Solvent-free adhesive for high-wettability flexible packaging compounding and preparation method thereof

A high wettability, flexible packaging technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of ink discoloration, adhesive shrinkage appearance spots, poor wettability, etc., to reduce crystallization non-toxicity, avoid spots and bubbles, high miscibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

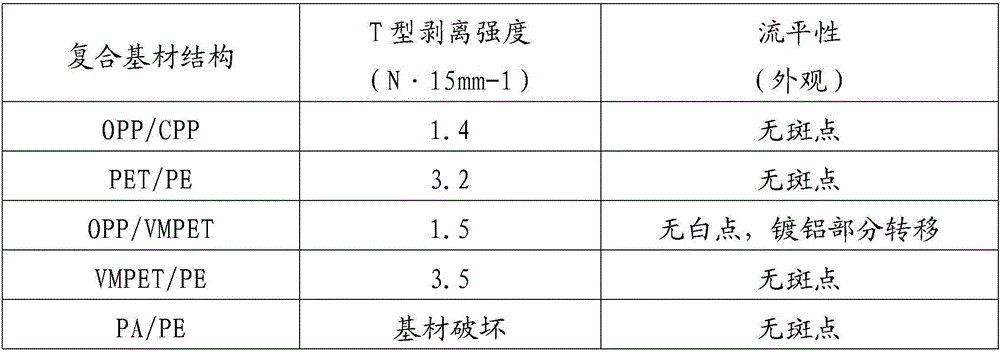

Embodiment 1

[0030] 1. Preparation of isocyanate-terminated prepolymer components:

[0031] Take 500g of polyoxypropylene diol DL-1000 and 200g of polyoxypropylene diol DL-400 and mix evenly, heat up to 120°C and turn on negative pressure vacuum dehydration, the negative pressure gradually increases from -0.01MPa to -0.08MPa , increase the pressure by 0.01MPa every 10 minutes, dehydrate for 1 hour after reaching -0.08MPa, cool down to 60°C, then add 500g of 2-4,4-4-diphenylmethane diisocyanate and react at 65°C for 3 hours to detect isocyanide Acid group content, when the isocyanate group content reaches 5%, add 333g isophorone diisocyanate, react at 80°C for 3 hours, continue to detect the isocyanate group content, when the isocyanate group content reaches 12.5 %-15% to stop the reaction to obtain the isocyanate-terminated prepolymer component;

[0032] It has been tested that the solid content of the isocyanate-terminated prepolymer component prepared through the above steps is 100%, th...

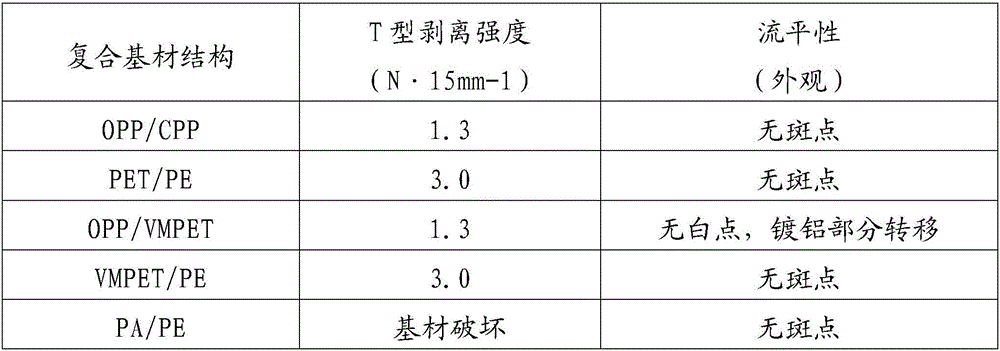

Embodiment 2

[0044] 1. Preparation of isocyanate-terminated prepolymer components:

[0045] Take 400g of polyoxypropylene diol DL-1000 and 240g of polyoxypropylene diol DL-400 and mix evenly, heat up to 120°C and turn on negative pressure vacuum dehydration, the negative pressure gradually increases from -0.01MPa to -0.08MPa , increase the pressure by 0.01MPa every 10 minutes, dehydrate for 1 hour after reaching -0.08MPa, cool down to 60°C, then add 500g of 2-4,4-4-diphenylmethane diisocyanate and react at 80°C for 3 hours to detect isocyanate Acid group content, when the isocyanate group content reaches 7%-8%, add 333g isophorone diisocyanate, react at 85°C for 3 hours, continue to detect the isocyanate group content, when the isocyanate group The reaction is stopped after the content reaches 12.5% to 15%, and the isocyanate-terminated prepolymer component is obtained;

[0046] After testing, the solid content of the isocyanate-terminated prepolymer component prepared through the above...

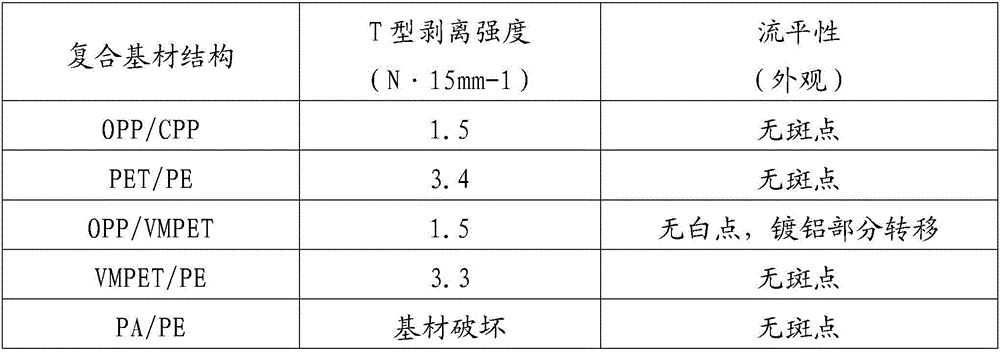

Embodiment 3

[0058] 1. Preparation of isocyanate-terminated prepolymer components:

[0059] Take 500g of polyoxypropylene diol DL-1000 and 200g of polyoxypropylene diol DL-400 and mix evenly, heat up to 120°C and turn on negative pressure vacuum dehydration, the negative pressure gradually increases from -0.01MPa to -0.08MPa , increase the pressure by 0.01MPa every 10 minutes, dehydrate for 1 hour after reaching -0.08MPa, cool down to 60°C, then add 450g of 2-4,4-4-diphenylmethane diisocyanate and react at 75°C for 3 hours to detect isocyanate Acid group content, when the isocyanate group content reaches 5%-6%, add 377g isophorone diisocyanate, react at 85°C for 3 hours, continue to detect the isocyanate group content, when the isocyanate group Stop the reaction after the content reaches 12.5%-15%, and obtain the isocyanate-terminated prepolymer component;

[0060] It has been tested that the solid content of the isocyanate-terminated prepolymer component prepared through the above steps ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com