Method for preparing high-purity perfluoropropane

An octafluoropropane, high-purity technology, applied in the field of preparation of octafluoropropane, can solve the problems of cumbersome process, increased raw material cost and maintenance cost, unfavorable large-scale production, etc., achieves good selectivity, promotes addition reaction, The effect of less content of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described below through specific embodiments.

[0045] A method for preparing high-purity octafluoropropane, comprising the steps of:

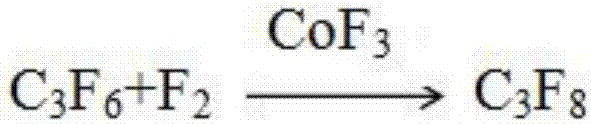

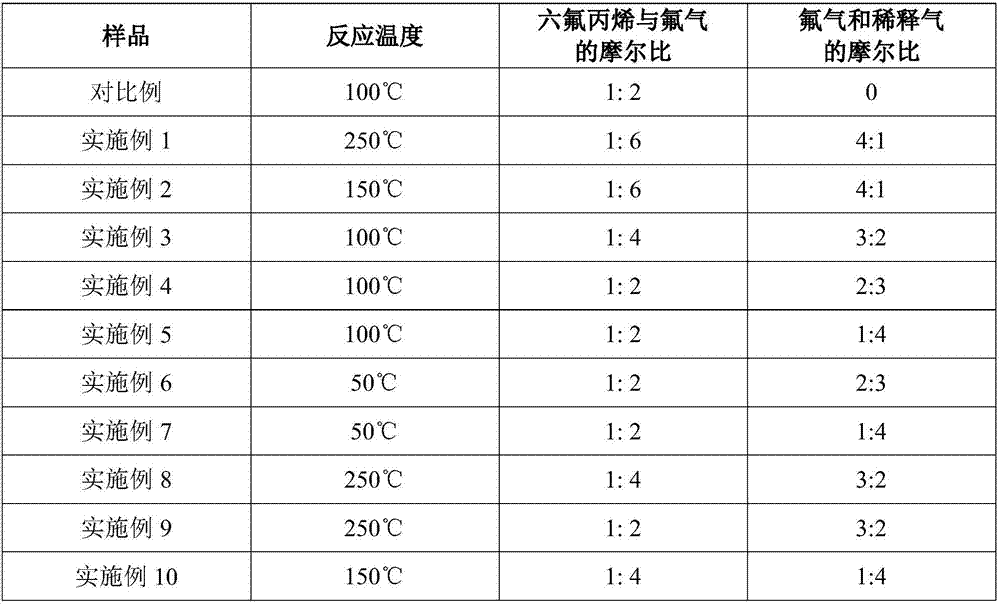

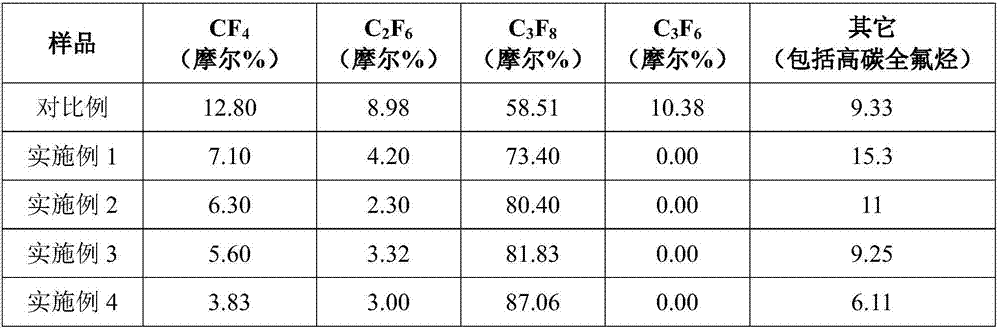

[0046] In the reactor, set the reaction temperature at 50-250°C, use cobalt trifluoride as the catalyst, hexafluoropropylene and fluorine as the reaction gas, and react to prepare octafluoropropane;

[0047] The molar ratio of the hexafluoropropylene to the fluorine gas is 1:2-6.

[0048] In order to continuously produce the purity of high-purity octafluoropropane and reduce production costs, this application uses hexafluoropropylene as a raw material, and under the action of a Co-based catalyst (i.e. activated cobalt trifluoride), it is added to fluorine gas The reaction produces octafluoropropane. The reaction temperature should not be too high, otherwise chain scission and polymerization will occur. This application controls the reaction temperature at 50-250°C.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com