Core-shell type emulsion particle emulsion for enhancing rubber and preparation method thereof

A technology of rubber reinforcement and latex particles, which is applied in the field of core-shell latex particle emulsion and its preparation, can solve the problems of increasing the density of rubber materials and losing light weight of polymer materials, reducing the density, eliminating friction and hysteresis in the interface area, light color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Preparation of nuclear emulsion

[0026] According to the formula in Table 1, add emulsifier sodium dodecylsulfonate (SDS) / alkylphenol polyoxyethylene ether series (OP-10) and deionized water into the reaction kettle, stir to make the emulsifier mix evenly, add Styrene monomer (St) and divinylbenzene (DVB), stir to emulsify the monomer, heat up to 70°C and stabilize for 10 minutes, dissolve the initiator potassium persulfate (KPS) in deionized water and add. Maintain the temperature while adding the pH regulator sodium bicarbonate (NaHCO 3 ), adjust the pH=7; react for 8 hours, at this time, the residual odor of the monomer basically disappears, and the polymerization is stopped.

[0027] raw material

mass (g)

Monomer: St

Polyene crosslinking monomer: DVB

Initiator: KPS

Emulsifier: OP-10

SDS

h 2 o

52.5

10.5

0.53

1.75

3.5

210

[0028] The second step: preparation of core-shell latex part...

Embodiment 2

[0039] Step 1: Preparation of nuclear emulsion

[0040] The preparation method is the same as in Example 1, and the raw materials are fed according to the ratio of raw materials in Table 4.

[0041] raw material

[0042] The second step: preparation of core-shell latex particle emulsion

[0043] The preparation method is the same as in Example 1, and the raw materials are fed according to the ratio of raw materials in Table 5.

[0044] raw material

[0045] The core-shell latex particles with a particle size of 60-90nm and a solid content of 21% were prepared through the above two steps. The ratio of the core layer to the shell layer monomer is 5:2.

[0046] Addition of core-shell latex filler to styrene butadiene rubber

[0047] Adding method is the same as embodiment 1.

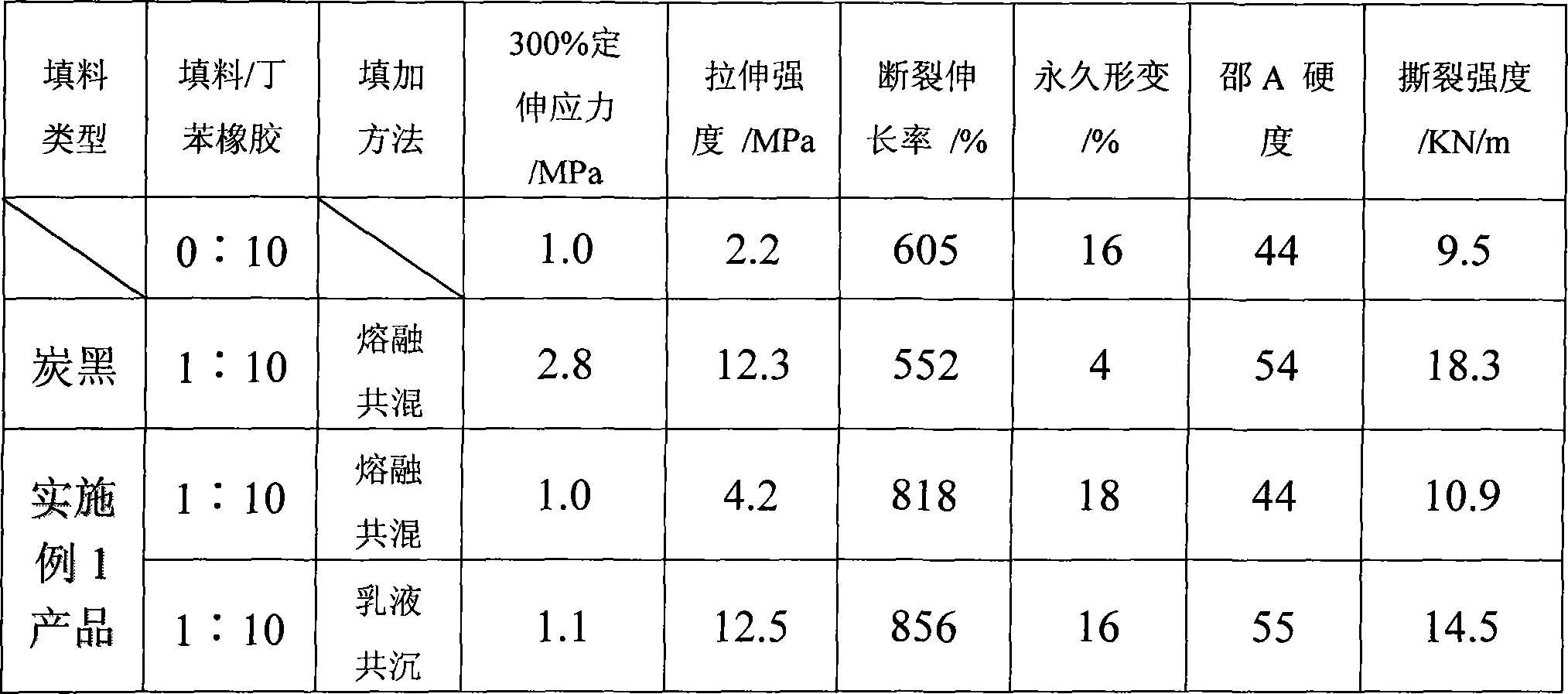

[0048] Table 6 Comparison of mechanical properties of styrene-butadiene rubber obtained by different fillers and filling methods

[0049]

[0050]

[0051] It can be se...

Embodiment 3

[0053] Step 1: Preparation of nuclear emulsion

[0054] According to the formula of table 7, add emulsifier MS-1 and deionized water (H 2 O), stirring to make the emulsifier mix evenly, adding monomers α-methylstyrene (α-MS) and acrylonitrile (AN) and cross-linking agent DVB in a certain proportion, stirring to emulsify the monomers, and stabilize after heating to 85°C After 10 minutes, the initiator ammonium persulfate (APS) was dissolved in deionized water and then added. Maintain the temperature while adding the pH regulator sodium bicarbonate (NaHCO 3 ), adjust the pH=7; react for 6 hours, at this time, the residual odor of the monomer basically disappears, and the polymerization is stopped.

[0055] name

mass (g)

Monomer: α-MS

AN

Polyene crosslinking monomer: DVB

Initiator: APS

Emulsifier: MS-1

h 2 o

30

20

10

0.6

4.5

110

[0056] The second step: preparation of core-shell latex particle emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com