Preparation method of perfluoropropane

A technology for octafluoropropane and hexafluoropropene, which is applied in the field of preparation of octafluoropropane, can solve the problems of cumbersome process, pulverization of fluorinating agent, complicated operation and the like, and achieves the effects of simple process, reduced production cost and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

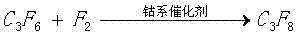

Method used

Image

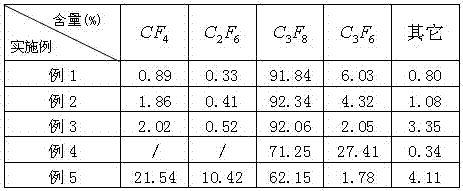

Examples

Embodiment 1

[0037] Put the cobalt-based catalyst into the reactor (dimensions ¢57×3.5×560), then heat the reactor, use nitrogen to purge the reaction device during the temperature rise, and after the internal temperature of the reactor rises to 280°C and the temperature is stable, the raw material Mixed gas (diluted fluorine gas with a concentration of 20% fluorine gas, nitrogen gas as the diluent gas, molar ratio of hexafluoropropylene to dilute fluorine gas is 1:6) with 0.16Nm 3 The flow rate of / h is passed into the reactor for reaction, and the mixed gas obtained by the reaction is sequentially passed into the alkali washing tower using potassium hydroxide and the adsorbent adopts the adsorber of activated alumina for treatment, and then enters the rectification system for purification to obtain high-purity Octafluoropropane, and the separated nitrogen can be used as the purge gas before the reaction of the reactor.

Embodiment 2

[0039] In this example, the fluorine concentration in the diluted fluorine gas is 30%, the molar ratio of hexafluoropropylene to the diluted fluorine gas is 1:4, the reaction temperature is set at 300°C, and the implementation steps and parameters are the same as in Example 1 .

Embodiment 3

[0041]In this example, the fluorine concentration in the diluted fluorine gas is 40%, the molar ratio of hexafluoropropylene to the diluted fluorine gas is 1:3, the reaction temperature is set at 300°C, and the implementation steps and parameters are the same as in Example 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com