Mixed soft magnetic powder for metal magnetic powder core

A technology of soft magnetic powder and mixed powder, applied in the field of mixed soft magnetic powder, can solve the problems of deterioration of magnetic properties, affecting dimensional accuracy, etc., and achieve the effects of suppressing the deterioration of magnetic properties, improving dimensional accuracy, and preventing the reduction of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

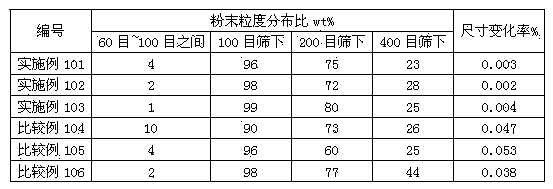

Examples

Embodiment 1

[0015] As the soft magnetic metal powder, select FeSi powder, use 100 mesh, 200 mesh, and 400 mesh screens to sieve the powder, and take the powder under the sieve for later use.

[0016] As the surface insulating layer of soft magnetic metal powder, it is first phosphating for inorganic insulation, and then silicone resin treatment for organic insulation. The mass ratio of the treatment liquid for phosphating treatment is: water: H 3 PO 4 :(NH 4 ) 2 HPO 4 =50:30:20. The thickness of the insulating layer after phosphating is 40-80nm. When treating the silicone resin, first dissolve the silicone resin in toluene to make the resin concentration 8%. The thickness of the organic insulating layer formed after the silicone resin treatment is 200-400nm.

[0017] The magnetic powder after the insulation treatment is mixed with the zinc stearate lubricant, and the mass ratio of the zinc stearate is 0.8% relative to the total mass of the mixed soft magnetic metal powder.

[0018...

Embodiment 2

[0025] As the soft magnetic metal powder, select FeSiAl powder, use 100 mesh, 200 mesh, 400 mesh sieves to sieve the powder, and take the sieved powder for later use.

[0026] As the surface insulating layer of soft magnetic metal powder, it is first phosphating for inorganic insulation, and then silicone resin treatment for organic insulation. The mass ratio of the treatment liquid for phosphating treatment is: water: H 3 PO 4 :(NH 4 ) 2 HPO 4 =50:30:20. The thickness of the insulating layer after phosphating is 40-80nm. When treating the silicone resin, first dissolve the silicone resin in toluene to make the resin concentration 7%. The thickness of the organic insulating layer formed after the silicone resin treatment is 200-400nm.

[0027] The magnetic powder after the insulation treatment is mixed with the zinc stearate lubricant, and the mass ratio of the zinc stearate is 0.5% relative to the total mass of the mixed soft magnetic metal powder.

[0028] The above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com