Method for adsorbing and separating octafluoropropane in sulfur hexafluoride by using metal-organic framework material

An organic framework and octafluoropropane technology, which is applied in the field of adsorption and separation of octafluoropropane and metal-organic framework materials in sulfur hexafluoride, can solve the problems of insignificant adsorption effect and the like, and achieve the effect of remarkable separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

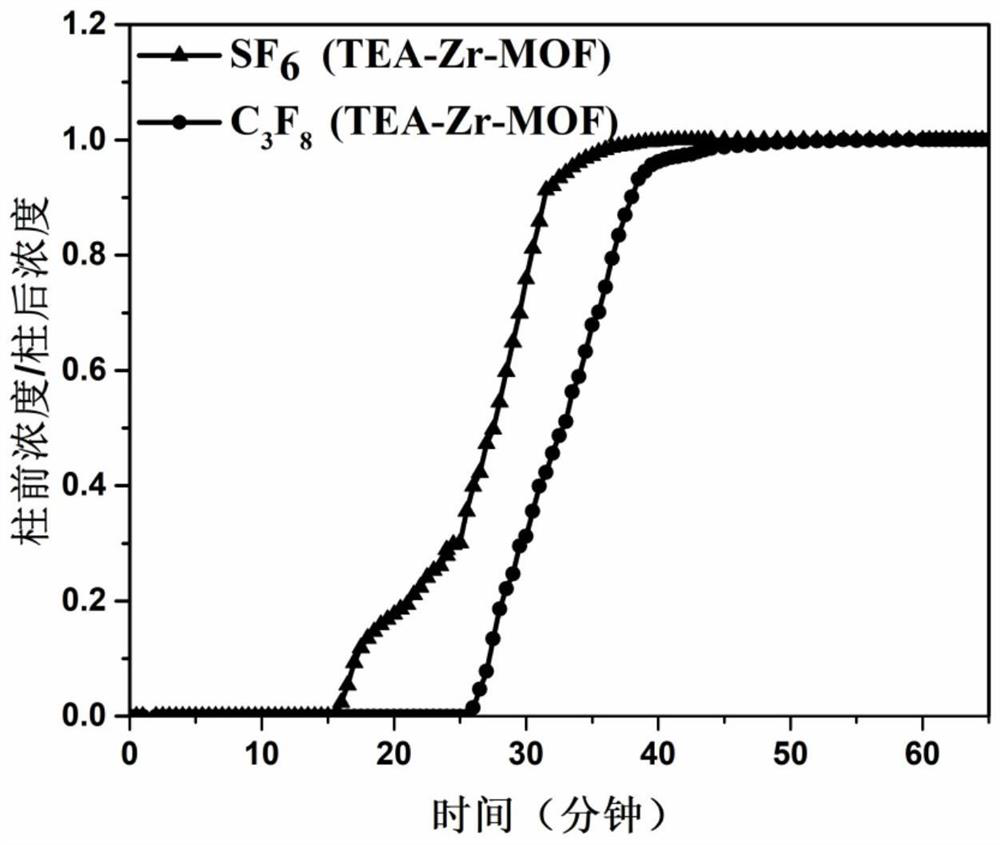

[0038] Example 1: Application of TEA-Zr-MOF metal-organic framework material to adsorb and separate octafluoropropane in sulfur hexafluoride

[0039] 1) Synthesis of TEA-Zr-MOF metal-organic framework materials by hydrothermal synthesis

[0040] First weigh 2.0974g ZrCl 4 , 1.4952g of terephthalic acid and 15.4mL of template agent (glacial acetic acid) were dissolved in 80mL of solvent DMF (the molar ratio of zirconium chloride, terephthalic acid and glacial acetic acid was 1:1:30), ultrasonic for 30 minutes Until the mixture is evenly dispersed; then pour the reaction solution into a 250mL reactor. Put the reaction kettle into a programmed temperature-controlled oven preheated to 120°C to react for 24 hours. After the reaction kettle is fully cooled, wash it with DMF solution and methanol solution for 3 times, and centrifuge the product in a centrifuge at 8000r / min for 5 minutes. , after drying at room temperature, put it into a vacuum oven at 150°C to activate for 12 hours...

Embodiment 2

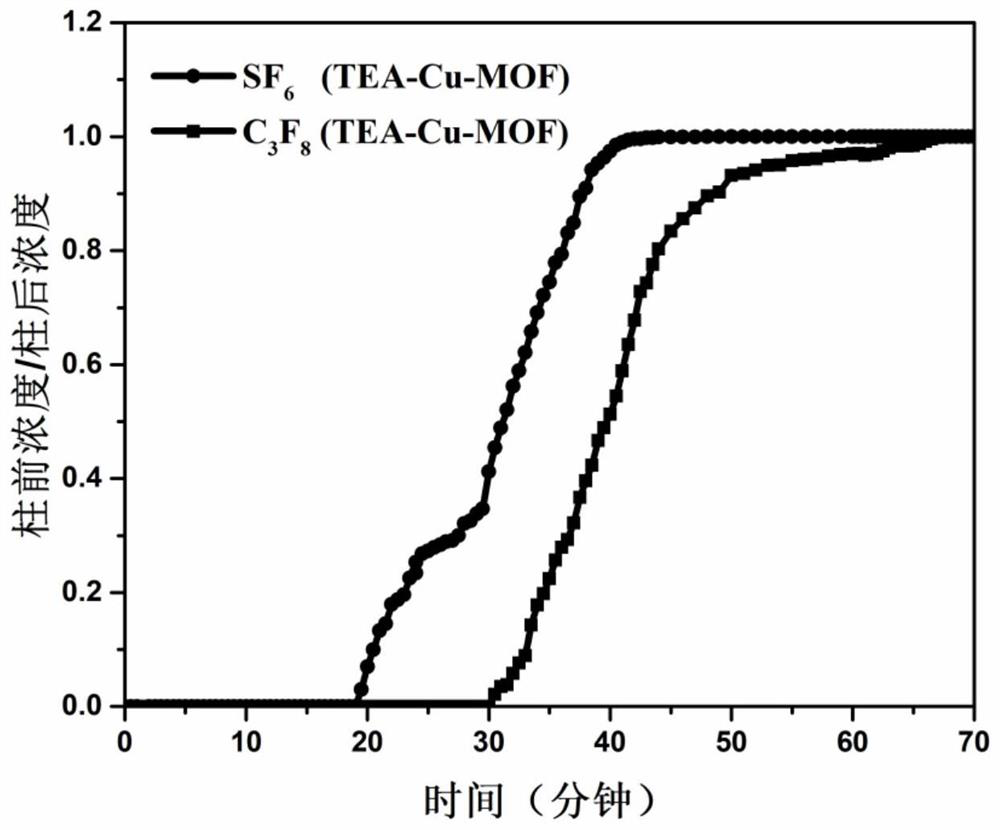

[0049] Adsorption separation of octafluoropropane from sulfur hexafluoride using TEA-Cu-MOF metal-organic framework

[0050] 1) Preparation of TEA-Cu-MOF metal-organic framework materials;

[0051] Cu(NO 3 ) 2 ·3H 2 O (6 g) and trimesic acid (3 g) were respectively dissolved in a mixed solvent consisting of deionized water (51 ml), ethanol (51 ml) and DMF (51 ml), and stirred uniformly respectively. Then the obtained copper ion solution and trimesic acid solution were mixed evenly, poured into a 250mL polytetrafluoroethylene reactor, and the reactor was placed in a temperature-controlled oven at 85°C for 24 hours. After the reactor was fully cooled, it was washed with DMF and ethanol three times each, and the washed and filtered powder was dried overnight in a vacuum oven at 80°C to obtain a blue powder MOF-199 metal-organic framework material.

[0052] Add a certain amount of triethanolamine to the active MOF-199, and soak it in a solution containing 10mL of methanol. It...

Embodiment 3

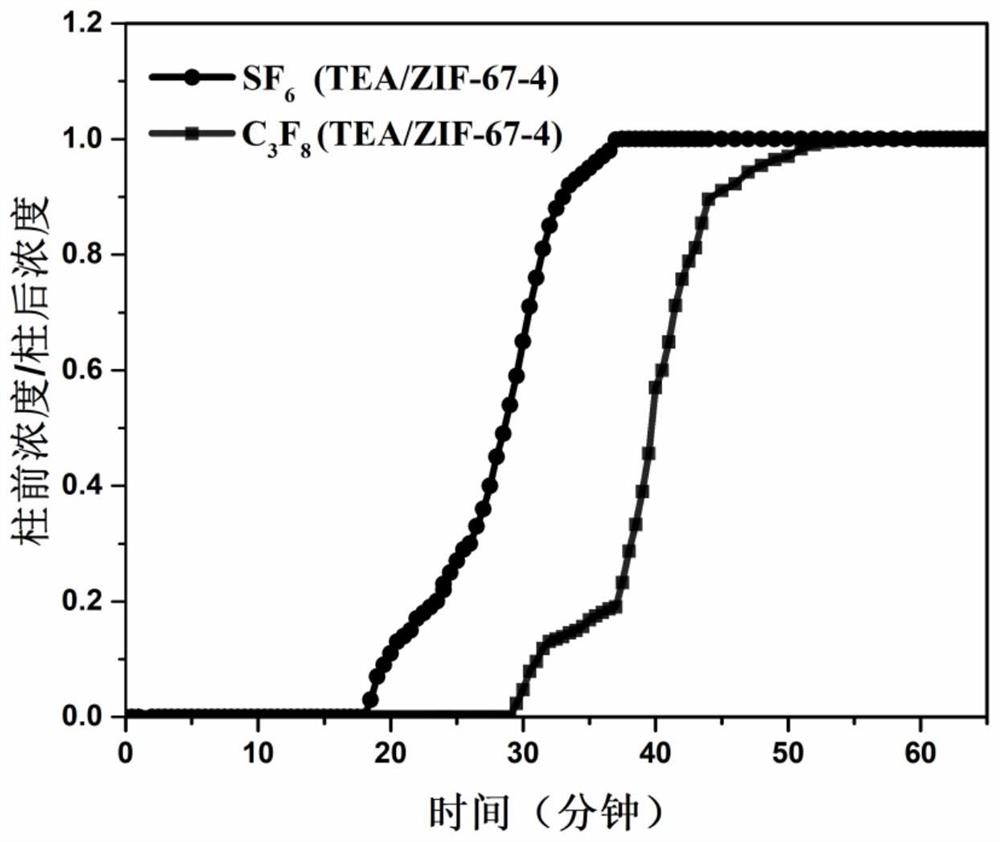

[0061] Application of TEA / TEA / ZIF-67-4 Metal-Organic Framework Adsorption Separation of Octafluoropropane from Sulfur Hexafluoride

[0062] 1) Preparation of TEA / ZIF-67-4 metal organic framework material

[0063] Weigh 2.9103g (10mmol) of cobalt nitrate hexahydrate and dissolve it in 150ml of methanol solution, fully dissolve it, and mark it as liquid A, weigh 3.3062g (40mmol) of dimethylimidazole and dissolve it in 150mL of methanol solution, and mark it as B after fully dissolving liquid; then uniformly mix liquid A and liquid B, and magnetically stir at room temperature for 20 h to obtain a purple powder product, which is collected by centrifugation and washed three times with methanol solution, and then vacuum-dried and activated at 60°C to obtain ZIF-67-4 metal-organic framework material.

[0064] Add a certain amount of triethanolamine to the active ZIF-67-4, and soak it in a solution containing 10mL of methanol. It was then stirred in a 100ml beaker for 12 hours, filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com