Process for preparing high-purity trifluoromethyl sulphonic acid

A technology of trifluoromethanesulfonic acid and trifluoromethanesulfonic acid salt, which is applied in the field of preparing high-purity trifluoromethanesulfonic acid, and can solve the problem that the hydrolysis reaction speed of trifluoromethanesulfonyl fluoride gas is slow and the reaction is insufficient. , loss of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

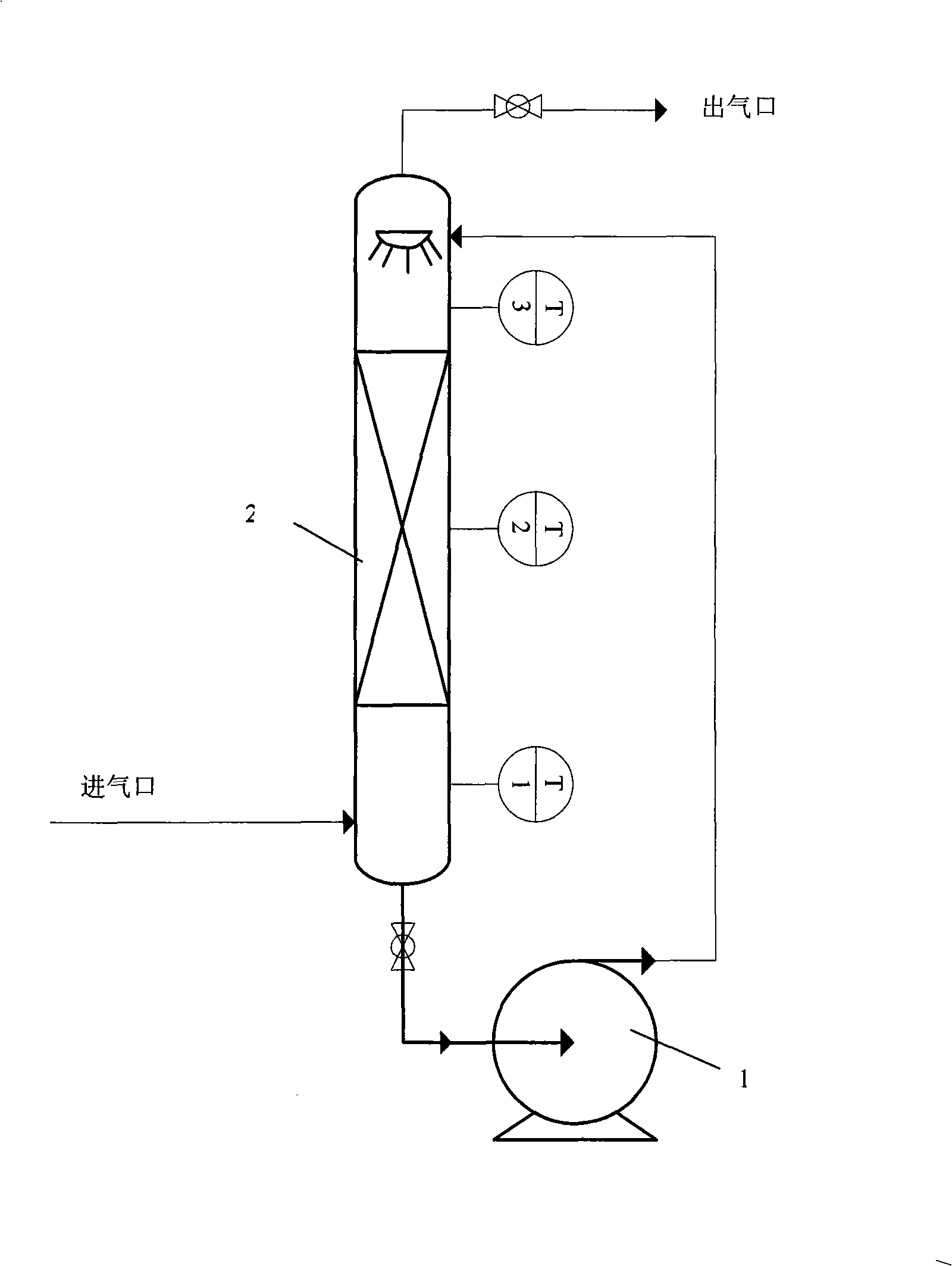

[0019] Add 8 kg of 20% KOH aqueous solution into the 10L hydrolysis tower through circulation pump 1, install 5 × 5θ nickel rings in the hydrolysis tower 2, and heat up the temperature of the hydrolysis tower 2 to 90-95 ° C, at this time, the trifluoromethanesulfonyl fluoride gas is discharged from the tower The air inlet at the bottom leads into the hydrolysis tower 2, and the KOH aqueous solution is guaranteed to circulate during the reaction process, and the circulation speed is about 5m 3 / h, the hydrolysis tower 2 is as shown in the accompanying drawing.

[0020] The ventilation flow rate of trifluoromethanesulfonyl fluoride is controlled so that the content of trifluoromethanesulfonyl fluoride in the gas outlet is less than 0.2%. The reaction was carried out for 12 hours, the pH of the solution in the hydrolysis tower 2 reached 11, the inlet valve was closed, the reaction was stopped, and the consumption of trifluoromethanesulfonyl fluoride was 2.2 kg. The hydrolysis so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com