Preparation method and application of shell-core carbon-coated metal phosphide nanometer composite particle

A technology of nanocomposite particles and metal nanoparticles, which is applied in the application of lithium-ion battery anode materials in the field of lithium-ion batteries, and in the field of preparation of core-shell carbon-coated metal phosphide nanocomposite particles, which can solve the complex preparation process and the preparation Long cycle time, electrode pulverization failure and other problems, to achieve the effect of simple preparation process, low raw material cost, and inhibition of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]The equipment used in this embodiment is an automatic control DC arc metal nano powder production equipment, which consists of a powder generation chamber, a powder particle size classification chamber, a powder collection chamber, a powder processing chamber, a vacuum system, a gas circulation system, a hydraulic transmission system, water cooling system and programming control system; the cathode and anode are installed in the powder generation chamber, and are connected to the external hydraulic transmission and programming control system through the wall of the powder generation chamber; when preparing the powder, the material is loaded into the anode, and the The cathode forms a gap of 10-30mm, the whole equipment is vacuumed and cooling water is passed through. After the active gas and condensed gas are introduced, the power supply and arc starter are started to form an arc between the cathode and anode, and the material starts to evaporate and condense to form nano...

Embodiment 2

[0034] The carbon-coated metal phosphide nanocomposite material prepared in Example 1 above was fabricated into a lithium ion electrode sheet. Wherein the electrode sheet is uniformly mixed with 80% carbon-coated nickel phosphide nanocomposite material, 10% Ketjen black and 10% polyvinylidene fluoride (PVDF) binder by mass ratio, and an appropriate amount of N-methylpyrrolidone is added (NMP) was dissolved, and the slurry was coated on a copper current collector to obtain an electrode; the experimental electrode was dried in a vacuum oven at 100°C for 12 hours, and the battery was assembled in a high-purity argon atmosphere glove box. The electrolyte is 1mol / L LiPF 6 solution, the solvent is ethylene carbonate (EC) and diethyl carbonate (DC) at a volume ratio of 1:1. A CR2025 button battery was assembled with polypropylene as the diaphragm and lithium sheets as the counter electrode.

[0035] The present invention prepares the negative electrode of the lithium ion battery wi...

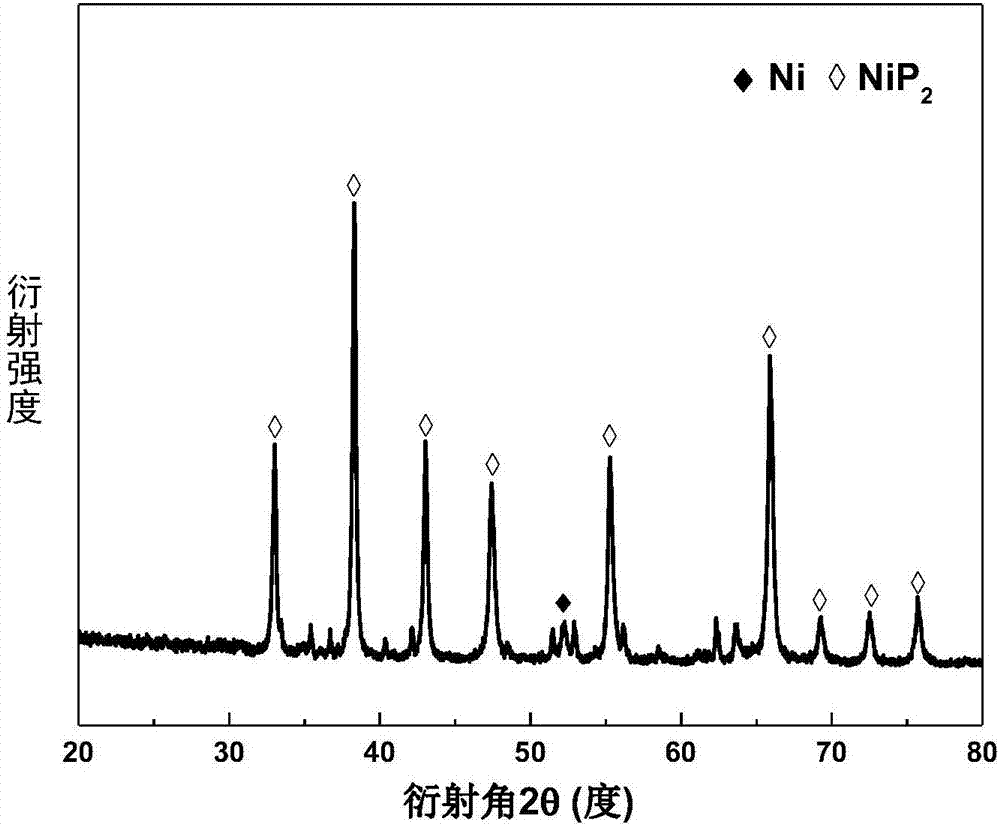

Embodiment 1

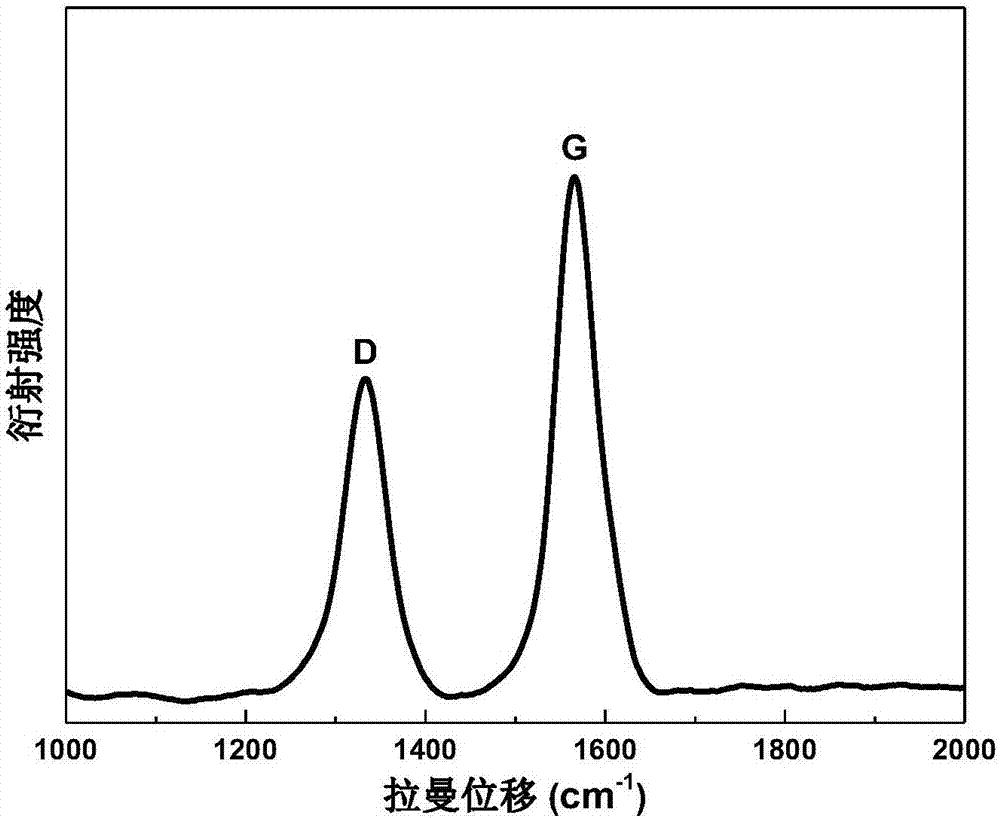

[0036] The Raman spectrum (Raman) of the carbon-coated nickel phosphide nanocomposite that embodiment one obtains is as follows figure 2 shown. From the relative intensities of D peak and G peak in the figure, it can be confirmed that the coated carbon in this material contains a large number of defects.

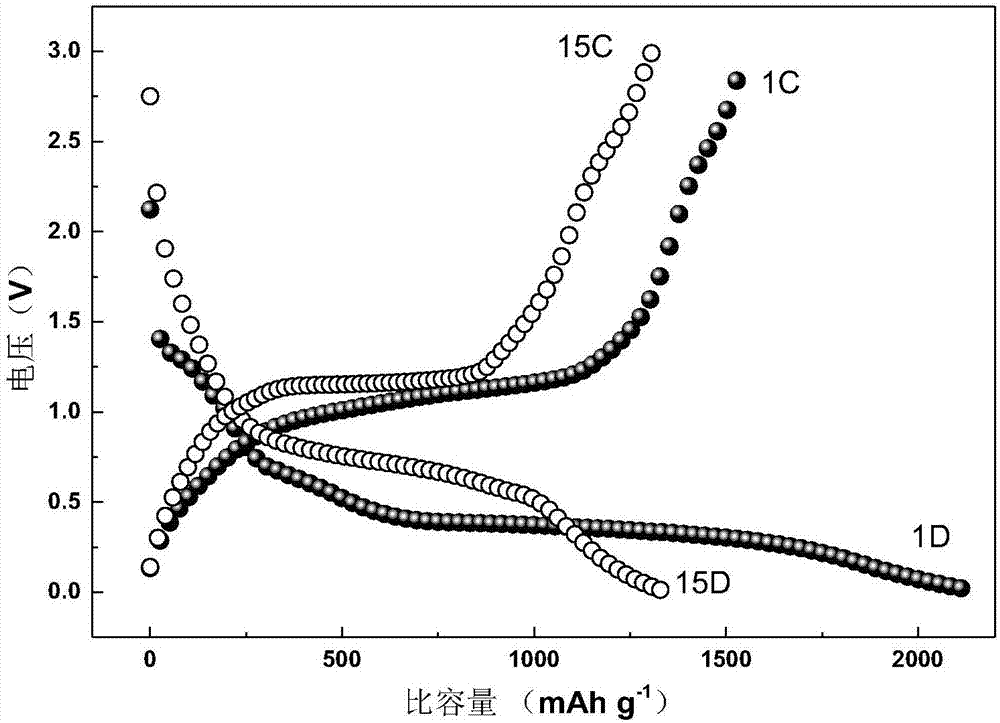

[0037] image 3 with Figure 4 They are charge and discharge curves and cycle stability performance curves carried out at a current density of 300mA / g in the range of 0.01 to 3V at room temperature, respectively. As can be seen from the figure, when the carbon-coated nickel phosphide composite material prepared by the present invention is used as the lithium-ion battery negative electrode material, it has an initial discharge specific capacity close to 2140mAh / g, Figure 4 It shows that its cycle performance is very stable. After the 15th cycle, its reversible specific capacity remained at 1300mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com