Novel ultrathin low-resistance chlorine-alkali industrial ion conduction membrane and preparation method thereof

An ion-conducting membrane, a technology for the chlor-alkali industry, applied in the field of new ultra-thin low-resistance chlor-alkali industrial ion-conducting membrane and its preparation, can solve the problems of increased membrane resistance and increased tank pressure, and achieve reduced adhesion and decreased tank voltage , the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

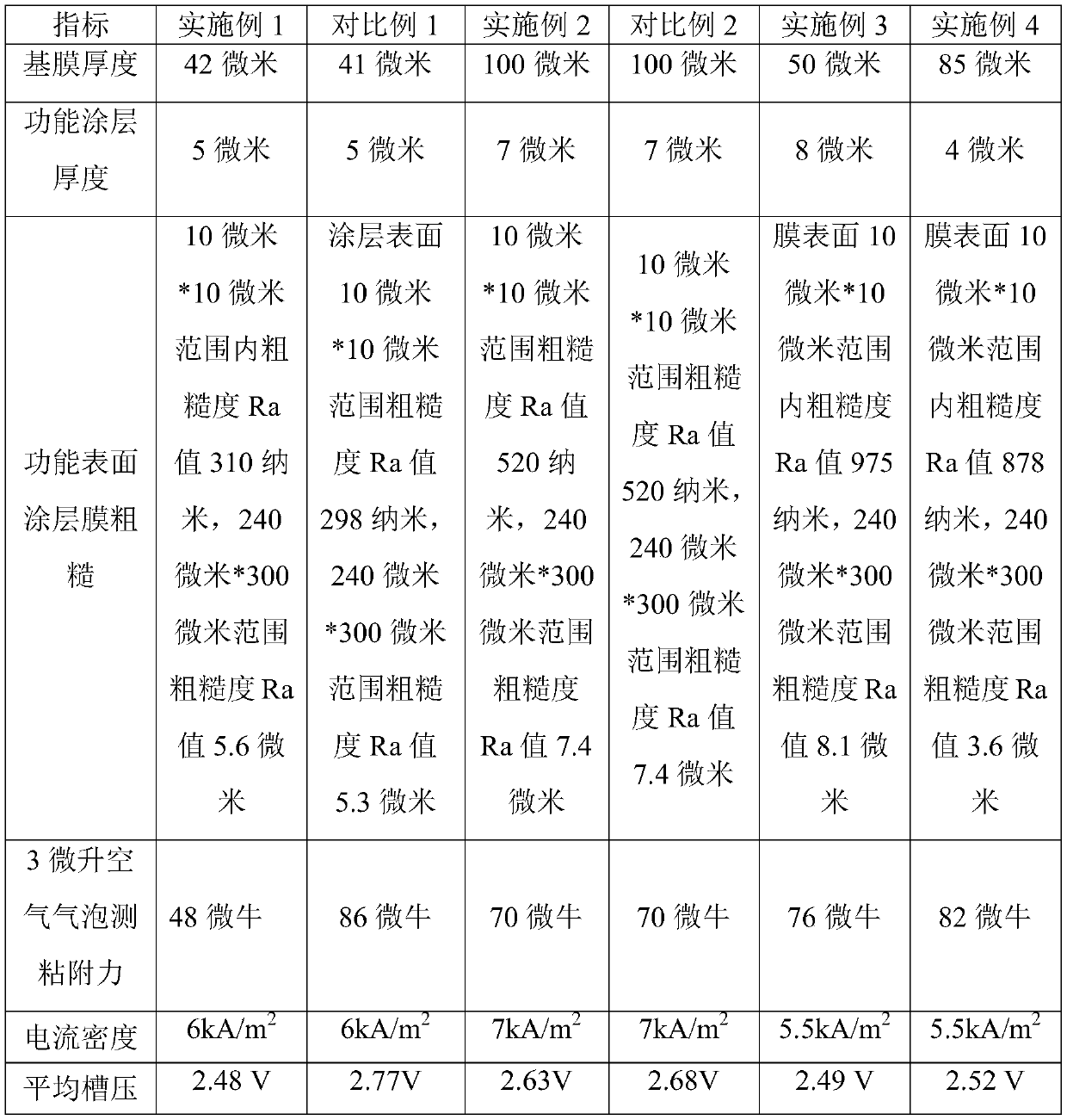

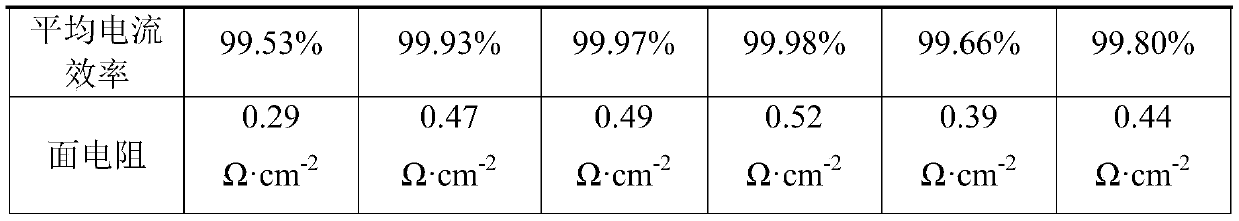

Examples

Embodiment 1

[0040] The novel ultra-thin low-resistance chlor-alkali industrial ion-conducting membrane described in Example 1 is composed of the first perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, perfluorocarboxylic acid polymer layer, and porous non-woven polymer layer and a functional surface coating; wherein, the functional surface coating is a porous rough structure composed of a perfluorinated ion polymer.

[0041] The preparation method of the novel ultra-thin low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 1 is prepared by the following steps:

[0042](1) Adopt the perfluorosulfonic acid resin of IEC=1.0mmol / g and the perfluorocarboxylic acid resin of IEC=0.8mmol / g to obtain material A through melt granulation according to mass ratio 10:3, dissolve material A in polar Perfluorosulfonic acid-perfluorocarboxylic acid resin solution is prepared in a solvent (a solvent made of ethanol and isopropanol at a weight ra...

Embodiment 2

[0055] The new ultra-thin low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 2 consists of a perfluorosulfonic acid polymer layer, a second perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, and a porous non-woven polymer layer and a functional surface coating; wherein, the functional surface coating is a porous rough structure composed of a perfluorinated ion polymer.

[0056] The preparation method of the novel ultra-thin low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 2 is prepared by the following steps:

[0057] (1) the perfluorosulfonic acid resin of IEC=1.0mmol / g is dissolved in the polar solvent (the solvent that ethanol and Virahol are made into by the weight ratio of 1:1) to prepare perfluorosulfonic acid resin solution; The polytetrafluoroethylene porous non-woven membrane is soaked in the trifluorotrichloroethane solvent of ultrasonic treatment and processed f...

Embodiment 3

[0071] The new ultra-thin low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 3 is composed of the first perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer and the second perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer. layer, a porous non-woven polymer layer and a functional surface coating; wherein the functional surface coating is a porous rough structure composed of a perfluoroionic polymer.

[0072] The preparation method of the novel ultra-thin low-resistance chlor-alkali industrial ion-conducting membrane described in this embodiment 3 is prepared by the following steps:

[0073] (1) Adopt the perfluorosulfonic acid resin of IEC=1.0mmol / g and the perfluorocarboxylic acid resin of IEC=0.8mmol / g to obtain material A through melt granulation according to mass ratio 10:1, dissolve material A in polar Perfluorosulfonic acid-perfluorocarboxylic acid resin solution is prepared in a solvent (a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com