Efficient flame-retardant silicone rubber as well as preparation method and application thereof

A silicone rubber and rubber technology, applied in the field of high-efficiency flame-retardant silicone rubber, can solve the problems of loss of other properties of silicone rubber products, and achieve the effect of improving resilience, improving flame retardant effect, good tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

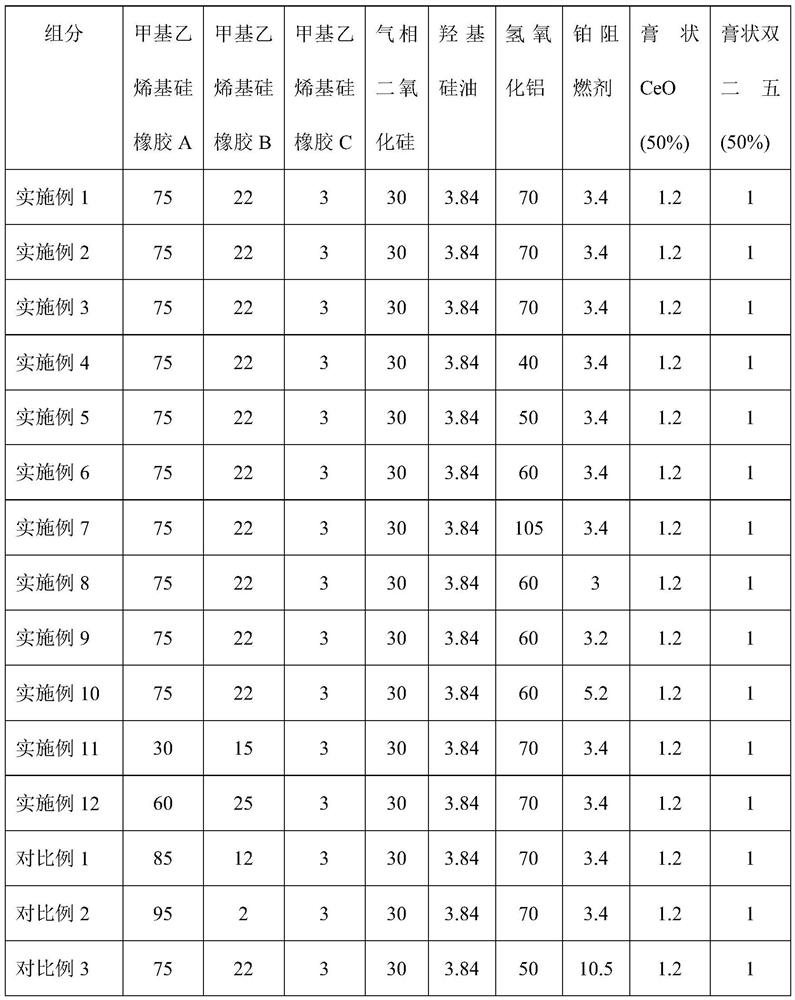

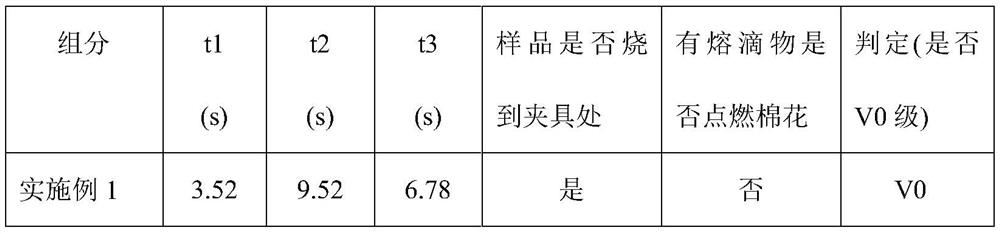

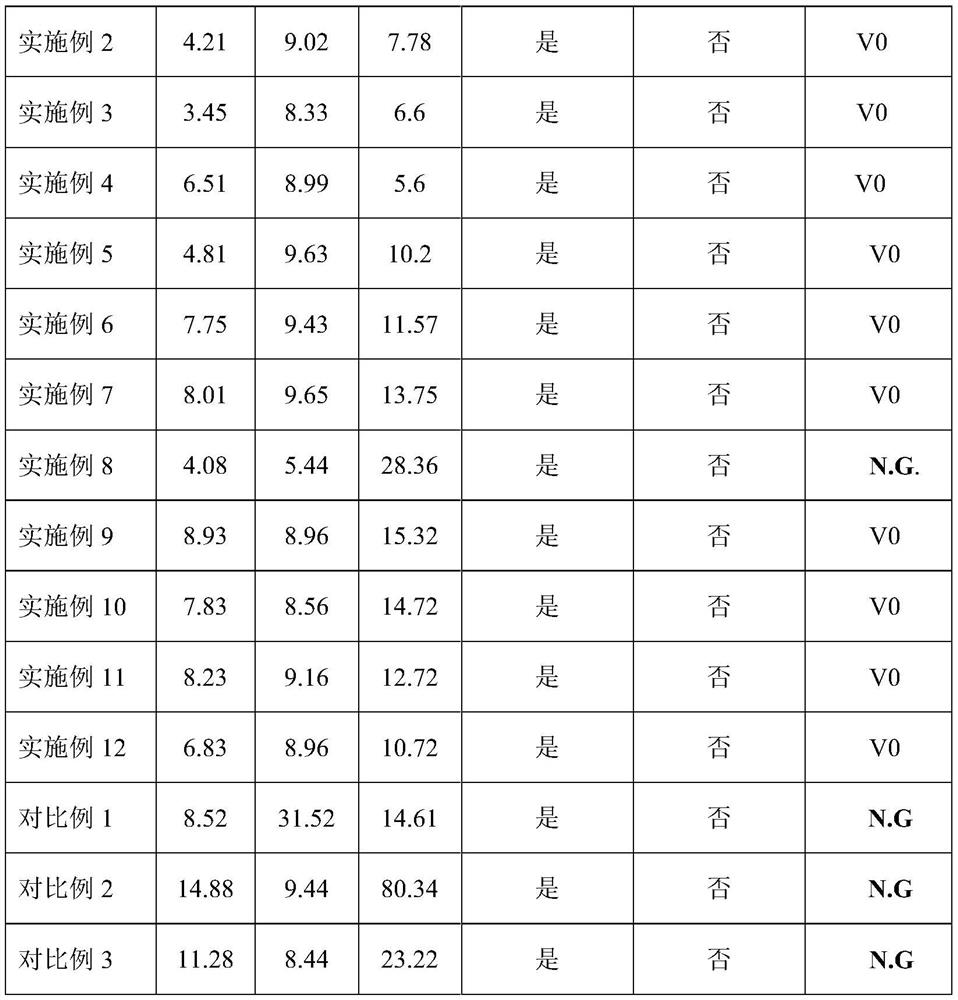

Embodiment 1

[0043] 75 parts by mass of methyl vinyl silicone rubber A with a vinyl mole fraction of 0.03%, 22 parts by mass of a vinyl mole fraction of 0.22% methyl vinyl silicone rubber B and 3 parts by mass of a vinyl mole fraction of 1% Methyl vinyl silicone rubber C is put into a kneader; 30 mass parts of fumed silica and 3.84 mass parts of hydroxyl silicone oil are added to the kneader and mixed and kneaded with the above-mentioned methyl vinyl silicone rubber;

[0044] After being mixed evenly, put 70 parts by mass of aluminum hydroxide and 3.4 parts by mass of chloroplatinic acid into a kneader and knead until completely dispersed, then take out the mixed glue;

[0045] Gradually raise the temperature of the kneader to 160°C, put in the mixed glue that has been taken out, close the cover and start vacuuming, the vacuum degree is -0.09Mpa, knead again for 1.5 hours, and perform the heat treatment step;

[0046] After the heat treatment is completed, take the mixture out, put it on t...

Embodiment 2

[0048] Except that chloroplatinic acid was replaced by chloroplatinic acid tetramethyldivinyldisiloxane complex (purchased from Shanghai Yueteng Biotechnology Co., Ltd.), the remaining components and their contents, as well as the experimental operation steps and implementation Example 1 is the same.

Embodiment 3

[0050] In addition to replacing chloroplatinic acid with 1,2,2,6,6-pentamethylpiperidinol (purchased from Wuhan Comic Biomedical Technology Co., Ltd.), the rest of the components and their contents, and the experimental procedures Same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com