Patents

Literature

37results about How to "Facilitate addition reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature quick-drying type polyurethane acrylate coating and preparation method thereof

ActiveCN104804633AImprove adhesionHigh mechanical strengthPolyurea/polyurethane coatingsAcrylic resinLow temperature curing

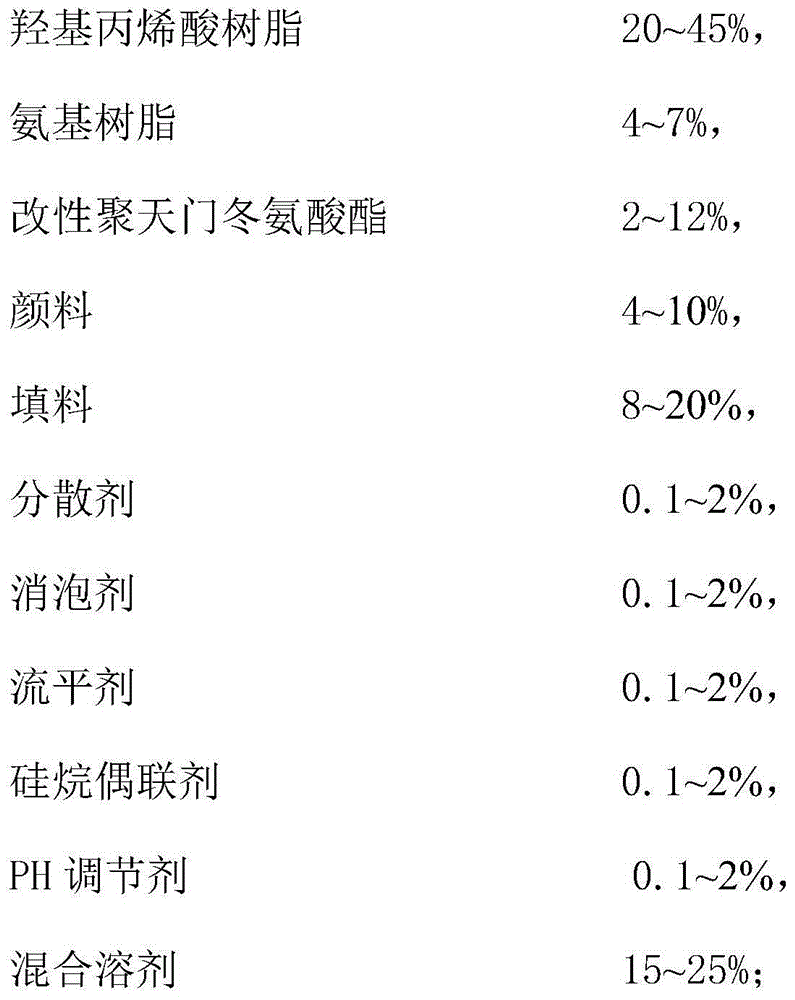

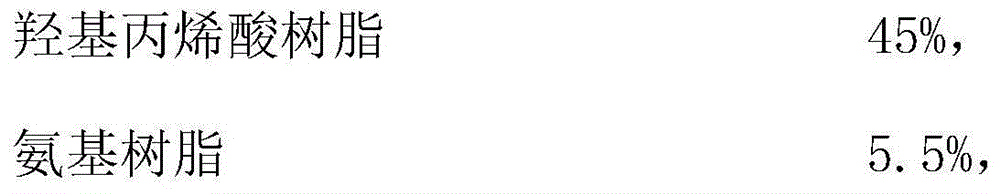

The invention discloses a low-temperature quick-drying type polyurethane acrylate coating. The coating consists of a component A and a component B by a mass ratio of 100 to (20-27), wherein the component A comprises the following components in percentage by mass: 20-45 percent of hydroxyl acrylic resin, 4-7 percent of amino resin, 2-12 percent of modified polyaspartic acid ester, 4-10 percent of a pigment, 8-20 percent of filler, 0.1-2 percent of a dispersant, 0.1-2 percent of a defoaming agent, 0.1-2 percent of a flatting agent, 0.1-2 percent of a silane coupling agent, 0.1-2 percent of a PH regulating agent and 15-25 percent of a mixed solvent; the component B is isophorone diisocyanate. The coating disclosed by the invention has the characteristics of being rapid, cured at low temperature, excellent in physical and mechanical properties and the like, is excellent in adhesive force to various base materials (iron, aluminum alloy, zinc plated plates, stainless steel and the like), and can be widely applicable to industrial coating of costly furniture, steel structures, railway locomotives and the like. The invention also discloses a preparation method of the low-temperature quick-drying type polyurethane acrylate coating.

Owner:东莞市惠尔明高分子材料科技有限公司

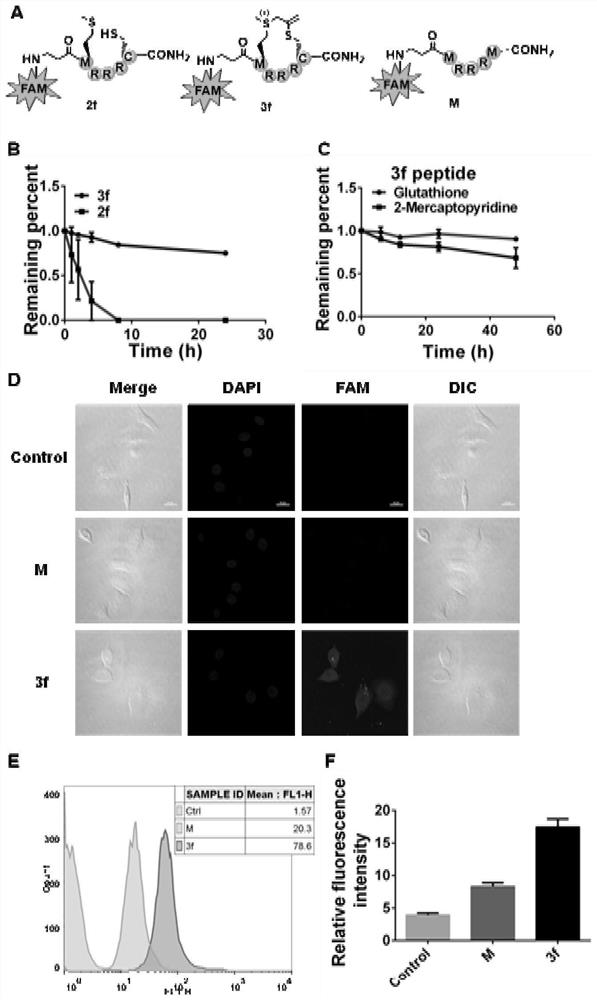

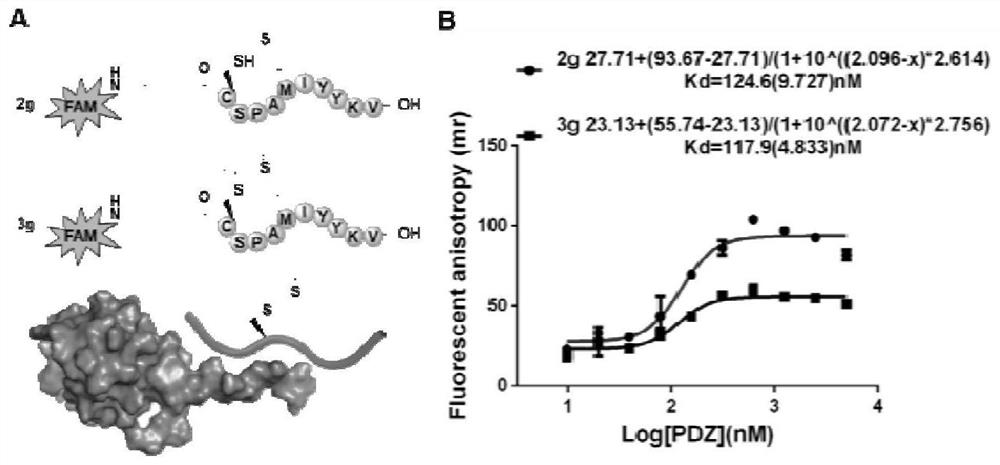

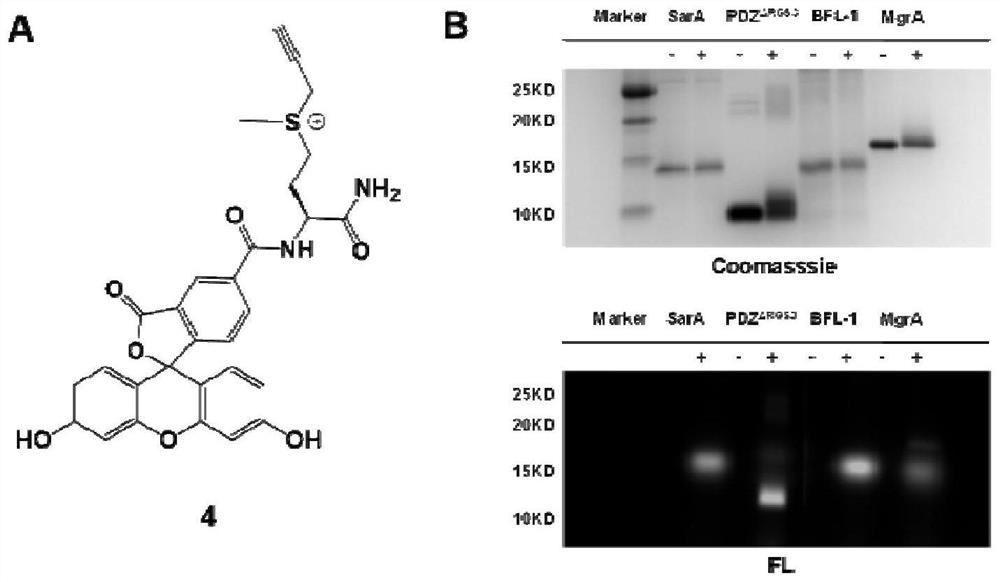

Method for selectively modifying cysteine through propargyl type sulfonium salt

InactiveCN112047996AMaintain stabilitySignificant technological progressPeptide preparation methodsBulk chemical productionMethionine biosynthesisSulfonium

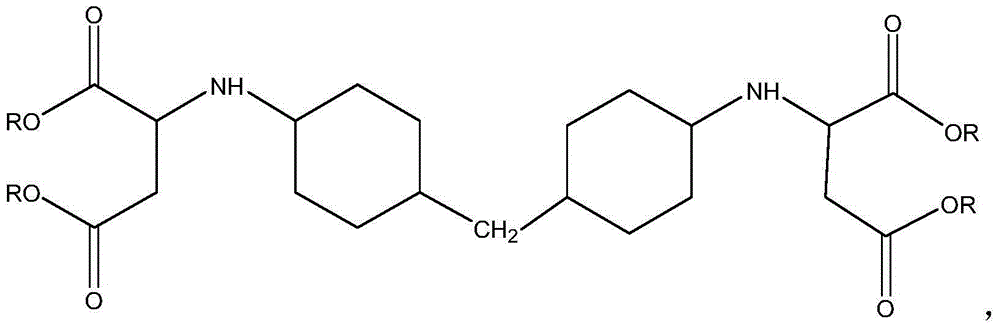

The invention provides a method for selectively modifying cysteine. Propargyl type sulfonium salt is adopted, propargyl activated at the center of the sulfonium salt and mercaptan are subjected to anaddition reaction, mercaptan attacks allene intermediate beta carbon in the propargyl type sulfonium salt, and protein cysteine or cysteine without protecting group polypeptide is selectively modified. The invention further provides application of the propargyl type sulfonium salt in preparing a probe for detecting cysteine or mercaptan in a living body. The reaction is applied to protecting group-free polypeptide close to methionine and cysteine, an intramolecular addition reaction can be conveniently carried out, and therefore cyclic polypeptide which is better in stability and beneficial for cell absorption is constructed.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

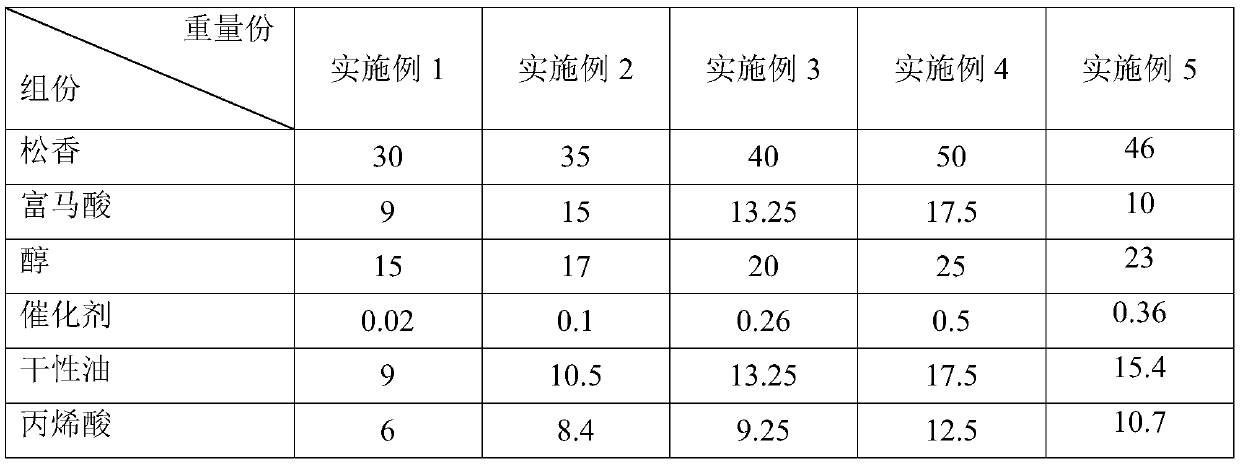

Non-cured rubber asphalt paint and self-adhesion coiled material composite construction method

InactiveCN110409513AImprove flatnessTight bondOther rubber coatingsUnderground chambersComposite constructionBond properties

The invention relates to the field of waterproof engineering construction methods, in particular to a non-cured rubber asphalt paint and self-adhesion coiled material composite construction method. The non-cured rubber asphalt paint and self-adhesion coiled material composite construction method comprises the following steps of S1, waterproof paint treatment; S2, base layer treatment; S3, joint reinforcing treatment; S4, self-adhesion coiled material pre-trial paving; S5, first bonding layer construction; S6, self-adhesion coiled material paving and lap joint; and S7, close-up seal. The methodhas the beneficial effects that a composite waterproof layer made through the construction method has the good anti-aging property, and even if the composite waterproof layer is used for a long time,the composite waterproof layer can still keep good structural strength and bonding property.

Owner:东莞市卓宝建筑工程有限公司

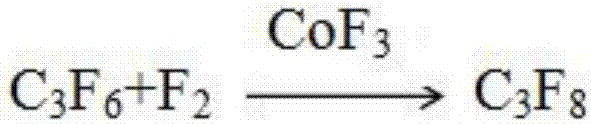

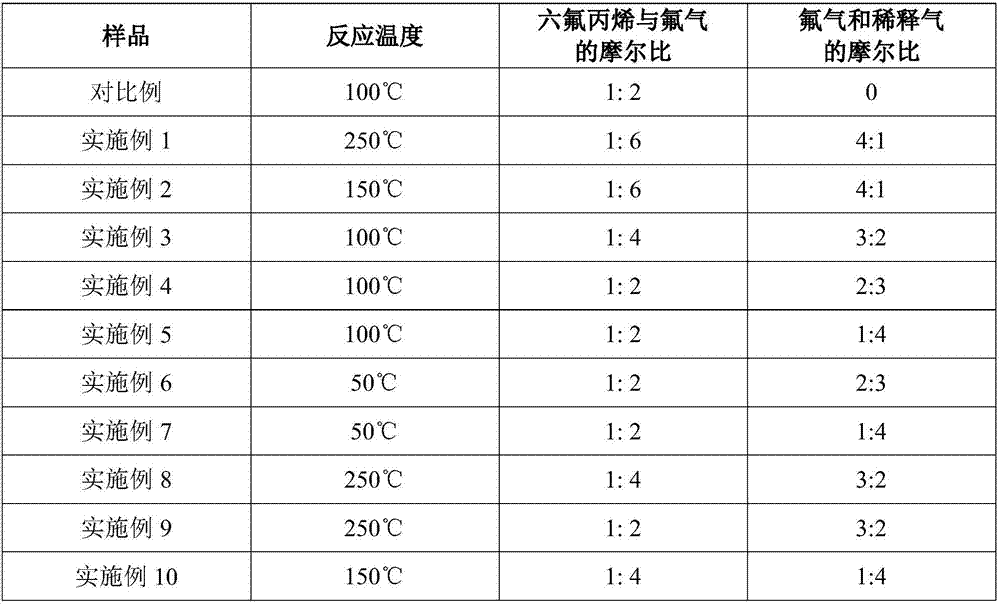

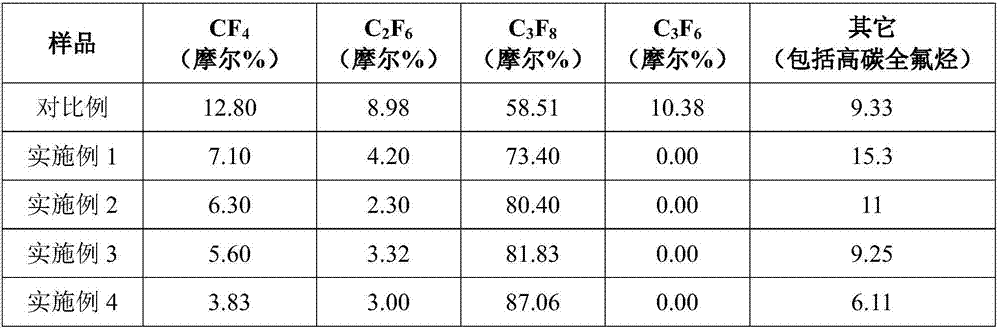

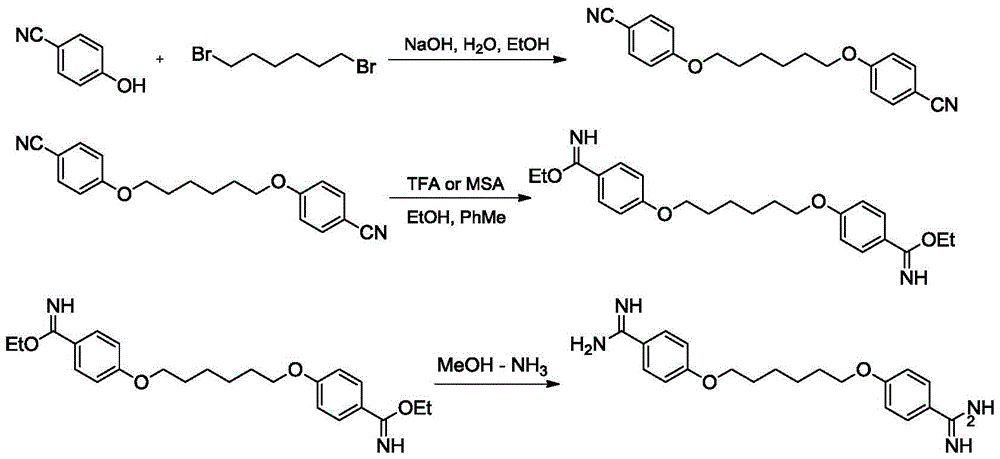

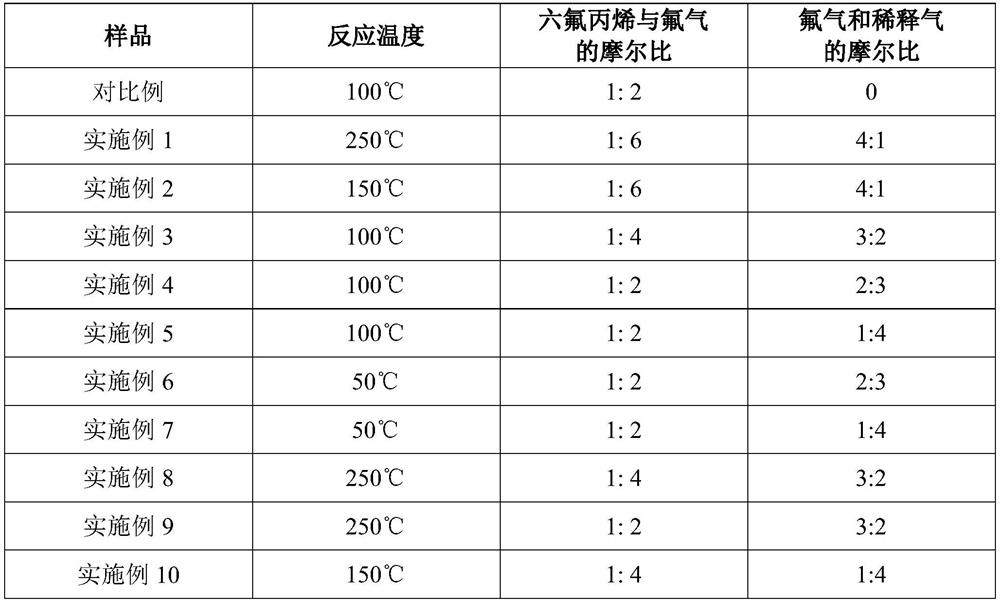

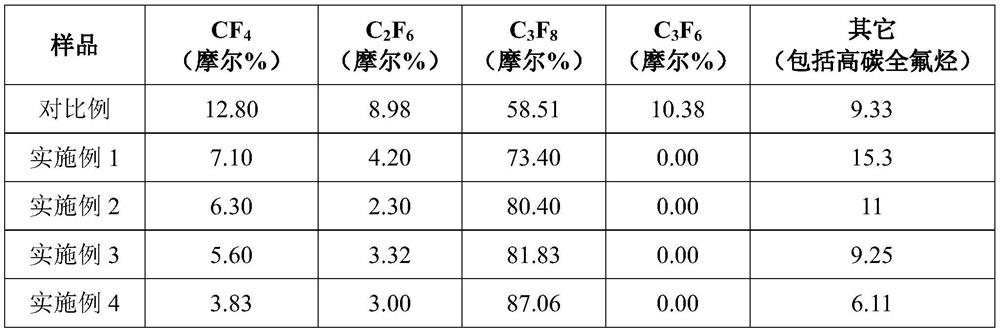

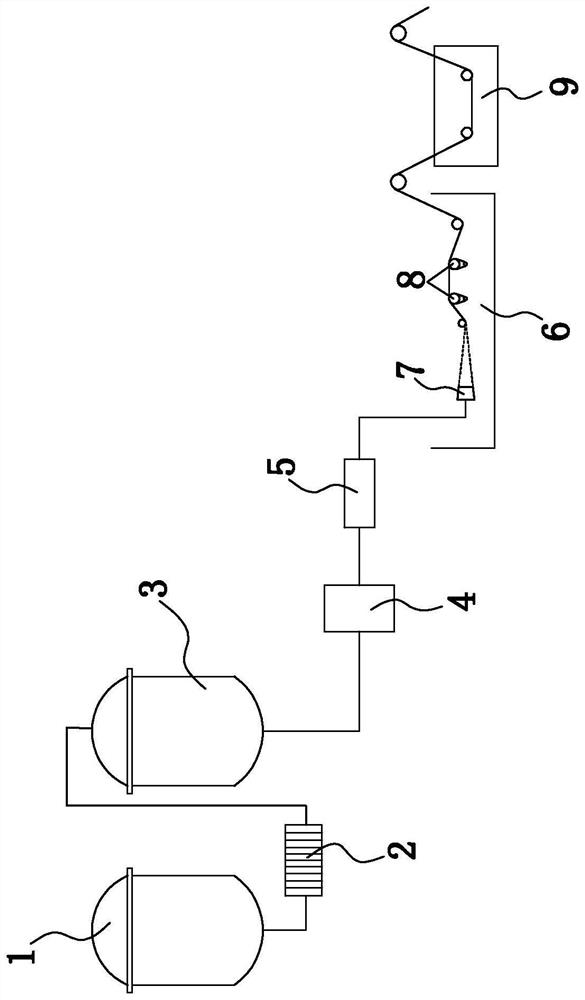

Method for preparing high-purity perfluoropropane

ActiveCN107098790AFacilitate addition reactionGood choicePreparation by halogen additionCobalt trifluorideAddition reaction

The invention relates to a method for preparing high-purity perfluoropropane. The method comprises the following steps: in a reactor, the reaction temperature is set to 50-250 DEG C, cobaltic fluoride is taken as a catalyst, hexafluoropropene and fluorine gas are taken as reaction gas, perfluoropropane is prepared after the reaction, and the mole ratio of hexafluoropropene to fluorine gas is 1:2-6. In the method, cobaltic fluoride is taken as the catalyst, continuous reaction is realized, an addition reaction of hexafluoropropene and fluorine gas is promoted, conversion rate of hexafluoropropene is almost 100%, and perfluoropropane yield can reach 90% and above, the reaction selectivity is good, and the by-product content is little. The high-purity perfluoropropane is prepared after subsequent purifying processing of the crude product, and the method has the advantages of low cost, high efficiency and industrial production.

Owner:FOSHAN HUATE GASES +1

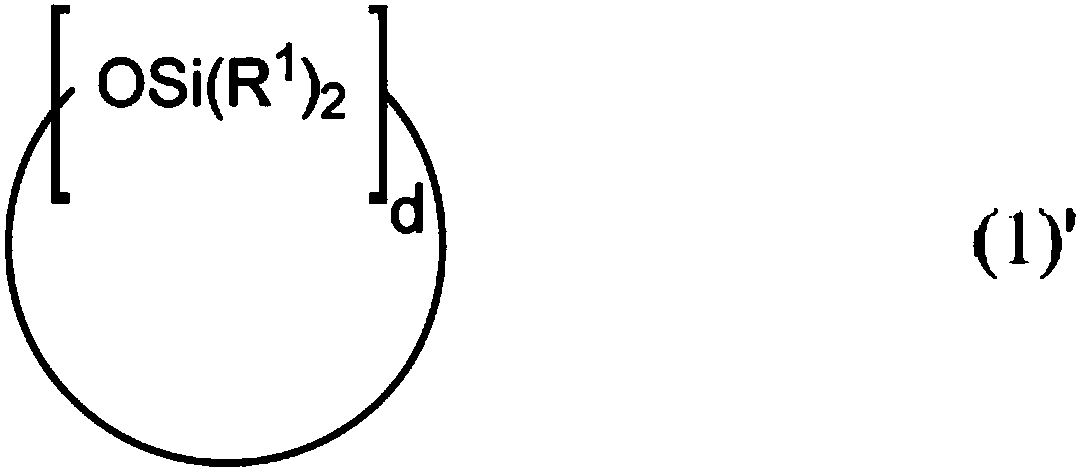

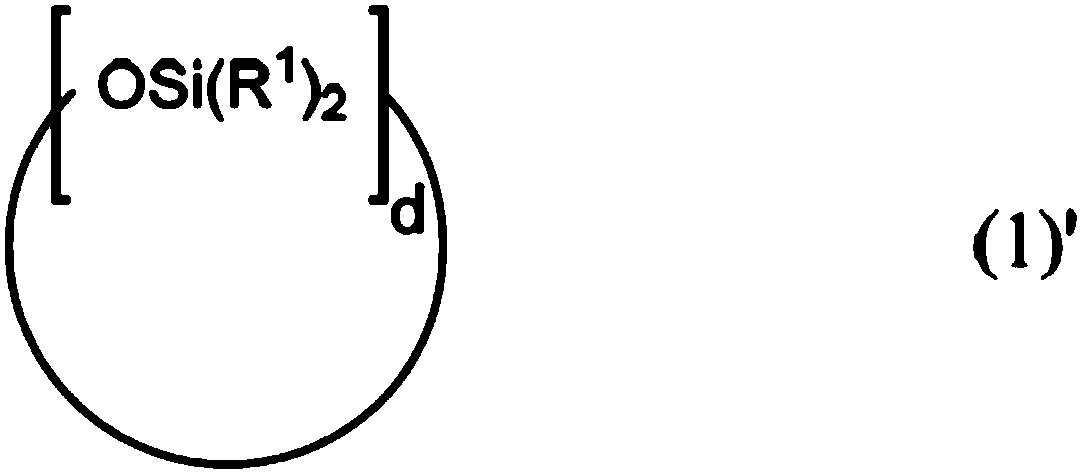

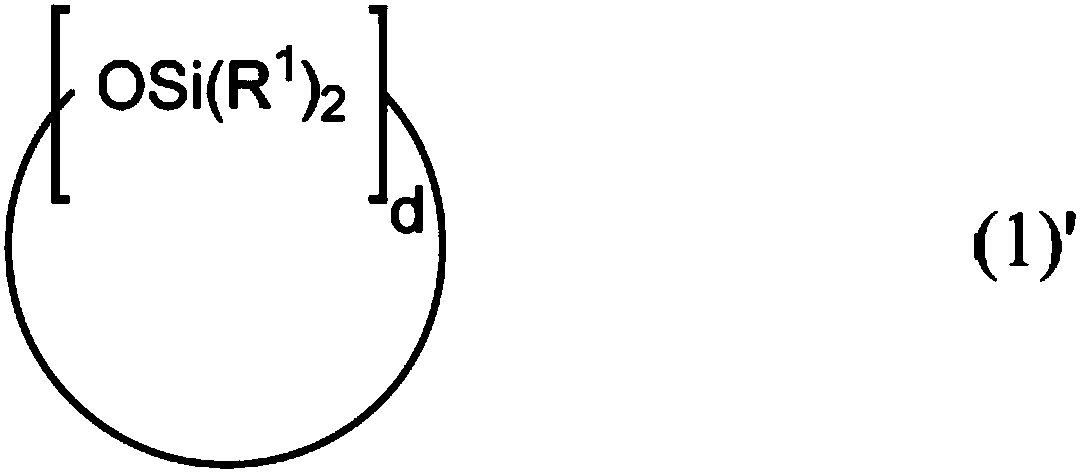

Novel isocyanide compound and hydrosilylation reaction catalyst

ActiveCN108473514AImprove solubilityEasy to getSilicon organic compoundsOrganic chemistry methodsPlatinumPolymer science

Provided are a novel isocyanide compound, a hydrosilylation reaction catalyst having excellent handling properties and storage properties that allows a hydrosilylation reaction to proceed under moderate conditions by using the isocyanide compound, and a method for producing an addition compound by a hydrosilylation reaction using the hydrosilylation reaction catalyst. A hydrosilylation reaction catalyst prepared from a catalyst precursor comprising a transition metal compound of groups 8, 9, or 10 of the periodic table, excluding platinum, such as an iron carboxylate, cobalt carboxylate, or nickel carboxylate, and a ligand comprising an isocyanide compound having an organosiloxane group.

Owner:SHIN ETSU CHEM CO LTD +1

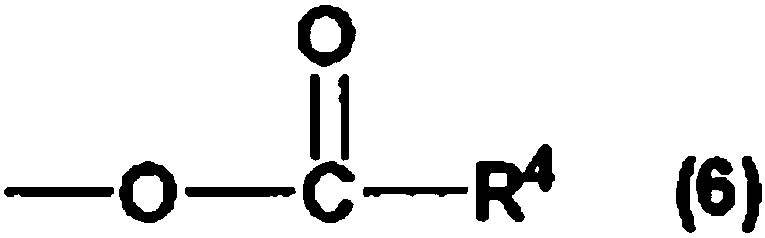

Antibody coupled drug intermediates with maleimide connector, and synthesis method thereof

InactiveCN111499685AAchieve couplingFacilitate addition reactionAntibody mimetics/scaffoldsPeptide preparation methodsImideAntiendomysial antibodies

The invention relates to the field of organic synthesis, and especially relates to a series of antibody coupled drug intermediates with a maleimide connector, and a synthesis method thereof. The intermediates are provided with the maleimide connector and can be rapidly subjected to a Michael addition reaction with sulfydryl groups on an antibody, antibody coupling is achieved, and cytotoxin is connected to the antibody.

Owner:LEVENA SUZHOU BIOPHARMA CO LTD

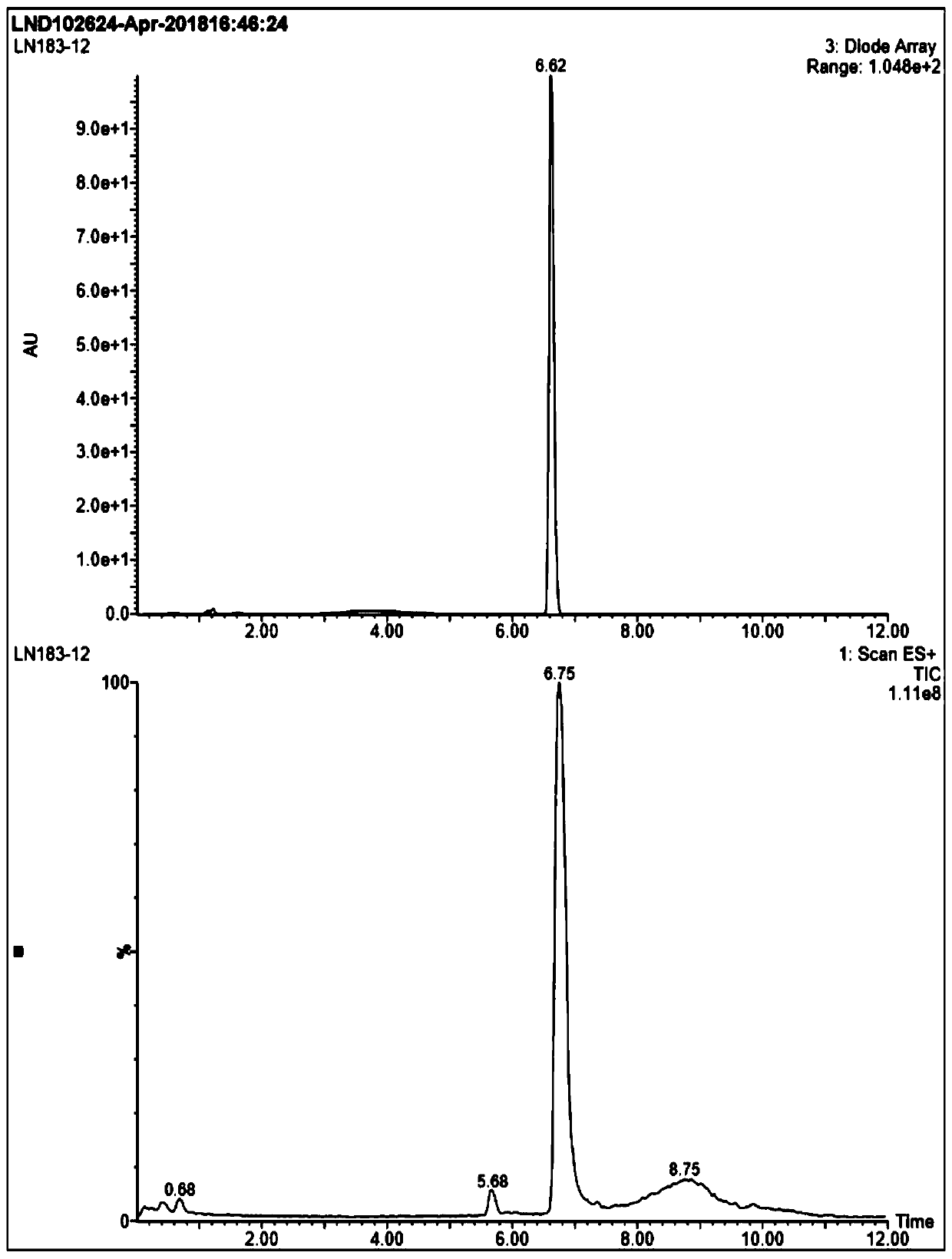

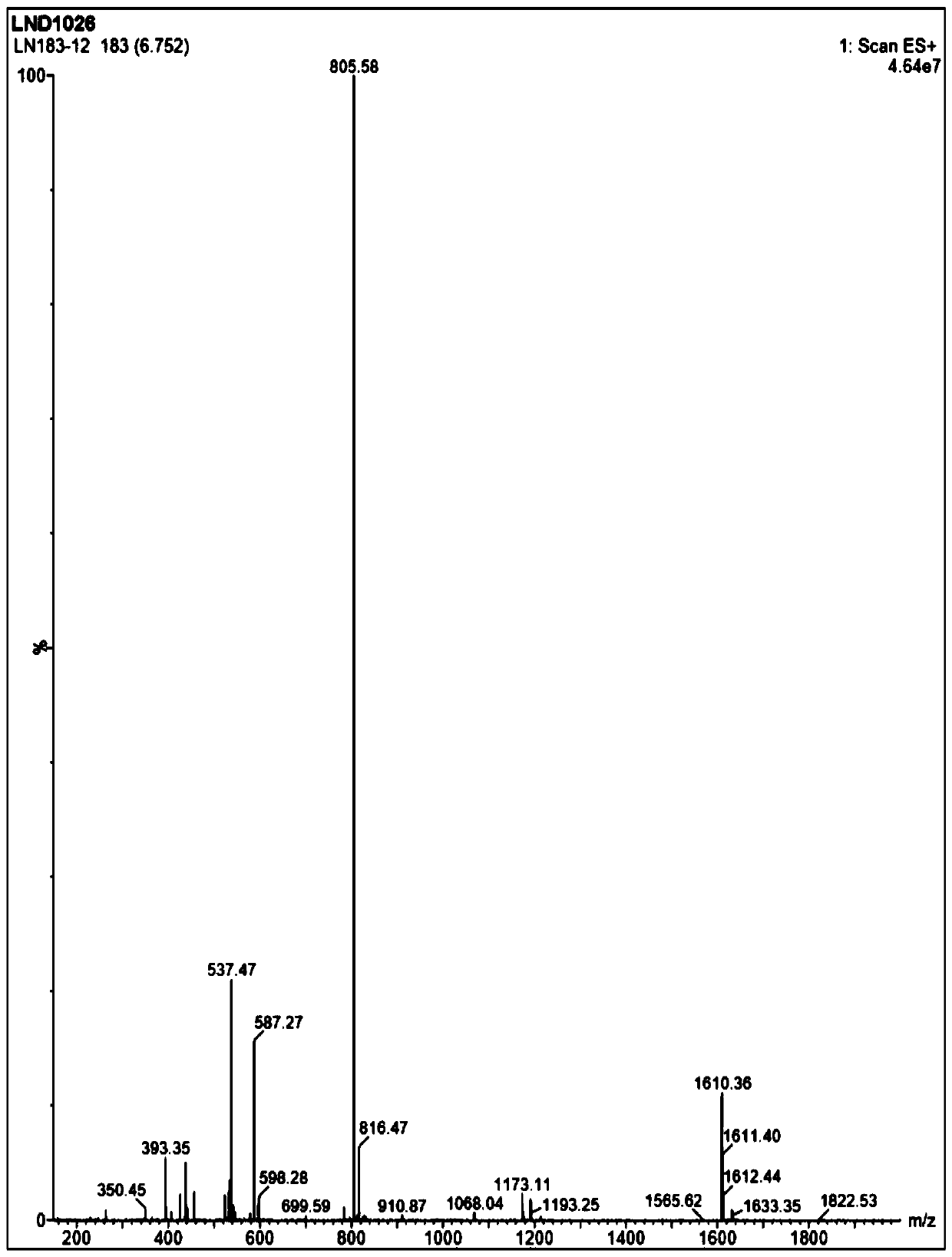

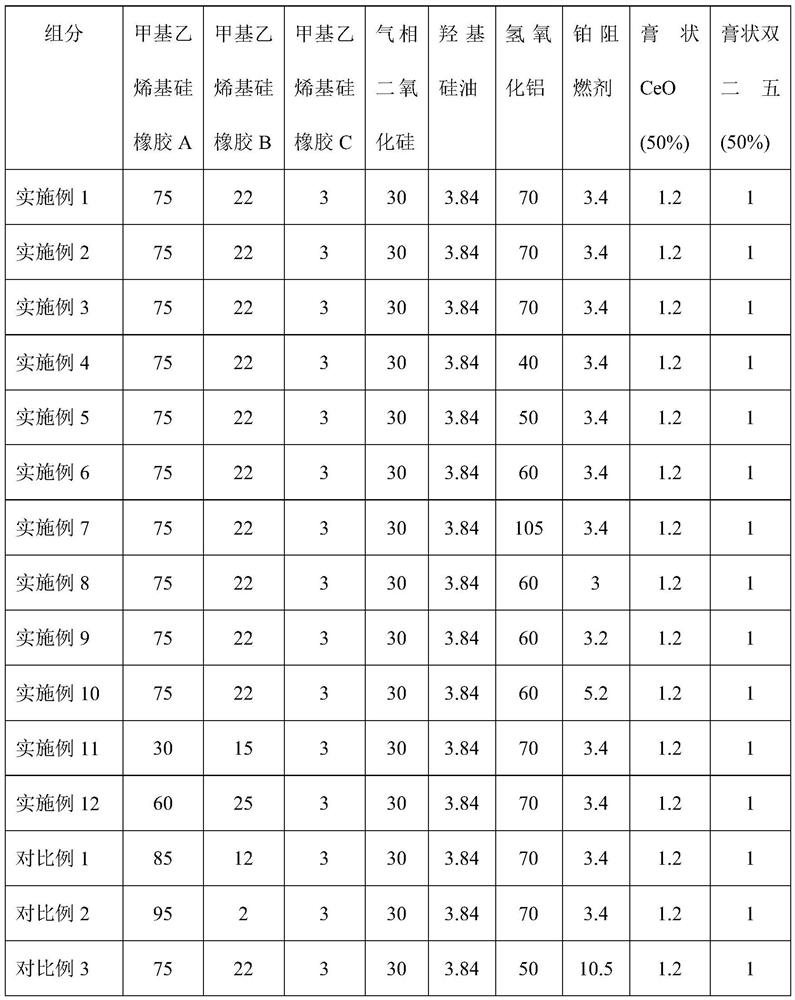

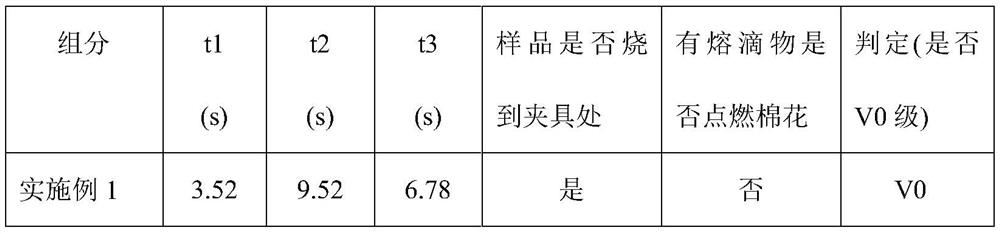

Efficient flame-retardant silicone rubber as well as preparation method and application thereof

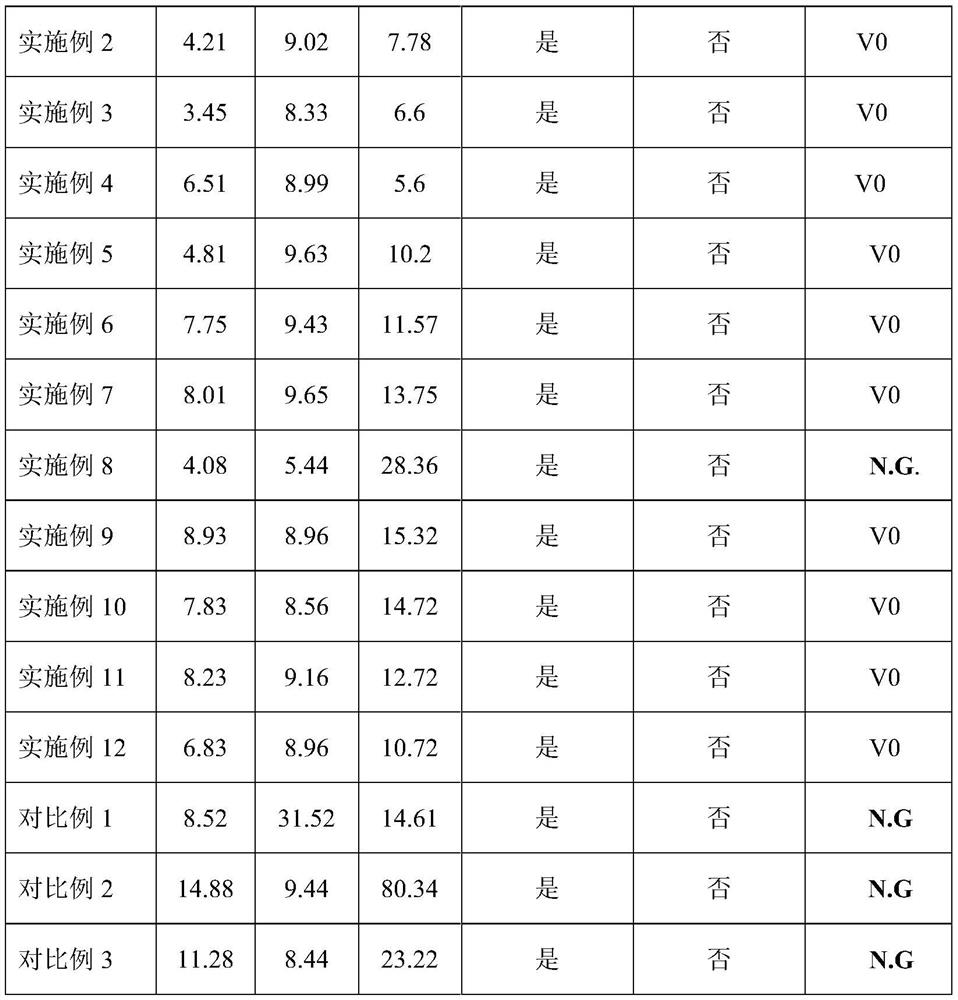

ActiveCN112500707AImprove flame retardant performanceGood mechanical propertiesPolymer scienceSilicone oil

The invention discloses flame-retardant silicone rubber, which is prepared from the following raw materials in parts by mass: 30-80 parts of methyl vinyl silicone rubber A, 10-35 parts of methyl vinylsilicone rubber B, 0-10 parts of hydroxyl silicone oil, 0-50 parts of white carbon black and 23.2-110 parts of a compound flame retardant, wherein the molar content of vinyl of the methyl vinyl silicone rubber A is 0.01-0.15%, and the molar content of vinyl of the methyl vinyl silicone rubber B is 0.2-0.5%. The preparation method of the flame-retardant silicone rubber comprises the following steps of: burdening, kneading, heat treatment, cooling, testing and packaging. The invention also discloses application of the silicone rubber in preparation of flame-retardant rubber products for transportation, electronic industry, instrument industry and aerospace industry. The flame retardance of the flame-retardant silicone rubber reaches the UL94 V0 level at the thickness of 1 mm, and the flame-retardant silicone rubber has the advantages of good mechanical property, long storage life and high stability.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Hydrosilylation reaction catalyst

InactiveCN106660031AEasy to getEasy to handleSilicon organic compoundsOrganic chemistry methodsPlatinumCobalt acetate

A hydrosilylation reaction catalyst prepared from: a catalyst precursor comprising a transition metal compound, excluding platinum, belonging to group 8-10 of the periodic table, e.g., iron acetate, cobalt acetate, nickel acetate, etc; and a ligand comprising a carbine compound such as 1,3-dimesitylimidazol-2-ylidene, etc.. The hydrosilylation reaction catalyst has excellent handling and storage properties. As a result of using this catalyst, a hydrosilylation reaction can be promoted under gentle conditions.

Owner:KYUSHU UNIV +1

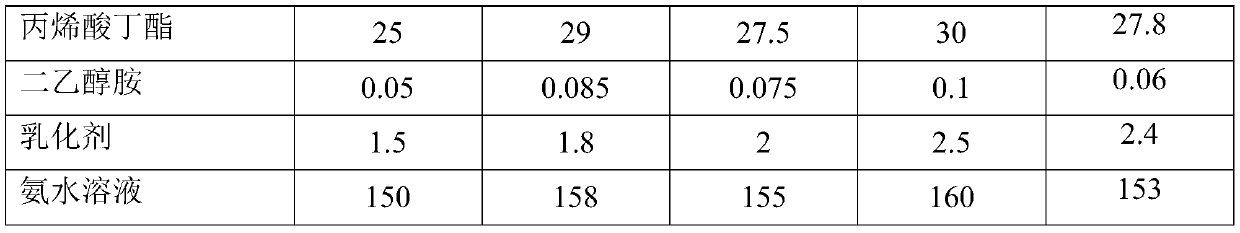

Method for synthesizing terpinum from turpentine oil and preparing terpineol and acetic ester

ActiveCN108752163ALess corrosiveHigh yieldOrganic compound preparationCarboxylic acid esters preparationAcetic anhydridePhosphoric acid

The invention discloses a method for synthesizing terpinum from turpentine oil and preparing terpineol and acetic ester. The method comprises the following steps: turpentine oil, water, phosphoric acid, alpha-hydroxy acid, a cocatalyst and an emulsifier are added into a reaction kettle, stirring is started, and a synthetic product is obtained after a reaction; the synthetic product is allowed to stand for crystallization, filtering is performed to obtain a hydrated terpinum crystal, a filter liquid is allowed to stand for delamination, and the upper layer is oil containing a hydrous product; the terpinum crystal is added into a dehydration reaction kettle and water is added thereto, stirring and heating are performed, and the reaction is allowed to obtain a crude terpineol product; the terpinum crystal is added into an esterification reaction kettle, acetic anhydride is added, stirring is performed, a temperature reaction is performed to obtain a crude acetic ester product; the crude terpineol product or the ethyl ester product is neutralized by lime water, water washing is performed, and a product after the water washing is subjected to vacuum fractionation to obtain a refined terpineol or acetic ester product. The method provided by the invention has the advantages of simple process, less discharge of three wastes, mild reaction conditions, high yield of terpineol, and relatively good social, ecological and economic benefits.

Owner:GUANGXI FORESTRY RES INST

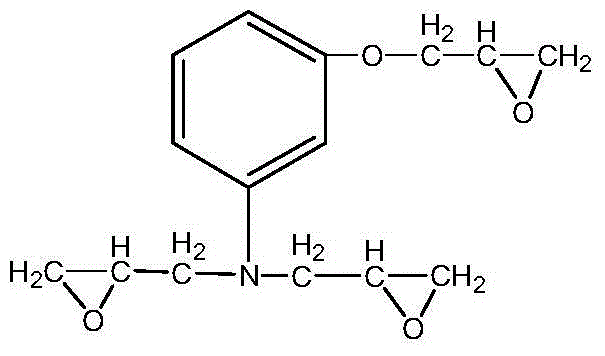

Preparation method of triglycidyl-meta-aminophenol epoxy resin

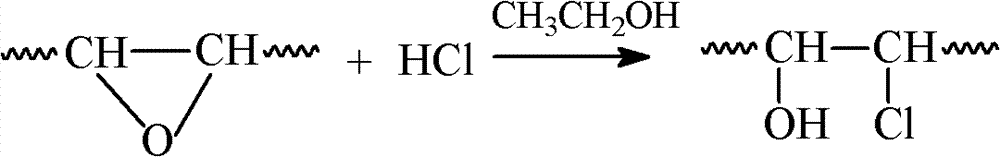

InactiveCN104478831AHigh energyFacilitate addition reactionOrganic chemistryChemistryAddition reaction

The invention discloses a preparation method of triglycidyl-meta-aminophenol epoxy resin. The ideal epoxy resin is prepared by adopting low-temperature addition reaction and vacuum dehydration ring-closure reaction, wherein the mole ratio of raw materials, namely meta-aminophenol to epoxy chloropropane is 1:(7-9), one of or a mixture of more than two of groups formed by benzyl diethyl ammonium chloride, benzyl triethyl ammonium chloride, benzyl trimethyl ammonium chloride, benzyl diethyl ammonium bromide, benzyl triethyl ammonium bromide and benzyl trimethyl ammonium bromide is used as a catalyst, the reaction temperature is 45-55 DEG C, and the reaction time is 6-7 hours; during the ring-closure reaction, the mole ratio of sodium hydroxide to meta-aminophenol is 1:(3-3.5), the reaction is performed at a temperature of 45-55 DEG C and a pressure of 0.06-0.07 MPa for 2-3 hours, and the obtained epoxy resin has the viscosity (measured at 25 DEG C) of 7000-8000mPa.S and the epoxy index of 9.0-9.4eq / Kg; and after the epoxy resin is cured by using 140-160wt% of methyl methenyl tetrabydrophthalic anhydride, the physical and mechanical properties of the epoxy resin are as follows: Tg is 241 DEG C, the impact strength is 16-20KJ / m<2>, the bending strength is 180-190MPa, and the tensile strength is 50-70MPa.

Owner:SHANGHAI HUAYI RESINS CO LTD

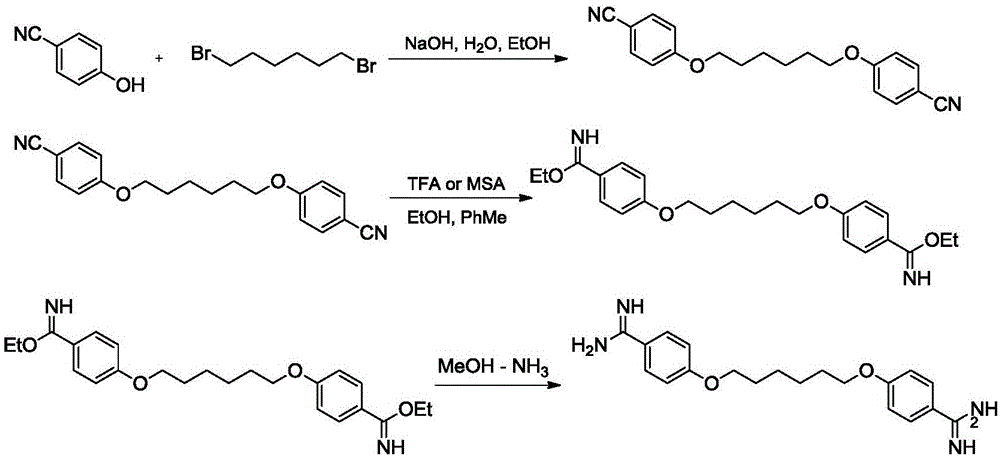

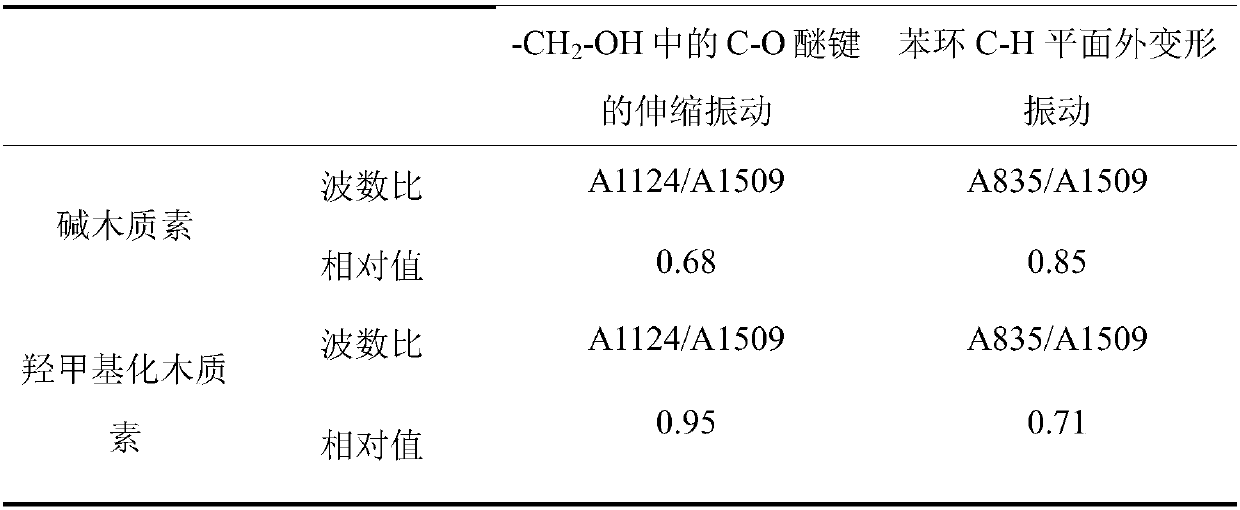

Synthetic method of hexamidine

ActiveCN105037206AReduce process stepsHigh yieldAntibacterial agentsAntimycoticsAminolysisSodium hydroxide

The invention discloses a synthetic method of hexamidine. Hexamidine is a key raw material for producing antibiotic medicines hexamidine salts (such as dihydrochloride and dihydroxyethyl sulfonate). The synthetic method of hexamidine comprises the following steps: 1, reacting p-cyanophenol with 1,6-dibromohexane in an ethanol-water solution of sodium hydroxide to prepare 1,6-(p-cyanophenyl)hexyl diether (an intermediate I); 2, carrying out alcoholysis on the intermediate I in ethanol-toluene under the catalysis of trifluoroacetic acid or methanesulfonic acid to prepare 1,6-(p-ethyl iminoformate phenyl)hexyl diether (an intermediate II); and 3, carrying out aminolysis on the intermediate II in a methanol-ammonia solution to prepare hexamidine. The total yield of three-step synthesis is greater than 72%, and a nuclear magnetism identification result shows that the above obtained product is a preconceived structure product. The method is suitable for large-scale industrial production.

Owner:XIAN WONDER SCI & TECH

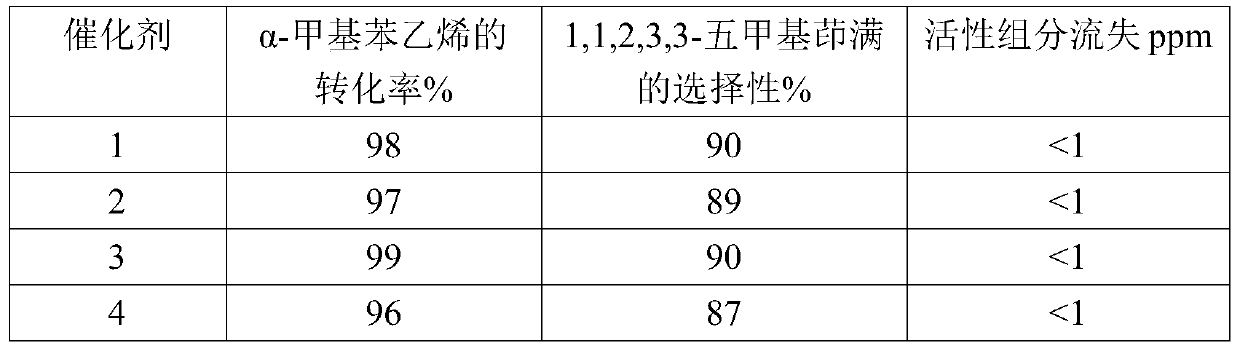

Composite metal photocatalysis system and preparation method and application thereof

ActiveCN110975940AFast transferEfficient transferOrganic-compounds/hydrides/coordination-complexes catalystsOrganic free radical generationPtru catalystCycloaddition

The invention discloses a composite metal photocatalysis system which is represented by Ni-M-X-Y-Z, wherein M is selected from the group consisting of Al, Ag, Bi, Cd, Ge, Sb and Sn; x is selected fromthe group consisting of triphenylphosphine, triethylphosphine, tributylphosphine, tri-tert-butylphosphine and tricyclohexylphosphine; Y is selected from the group consisting of carbon nanorods, molecular sieves, ordered mesoporous carbon and silicon dioxide; Z is selected from the group consisting of diphenyl disulfide, dicumyl peroxide, hydrazine and 2,4-dinitrophenylhydrazine; the mass fractionof Ni is 10-20%; the mass fraction of M is 20-30%; the mass fraction of X is 20-40%; the mass fraction of Y is 15-40%,; and the mass fraction of Z is 10-30%. The catalytic system is used for preparing 1,1,2,3,3-pentamethylindane through free radical cycloaddition of alpha-methylstyrene and 2-methyl-2-butene, an conversion rate is larger than 90%, and selectivity is larger than 85%; and a catalystis stable and not prone to loss in the free radical cycloaddition reaction. A method provided by the invention is easy to operate and good in economic benefit.

Owner:WANHUA CHEM GRP CO LTD

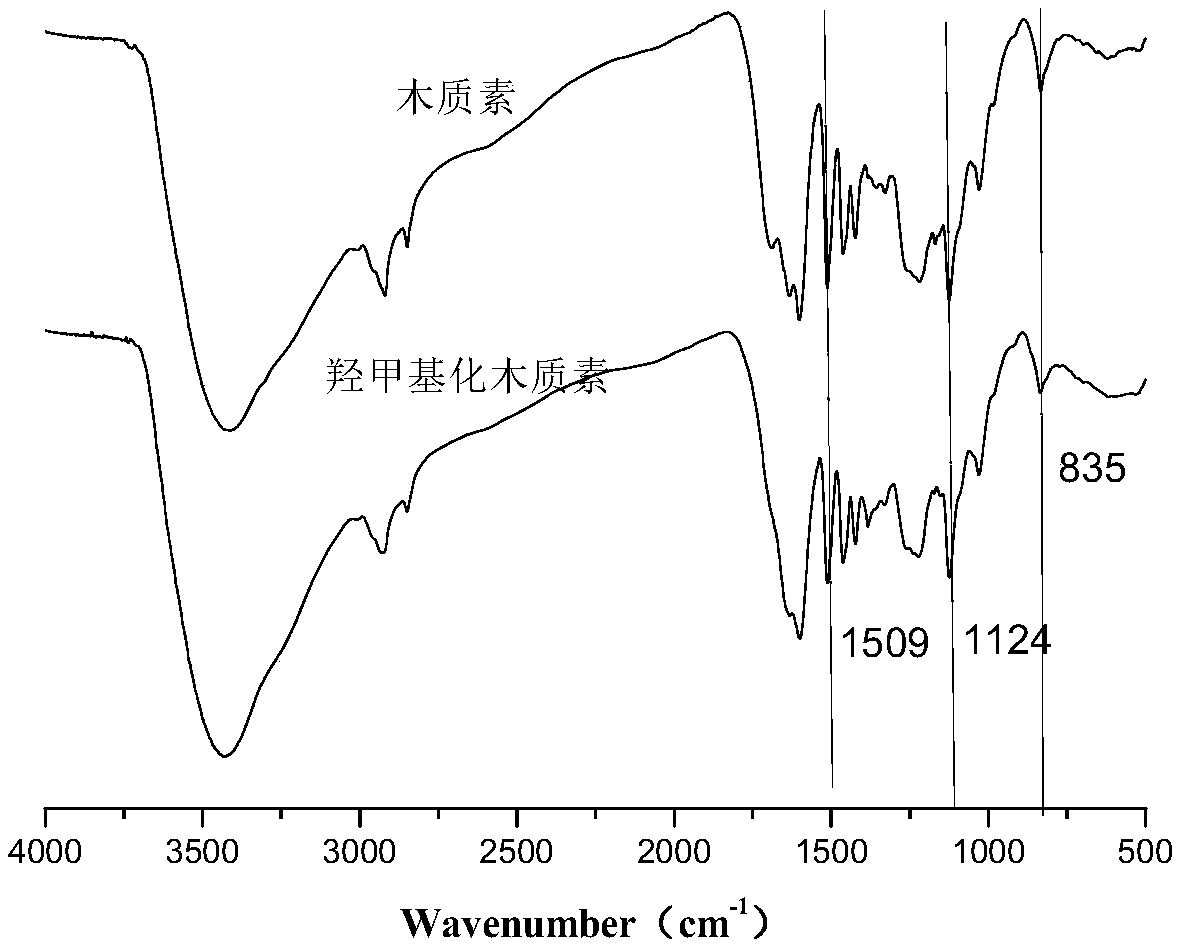

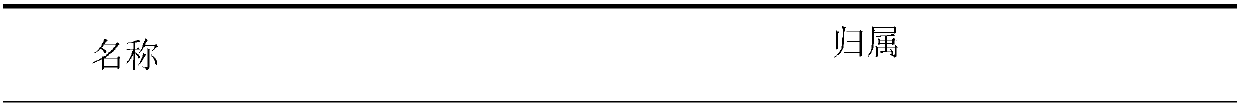

Preparation method of hydroxymethylated lignin

The invention discloses a preparation method of hydroxymethylated lignin. The method comprises the following steps: adding certain amounts of lignin, a formaldehyde solution and a solid base into a hydrothermal reactor, performing uniform stirring, sealing the reactor, heating the reactor to a specific temperature, carrying out a reaction for a period of time, cooling the obtained reaction productto room temperature, and carrying out washing, suction filtration and drying on the product to obtain the hydroxymethylated lignin. The method for preparing the hydroxymethylated lignin by a hydrothermal process has the advantages of easiness in operation, simplicity in post-treatment, no acidification precipitation step, facilitation of further high-value utilization of the hydroxymethylated lignin, and good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

The synthetic method of hexamidine

ActiveCN105037206BReduce process stepsHigh yieldAntibacterial agentsAntimycoticsAminolysisSodium hydroxide

The invention discloses a synthetic method of hexamidine. Hexamidine is a key raw material for producing antibiotic medicines hexamidine salts (such as dihydrochloride and dihydroxyethyl sulfonate). The synthetic method of hexamidine comprises the following steps: 1, reacting p-cyanophenol with 1,6-dibromohexane in an ethanol-water solution of sodium hydroxide to prepare 1,6-(p-cyanophenyl)hexyl diether (an intermediate I); 2, carrying out alcoholysis on the intermediate I in ethanol-toluene under the catalysis of trifluoroacetic acid or methanesulfonic acid to prepare 1,6-(p-ethyl iminoformate phenyl)hexyl diether (an intermediate II); and 3, carrying out aminolysis on the intermediate II in a methanol-ammonia solution to prepare hexamidine. The total yield of three-step synthesis is greater than 72%, and a nuclear magnetism identification result shows that the above obtained product is a preconceived structure product. The method is suitable for large-scale industrial production.

Owner:XIAN WONDER SCI & TECH

A method for preparing high-purity octafluoropropane

ActiveCN107098790BRealize industrial productionFacilitate addition reactionPreparation by halogen additionPtru catalystHexafluoropropylene

The invention relates to a method for preparing high-purity octafluoropropane, comprising the steps of: setting the reaction temperature to 50-250°C in a reactor, using cobalt trifluoride as a catalyst, hexafluoropropylene and fluorine as reaction gases, The reaction prepares octafluoropropane; the molar ratio of the hexafluoropropylene to the fluorine gas is 1:2-6. In this preparation method, cobalt trifluoride is used as a catalyst to realize continuous reaction, which promotes the addition reaction of hexafluoropropylene and fluorine gas, the conversion rate of hexafluoropropylene is almost 100%, and the yield of octafluoropropane can reach More than 90%, the selectivity of the reaction is good, and the content of by-products is small. The obtained crude product can prepare high-purity octafluoropropane after subsequent purification treatment, which is a low-cost, high-efficiency octafluoropropane production method that can realize industrial production.

Owner:FOSHAN HUATE GASES +1

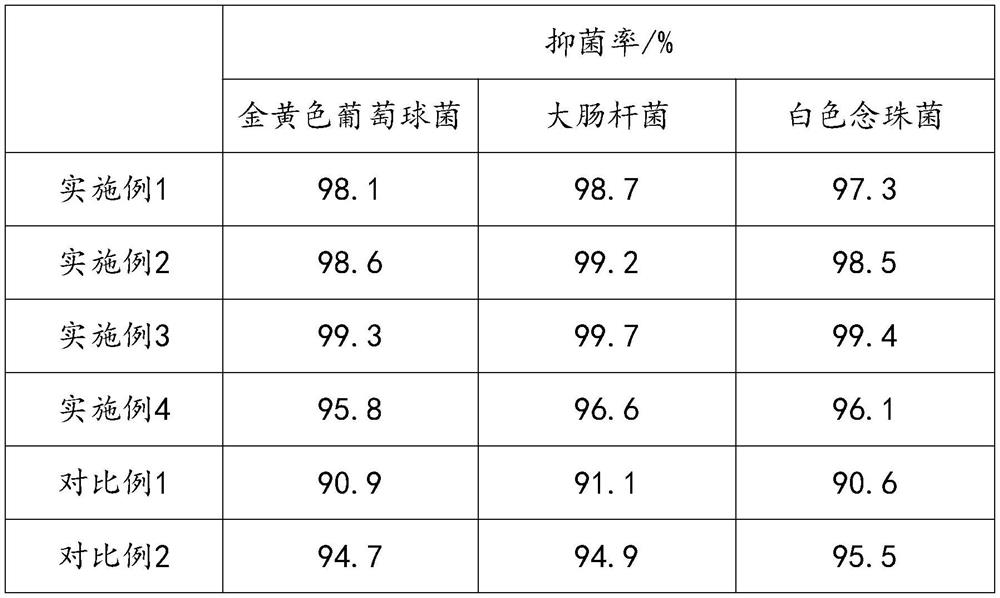

Preparation method of chitosan fiber non-woven fabric applied to surface layer of paper diaper

ActiveCN114318669ABiodegradableImprove antibacterial propertiesArtificial filament washing/dryingWet spinning methodsWoven fabricPolymer chemistry

The invention relates to the field of disposable hygienic products, and provides a preparation method of a chitosan fiber non-woven fabric applied to the surface layer of a paper diaper, and the preparation method comprises the following steps: 1) preparing N-carboxyethyl chitosan; (2) preparing modified chitosan; (3) preparing modified chitosan fibers; and (4) preparing the chitosan fiber non-woven fabric. The prepared chitosan fiber non-woven fabric can effectively prevent diaper rash and better protect baby skin.

Owner:FUJIAN HENGAN HLDG CO LTD +2

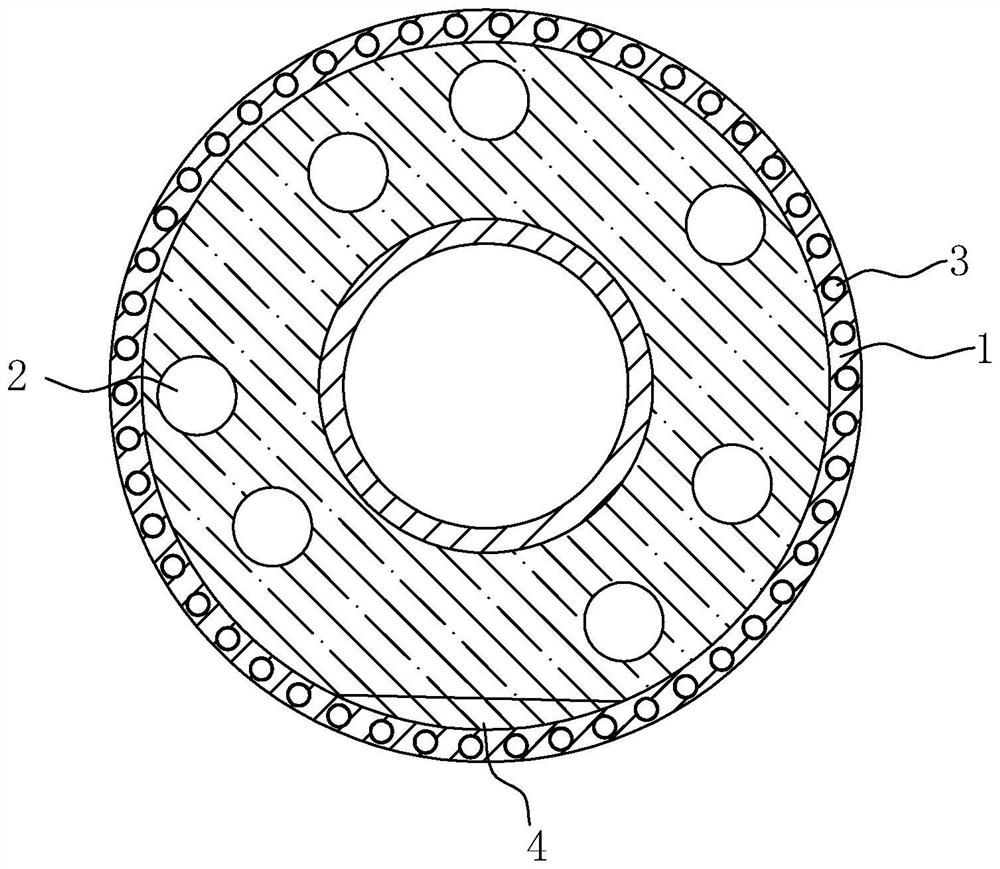

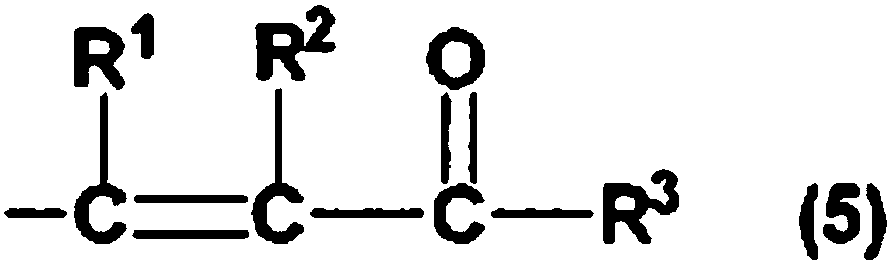

Acrylate modified silicone oil and preparation method thereof

ActiveCN114213663AImprove composite qualityFacilitate cross-linkingChemical recyclingPolymer sciencePtru catalyst

The invention relates to the field of modified silicone oil, and particularly discloses acrylate modified silicone oil and a preparation method thereof. The acrylate modified silicone oil is characterized by being prepared from the following raw materials in parts by weight under the action of a catalyst: 100-120 parts of hydrogen-containing silicone oil, 150-200 parts of allyl acrylate, 2-5 parts of a polymerization inhibitor and 10-12 parts of a chain transfer agent, wherein the catalyst is a rhodium catalyst. The preparation method comprises the following steps: S1, uniformly mixing allyl acrylate, a rhodium catalyst and a polymerization inhibitor in proportion, and cooling to 5-8 DEG C to obtain a mixed raw material; s2, adjusting the temperature of the hydrogen-containing silicone oil to 10-15 DEG C to obtain pretreated hydrogen-containing silicone oil; s3, mixing the pretreated hydrogen-containing silicone oil and a mixed raw material for hydrosilylation reaction; the step S1 and the step S2 are not divided into a sequence. The method has the advantage that the product quality is improved.

Owner:杭州崇耀科技发展有限公司

Modified polyimide secondary battery adhesive and preparation method thereof

PendingCN114709420AImprove cycle stabilityImprove solubilityCell electrodesElectrolytic agentElectrical battery

The invention relates to the technical field of lithium ion batteries, in particular to a modified polyimide secondary battery adhesive and a preparation method thereof. The secondary battery adhesive is prepared from the following raw materials: polyimide powder, a lipid compound and a positive electrode material, the polyimide powder is prepared from the following raw materials: an organic amine compound, an additive, a heteroaromatic compound, acid anhydride, an aprotic polar solvent, an ultra-dry solvent, a nitrogen-containing organic compound and an acetylation reagent. Polyimide is modified by adding a compound containing an epoxy group, so that the prepared adhesive contains a large number of polyimide structures, the dimensional stability and heat resistance of the adhesive in an electrolyte are ensured, and meanwhile, the adhesive force of the adhesive on a copper foil can be effectively improved by a molecular chain segment containing the epoxy structure. The prepared modified polyimide secondary battery adhesive is applied to a lithium ion battery, and the electrochemical performance and safety of the battery can be effectively improved.

Owner:江苏环峰电工材料有限公司

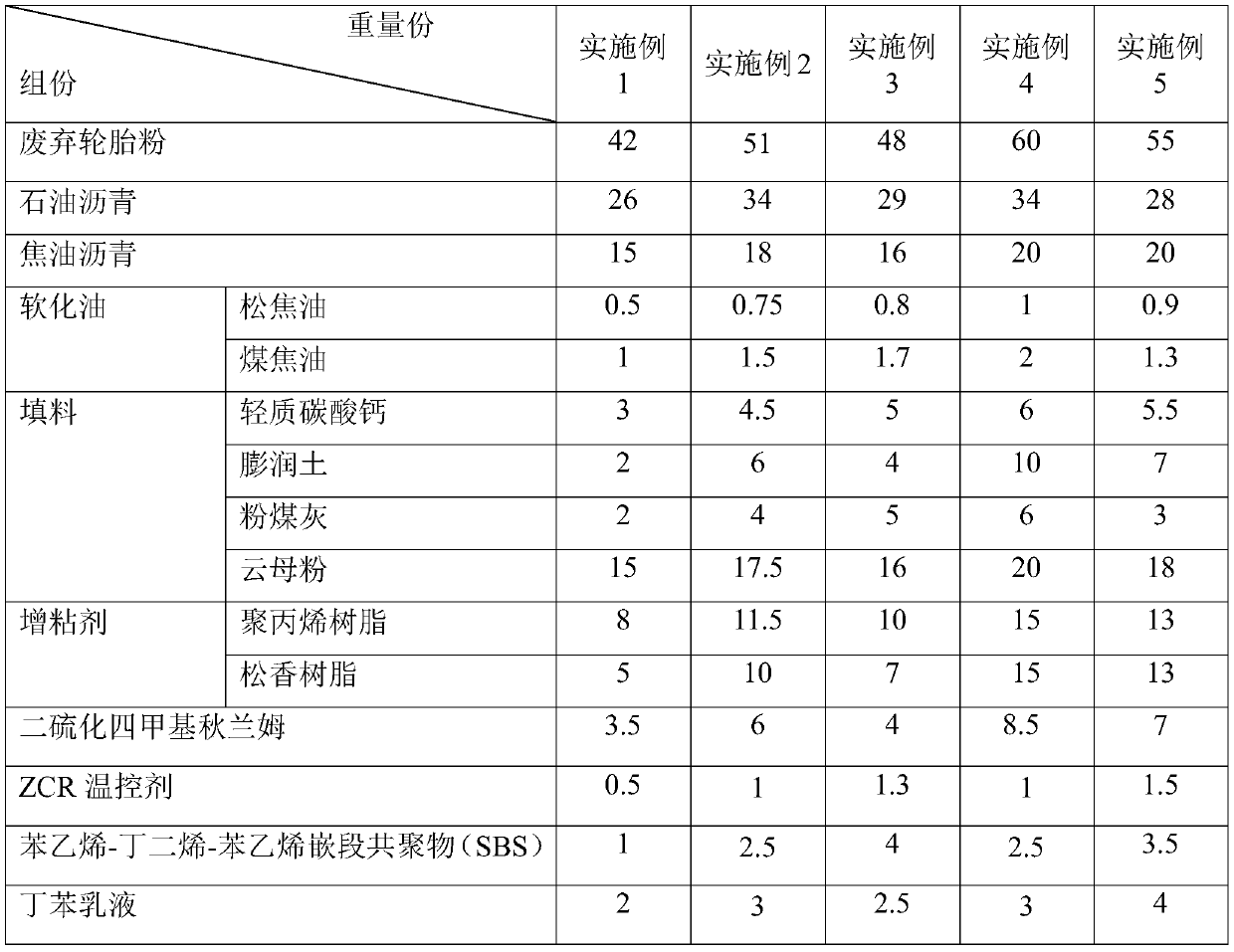

Modified Rosin Resin

InactiveCN102911600BImprove wettabilityGood discoloration effectRosin coatingsNatural resin chemical modificationCresolGlycerol

The invention discloses modified rosin resin and belongs to the technical field of chemical industry. The modified rosin resin comprises, by weight, 55-60% of first-grade rosin, 5-10% of fumaric acid, 15-24.82% of glycerol, 10-20% of low-iodine-value fatty acid, 0.01-0.05% of anthraquinone, 0.02-0.05% of tri-(2, 4-di-tertiary butyl phenyl) phosphite ester, 0.01-0.05% of 2, 6- di-tertiary butyl p-cresol, 0.03-0.05% of 4, 4-di-(6-tertiary butyl-m-methylphenyl) thiophenol, and 0.01-0.05% of tri-nonyl phenyl phosphite ester. The modified rosin resin can solve the problem that road paint prepared is prone to discolor and poor in liquidity during actual production and application processes.

Owner:DRAGON FISH PAINT

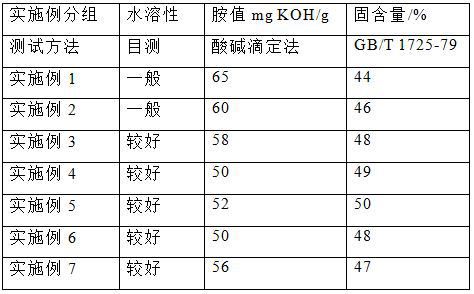

Preparation method of waterborne epoxy curing agent

PendingCN114835881AImprove temperature resistanceGood chemical resistanceEpoxy resin coatingsEpoxyPolymer science

The invention discloses a preparation method of a water-based epoxy curing agent, which comprises the following specific preparation processes: (1) taking polyether amine, putting the polyether amine into a four-mouth reaction bottle, slowly dropwise adding a first epoxy compound in a nitrogen atmosphere, then heating to 80-150 DEG C, and reacting to obtain a polyether amine-epoxy adduct; and (2) putting benzyl polyamine and alcohol ether into a four-mouth reaction bottle, slowly adding the polyether amine-epoxy adduct in a nitrogen atmosphere, heating to 50-80 DEG C, reacting, cooling to 40-60 DEG C, slowly dropwise adding a second epoxy compound, heating to 50-80 DEG C, reacting, slowly adding water, and dispersing for 15-30 minutes to obtain the waterborne epoxy curing agent. According to the preparation method of the waterborne epoxy curing agent provided by the invention, the emulsifying property and the curing property are improved by improving the molecular structure of the curing agent.

Owner:江西百盛精细化学品有限公司

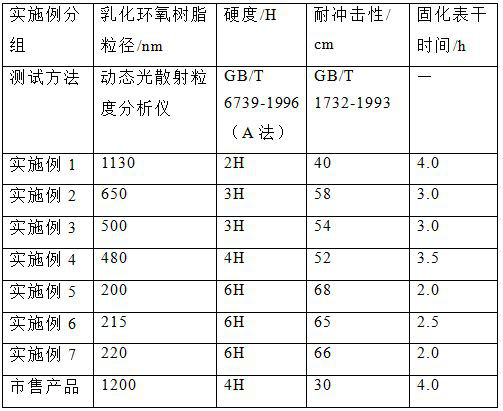

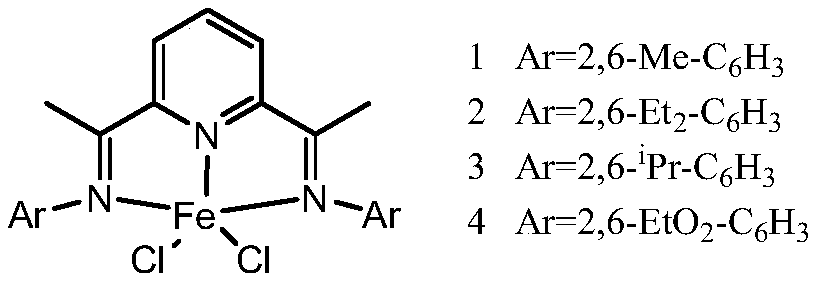

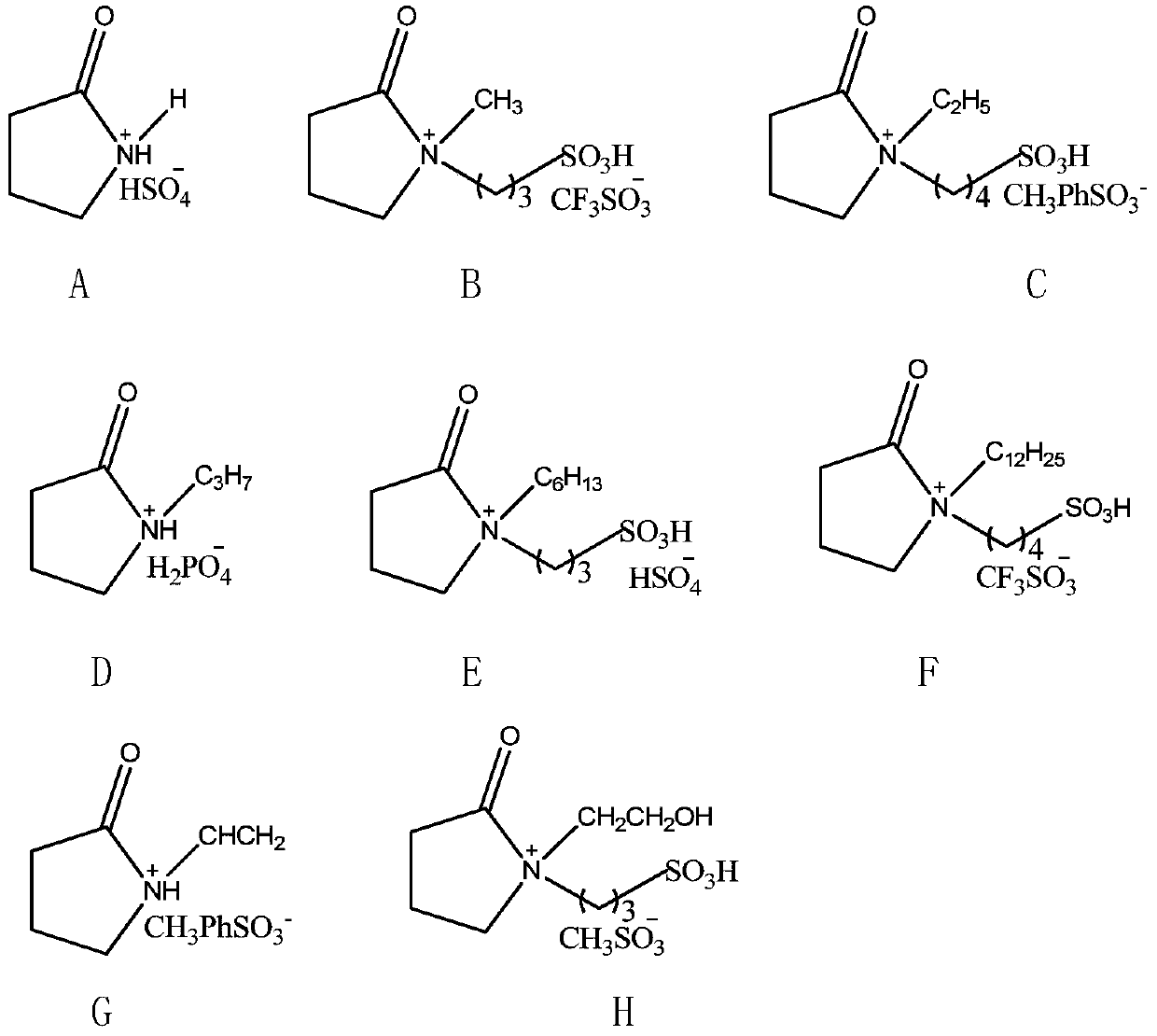

A kind of preparation method and application of iron-based pyrrolidone ionic liquid catalyst

ActiveCN107597184BStrong acidLow toxicityGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenSilanes

Belonging to the catalysis field, the invention provides a preparation method of an iron-based pyrrolidone ionic liquid catalyst and a method for catalysis of olefin hydrosilylation reaction with thecatalyst in order to solve the problems of high catalyst cost and non-recyclability of catalyst in current hydrosilylation reaction. The catalyst prepared by the method provided by the invention can be used for catalyzing hydrosilylation reaction of olefin and hydrogen-containing alkoxy silane, the reaction conditions are mild, the raw material conversion rate is high, and the catalyst is convenient for recycling.

Owner:CHANGZHOU UNIV

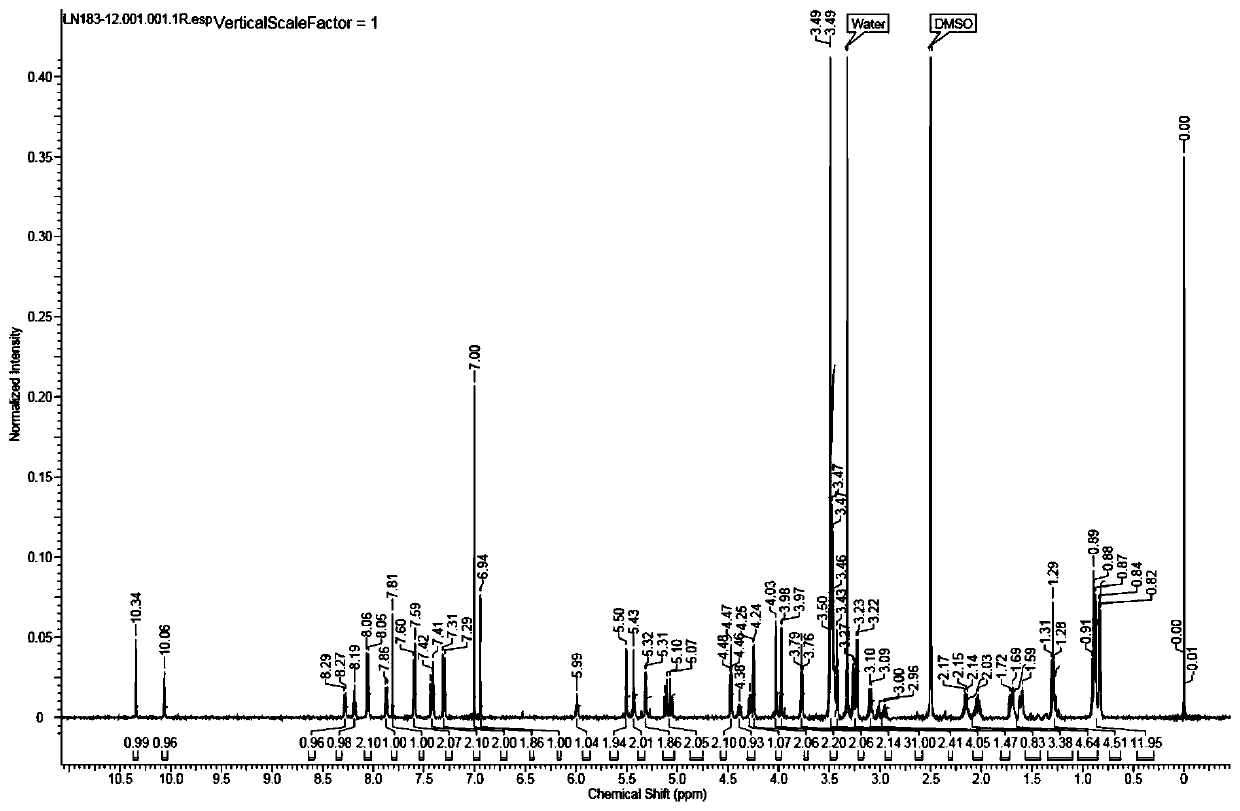

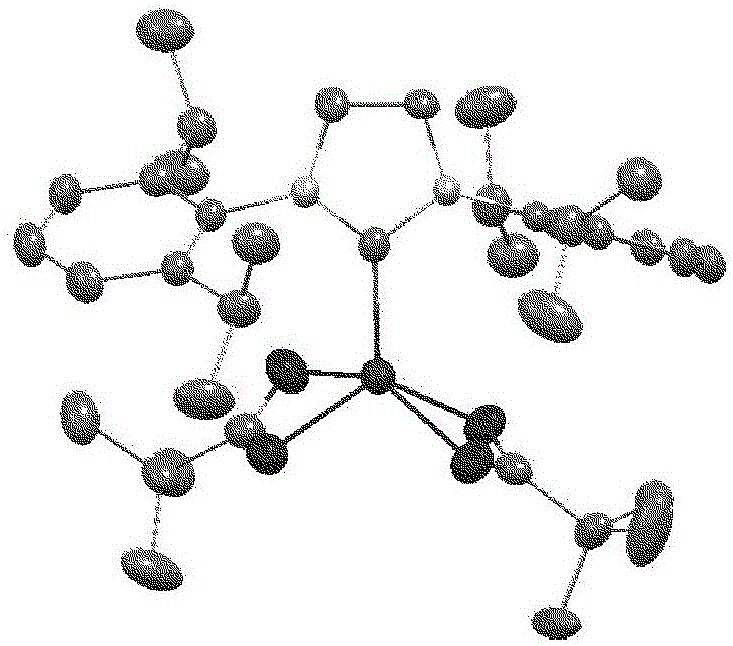

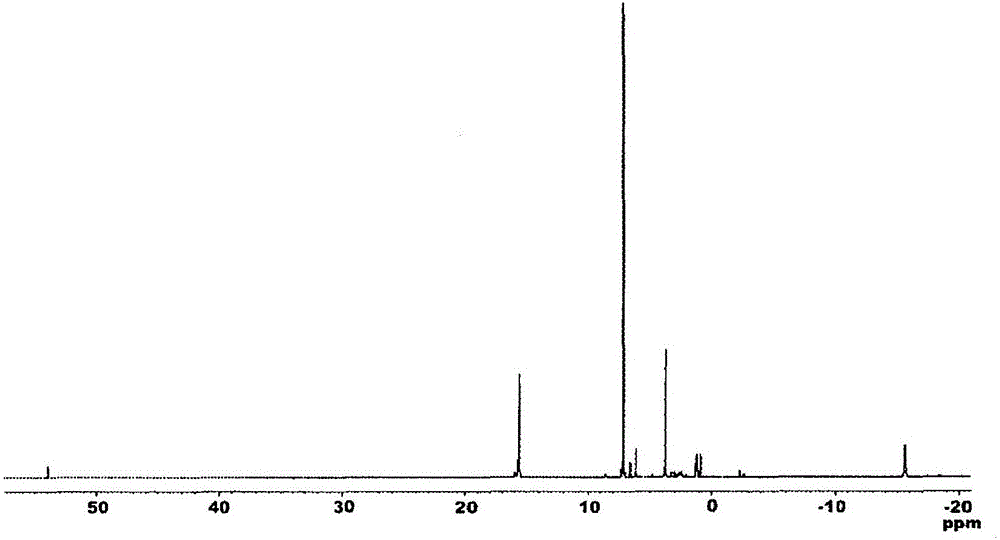

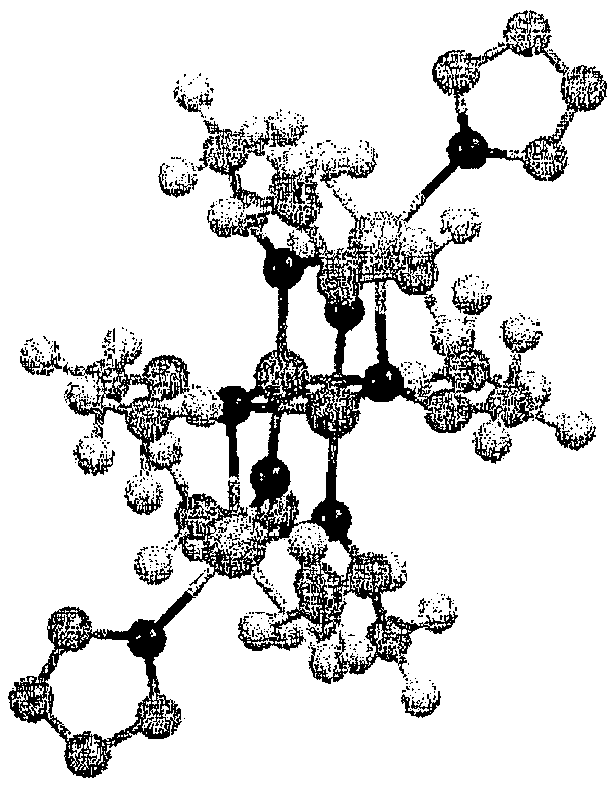

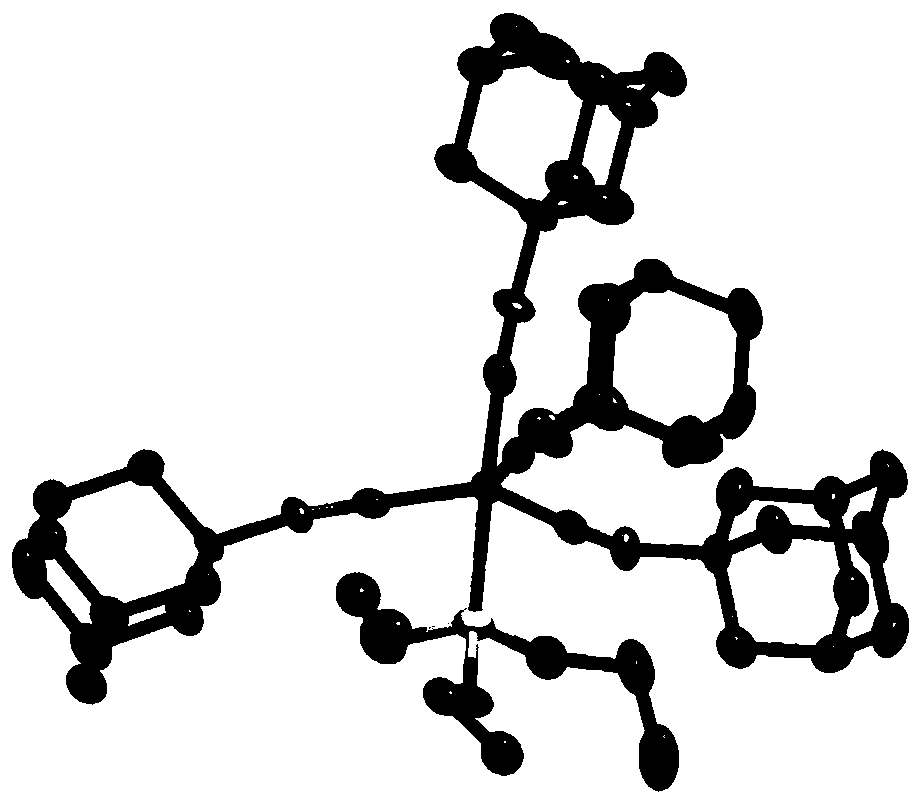

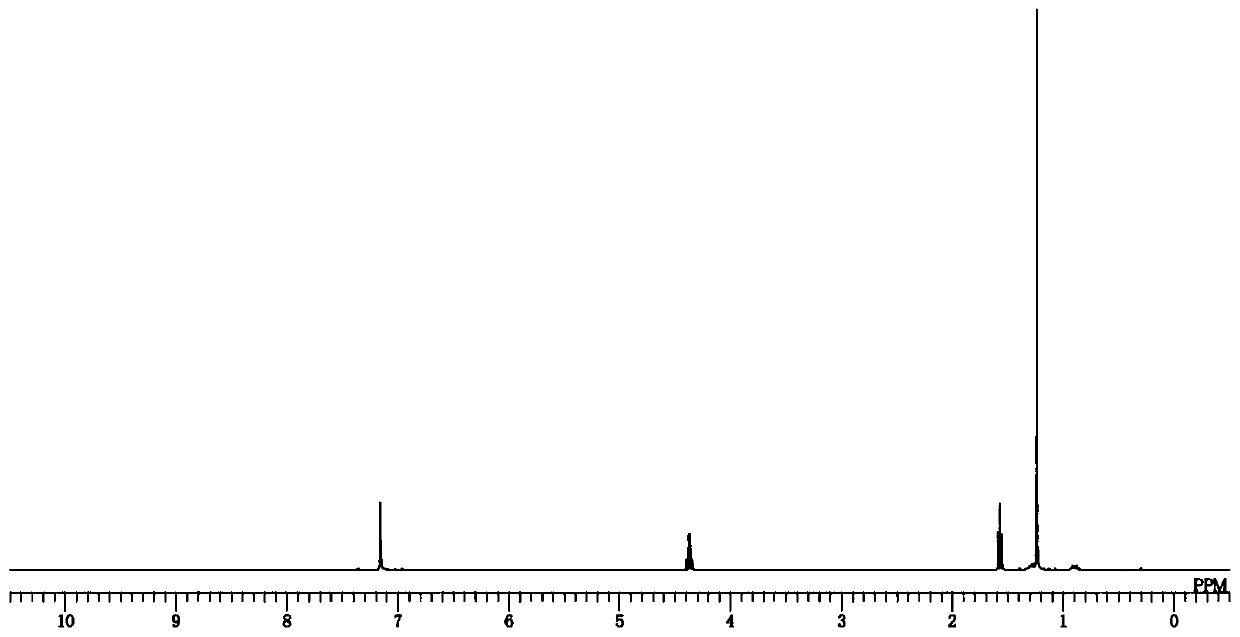

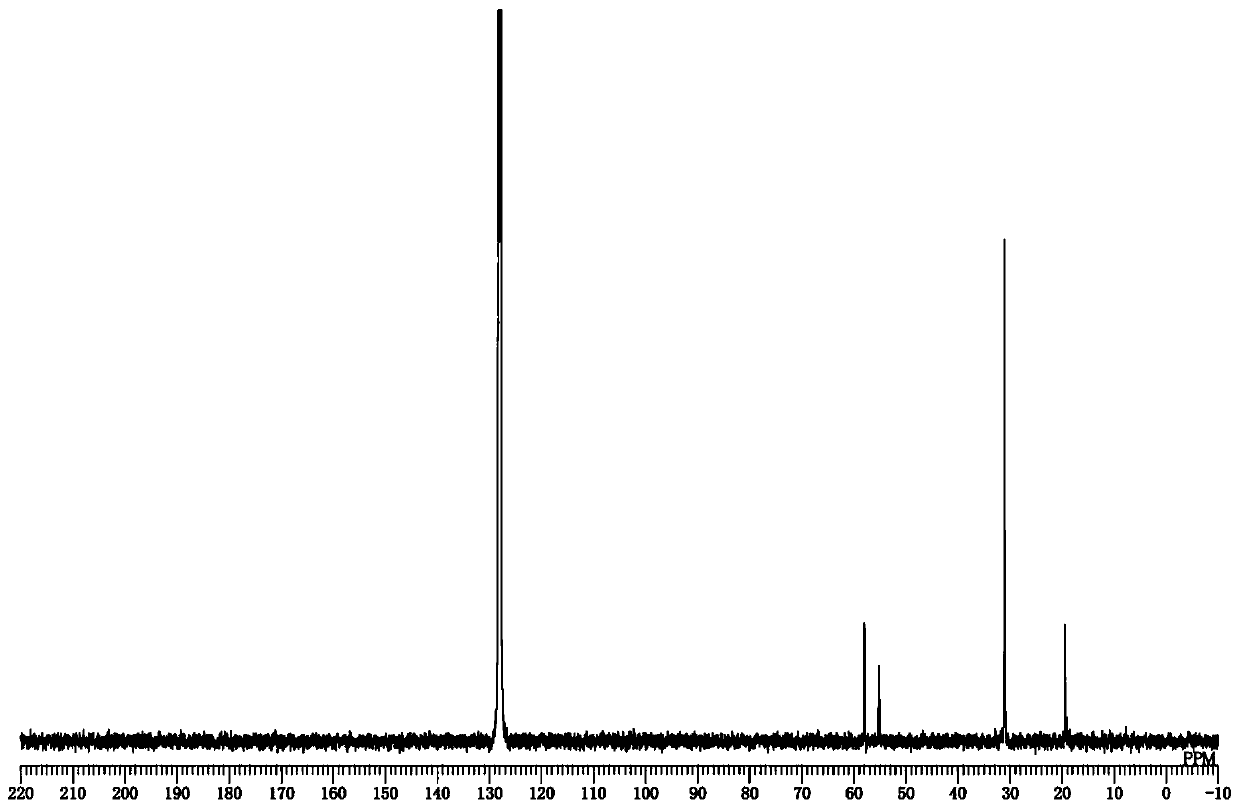

A pyrido[1,2-a][1,2,4]triazole carbene ligand and its synthesis method and application

ActiveCN110483502BFacilitate addition reactionOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsCombinatorial chemistryAlkyne

Owner:ZHEJIANG UNIV OF TECH

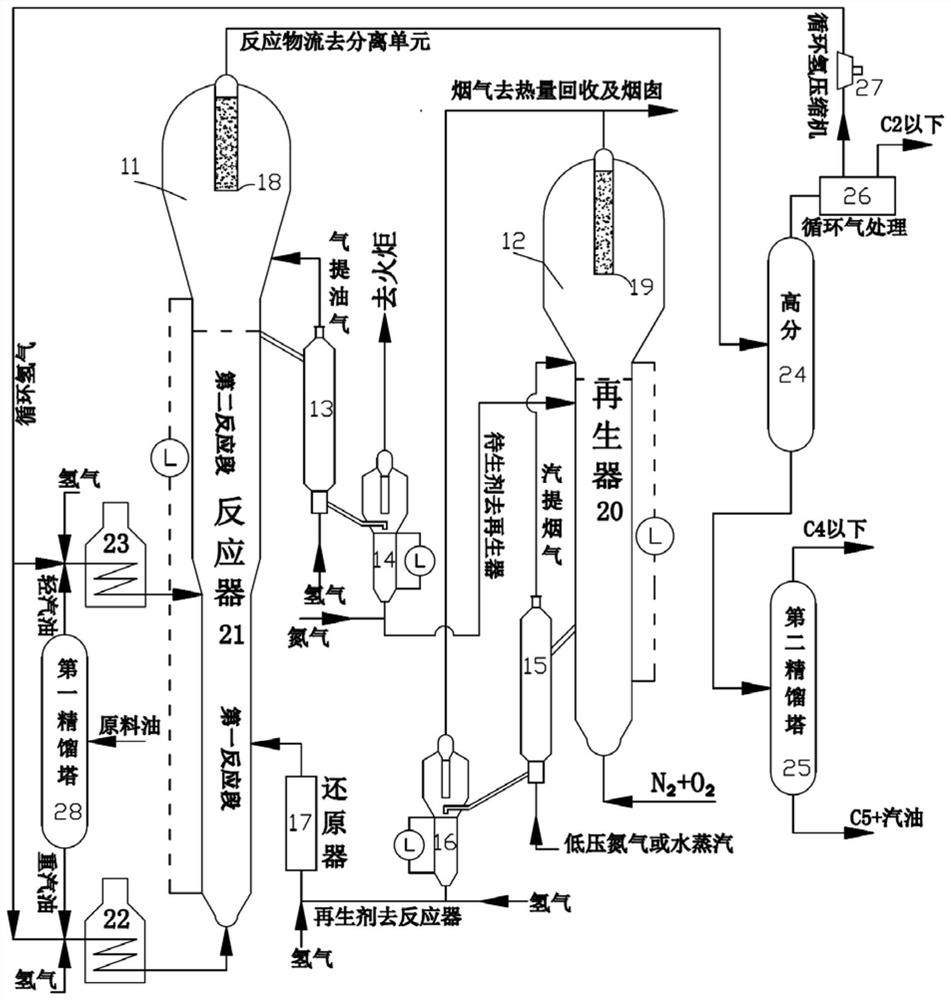

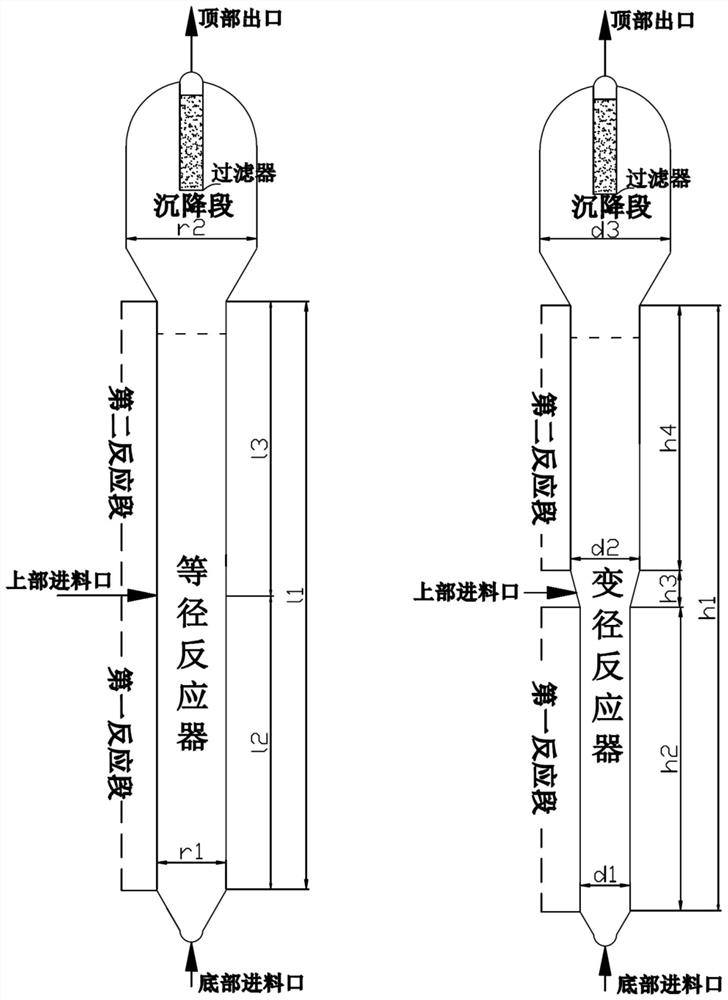

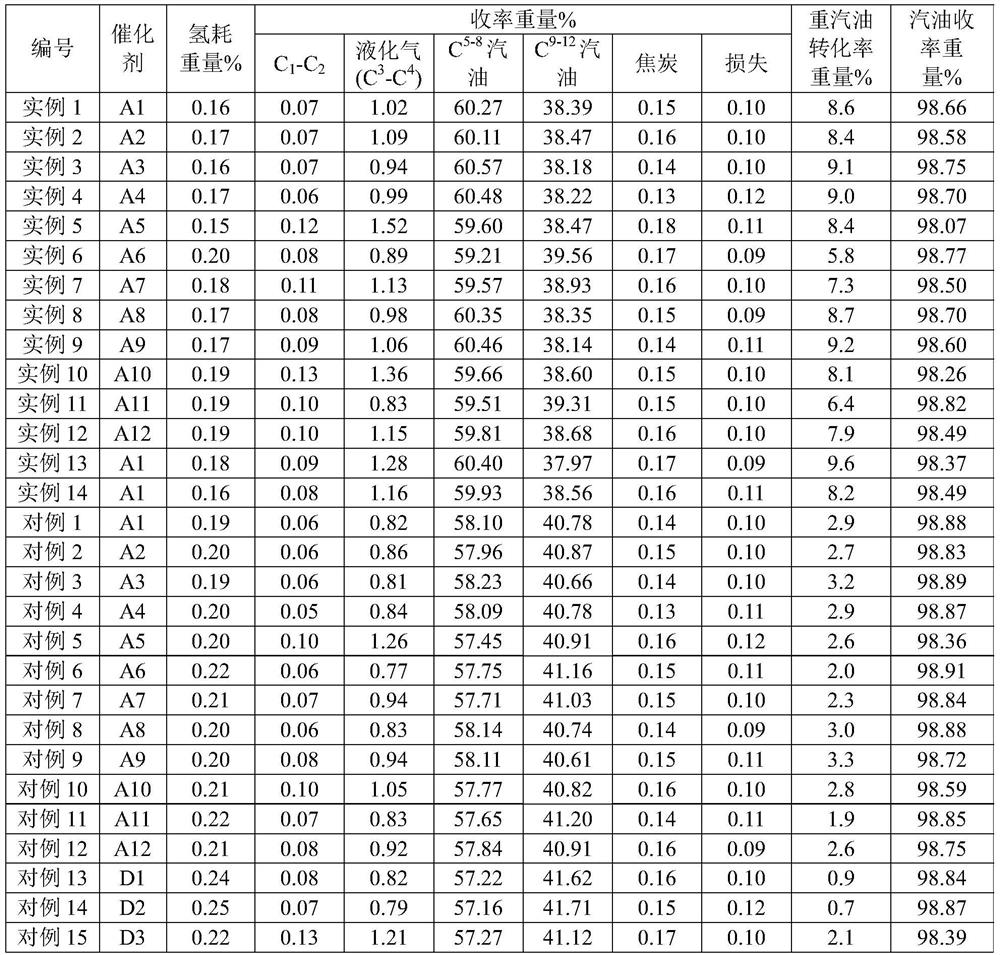

Method and system for producing clean gasoline from sulfur-containing light oil

ActiveCN111100702BHigh yieldStrong desulfurization abilityTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystFluidized bed

The invention relates to the fields of adsorption desulfurization and hydrocarbon conversion, and discloses a method and system for producing clean gasoline from sulfur-containing light oil. The method includes: entering the first rectification tower into light sulfur-containing light raw materials and cutting them into light gasoline and heavy gasoline , heat the mixture flow of heavy gasoline and light gasoline and hydrogen source respectively, and send them to the first reaction section and the second reaction section of the pressurized fluidized bed reactor respectively to contact with the catalyst for reaction, and send the product stream to High-pressure separation is carried out in the high-pressure separator, and the obtained light component stream is separated and treated to obtain a circulating hydrogen stream, which is recycled as a part of the hydrogen source, and the obtained heavy component stream is sent to the second rectification tower for rectification treatment. Separation of liquefied gas and gasoline. The method and system for producing clean gasoline from sulfur-containing light oil of the present invention are suitable for prolific production of low-sulfur, high-octane gasoline and liquefied gas over a long period of time, and the liquid yield is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified abietate for water-based alkyd resin and method for manufacturing modified abietate

InactiveCN103421430BImprove wettabilityGood discoloration effectNatural resin chemical modificationWater basedCis-Butenedioic Acid

The invention discloses modified abietate for water-based alkyd resin and a method for manufacturing the modified abietate, and relates to the field of chemical technologies. The modified abietate comprises, by weight, 55-60% of first-grade rosin, 10-15% of soybean oil fatty acid, 1-5% of diphenol-based methane, 1-5% of paraformaldehyde, 19.8-27.5% of maleic anhydride and 0.2-0.5% of zinc oxide. The modified abietate and the method have the advantages that the cost of the water-based alkyd resin with the modified abietate can be lowered to a certain degree during actual production and application, and pollution can be reduced.

Owner:DRAGON FISH PAINT

Pretreatment method of catalyst for cyclic carbonate synthesis and application of pretreatment method

ActiveCN113426440ASynergistic activationFacilitate addition reactionOrganic chemistryHeterogenous catalyst chemical elementsChemistryEpoxide

The invention provides a pretreatment method of a catalyst for cyclic carbonate synthesis and application of the pretreatment method. A metal oxide-based catalyst is treated for 4-10 h in a nitrogen or argon atmosphere under the condition that the pressure is 0.5-2.0 MPa and the temperature is 400-600 DEG C under the off-line condition. After the treatment is finished, adjusting the temperature to 130-300 DEG C, switching to CO2-nitrogen / argon mixed gas containing 5-100v% of CO2, and carrying out pretreatment on the catalyst for 2-60 hours under the pressure of 1.0-4.0 MPa. According to the method, the structure and the surface acid-base property of the catalyst are regulated and controlled through pretreatment of the metal oxidation-based catalyst, synergistic activation of epoxide and CO2 is achieved, the yield of cyclic carbonate is increased, meanwhile, the catalyst is pretreated through an off-line scheme, the cost of cycloaddition reaction equipment can be remarkably reduced, and the economical efficiency of the process can be improved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for detecting epoxy equivalent weight

InactiveCN102507574BDissolve fastShorten the dissolution timeMaterial analysis by observing effect on chemical indicatorEpoxyPolyethylene glycol

The invention provides a method for detecting an epoxy equivalent weight. The method comprises the following steps of: (a) uniformly mixing butanone, ethanol and hydrochloric acid to obtain a hydrochloric acid-ethanol-butanone solution; preheating polyethylene glycol to 100-110 DEG C, adding an epoxy compound, dissolving and cooling to obtain a sample solution to be detected; (b) adding the hydrochloric acid-ethanol-butanone solution to the sample solution to be detected, and vibrating; and (c) titrating the mixed solution obtained in the step b by using a sodium hydroxide standard solution till the solution is neutral, and calculating the epoxy equivalent weight according to the use amount of the sodium hydroxide. The method for detecting the epoxy equivalent weight, provided by the invention, has the characteristics of wide application range, short detection time, accurate result and capability of controlling the end point of an epoxy resin synthetic reaction in time.

Owner:CHONGQING POLYCOMP INT

One-step synthesis of brominated sbs production process

Owner:山东东信阻燃科技有限公司

Hydrosilylation reaction catalyst

ActiveCN107847921AHigh exposure reactivityEasy to getSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsCobalt acetateIsocyanide compound

Owner:KYUSHU UNIV +1

Cobalt complex, production method therefor, and catalyst for hydrosilylation reaction

InactiveCN111132990AImprove thermal stabilityImprove stabilitySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHalogen

Owner:KYUSHU UNIV +1

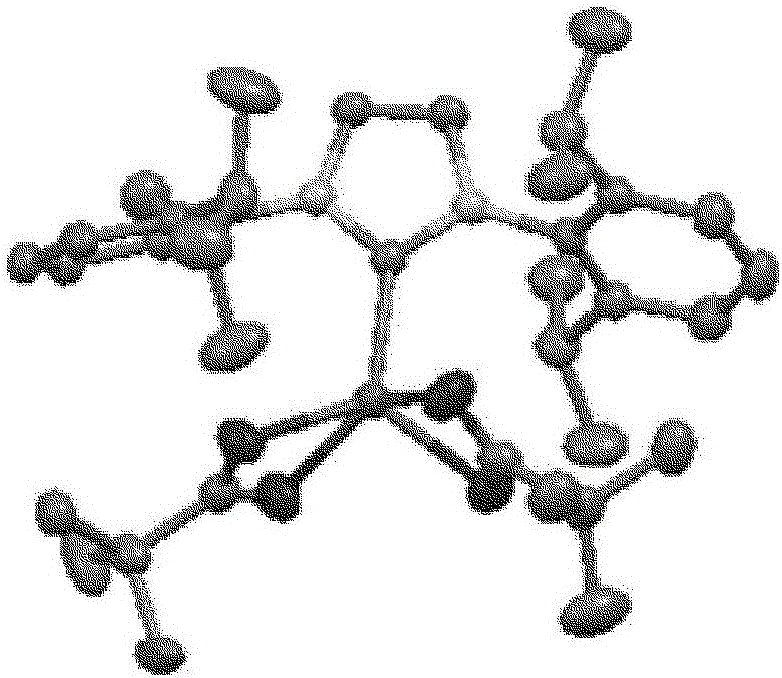

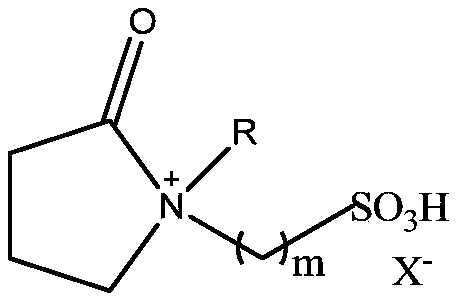

Pyrido[1,2-a][1,2,4]triazole carbene ligand as well as synthesis method and application thereof

ActiveCN110483502AFacilitate addition reactionOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsCarbeneAddition reaction

The invention provides a pyrido[1,2-a][1,2,4]triazole carbene ligand as well as a synthesis method and application thereof. A pyrido[1,2-a][1,2,4]triazole carbene-gold complex formed from the pyrido[1,2-a] [1,2,4]triazole carbene ligand shown as a formula V and gold can be applied to alkyne catalytic addition reaction, has Lewis acid / alkali double activation centers, and can depend on the 'synergistic activation effect' of the double activation centers, so that the catalytic effect which cannot be achieved or cannot be achieved by a conventional ligand is achieved, and the addition reaction ofa nucleophilic reagent to multiple bonds can be greatly accelerated.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![A pyrido[1,2-a][1,2,4]triazole carbene ligand and its synthesis method and application A pyrido[1,2-a][1,2,4]triazole carbene ligand and its synthesis method and application](https://images-eureka.patsnap.com/patent_img/1e07c2ad-be3f-40bd-bdac-a513d4d42d4a/FDA0002620584750000011.png)

![A pyrido[1,2-a][1,2,4]triazole carbene ligand and its synthesis method and application A pyrido[1,2-a][1,2,4]triazole carbene ligand and its synthesis method and application](https://images-eureka.patsnap.com/patent_img/1e07c2ad-be3f-40bd-bdac-a513d4d42d4a/FDA0002620584750000021.png)

![A pyrido[1,2-a][1,2,4]triazole carbene ligand and its synthesis method and application A pyrido[1,2-a][1,2,4]triazole carbene ligand and its synthesis method and application](https://images-eureka.patsnap.com/patent_img/1e07c2ad-be3f-40bd-bdac-a513d4d42d4a/FDA0002620584750000031.png)

![Pyrido[1,2-a][1,2,4]triazole carbene ligand as well as synthesis method and application thereof Pyrido[1,2-a][1,2,4]triazole carbene ligand as well as synthesis method and application thereof](https://images-eureka.patsnap.com/patent_img/9fb0d993-03b5-4899-912f-ec9ecbf42966/FDA0002152410840000011.png)

![Pyrido[1,2-a][1,2,4]triazole carbene ligand as well as synthesis method and application thereof Pyrido[1,2-a][1,2,4]triazole carbene ligand as well as synthesis method and application thereof](https://images-eureka.patsnap.com/patent_img/9fb0d993-03b5-4899-912f-ec9ecbf42966/FDA0002152410840000031.png)

![Pyrido[1,2-a][1,2,4]triazole carbene ligand as well as synthesis method and application thereof Pyrido[1,2-a][1,2,4]triazole carbene ligand as well as synthesis method and application thereof](https://images-eureka.patsnap.com/patent_img/9fb0d993-03b5-4899-912f-ec9ecbf42966/BDA0002152410850000021.png)