Low-temperature quick-drying type polyurethane acrylate coating and preparation method thereof

An acrylic polyurethane, quick-drying technology, applied in the field of coatings, can solve the problem that the coating film cannot be cured quickly, achieve excellent adhesion, good weather resistance, and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

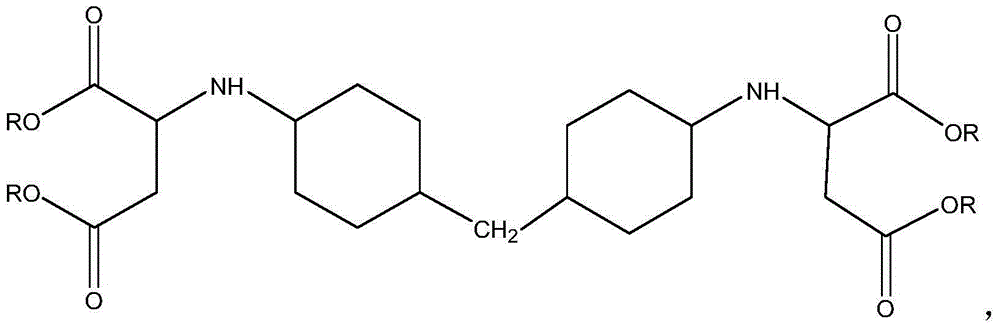

Method used

Image

Examples

Embodiment 1

[0026] 1. Group distribution ratio

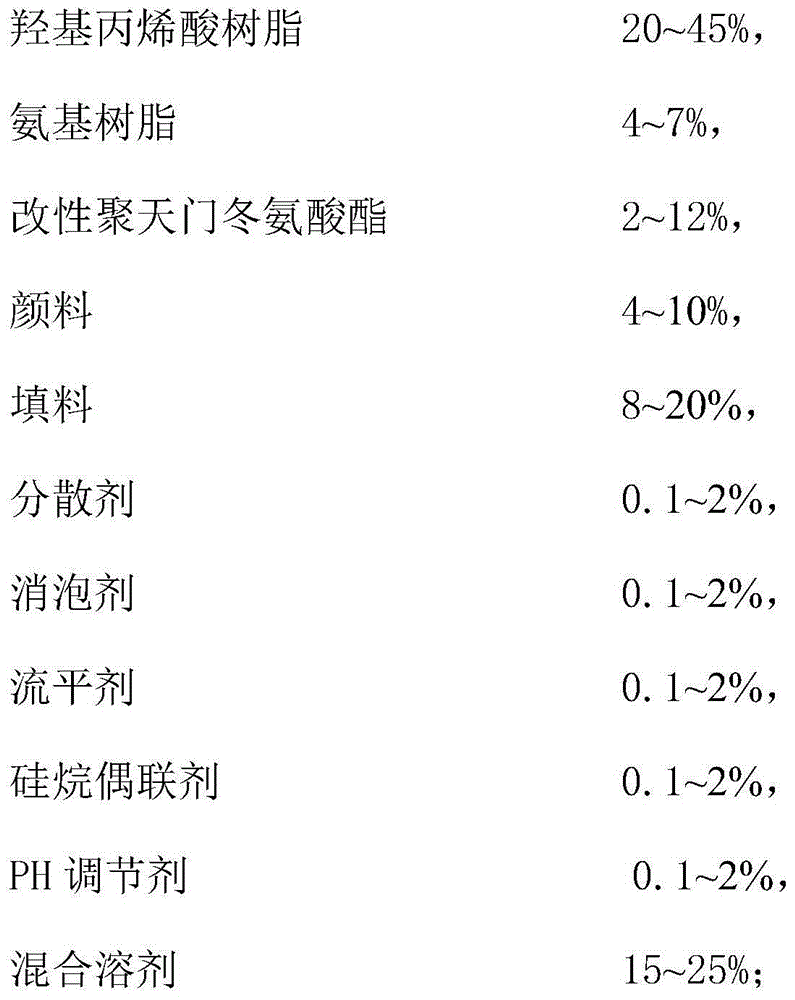

[0027] 1. The composition composition and mass percentage content of component A are:

[0028]

[0029]

[0030] 2. Component B is: isophorone diisocyanate, according to the mass ratio A:B=100:20.

[0031] 2. Preparation method

[0032] 1. Add hydroxyacrylic resin and modified polyaspartic acid ester into the stirring tank, and add amino resin, 80% dispersant, and 80% defoamer in sequence while stirring at a stirring speed of 2000-3000r / min. 80% leveling agent, 80% silane coupling agent, 80% PH regulator and mixed solvent, stir and disperse for 8-15 minutes, reduce the stirring speed to 500r / min, add the pigment and filler and stir evenly, and then Grind with a sand mill to a fineness of 30 μm, filter and discharge to obtain component A;

[0033] 2. Add the aliphatic isocyanate and the remaining 20% dispersant, 20% defoamer, 20% leveling agent, 20% silane coupling agent, and 20% PH regulator to the batching tank, at 2000-3000r / ...

Embodiment 2

[0038] 1. Group distribution ratio

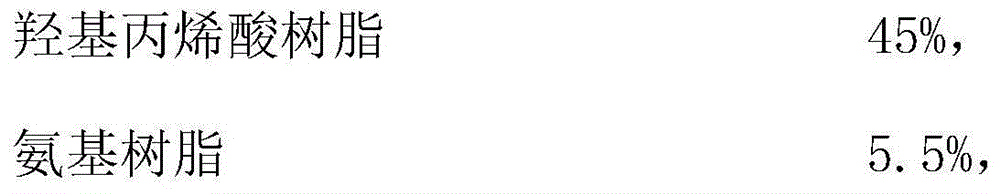

[0039] 1. The composition composition and mass percentage content of component A are:

[0040]

[0041] 2. Component B is: isophorone diisocyanate, according to the mass ratio A:B=100:22.

[0042] Two, preparation method is identical with embodiment 1.

[0043] Three, the effect of this embodiment

[0044] The low-temperature quick-drying acrylic polyurethane coating prepared in this example can be tested at a low temperature of 3°C to 5°C, can reach surface dryness in 30 minutes, dry in 4 hours, and reach the best mechanical properties after 14 hours; Adhesion reaches grade 1; the appearance is smooth and smooth; the number of washes can reach 9700 times.

Embodiment 3

[0046] 1. Group distribution ratio

[0047] 1. The composition composition and mass percentage content of component A are:

[0048]

[0049] 2. Component B is: isophorone diisocyanate, according to the mass ratio A:B=100:27.

[0050] Two, preparation method is identical with embodiment 1.

[0051] Three, the effect of this embodiment

[0052] The low-temperature quick-drying acrylic polyurethane coating prepared in this example can be tested at a low temperature of 0°C to 5°C, can reach surface dryness in 25 minutes, dry in 3 hours, and reach the best mechanical properties after 13 hours; Adhesion reaches level 1; appearance is smooth and smooth; washing resistance reaches 9800 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com