Acrylate modified silicone oil and preparation method thereof

A technology of acrylate and allyl acrylate, which is applied in the field of acrylate-modified silicone oil and its preparation, can solve the problem of low product quality and yield of acrylate-modified silicone oil, difficulty in synthesizing acrylate-modified silicone oil, and preparation methods to be solved. Improvement and other problems, to achieve the effect of improving crosslinking phenomenon and self-polymerization phenomenon, promoting hydrosilylation reaction, and improving synthesis quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

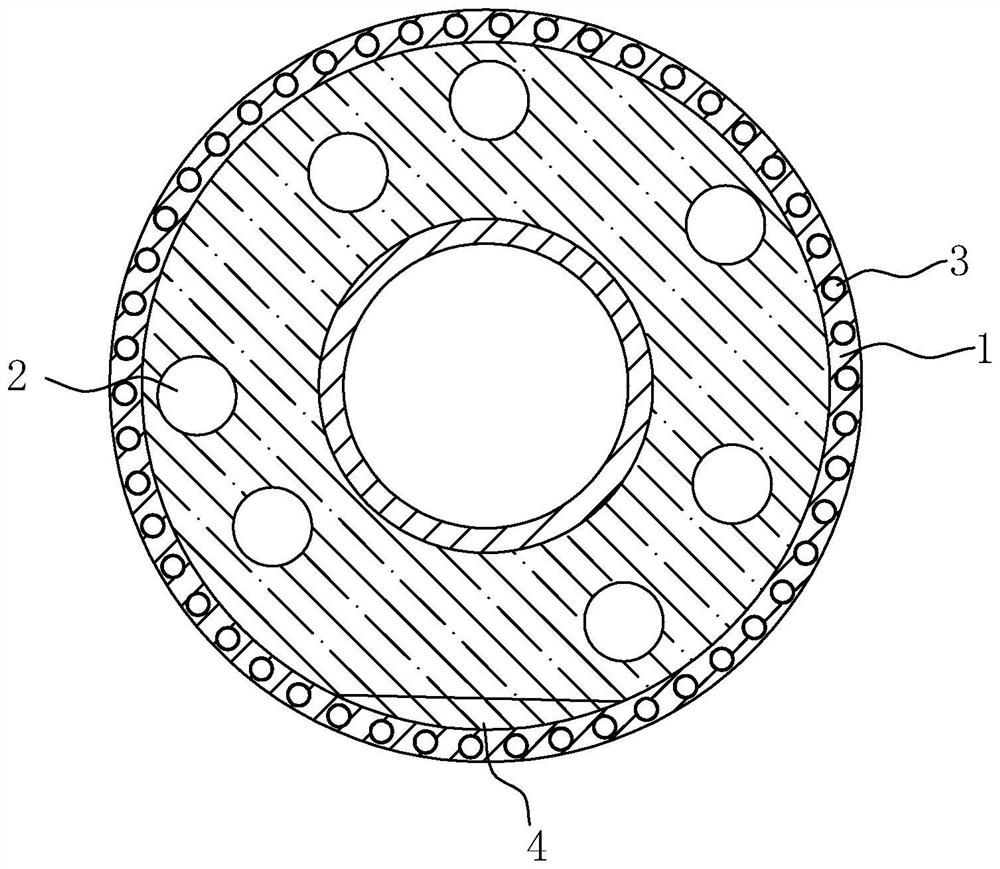

Image

Examples

Embodiment 1

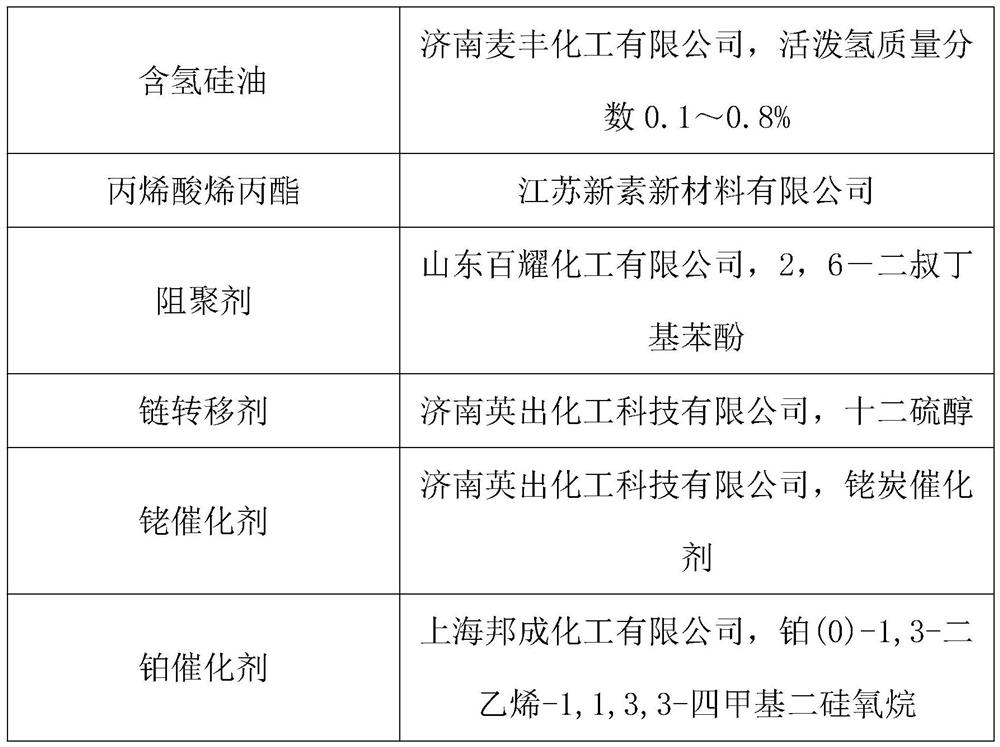

[0050] The preparation method of the acrylic acid modified silicone oil provided by embodiment 1 may further comprise the steps:

[0051] S1: Stir allyl acrylate, rhodium catalyst and polymerization inhibitor in the preparation tank at a stirring speed of 200r / min for 1 hour according to the above ratio, and cool down to 8°C during the stirring process to obtain a mixed raw material;

[0052] S2: put hydrogen-containing silicone oil into the feeding tank, and stir at a stirring speed of 200r / min, and adjust the temperature to 15°C to obtain pretreated hydrogen-containing silicone oil;

[0053] S3: Add the pretreated hydrogen-containing silicone oil to the mixed raw materials, stir the mixed solution at a stirring speed of 100r / min, wait for the temperature to stabilize and then raise the temperature to 70°C, and continue the heat preservation reaction for 2h;

[0054] Step S1 and step S2 are in no particular order.

[0055] After the above steps, the acrylic modified silicone...

Embodiment 15

[0059] The difference from Example 13 is that when preparing the acrylic modified silicone oil, the temperature of the mixed raw material is controlled at 7°C, and the temperature of the hydrogen-containing silicone oil is 14°C.

Embodiment 16

[0061] The difference from Example 13 is that when preparing the acrylic modified silicone oil, the temperature of the mixed raw materials is controlled at 6°C, and the temperature of the hydrogen-containing silicone oil is 12°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com