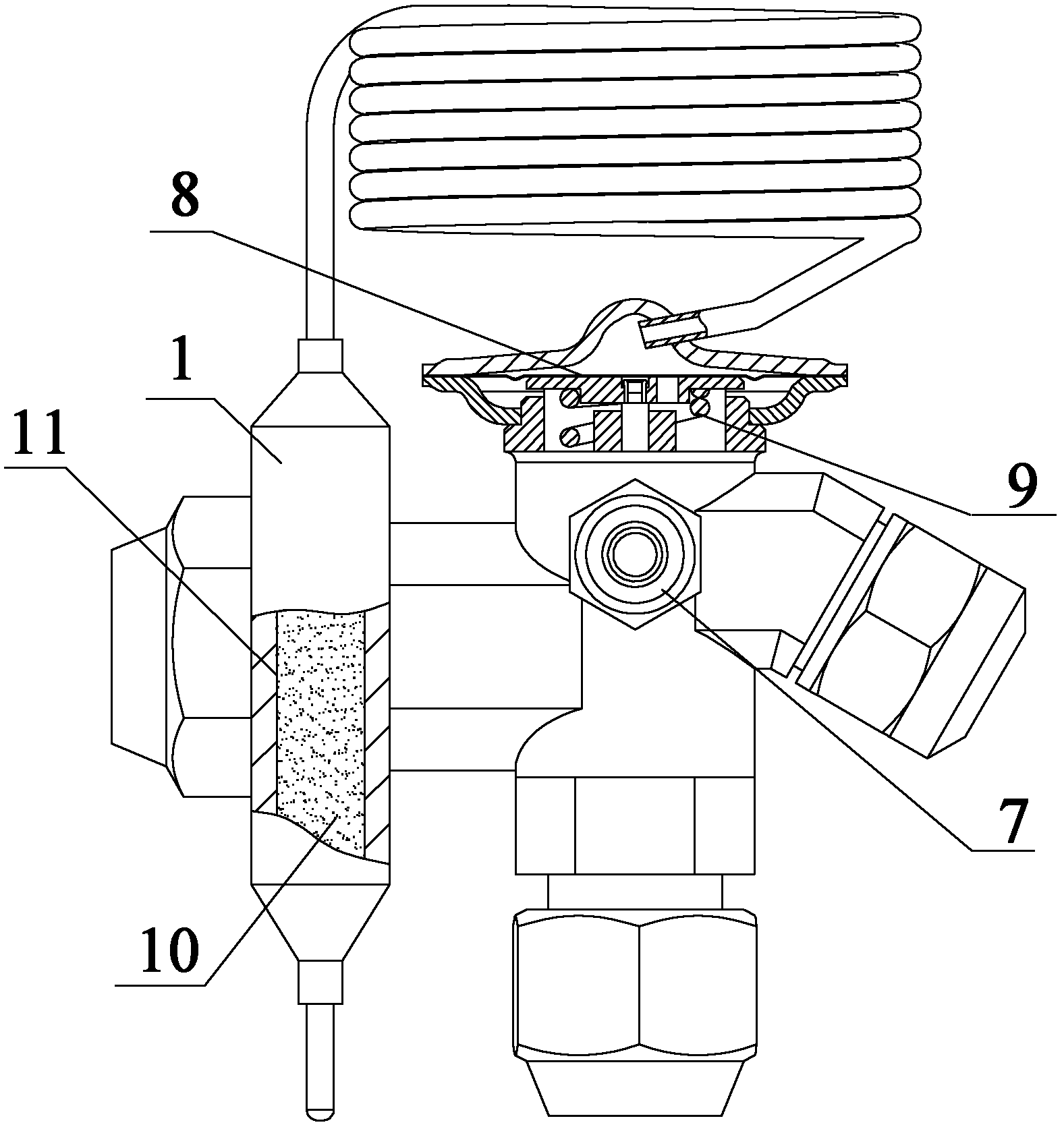

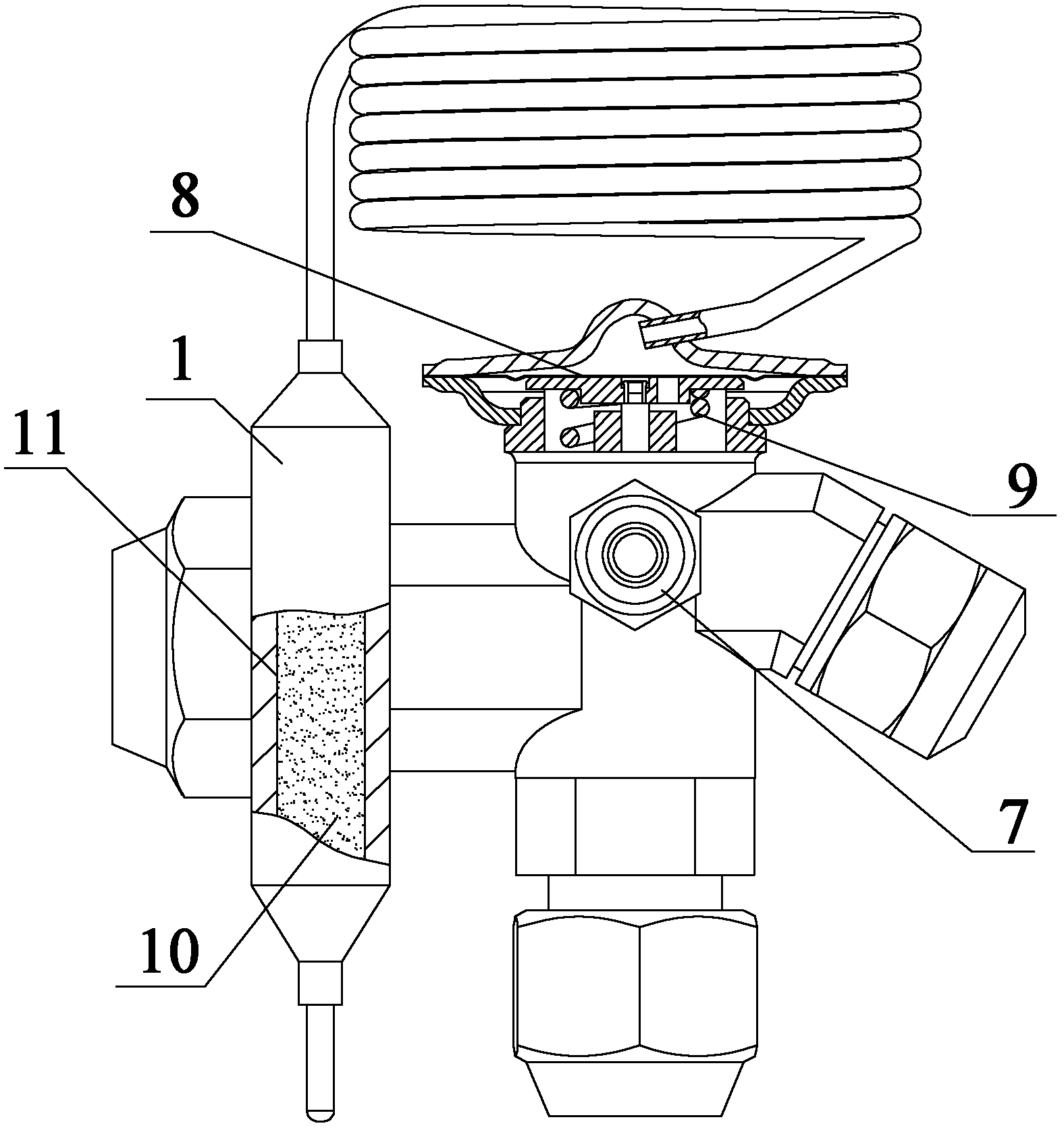

Temperature-sensing element

A temperature sensing element and temperature bulb technology, which is applied in the field of thermal expansion valves, can solve the problems of different superheat control characteristics, poor stability, and inability to meet design requirements of refrigeration systems, so as to ensure temperature control accuracy and operation stability. Good performance and improve overall energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The composition of the temperature-sensitive working medium is calculated by mass ratio, 47% of chlorotetrafluoroethane and 53% of octafluoropropane, which are filled in a gaseous state. In addition, the non-condensable gas filled is helium, and the filling is 3A type. Molecular sieves such as aluminosilicate 2 / 3K 2 O·1 / 3Na 2 O·Al 2 o 3 2SiO2 2 9 / 2H 2 O.

Embodiment 2

[0022] The composition of the temperature-sensitive working medium is calculated by mass ratio, 45% of chlorotetrafluoroethane and 55% of octafluoropropane, which are filled in a liquid state. In addition, the non-condensable gas to be filled is nitrogen, and the filling is activated carbon.

Embodiment 3

[0024] The composition of the temperature-sensitive working medium is calculated by mass ratio, 50% of chlorotetrafluoroethane and 50% of octafluoropropane, which are filled in liquid form, and the non-condensable gas filled is carbon dioxide, and the filling material is 4A molecular sieve such as aluminosilicate Na 2 O·Al 2 o 3 2SiO2 2 9 / 2H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com