Rectification device and rectification process used for electronic grade sulfur hexafluoride production

A technology of sulfur hexafluoride and electronic grade, which is applied in the direction of sulfur and halogen compounds, can solve the problems of inability to remove and produce electronic grade sulfur hexafluoride, and achieve the effect of low equipment cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

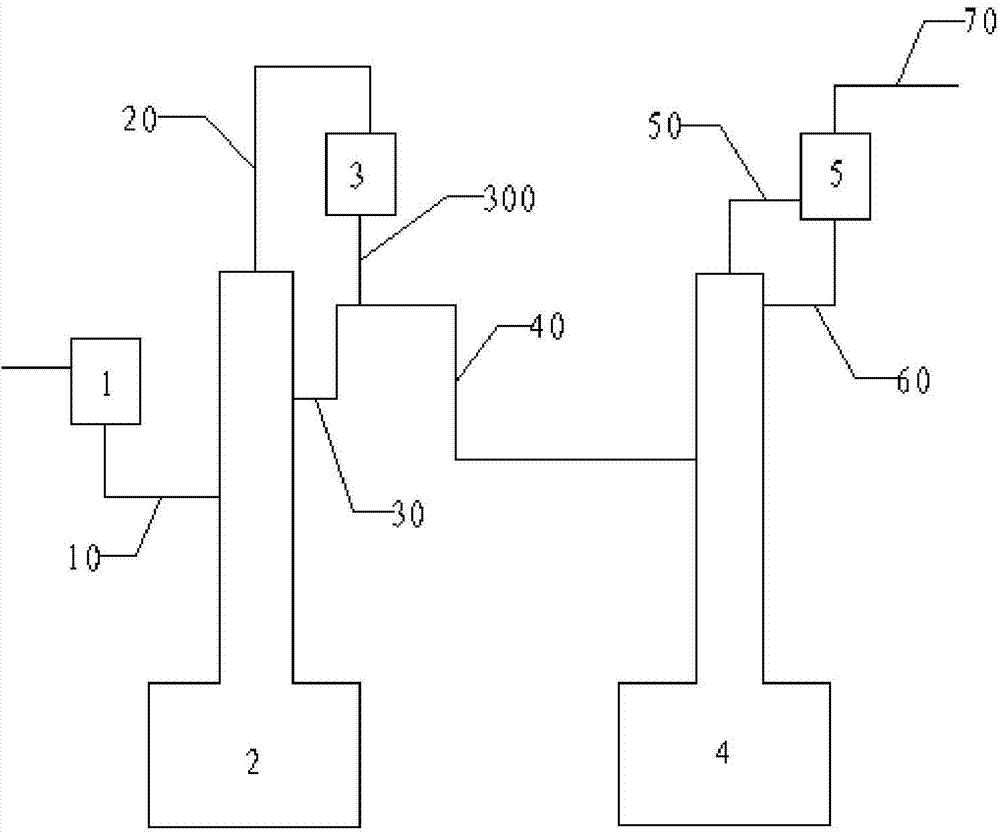

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

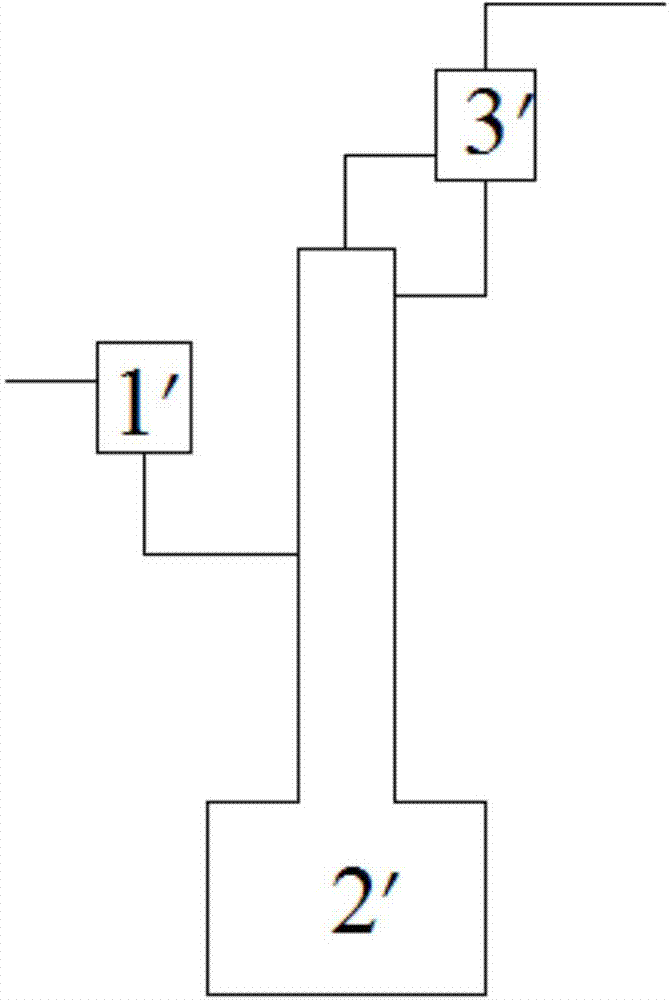

[0029] Please refer to figure 2 As shown, the rectification device for the production of electronic-grade sulfur hexafluoride in this embodiment includes a precooler 1, a first rectification tower 2, a first condenser 3, a second rectification tower 4 and a second condenser device 5;

[0030] The inlet end of the precooler 1 is used to access the pressurized sulfur hexafluoride crude gas, and the outlet end of the precooler 1 is connected to the middle part of the first rectification tower 2 through the first pipeline 10 Pass;

[0031] The top of the first rectifying tower 2 communicates with the inlet end of the first condenser 3 through a second pipeline 20;

[0032] The outlet end of the first condenser 3 is connected with a third p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com