Novel ultra-thin low-resistance ion-conducting membrane for chlor-alkali industry and preparation method thereof

An ion-conducting membrane and chlor-alkali industry technology, applied in the field of new ultra-thin low-resistance ion-conducting membrane for chlor-alkali industry and its preparation, can solve the problems of perfluororesin particles falling off easily, difficulty in mass production, high manufacturing cost, etc. The effect of reducing the resistance of the composite film, reducing the amount of use, and reducing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

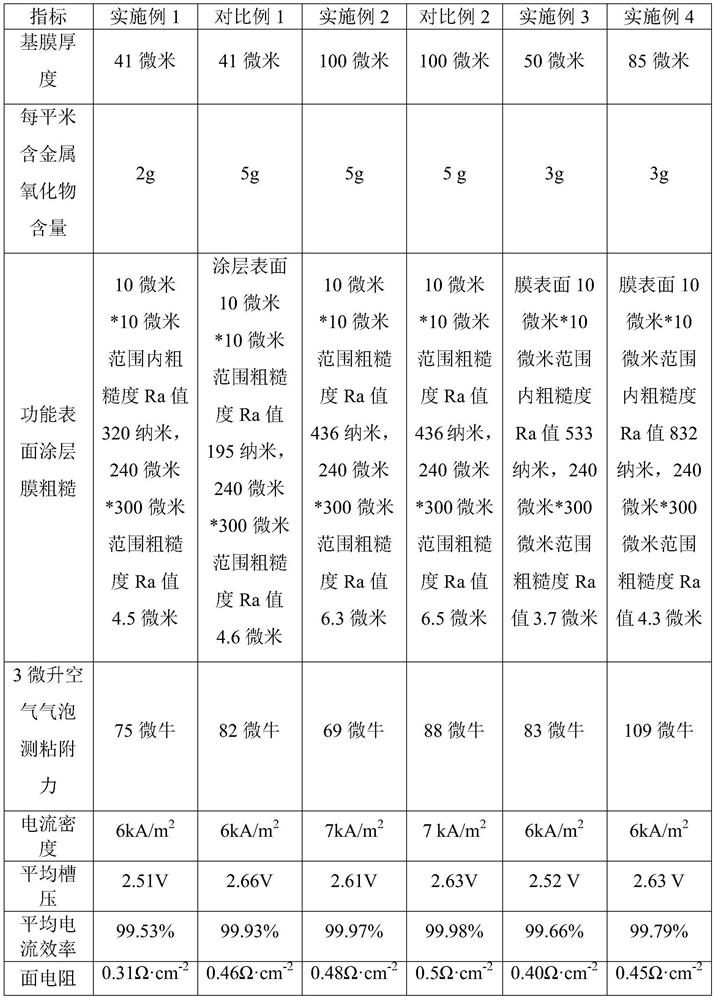

Examples

Embodiment 1

[0045] The new ultra-thin low-resistance ion-conducting membrane for chlor-alkali industry described in this embodiment 1 consists of a first perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, a perfluorocarboxylic acid polymer layer, and a porous non-woven polymer layer. and a functional surface coating; wherein the functional surface coating is a porous rough structure composed of a mixture of perfluoroionic polymers and metal oxides.

[0046] The preparation method of the novel ultra-thin low-resistance ion-conducting membrane for chlor-alkali industry described in the present embodiment 1, the steps are as follows:

[0047] (1) Adopt the perfluorosulfonic acid resin of IEC=1.0mmol / g and the perfluorocarboxylic acid resin of IEC=0.8mmol / g to obtain material A through melt granulation according to mass ratio 10:1, dissolve material A in polar Perfluorosulfonic acid-perfluorocarboxylic acid resin solution is prepared in a solvent (a solvent made of ethan...

Embodiment 2

[0063] The novel ultra-thin low-resistance ion-conducting membrane for chlor-alkali industry described in this embodiment 2 consists of a perfluorosulfonic acid polymer layer, a second perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer, and a porous non-woven polymer layer and a functional surface coating; wherein the functional surface coating is a porous rough structure composed of a mixture of perfluoroionic polymers and metal oxides.

[0064] The preparation method of the novel ultra-thin low-resistance ion-conducting membrane for chlor-alkali industry described in the present embodiment 2, the steps are as follows:

[0065] (1) the perfluorosulfonic acid resin of IEC=1.0mmol / g is dissolved in the polar solvent (the solvent that ethanol and Virahol are made into by the weight ratio of 1:1) to prepare perfluorosulfonic acid resin solution; The polytetrafluoroethylene porous non-woven membrane is soaked in the trifluorotrichloroethane solvent of ultrason...

Embodiment 3

[0080] The new ultra-thin low-resistance ion-conducting membrane for chlor-alkali industry described in this embodiment 3 is composed of the first perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer and the second perfluorocarboxylic acid-perfluorosulfonic acid polymer composite layer. layer, a porous non-woven polymer layer and a functional surface coating; wherein, the functional surface coating is a porous rough structure composed of a mixture of perfluoroionic polymers and metal oxides.

[0081] The preparation method of the bubble-repellent coating with ion-conducting function described in this embodiment 3 consists of the following steps:

[0082] (1) Adopt the perfluorosulfonic acid resin of IEC=1.0mmol / g and the perfluorocarboxylic acid resin of IEC=0.8mmol / g to obtain material A through melt granulation according to mass ratio 10:1, dissolve material A in polar Perfluorosulfonic acid-perfluorocarboxylic acid resin solution is prepared in a solvent (a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com