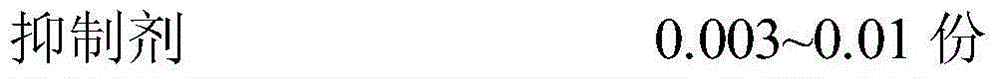

Method used

Image

Examples

Embodiment 1

[0044] A low-density thermally conductive potting compound, comprising the following components by weight:

[0045] Vinyl silicone oil

100 copies

Hydrogen silicone oil (crosslinking agent)

12 copies

Chloroplatinic acid (catalyst)

0.4 parts

Aluminum nitride (thermally conductive filler)

220 copies

Calcium carbonate (reinforcing filler)

5 copies

Magnesium hydroxide (flame retardant filler)

30 copies

Hollow glass microspheres (low density filler)

50 copies

Polyvinylsiloxane (Inhibitor)

0.01 part

[0046] The preparation process of the low-density heat-conducting potting compound is as follows:

[0047] (1) Prepare the base material

[0048] At room temperature of 25°C, add 100 parts of vinyl silicone oil into the vacuum kneader and start the kneader; then mix 220 parts of aluminum nitride, 30 parts of magnesium hydroxide, 5 parts of calcium carbonate and 50 parts of hollow glass micro...

Embodiment 2

[0054] A low-density thermally conductive potting compound, comprising the following components by weight:

[0055] Vinyl silicone oil

100 copies

Hydrogen silicone oil (crosslinking agent)

8 servings

Chloroplatinic acid-isopropanol (catalyst)

0.01 part

Boron nitride (thermally conductive filler)

180 copies

Fumed silica (reinforcing filler)

8 servings

Aluminum hydroxide (flame retardant filler)

20 copies

Hollow glass microspheres (low density filler)

38 copies

Maleate (inhibitor)

0.008 copies

[0056] The preparation process of the low-density heat-conducting potting compound is as follows:

[0057] (1) Prepare the base material

[0058] At room temperature of 25°C, add 100 parts of vinyl silicone oil into the vacuum kneader and start the kneader; then 180 parts of boron nitride, 20 parts of aluminum hydroxide, 8 parts of fumed silica and 38 parts of hollow glass microspheres Unifo...

Embodiment 3

[0064] A low-density thermally conductive potting compound, comprising the following components by weight:

[0065] Vinyl silicone oil

100 copies

Hydrogen silicone oil (crosslinking agent)

14 copies

Custer Catalyst (Catalyst)

0.3 parts

Boron nitride (thermally conductive filler)

200 copies

Fumed silica (reinforcing filler)

10 copies

Zinc borate (flame retardant filler)

30 copies

Hollow phenolic microspheres (low density filler)

45 copies

1-ethynyl-1-cyclohexanol (inhibitor)

0.003 copies

[0066] The preparation process of the low-density heat-conducting potting compound is as follows:

[0067] (1) Prepare the base material

[0068] At room temperature of 25°C, add 100 parts of vinyl silicone oil into the vacuum kneader and start the kneader; then add 200 parts of boron nitride, 30 parts of zinc borate, 10 parts of fumed silica and 45 parts of hollow phenolic microspheres Uniformly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com