Lithium silicon alloy material with surface modification layer, preparation method thereof, electrode and electrochemical energy storage device and negative electrode lithium-supplementing method

A technology of lithium-silicon alloy and surface modification, which is applied in the field of negative electrode materials and carbon material particles coated with low-melting point materials, can solve the problems of low efficiency, flammable and explosive, and difficult storage and transportation of silicon negative electrodes for the first time, and achieve The effect of improving the first charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

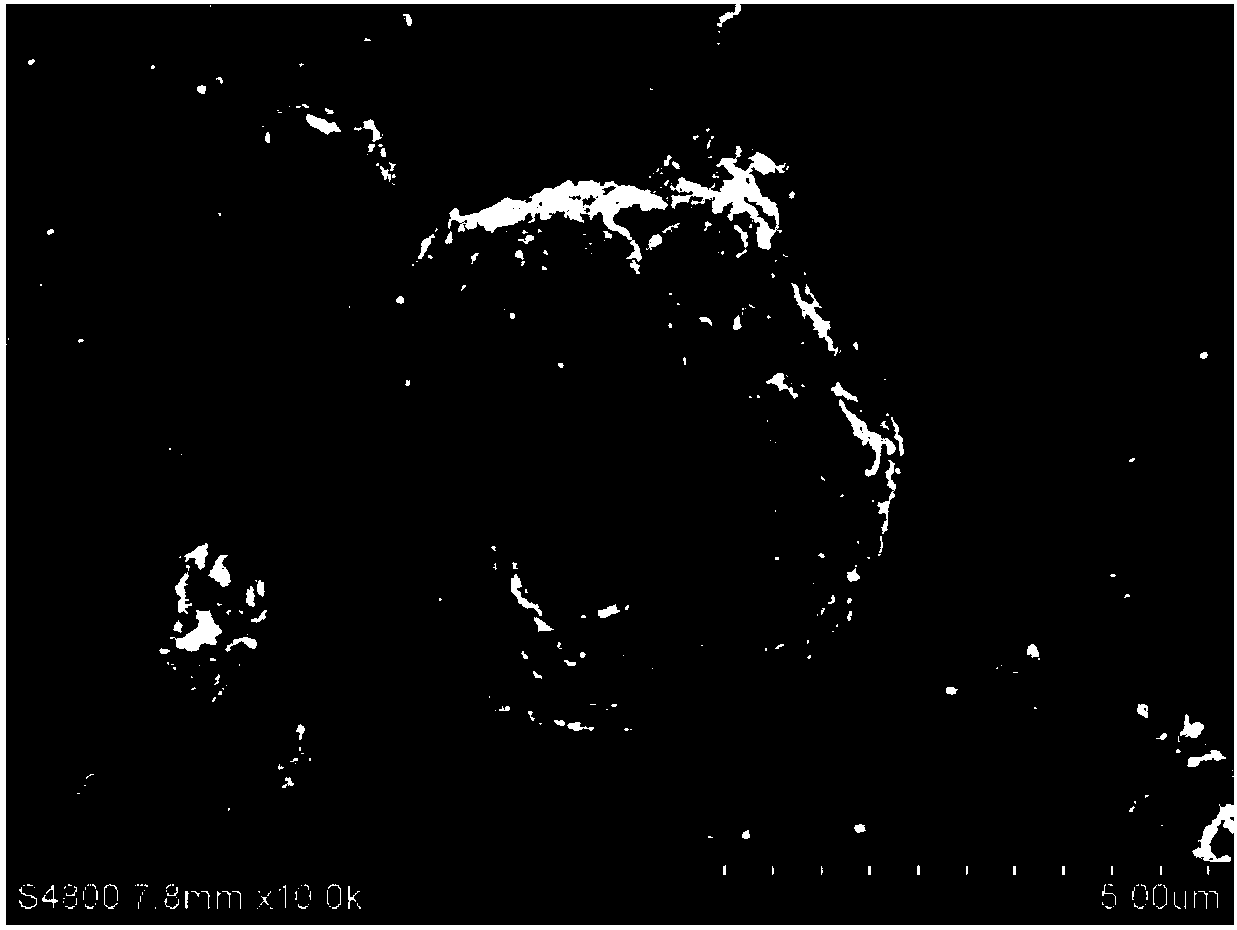

[0039] First, metal lithium (Tianjin Zhongneng Lithium Industry Co., Ltd.) and silicon powder (Aladdin Reagent Company S108978-10g) are put into a reactor that is inert to metal lithium at a molar ratio of 4.4:1, and then heated. When the temperature reaches 300°C , start stirring, and stir for 3 hours to prepare a lithium-silicon alloy bulk material. The obtained alloy block was crushed (TYNSM-0.3L-B of Taoyue (Shanghai) Machinery Technology Co., Ltd.) to prepare lithium-silicon alloy powder particles with an average particle size of about 2 microns.

[0040] Example 1

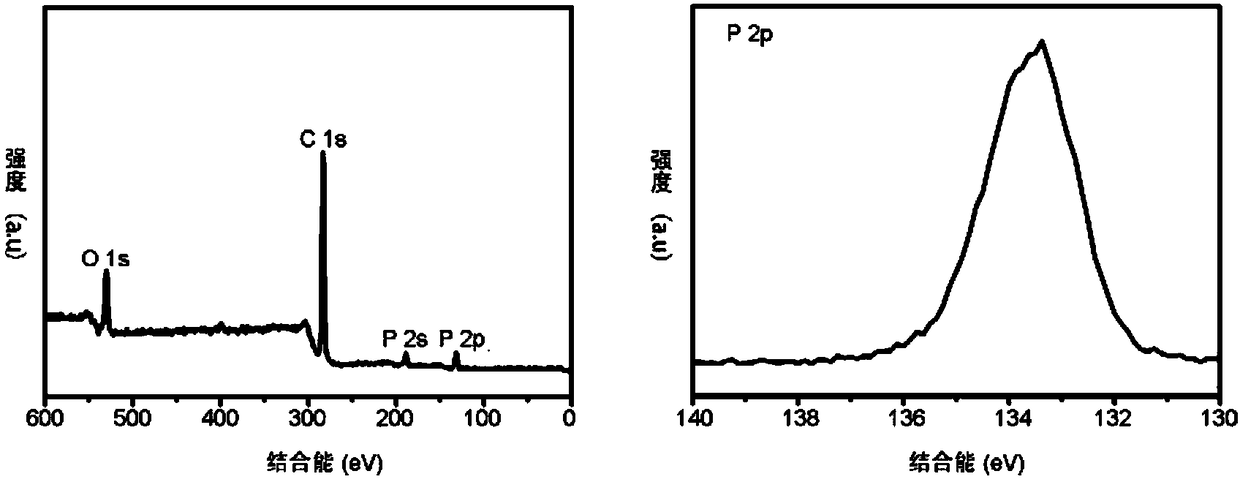

[0041] Get 1g of the lithium-silicon alloy particles prepared in Synthesis Example 1 and disperse them in 100ml of n-hexane solution, then add 10ml of 0.1%wt octadecyl phosphoric acid (Alfa Aesar 020645) in tetrahydrofuran (Aladdin Reagent Co., Ltd. T103259) , stirred and reacted at room temperature for 10 minutes, filtered off the liquid after the stirring was completed, and dried the powder to obtain a lit...

Embodiment 2

[0046] Take 1 g of the lithium-silicon alloy powder particles prepared in Synthesis Example 1, pass through a sand mill to prepare particles with a particle size of 1 micron, disperse them in 100 ml of n-pentane (Aladdin Reagent Co., Ltd. P110847) solution, and then add 20ml of 0.1%wt PMMA (Aladdin Reagent Co., Ltd. P141442) tetrahydrofuran solution, after vigorous stirring, PMMA precipitates on the surface of the lithium-silicon alloy material. After filtering, washing and drying, the PMMA-lithium silicon alloy material is obtained.

Embodiment 3

[0048] Get 1g of the lithium-silicon alloy powder particles prepared in Synthesis Example 1, pass through a sand mill to prepare particles with a particle size of 1 micron, disperse them in 100ml of n-hexane (Aladdin Reagent Co., Ltd. H109657) solution, and then add 20ml 0.1% wt of paraffin (Aladdin Reagent Co., Ltd. P100930) n-hexane solution, kept stirring while heating and evaporating the solvent, the paraffin precipitated on the surface of the lithium-silicon alloy particles, and the paraffin-lithium-silicon alloy material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com