Method for synthesizing TiO2/C (titanium dioxide/carbon) composite material on basis of MOF (metal organic framework) structure and application

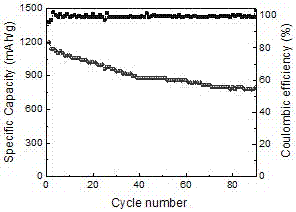

A metal-organic framework, carbon composite technology, applied in structural parts, electrical components, battery electrodes, etc., to achieve the effect of improving cycle performance, large specific surface area, and inhibiting volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

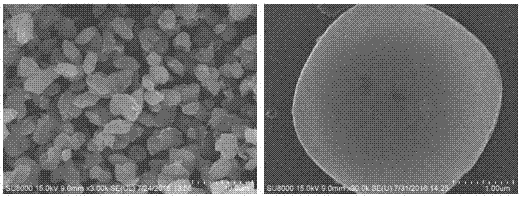

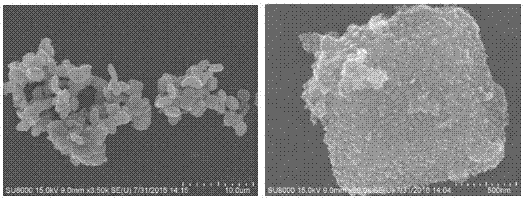

[0025] (1) Weigh 0.5g terephthalic acid, add it to the mixed solution of DMF and methanol (1ml methanol solvent, 9ml DMF solvent), slowly add 0.26ml tetrabutyl titanate dropwise during the stirring process, and continue stirring for 30min, The mixed solution was transferred to a polytetrafluoroethylene reactor, and hydrothermally reacted at 120°C for 12h. After the temperature dropped, it was centrifuged and washed with methanol for more than three times, and then dried in an oven at 40°C for 24h to obtain a white Ti-MOF powder.

[0026] (2) Weigh 50 mg of the white Ti-MOF powder that has been prepared, grind it evenly, and calcinate it at 600 °C for 2 h at a heating rate of 5 °C / min under argon gas. After cooling down, black powder TiO 2 / C Composite.

[0027] (3) Add 50 mgTiO 2 Grind the / C composite material with 200 mg of pure sulfur evenly, put it into a tube furnace with argon as a protective gas, and calcinate at 155°C for 12 hours to obtain TiO 2 / C / S Composite.

Embodiment 2

[0029] (1) Weigh 0.5g terephthalic acid, add it to the mixed solution of DMF and methanol (1ml methanol solvent, 9ml DMF solvent), slowly add 0.26ml tetrabutyl titanate dropwise during the stirring process, and continue stirring for 30min, The mixed solution was transferred to a polytetrafluoroethylene reactor, and hydrothermally reacted at 120°C for 12h. After the temperature dropped, it was centrifuged and washed with methanol for more than three times, and then dried in an oven at 40°C for 24h to obtain a white Ti-MOF powder.

[0030] (2) Weigh 50 mg of the white Ti-MOF powder that has been prepared, grind it evenly, and calcinate it at 700°C for 2 h at a heating rate of 5°C / min under argon gas. After cooling down, black powder TiO 2 / C Composite.

[0031] (3) Add 50 mgTiO 2 Grind the / C composite material with 200 mg of pure sulfur evenly, put it into a tube furnace with argon as a protective gas, and calcinate at 155°C for 12 hours to obtain TiO 2 / C / S Composite.

Embodiment 3

[0033] (1) Weigh 0.5g terephthalic acid, add it to the mixed solution of DMF and methanol (1ml methanol solvent, 9ml DMF solvent), slowly add 0.26ml tetrabutyl titanate dropwise during the stirring process, and continue stirring for 30min, The mixed solution was transferred to a polytetrafluoroethylene reactor, and hydrothermally reacted at 120°C for 12h. After the temperature dropped, it was centrifuged and washed with methanol for more than three times, and then dried in an oven at 40°C for 24h to obtain a white Ti-MOF powder.

[0034] (2) Weigh 50 mg of the white Ti-MOF powder that has been prepared, grind it evenly, and calcinate it at 800°C for 2 h at a heating rate of 5°C / min under argon gas. After cooling down, black powder TiO 2 / C Composite.

[0035] (3) Add 50 mg TiO 2 Grind the / C composite material with 200 mg of pure sulfur evenly, put it into a tube furnace with argon as a protective gas, and calcinate at 155°C for 12 hours to obtain TiO 2 / C / S Composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com