Method for recovering octafluoropropane from hexafluoropropylene production process

A technology of octafluoropropane and hexafluoropropene, which is applied in the field of chemical product recycling, can solve problems such as environmental pollution, increase in unit consumption, and affect the quality of system cracking and rectification, so as to achieve low operating costs, reduce unit consumption, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

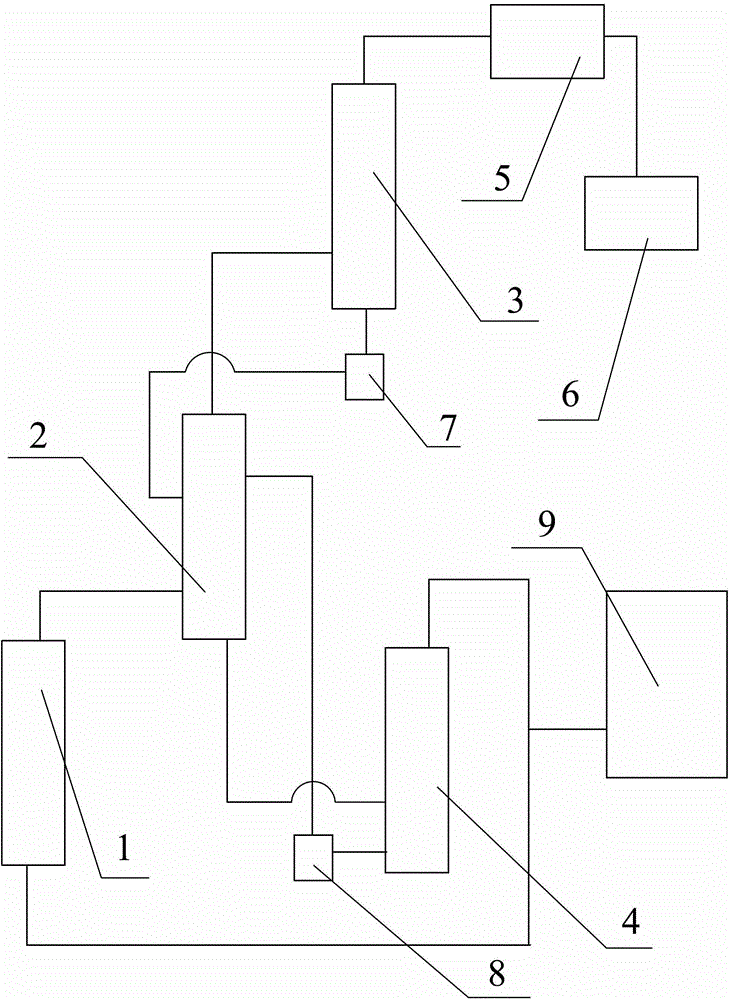

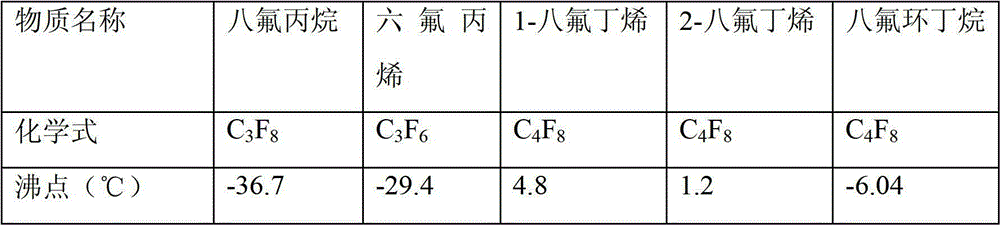

[0032] like figure 1 As shown, the material gas containing octafluoropropane, hexafluoropropylene, 1-octafluorobutene, 2-octafluorobutene, and octafluorocyclobutane enters the light removal tower, and the pressure at the top of the light removal tower is controlled to 0.75MPa , the reflux ratio is 9:1, the top temperature is 15°C, the azeotrope of octafluoropropane and hexafluoropropylene is separated from other components, and the purity of octafluoropropane at the top of the tower is 83.3% (volume percentage), and hexafluoropropylene 16.7% (volume percentage), the bottom of the tower returns to the hexafluoropropylene rectification tower of the system for rectification, and the top of the tower enters the extraction tower. N-methylpyrrolidone is used as the extraction agent. The pressure at the top of the tower is controlled at 0.6MPa, and the liquid-gas ratio is 8:1 , the temperature at the top of the tower was 14°C. Octafluoropropane is obtained from the top of the tower,...

Embodiment 2

[0034] like figure 1 As shown, the material gas containing octafluoropropane, hexafluoropropylene, 1-octafluorobutene, 2-octafluorobutene, and octafluorocyclobutane enters the light removal tower, and the pressure at the top of the light removal tower is controlled to be 0.7MPa , the reflux ratio was 10:1, and the tower top temperature was 14°C. The azeotrope of octafluoropropane and hexafluoropropylene is separated from other components, and the purity of octafluoropropane at the top of the tower is 89.6% (volume percentage), and the purity of hexafluoropropylene is 10.4% (volume percentage). Distillation tower rectification, tower top enters extraction tower, extractant is the DMF solution that adds sodium chloride, and the quality of sodium chloride is 3% of DMF. The control tower top pressure is 0.55MPa, the liquid-gas ratio is 10:1, and the tower top temperature is 12°C. Octafluoropropane is obtained from the top of the tower, the recovery rate of octafluoropropane is 9...

Embodiment 3

[0036] like figure 1As shown, the material gas containing octafluoropropane, hexafluoropropylene, 1-octafluorobutene, 2-octafluorobutene, and octafluorocyclobutane enters the light removal tower, and the pressure at the top of the light removal tower is controlled to be 0.65MPa , the reflux ratio is 11:1, and the tower top temperature is 15°C. The azeotrope of octafluoropropane and hexafluoropropylene is separated from other components, and the purity of octafluoropropane at the top of the tower is 84.6% (volume percentage), and the purity of hexafluoropropylene is 15.4% (volume percentage). Distillation tower rectification, the top of the tower enters the extraction tower, the mixed solvent of toluene toluene and methanol (volume ratio 3:1) is the extraction agent, the pressure at the top of the tower is controlled at 0.5MPa, the liquid-gas ratio is 9:1, and the temperature at the top of the tower is 13 ℃. Octafluoropropane is obtained from the top of the tower, the recover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com