Patents

Literature

70results about How to "Guaranteed temperature control accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

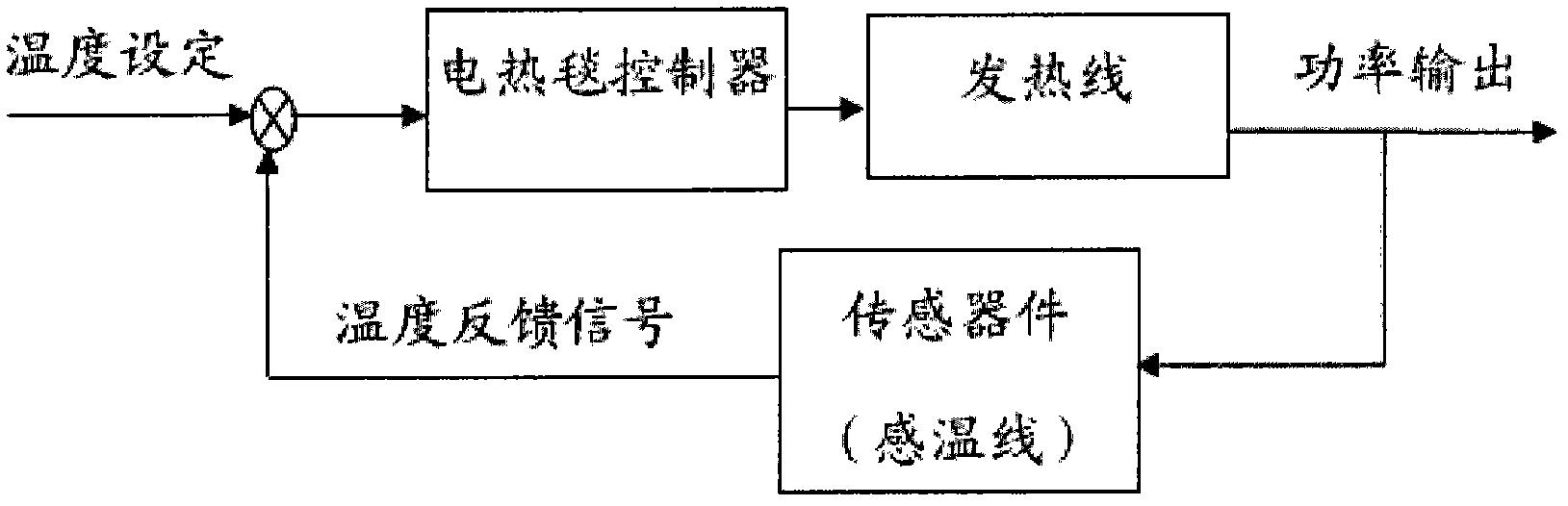

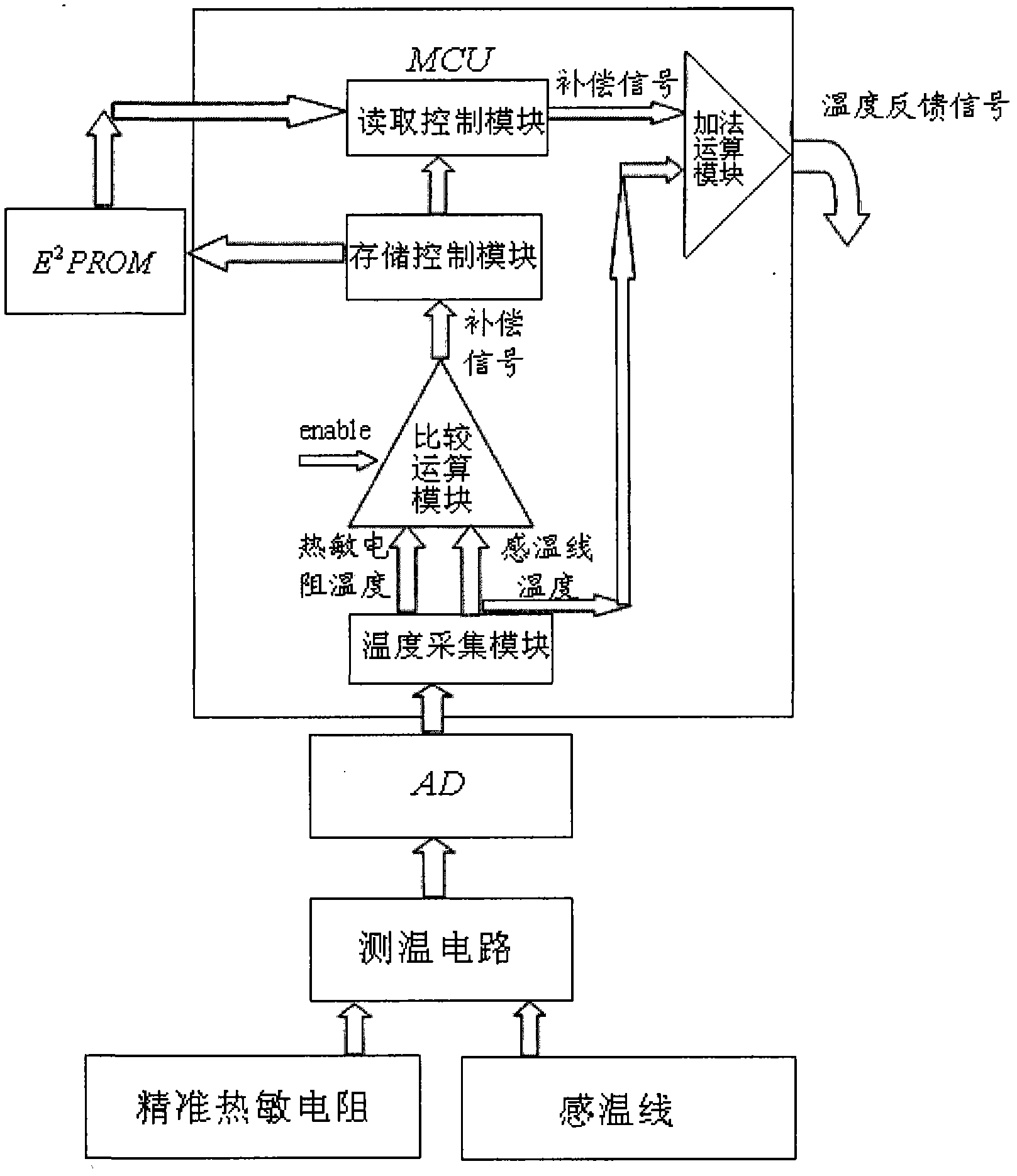

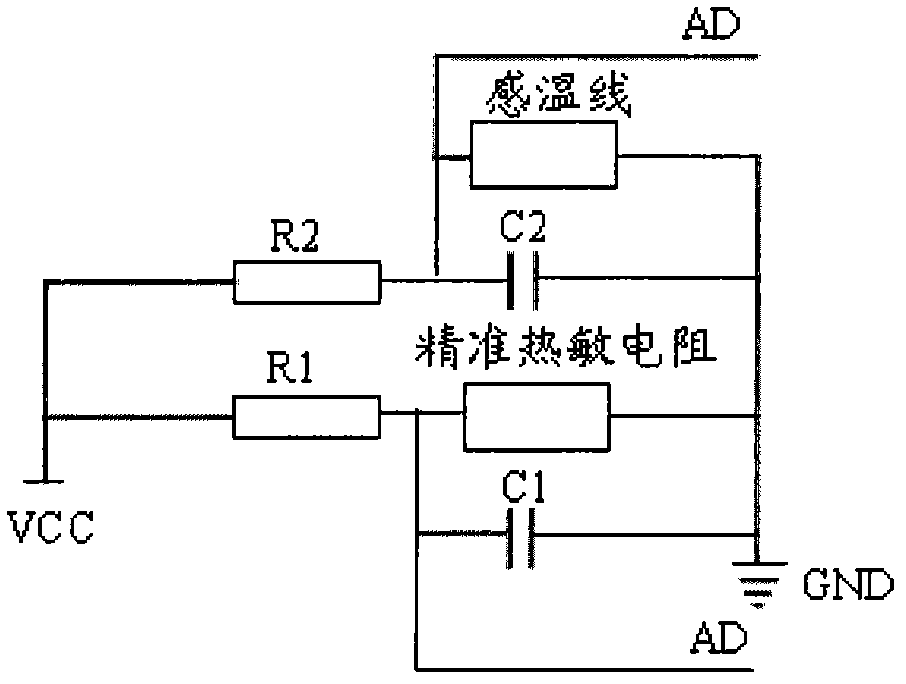

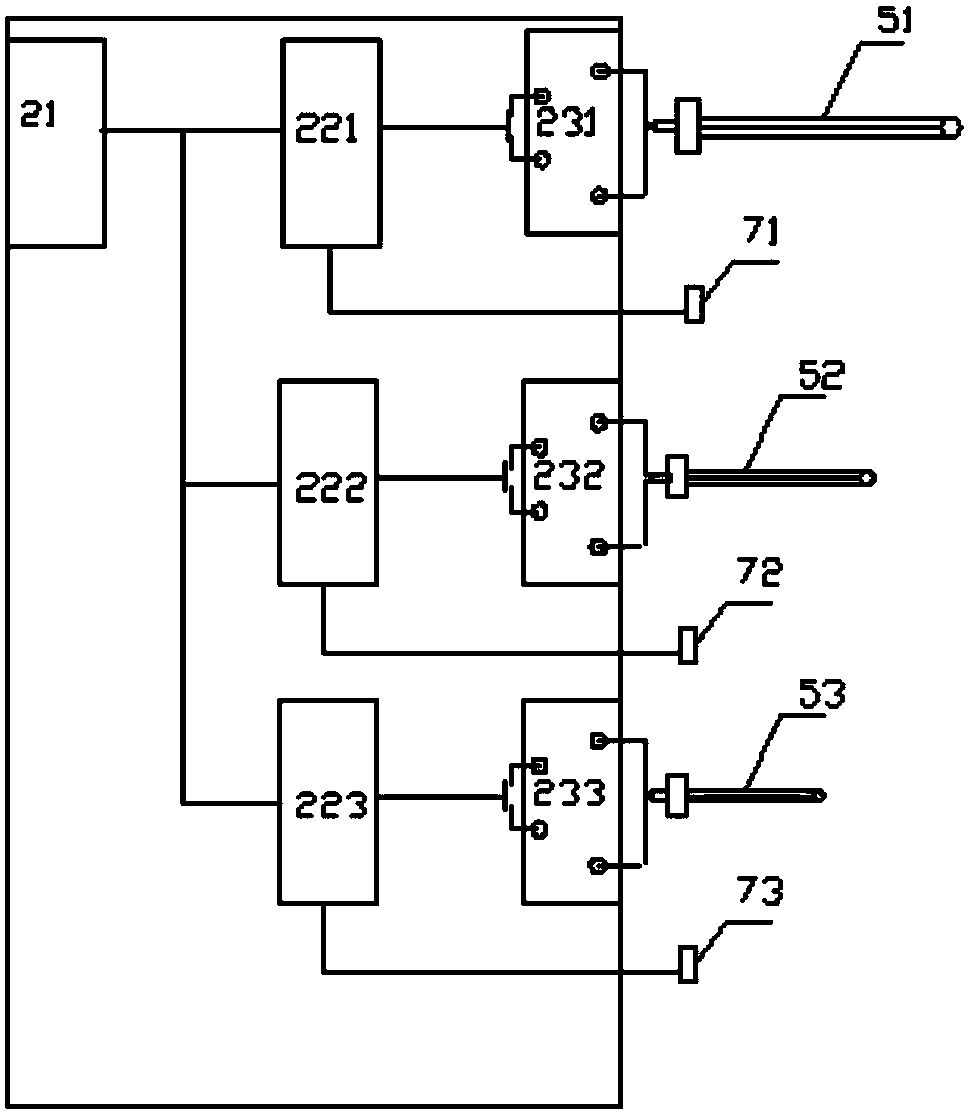

System and method for intelligently and automatically correcting temperature line of temperature control electric blanket

InactiveCN101943922AImprove calibration accuracyHigh speedThermometer detailsSleeping rugProduction rateTemperature control

The invention relates to a system and a method for intelligently and automatically correcting the temperature line of a temperature control electric blanket. The temperature line correction process of the system is automatically controlled and finished by MCU software and does not need manual regulation any more. The method comprises the following steps of: skillfully selecting a temperature reference point by adopting an accurate thermistor; acquiring the temperature signal of the accurate thermistor and the temperature signal of the temperature line; comparing the temperature signal of the accurate thermistor with the temperature signal of the temperature line to obtain a difference value; storing the difference value as a compensation signal in an E2PROM; automatically reading the compensation signal when the temperature line is used every time; and superimposing the compensation signal on the actual temperature of the temperature line so as to finish the automatic correction of the temperature line and fulfill the aim of ensuring the temperature control precision and the consistency of mass-produced products. The method breaks through the bottleneck of manual correction of electric blankets during the mass production, obviously improves the temperature control precision of the mass-produced products and greatly improves the production rate and daily output at the same time, and has the characteristics of intelligence, precision, convenience, and time and labor saving.

Owner:BEIJING MXTRONICS CORP +1

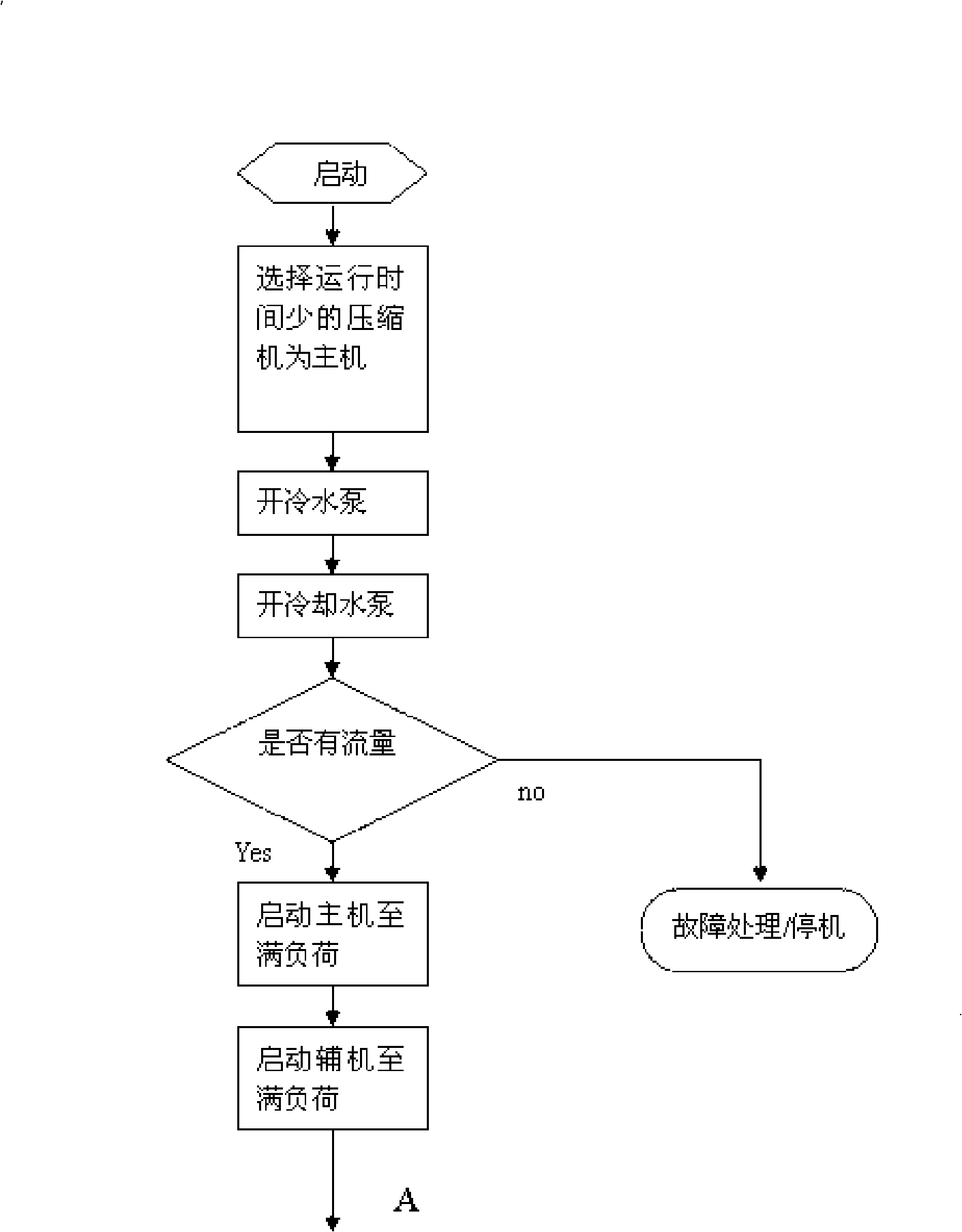

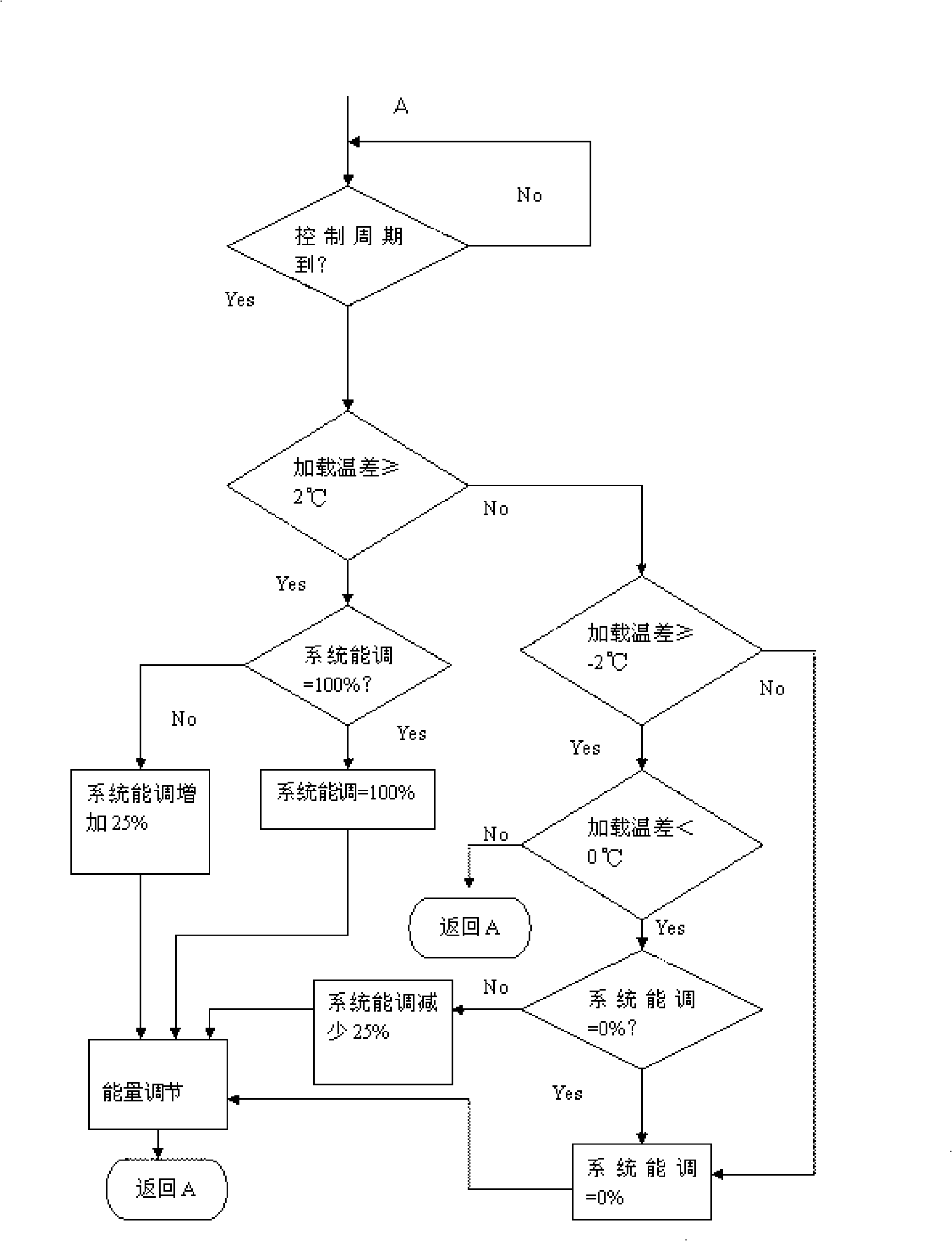

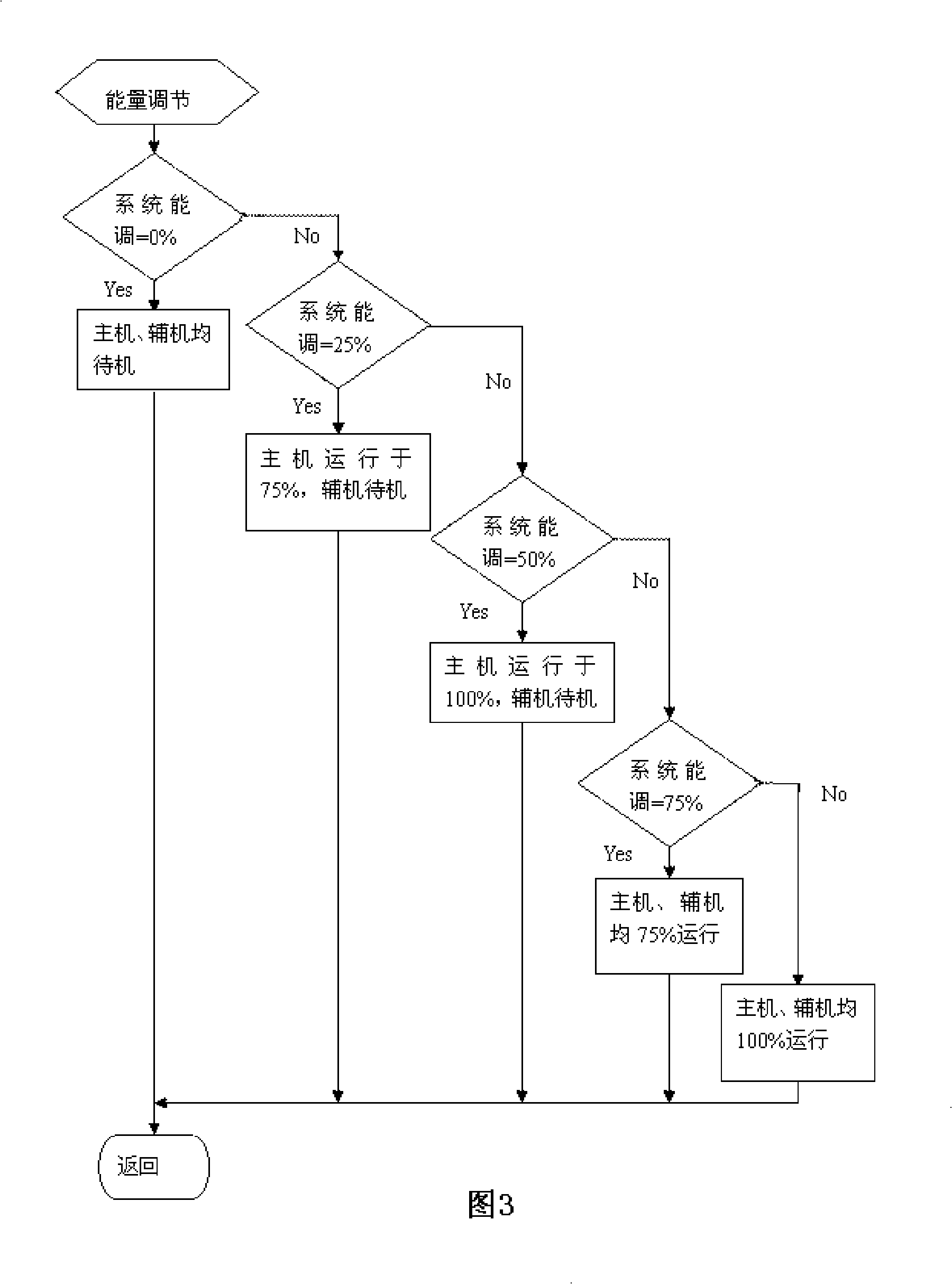

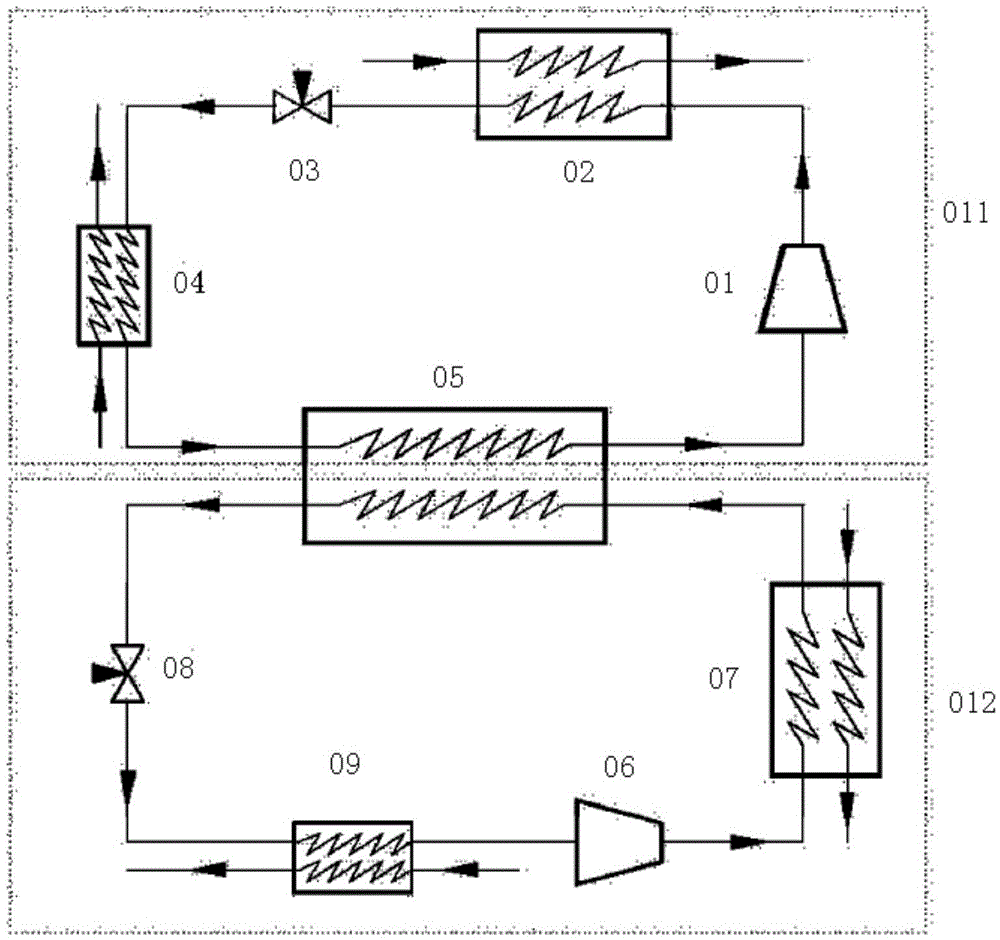

Energy regulation control method of dual-system screw type water chilling unit

InactiveCN101403556ATroubleshooting prone to failure issuesImprove reliabilityRefrigeration safety arrangementFailure rateTemperature control

The invention discloses an energy adjusting and controlling method with low failure rate and saved energy for a double-system screw chiller unit, which comprises a starting stage control and an operation stage control for setting up the control cycle. In the operation stage control, two screw compressors are in a 75 percent or 100 percent operating state or in a standby state. In the operation stage, an energy demand of the double-system screw chiller unit is adjusted according to the difference between the measured temperature and the set temperature. When screw compressors are in a 75 percent or 100 percent operating state, the lubrication is sufficient and the energy efficiency ratio is high so as to solve the failure problems arising from the long operation of single screw compressor in a 25 percent or 50 percent operating state, reduce the working energy consumption, improve the working stability of the double-system screw chiller unit, prolong the service life of the double-system screw chiller unit and reduce the operation and maintenance cost of the double-system screw chiller unit. Though reducing the number of adjusting levels, the energy adjusting and controlling method can still ensure the temperature controlling precision and meet the needs of the users, which is particularly suitable for the double-system screw chiller unit.

Owner:四川长虹空调有限公司

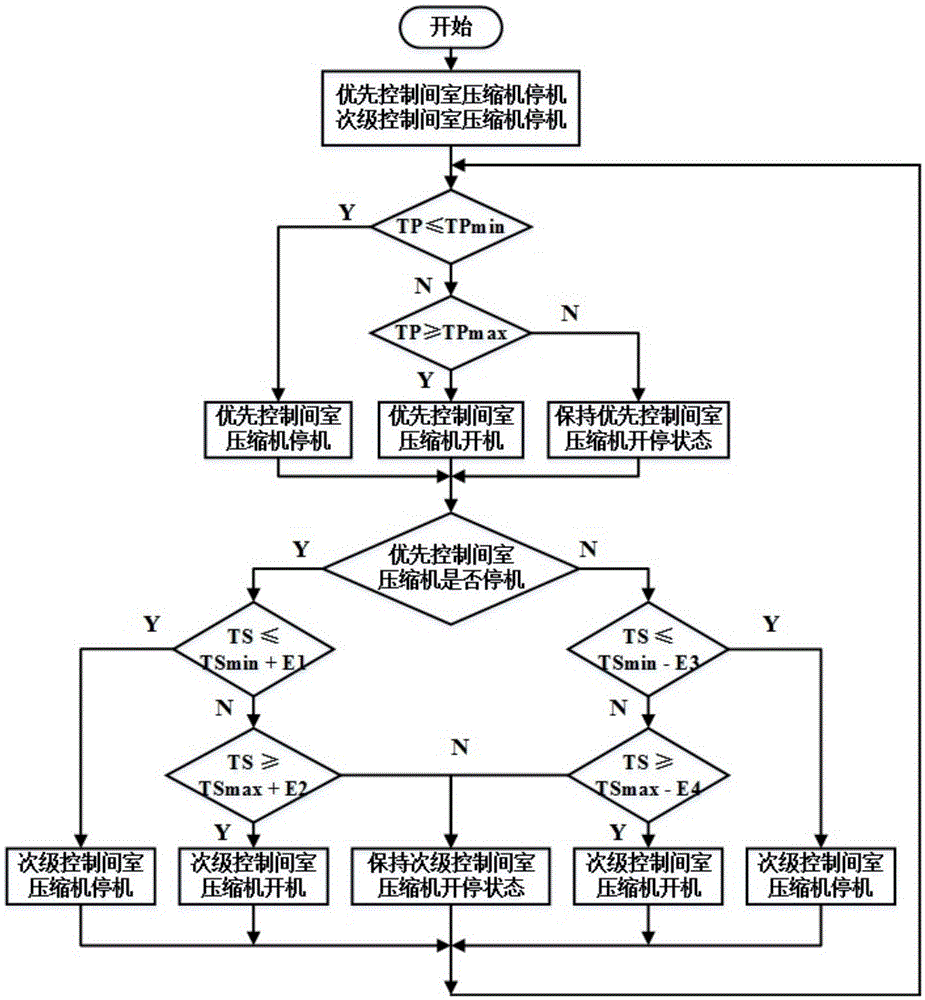

Temperature and coupling running controlling method of double-compressor and double-refrigerating circuit refrigerator

ActiveCN105526762AExtended boot timeExtended downtimeMechanical apparatusCompression machines with non-reversible cycleEnergy couplingEngineering

The invention discloses a temperature and coupling running controlling method of a double-compressor and double-refrigerating circuit refrigerator. The temperature and coupling running controlling method comprises the following steps: picking up current temperatures of a priority control compartment and a secondary control compartment; and monitoring the startup-shutdown state of a compressor in the priority control compartment: if the compressor in the priority control compartment is in a shutdown state, carrying out logic comparison on the picked current temperature of the secondary control compartment and a set starting temperature, a set shutdown temperature and set temperature offsets E1 and E2 to control the compressor to start up or shut down; and if the compressor in the priority control compartment is in a startup state, carrying out logic comparison on the picked current temperature of the secondary control compartment and a set starting temperature, a set shutdown temperature and set temperature offsets E3 and E4 to control the compressor to start up or shut down. When the temperature and coupling running controlling method is applied to the double-compressor and double-refrigerating circuit refrigerator with energy coupling, simultaneous starting and refrigerating time, i.e. coupling running time, of two refrigerating circuits can be prolonged, and the running efficiency of a system is improved.

Owner:ZHEJIANG UNIV

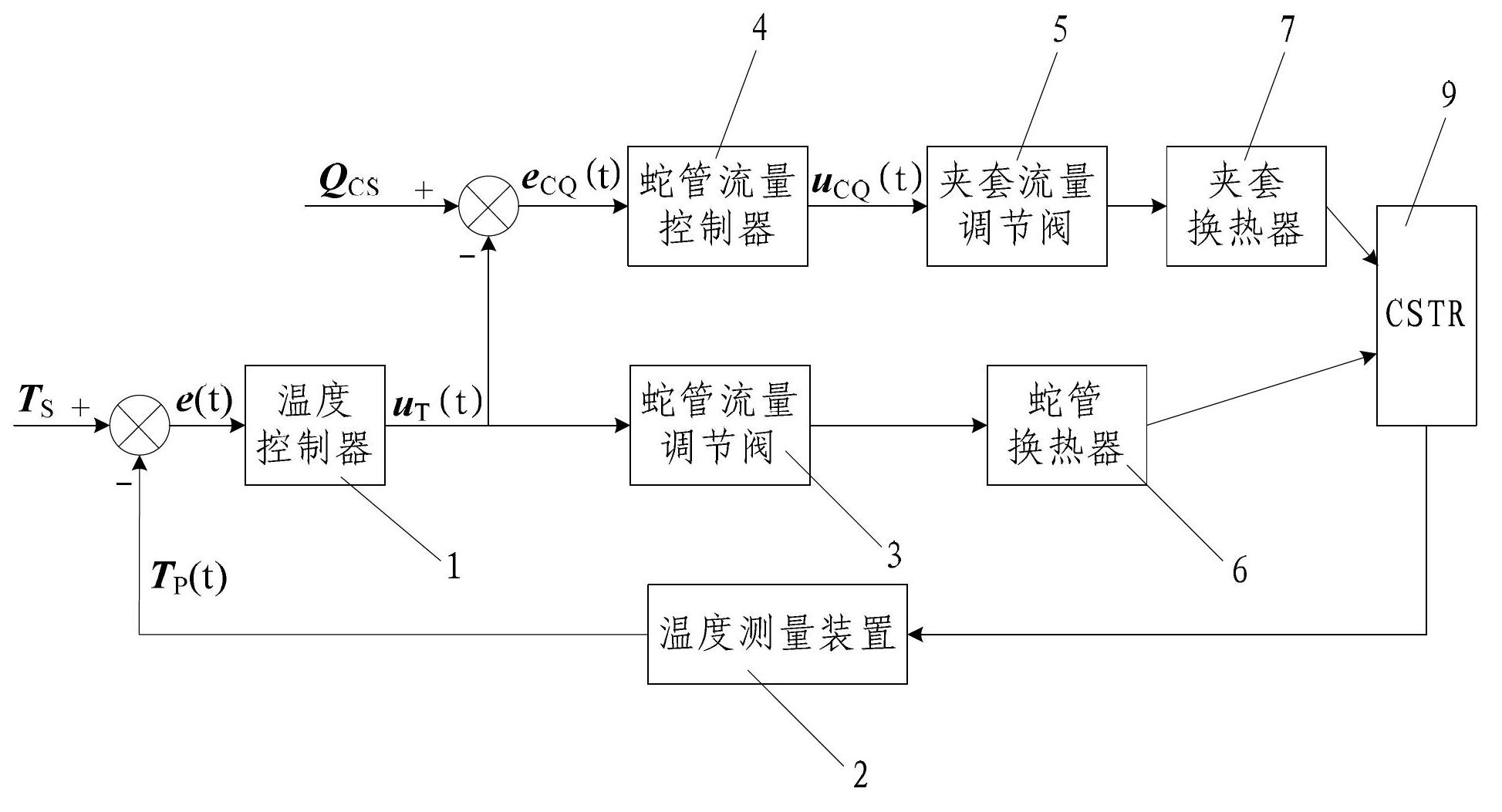

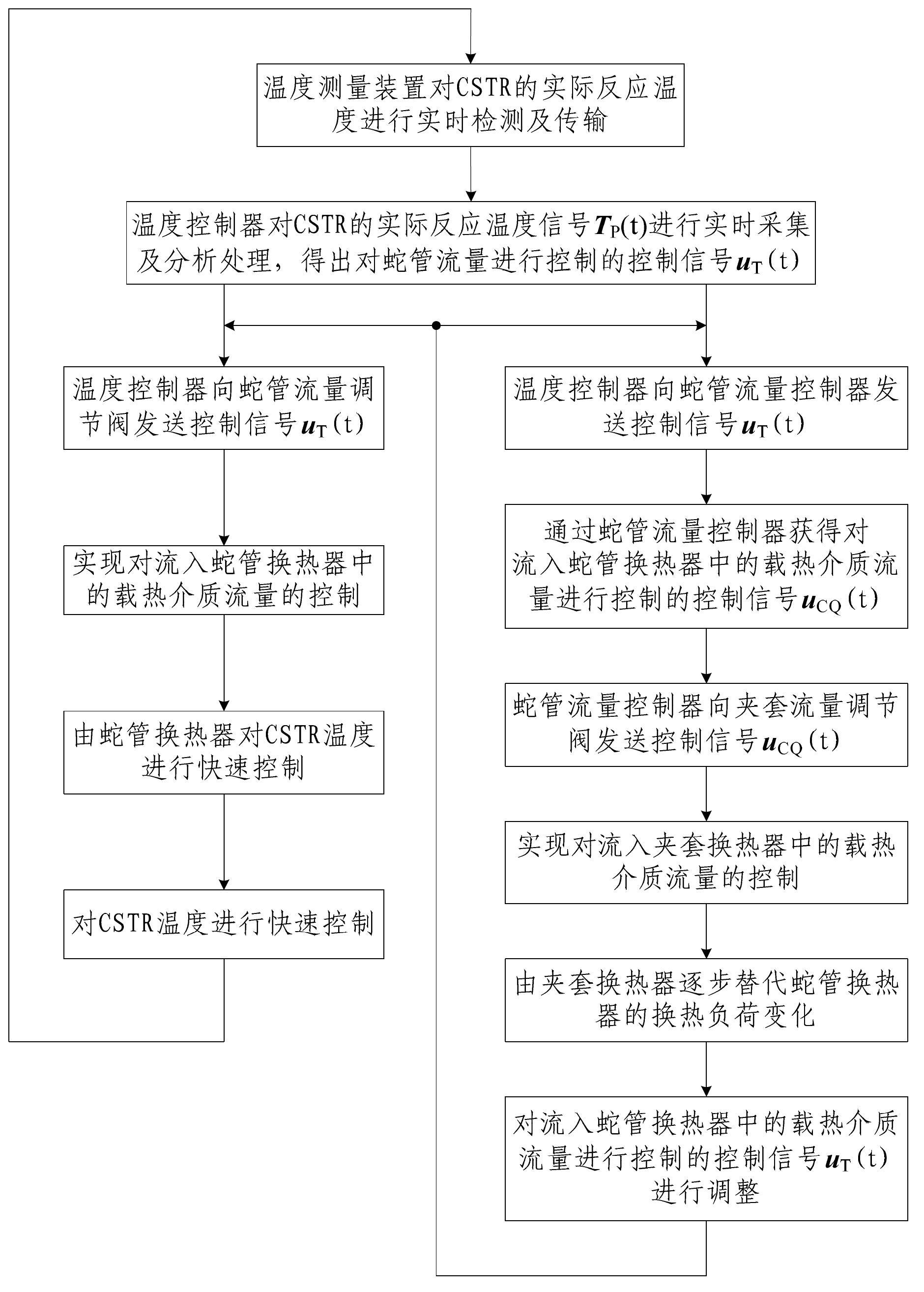

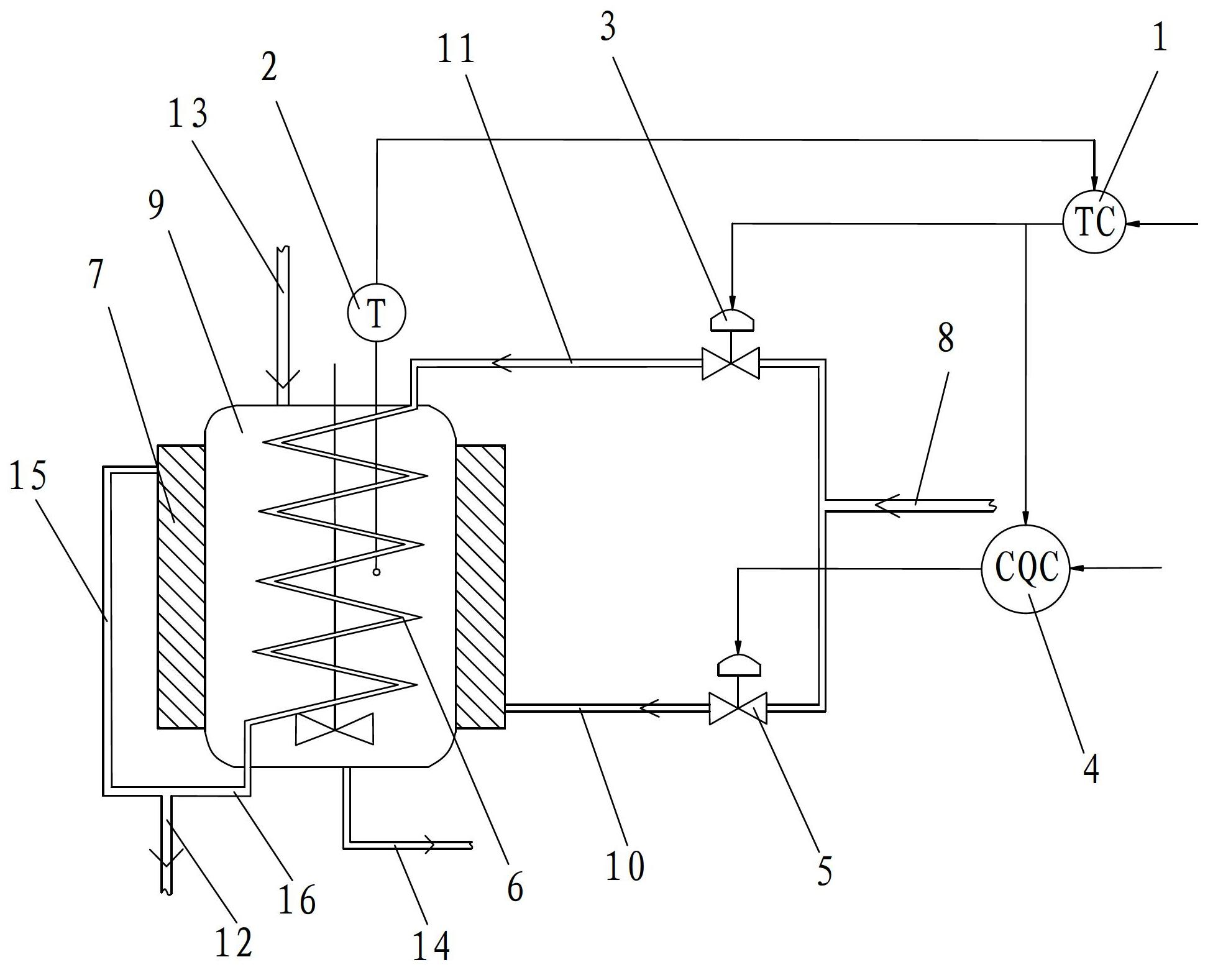

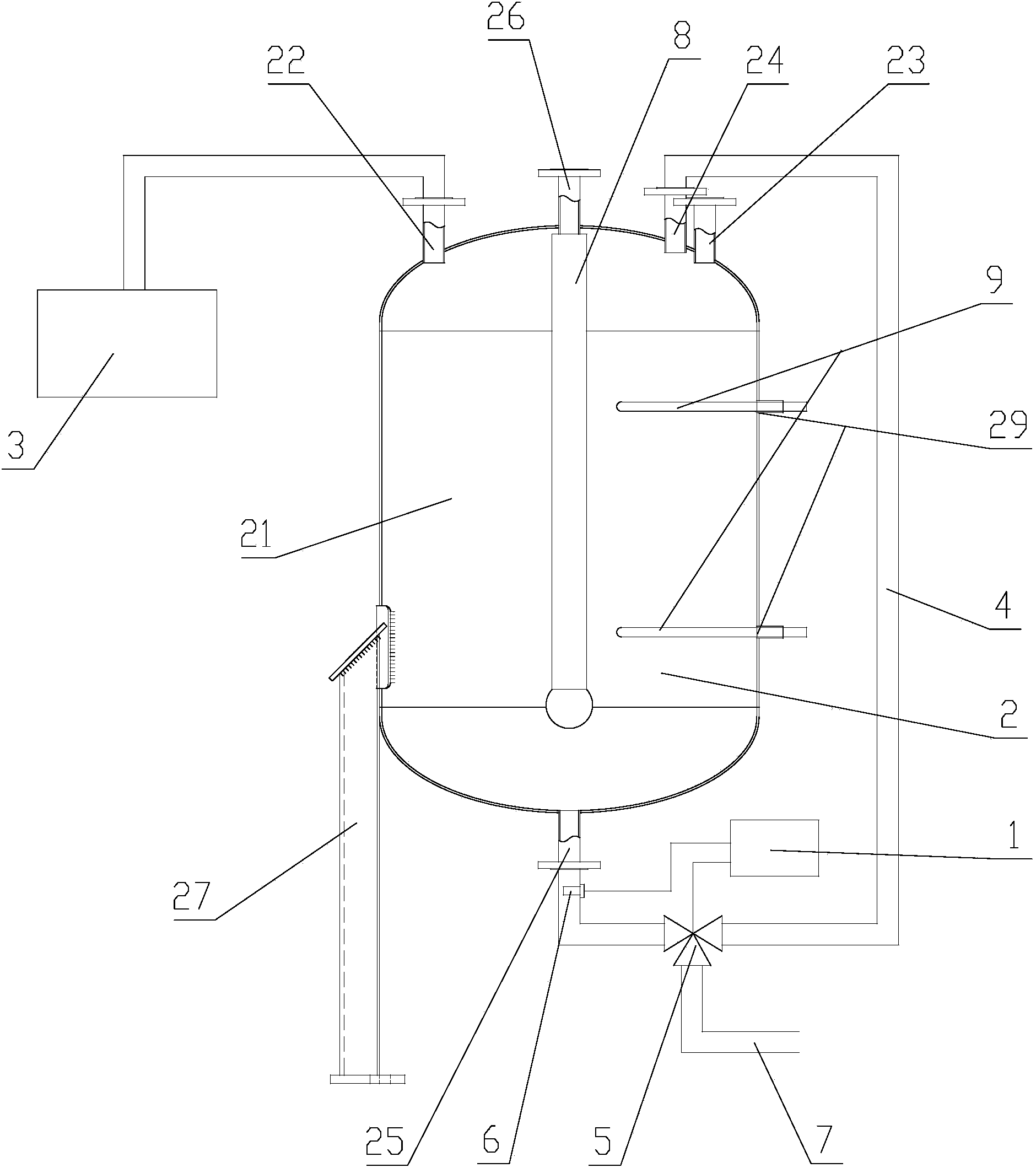

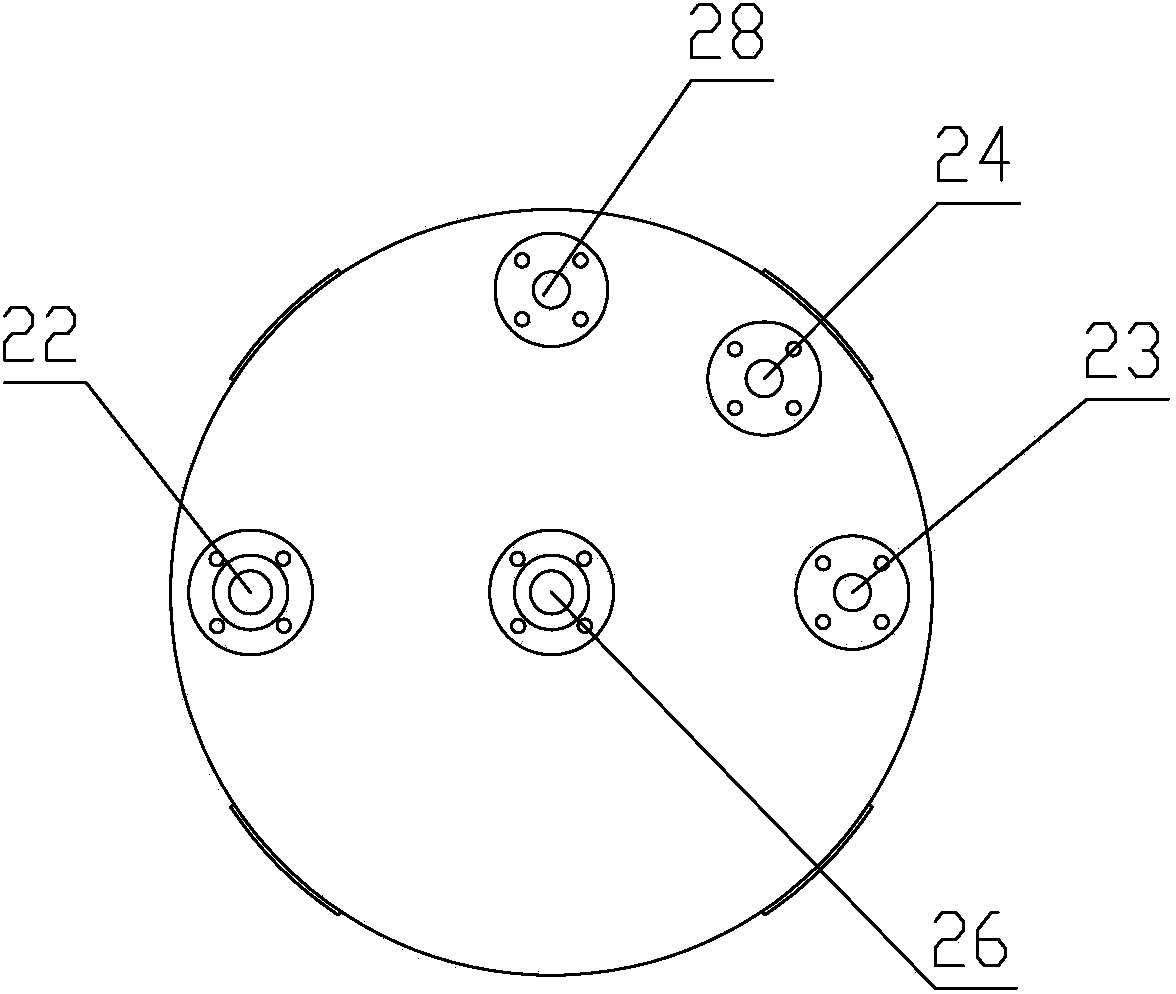

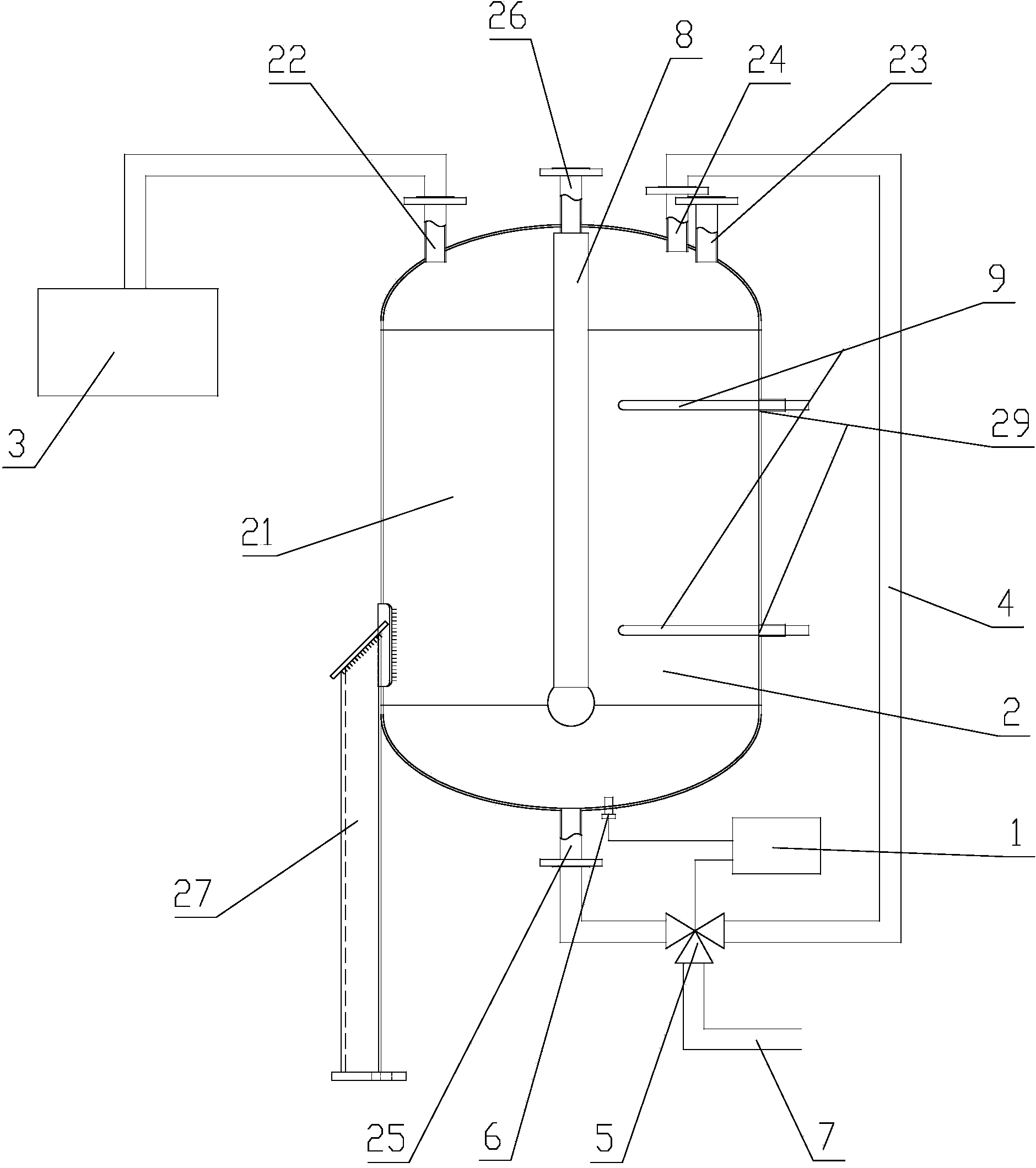

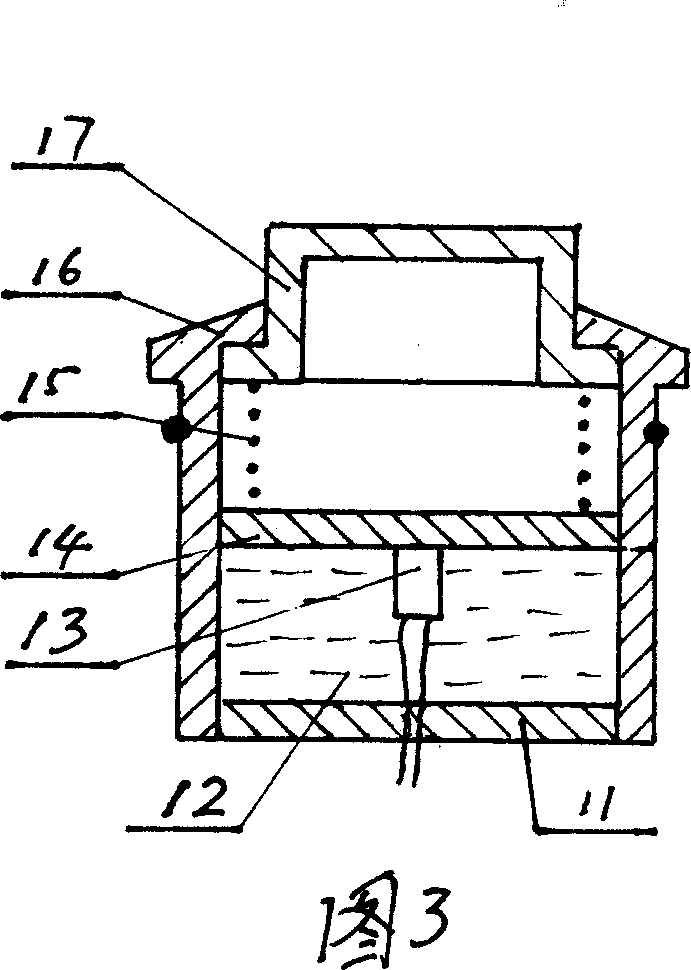

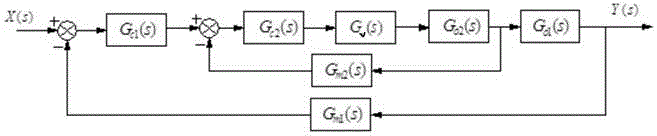

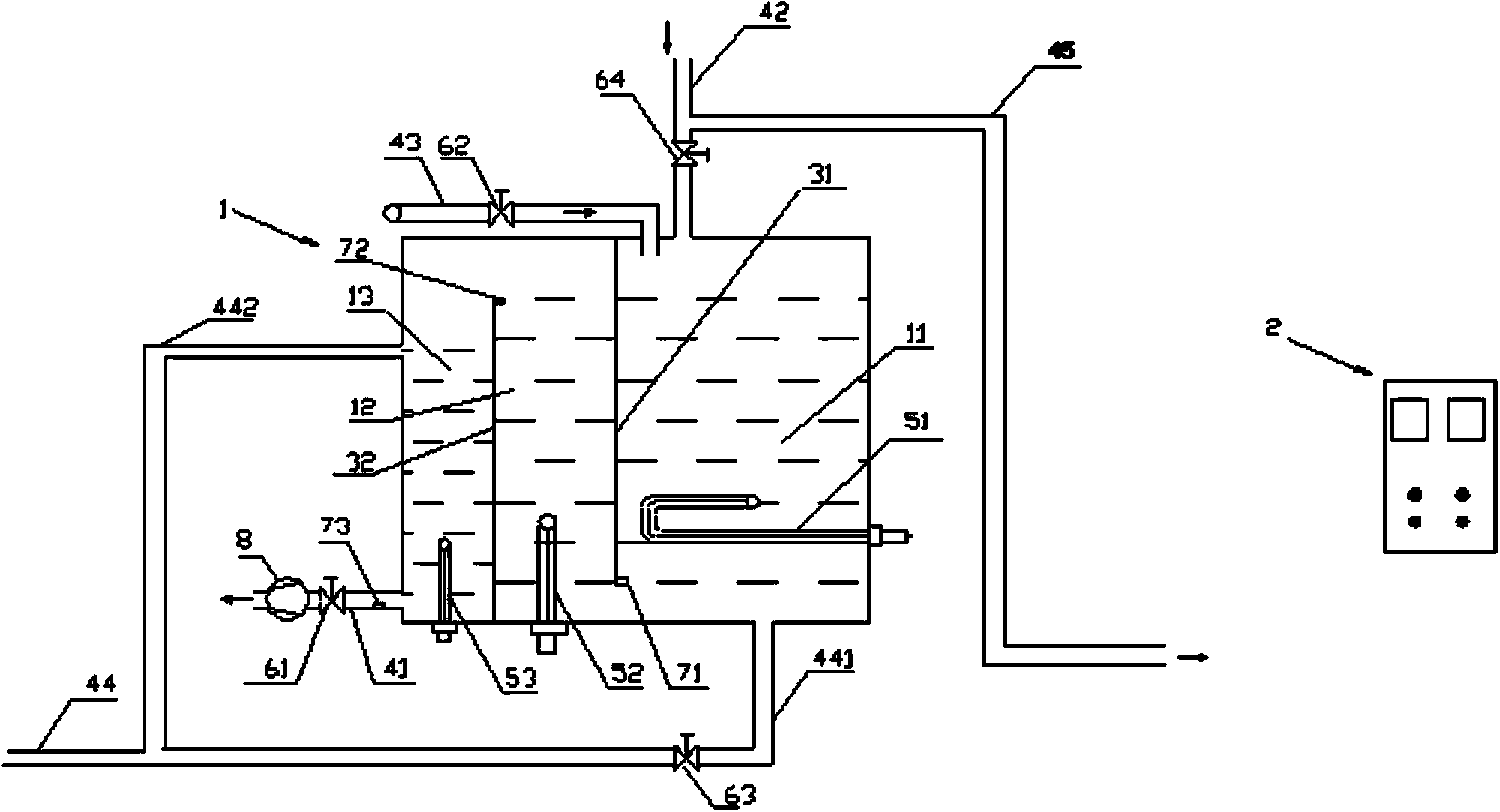

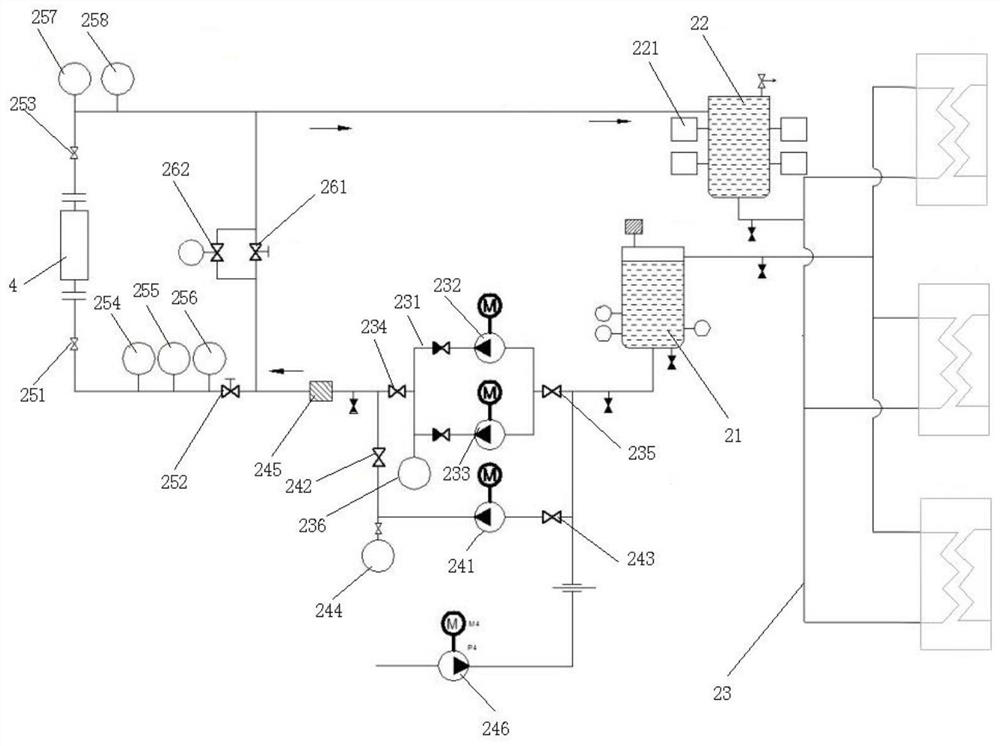

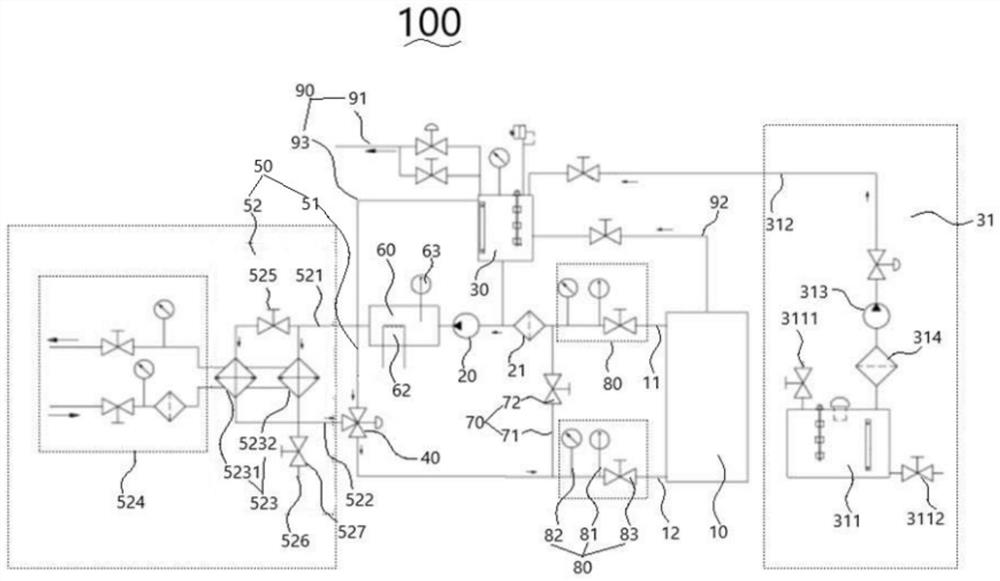

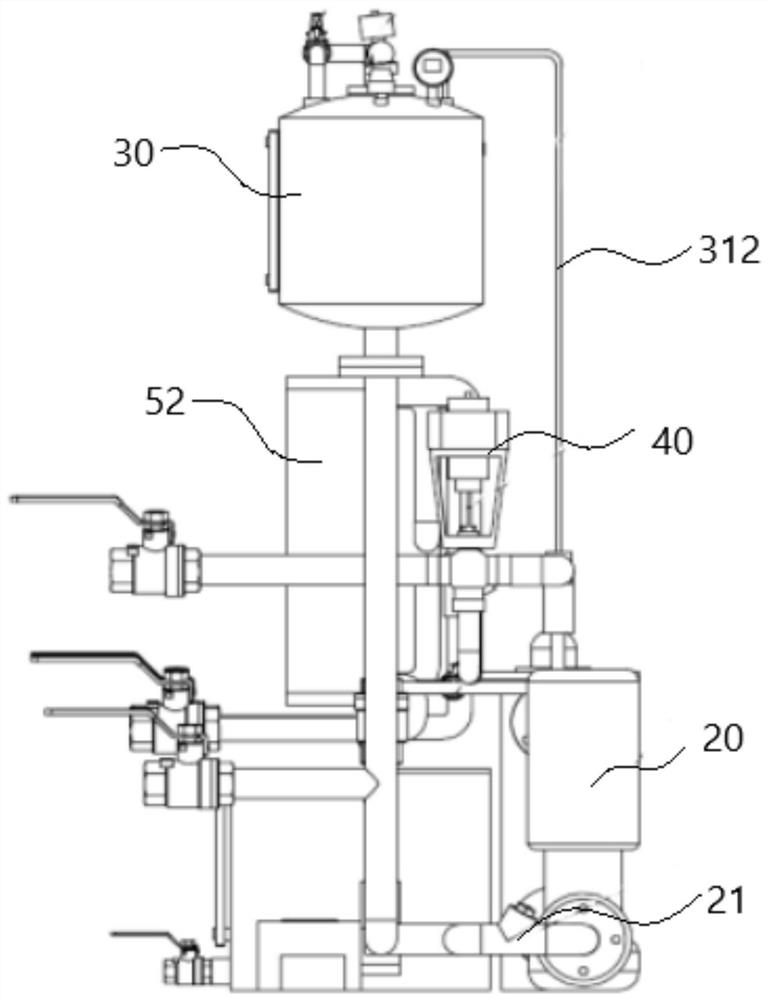

CSTR (continuous stirred-tank reactor) temperature control system and method based on coil heat exchanger and jacketed heat exchanger

InactiveCN102681565ANovel and reasonable designEasy to implementTemperature control using electric meansHeat exchange apparatusTemperature controlControl system

The invention discloses a CSTR (continuous stirred-tank reactor) temperature control system and method based on a coil heat exchanger and a jacketed heat exchanger. The control system comprises a temperature controller. An input end of the temperature controller is connected with a temperature measuring device, an output end of the temperature controller is connected with a coil flow regulating valve and a coil flow controller, and an output end of the coil flow controller is connected with a jacket flow regulating valve. The control method includes detecting a CSTR temperature signal in real time and transmitting the same; collecting the CSTR temperature signal in real time and analyzing and processing the same; controlling heat-carrying agent flow of the coil heat exchanger by the temperature controller and the coil flow regulating valve; and controlling the heat-carrying agent flow of the jacketed heat exchanger by the coil flow controller and the jacket flow regulating valve to correspondingly regulate heat-carrying agent flow of the coil heat exchanger. The CSTR temperature control system and the control method are novel and reasonable in design, quick in control speed, high in control precision, high in heat exchanging efficiency, low in heat-carrying agent consumption, favorable for saving energy and reducing consumption, and convenient to implement.

Owner:XIAN UNIV OF SCI & TECH

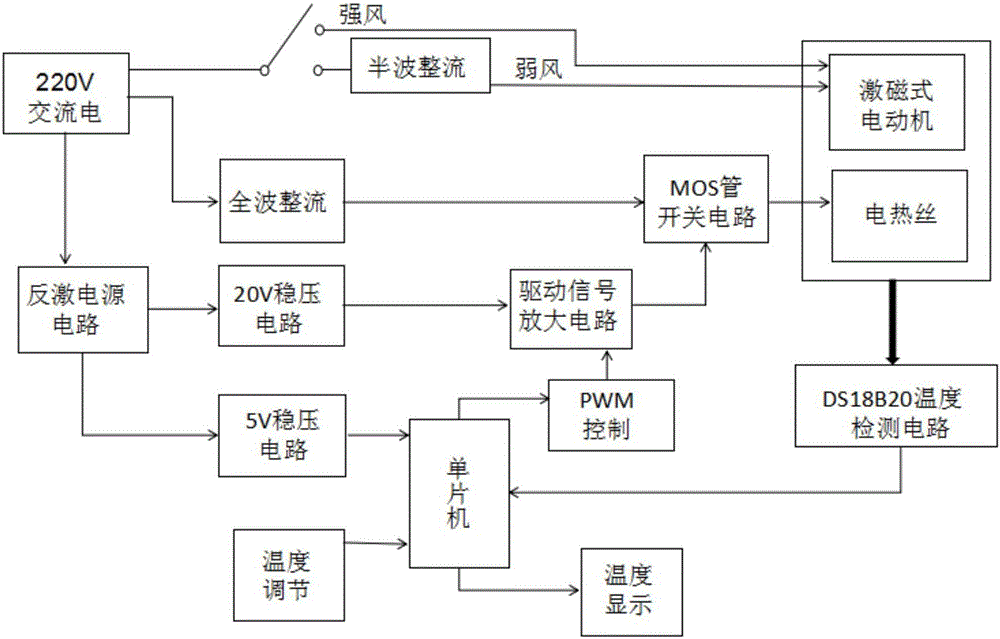

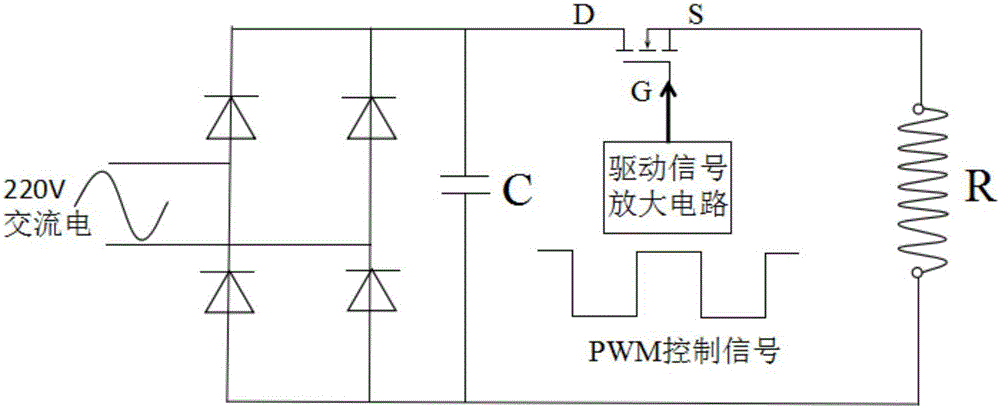

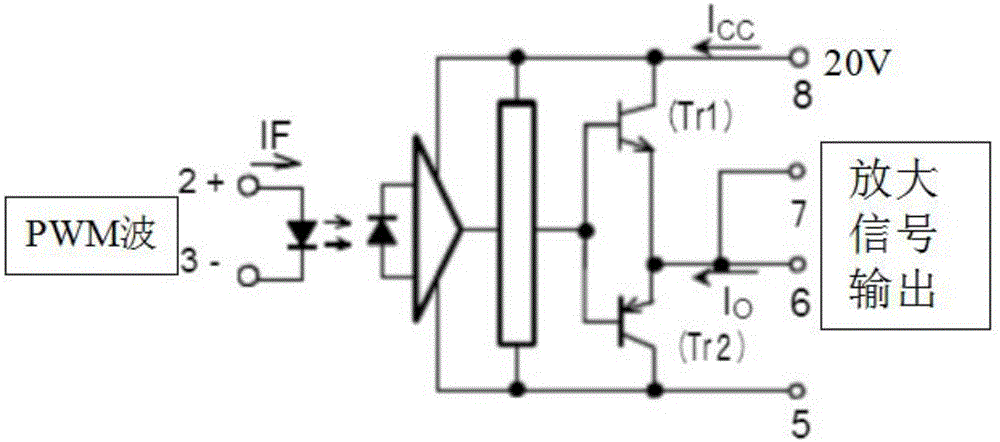

Hairdryer and constant temperature intelligent control circuit and method thereof

InactiveCN106617613AImprove accuracyExpand the use of the crowdHair dryingTemperature controlPid control algorithm

The invention discloses a hairdryer and constant temperature intelligent control circuit and method thereof, belonging to the field of intelligent control. The hairdryer and constant temperature intelligent control circuit and method thereof comprise a constant temperature intelligent control circuit. The constant temperature intelligent control circuit comprises a temperature setting knob, a temperature control circuit and a detection circuit. The temperature detection circuit is arranged on an air outlet of the hairdryer. The temperature control circuit is disposed in a handle of the hairdryer. The temperature setting knot is positioned on the handle of the hairdryer. The temperature setting knob is connected with the constant temperature intelligent control circuit. The temperature detection circuit is connected with the temperature control circuit. A heating circuit and a switch tube circuit are connected with the whole rectifying circuit. The switch tube circuit is connected with the heating circuit. The constant temperature intelligent control method adopts an incremental PID control algorithm, ensuring the consistency about the outlet temperature and the setting temperature of the hairdryer. The intelligent control circuit has the advantages of effectively making the temperature regulation in the outlet of the hairdryer adaptable to the individual required comfortable temperature, avoiding the hair damage under the high temperature, keeping the hair healthy as well as protecting the hair to make people feel comfortable.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

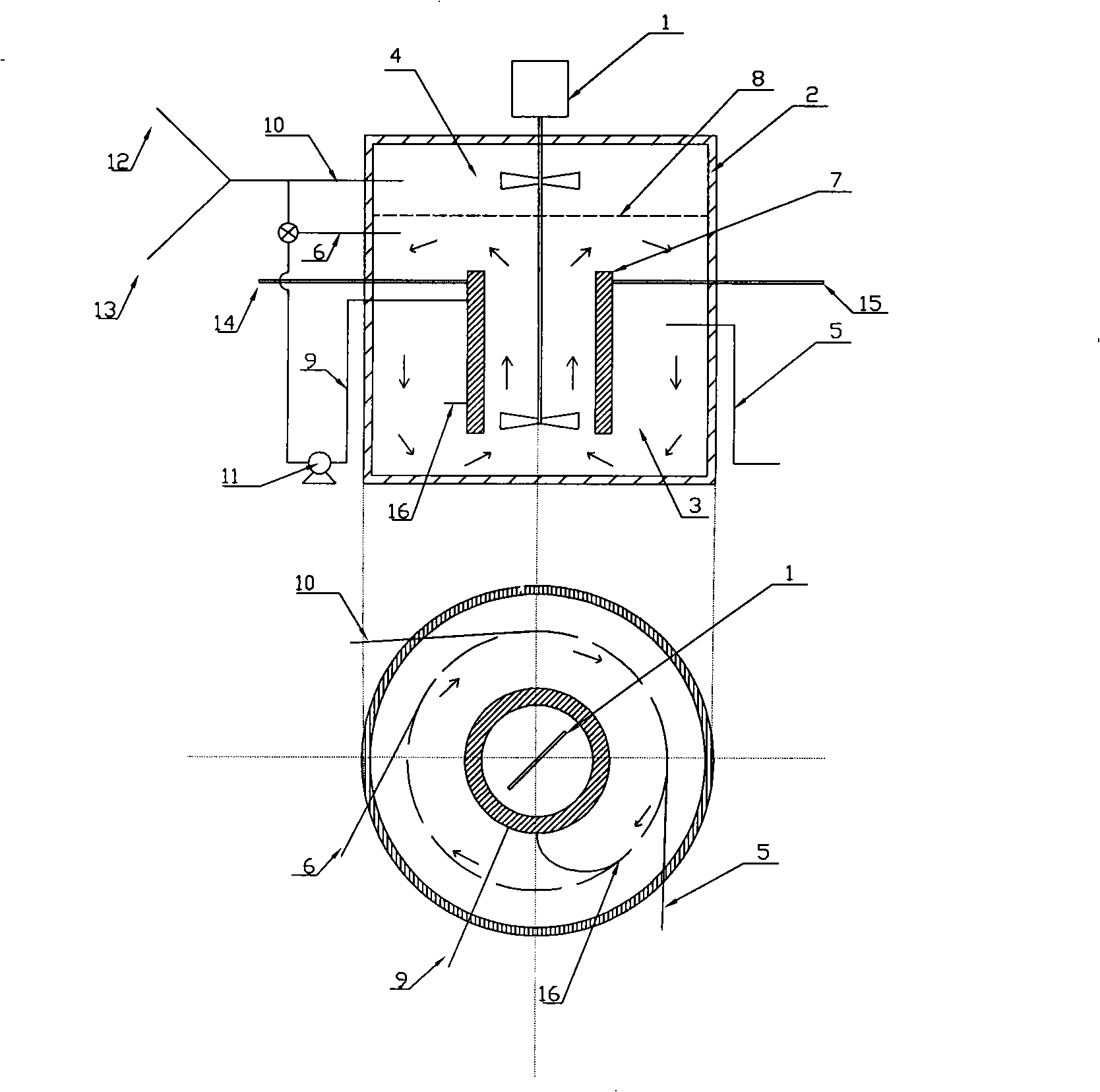

Constant temperature bath based on mixing cold and hot liquid to control temperature

InactiveCN101284251AUniform temperatureImprove temperature balanceTemperature control without auxillary powerWater/sand/air bathsTemperature controlMetallic materials

The invention relates to a thermostatic bath based on the mixed temperature control of cold and hot liquids, a main body thereof is a thermostatic bath body which adopts metal materials with large thermal conductivities and has a certain thickness; the thermostatic bath is characterized in that: the thermostatic bath is divided into a work area and a temperature regulation area, the middle is separated by a metal partition plate with a hole; a stirrer is provided with stirring paddles in both the temperature regulation area and the work area, horizontal stirring is implemented in the temperature regulation area, stirring on the vertical direction is implemented in the work area; an annular heat exchanger is arranged in the work area, the heat exchanger surrounds the stirring paddles; the side wall of the work area is provided with a hole and is connected with a return pipeline and a self-circulating pipeline; the side wall of the temperature regulation area is provided with a hole and is connected with a liquid injection pipeline. The thermostatic bath based on the mixed temperature control of cold and hot liquids of the invention can carry greater heat load, have large capacity, high precision and high anti-interference ability and facilitate the work of the heat exchanger in the internal temperature field thereof.

Owner:BEIHANG UNIV

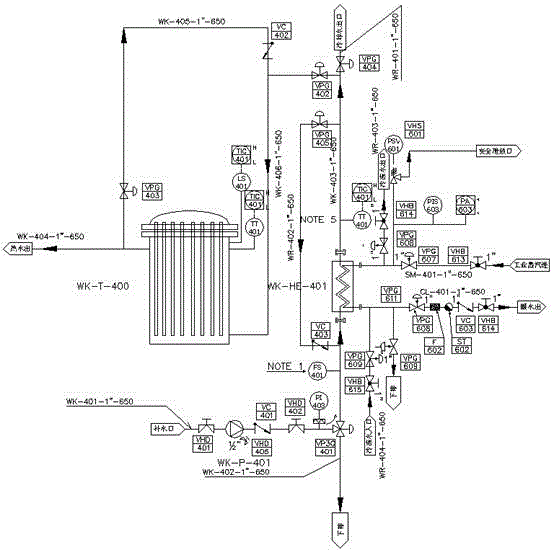

Hot water pot steam heating system

InactiveCN103528392AGuaranteed temperature control accuracyGuarantee the safety of useDirect contact heat exchangersTemperature controlReflux

Relating to the technical field of heat conversion, the invention discloses a hot water pot steam heating system, which is designed to solve the problems of inaccurate heating temperature and the like in existing hot water pots. The hot water pot steam heating system comprises a controller, a hot water pot and a steam supply device connected to the hot water pot. The hot water pot comprises a pot body, which is provided with a cold water inlet, a hot water outlet and a steam inlet connected to the steam supply device. The tank body is also provided with a hot water reflux inlet. The hot water outlet is connected to the hot water reflux inlet through a hot water reflux pipeline. The hot water reflux pipeline is provided with a reversing valve, the input end of which is connected to the hot water outlet. Two output ends of the reversing valve are respectively connected to the hot water reflux inlet and a hot water output pipeline. A temperature sensor for detecting the temperature of hot water at the hot water outlet is disposed close to the hot water outlet. The controller is connected to the temperature sensor and the reversing valve. The heating system can achieve very high temperature control precision.

Owner:KUNSHAN SHENGXING EQUIP INSTALLATION

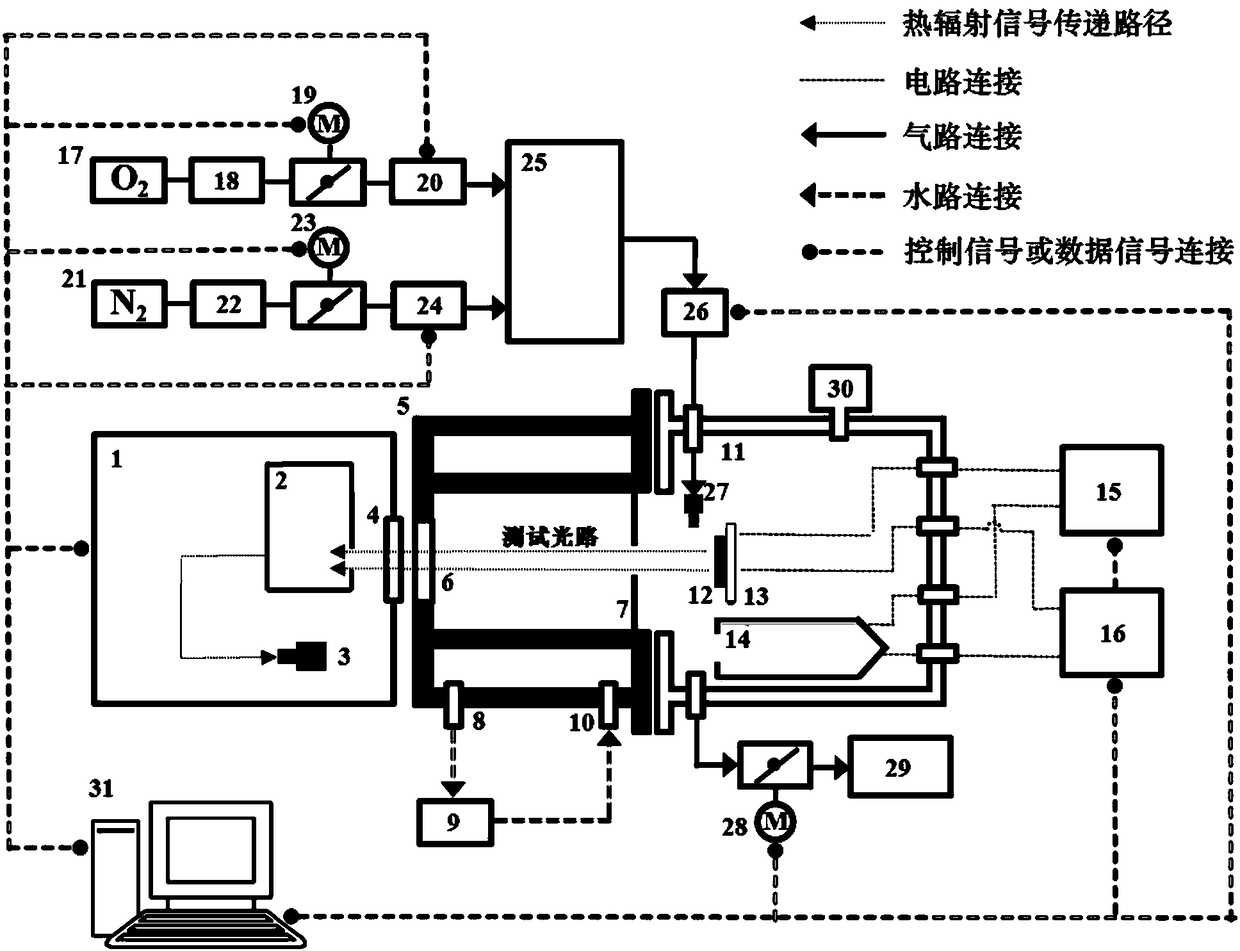

Variable oxygen partial pressure environment high temperature heat radiation performance test device, and method

ActiveCN108490022ATest accurateAvoid interferenceMaterial heat developmentControl mannerAtmospheric air

The invention discloses a variable oxygen partial pressure environment high temperature heat radiation performance test device, and a test method. According to the test method, a high temperature aerobic test environment with controllable temperature and oxygen partial pressure is established on the surface of a sample, so that accurate test on material high temperature heat radiation performanceat variable oxygen partial pressure environment is realized; a variable oxygen partial pressure high temperature gas purging system is used for forming oxygen / nitrogen mixed gas purging gas flow on the surface of the sample, realizing real-time controlling of the oxygen partial pressure and gas absolute pressure of the heating environment of the sample, avoiding influences of heat radiation signals emitted by polar molecules such as water and carbon dioxide in atmosphere at high temperature on test results, and ensuring heat radiation test accuracy; synchronous heating and constant temperaturecontrol of purging gas and the sample are adopted, so that heat convection effect between the sample surface and the purging gas is inhibited effectively, and accurate temperature control of the sample surface temperature is ensured.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

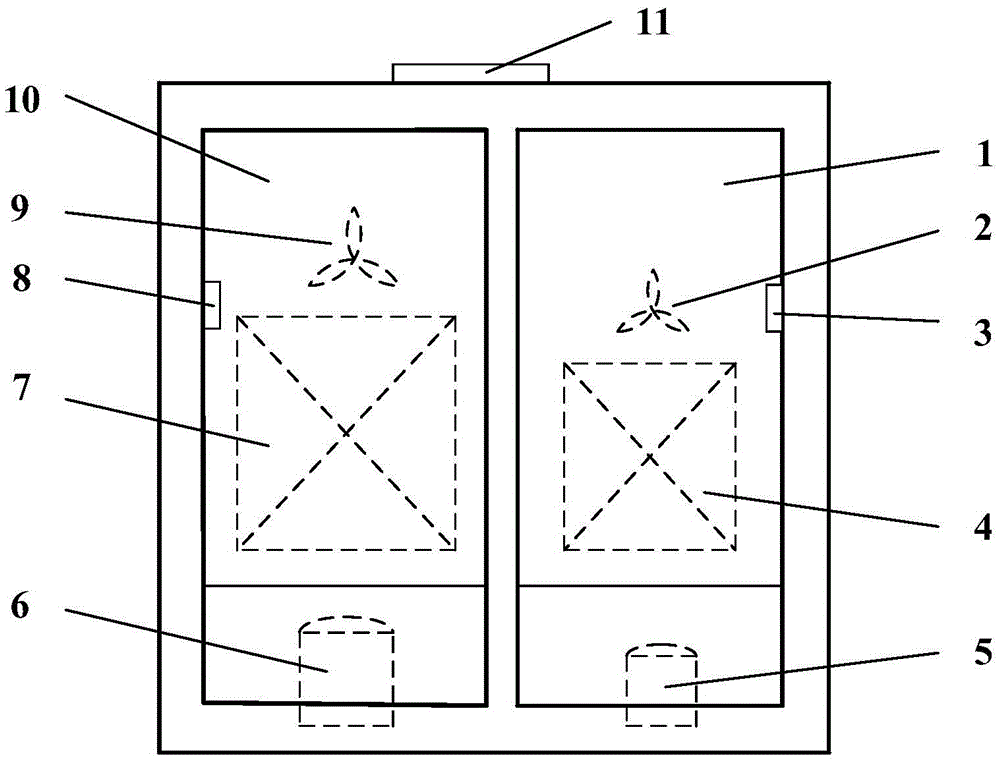

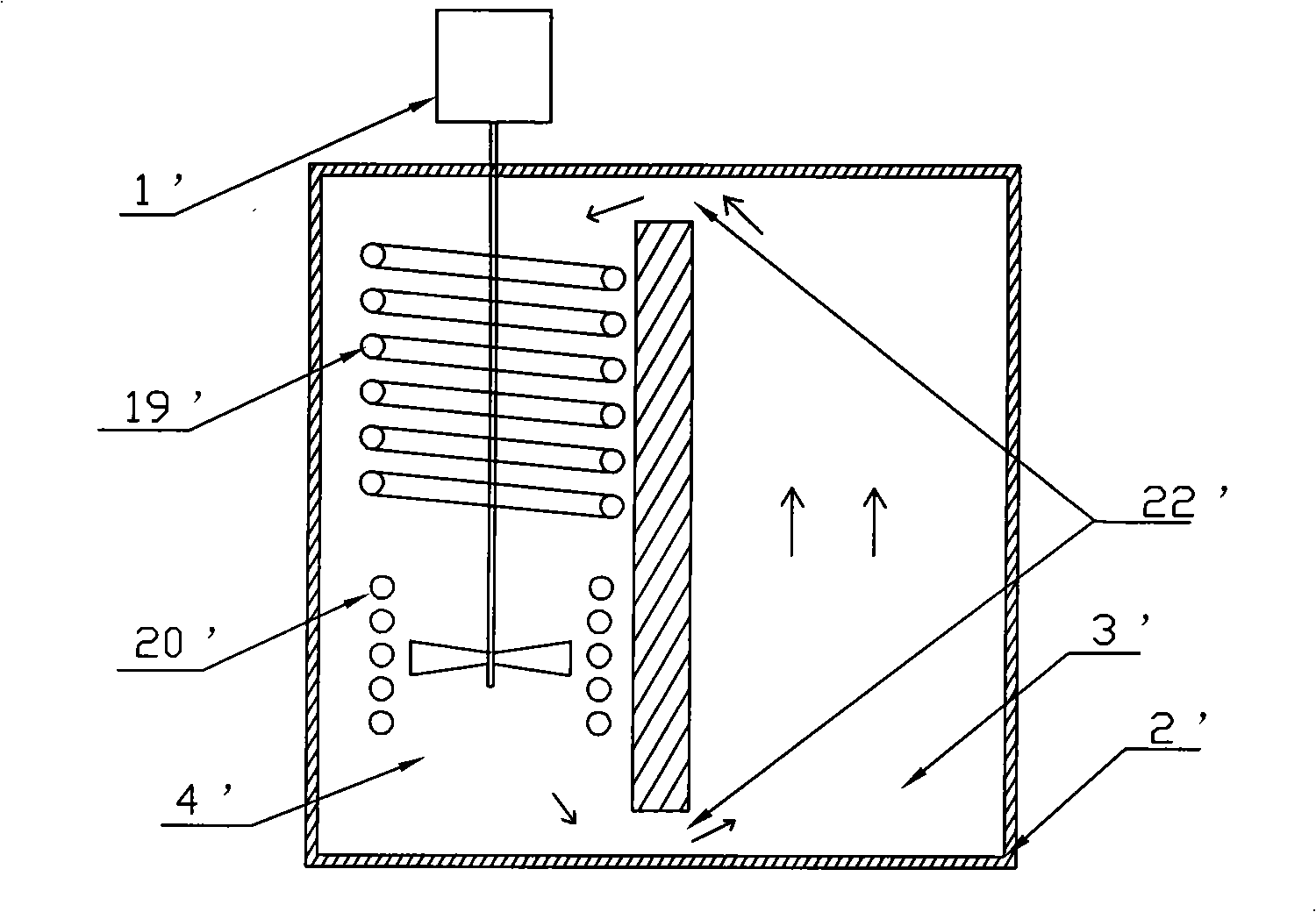

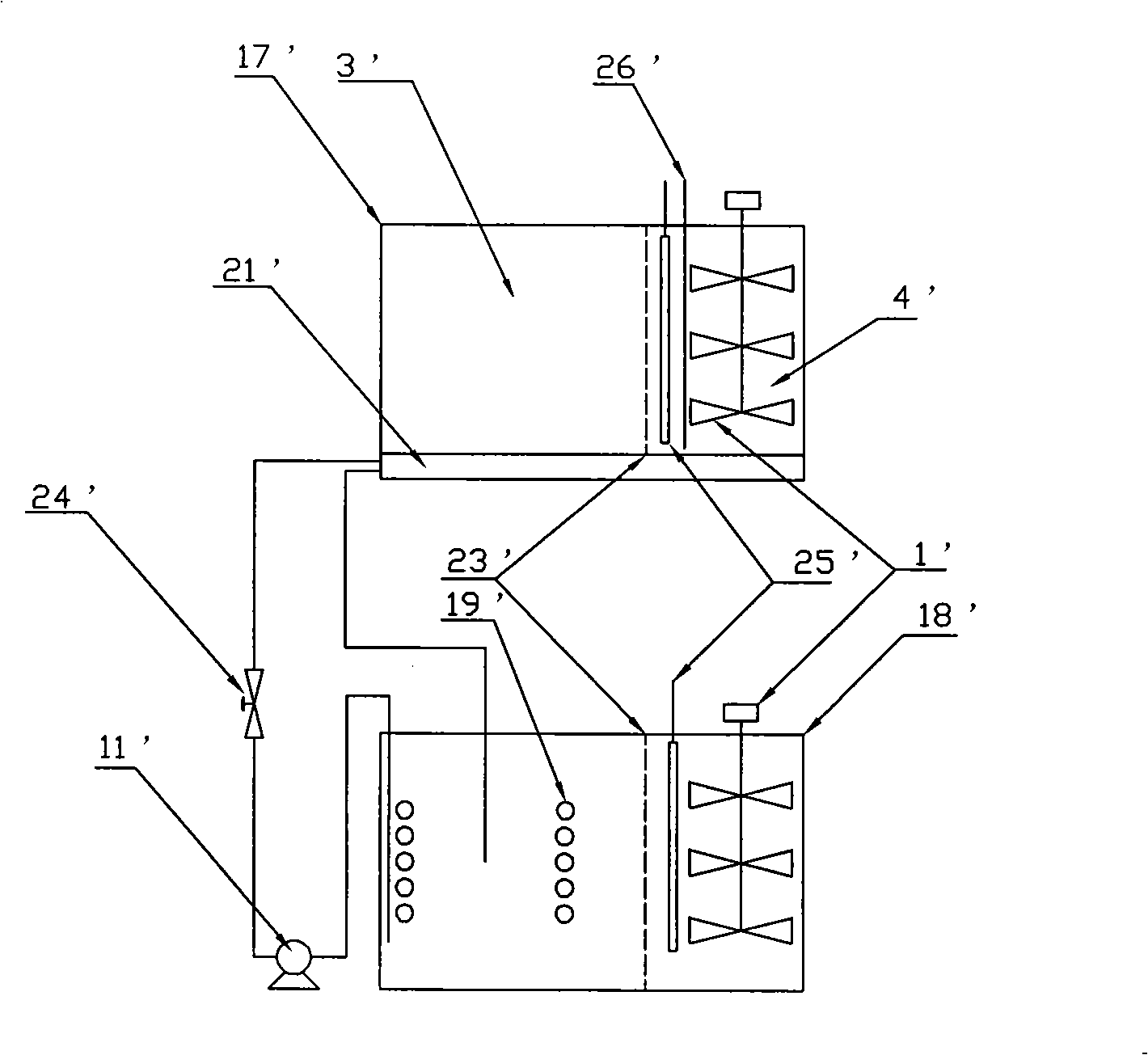

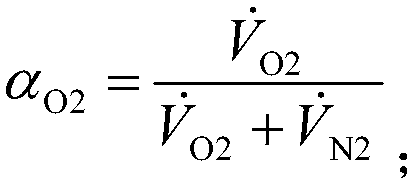

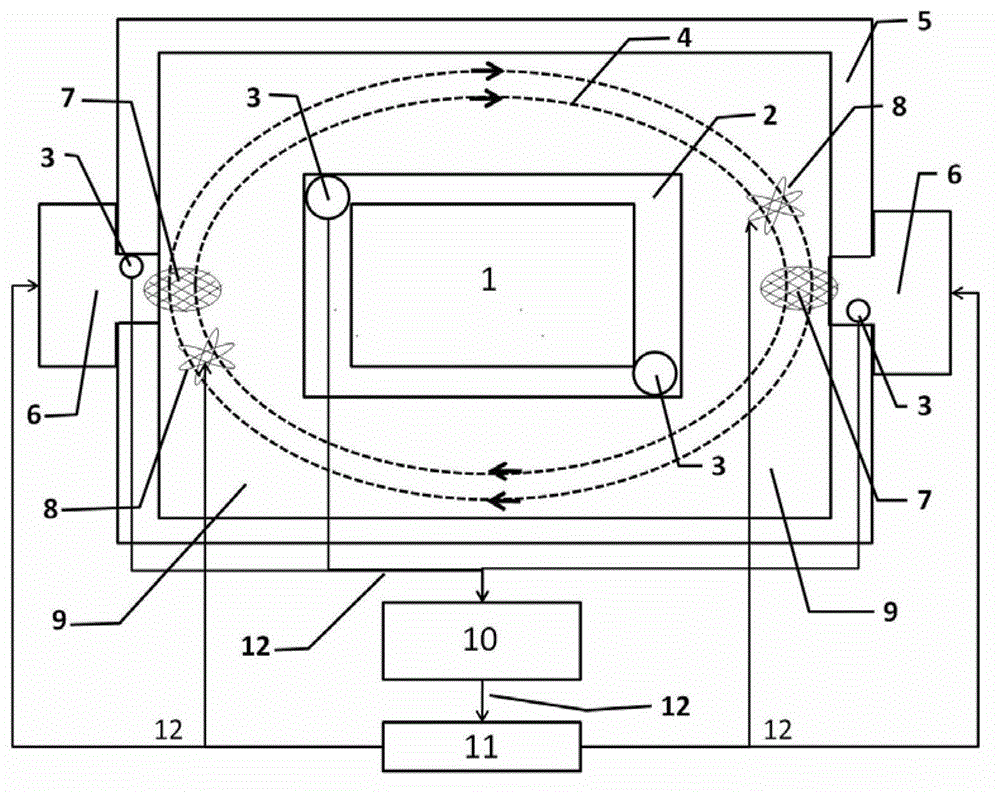

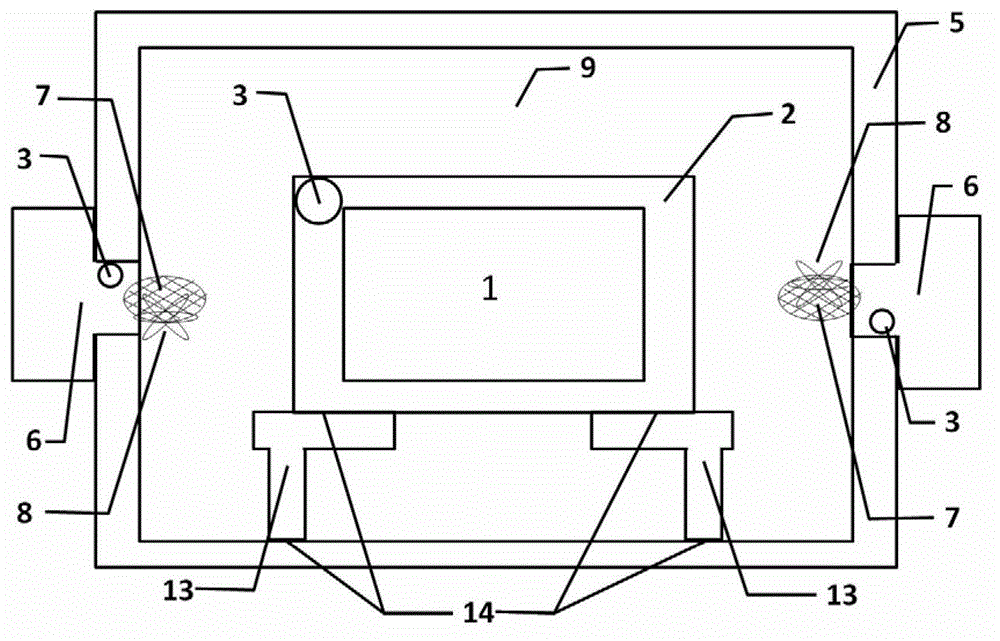

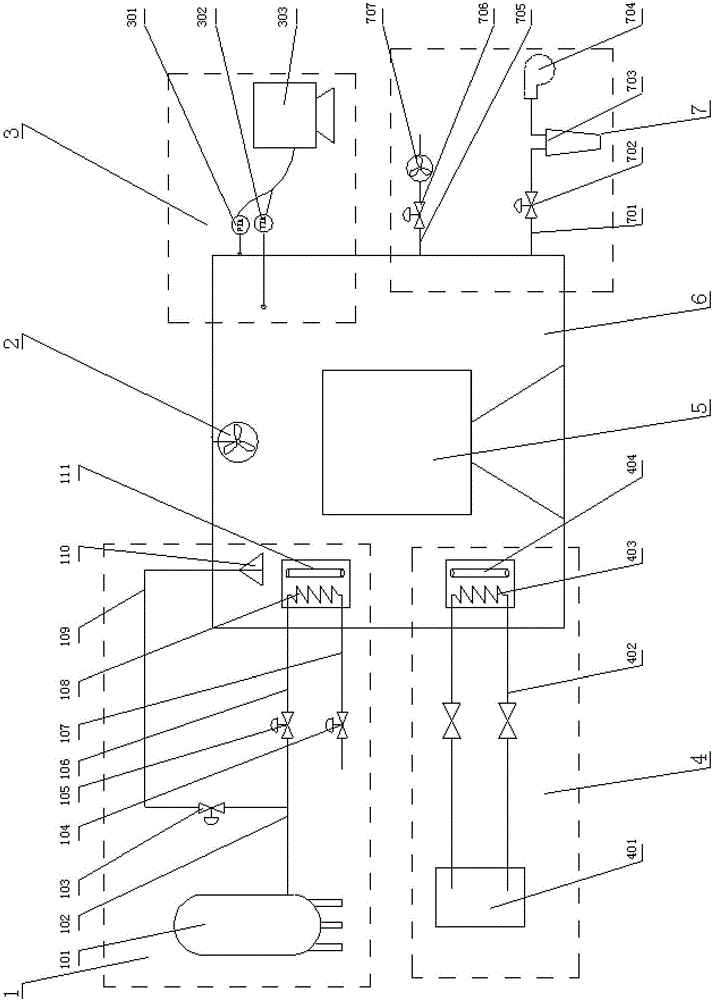

Precious object low-temperature preservation system

InactiveCN105444495ARealize intelligent controlGuaranteed temperature control accuracyLighting and heating apparatusStationary refrigeration devicesTemperature controlRefrigeration compressor

The invention provides a precious object low-temperature preservation system. The precious object low-temperature preservation system comprises an airtight space, and a refrigeration system consisting of a condenser, a refrigeration compressor, an evaporator and an air blowing component, wherein air return channels communicated with each other are respectively formed in the side walls and the bottom of the airtight space; an air inlet is formed in the air return channel in the bottom; an air flow stabilizing layer is arranged at the top of the airtight space; the evaporator is mounted at the top of the airtight space, and is communicated with the airtight space; and the condenser and the refrigeration compressor are mounted out of the airtight space. The precious object low-temperature preservation system can acquire temperature parameters in the airtight space in real time, and adjusts the temperature in the airtight space through the refrigeration system. Meanwhile, the special structure of the airtight space guarantees the control precision and uniformity of the temperature in the space, realizes intelligent temperature control, satisfies the preservation environmental requirements of precious objects, and accords with the requirements of product simpleness, stability and reliability of users.

Owner:TIANJIN CNRO SCI TECH

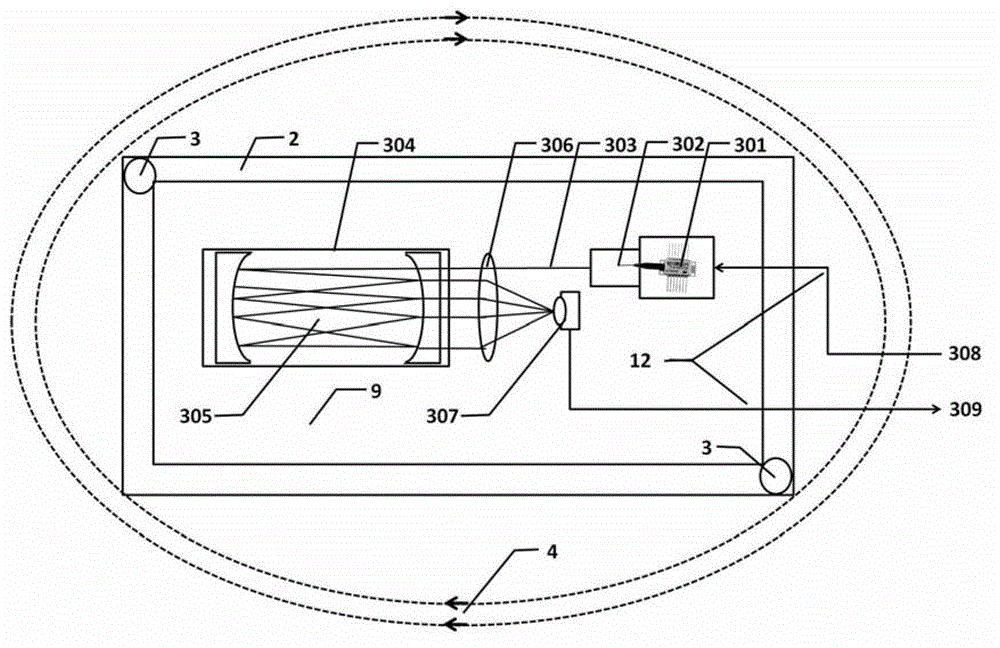

Temperature accurate control device used for integrated cavity spectrum technology isotope analysis

ActiveCN103149955ASolving Temperature Stability IssuesHigh sensitivityTemperatue controlColor/spectral properties measurementsLaser lightPt element

A temperature accurate control device used for an integrated cavity spectrum technology isotope analysis comprises a one-time sealing shell of an optical path system and a second-time sealing system of temperature stable and accurate control. The optical path system is installed inside the one-time sealing shell and the temperature accurate control device is characterized in that an optical laser, a distributed feed back (DFB) optical laser light source, a light beam converging collimating lens assembly, a laser path, an optical cavity, a laser beam converging lens and an InGaAs detector are integrated inside the optical path system. The optical laser, the DFB optical laser light source, the light beam converging collimating lens assembly, the laser path, the optical cavity, the laser beam converging lens and the InGaAs detector are all in the nitrogen condition to be prevented from being interfered by outside gas. The second-time sealing system of the temperature stable and accurate control comprises a second-time sealing shell, platinum resistor temperature sensors, rigid supports, semiconductor refrigeration piles, net-shaped heat exchangers, fans and shock absorption foams and further comprises a temperature controller, a driving circuit module, wherein the temperature controller and the driving module are arranged outside the second-time sealing shell and various control commands and electrical signals are all connected in a sealed mode through cables. The temperature accurate control device used for the integrated cavity spectrum technology isotope analysis has the advantages of being simple in structure, convenient to operate, quick in response, good in resistance to shock, high in temperature control precision and good in stability.

Owner:ANHUI CASZT PHOTOELECTRIC MEASUREMENT & CONTROL TECH CO LTD

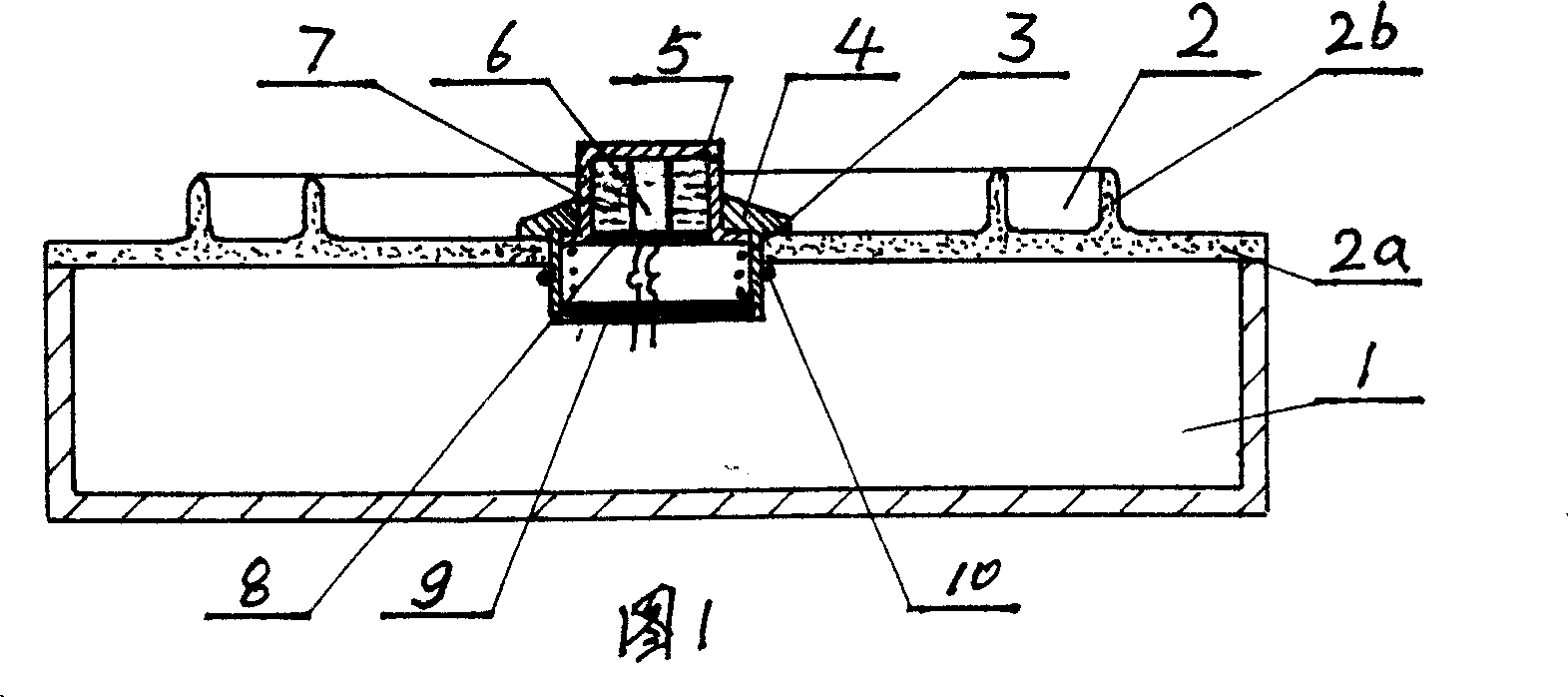

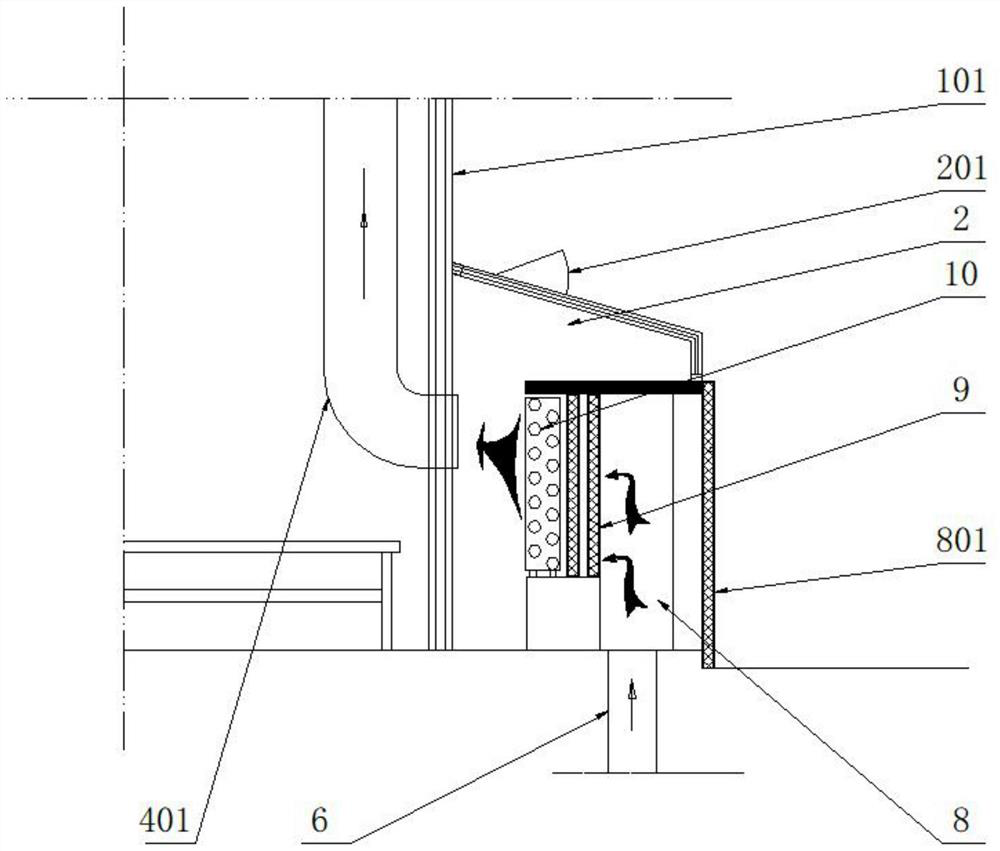

Electromagnetic oven

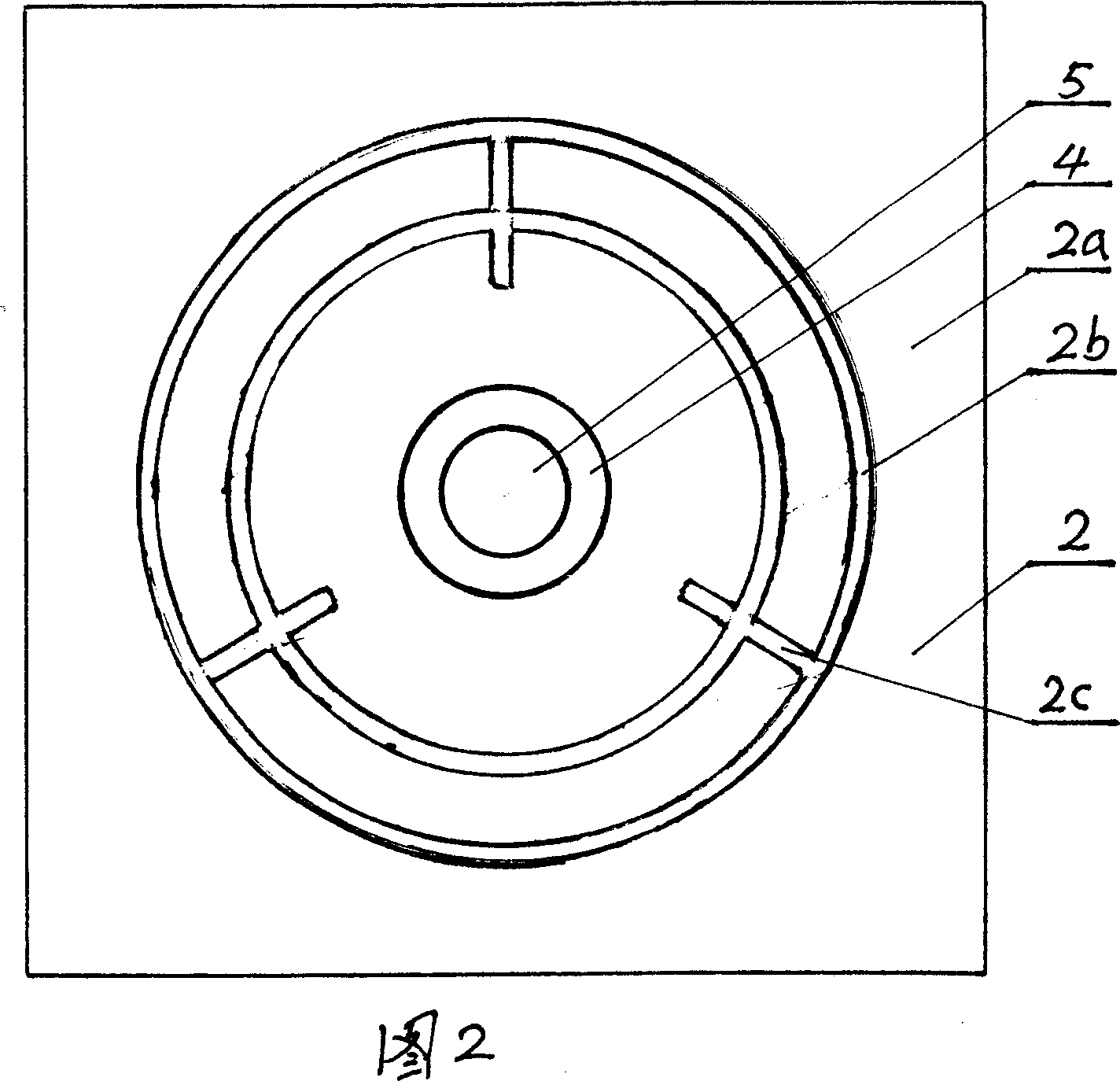

InactiveCN101055094AEnsure direct contactGuaranteed temperature control accuracyDomestic stoves or rangesLighting and heating apparatusEngineeringSilica gel

The invention discloses an induction cooker which includes body 1, panel 2 equipped on the body 1, temperature probe device equipped on the panel 2 and which includes temperature probe body 4 and probe cap 5 and so on, wherein the probe cap 5 can slide in relation to the temperature probe body 4, and temperature probe 6 and heat conduction silica gel 7 are installed in the probe cap. The panel includes panel body 2a, protruding ring 2b and protruding rib 2c, and the temperature probe device is mounted on the panel body 2a in the protruding ring 2a, therefore, the temperature probe device can directly contact with pan bottom thereby accurately and quickly detecting the temperature of the pan bottom, and can reduce the cooker temperature thereby improving working condition for electronic element then prolonging service life.

Owner:袁明

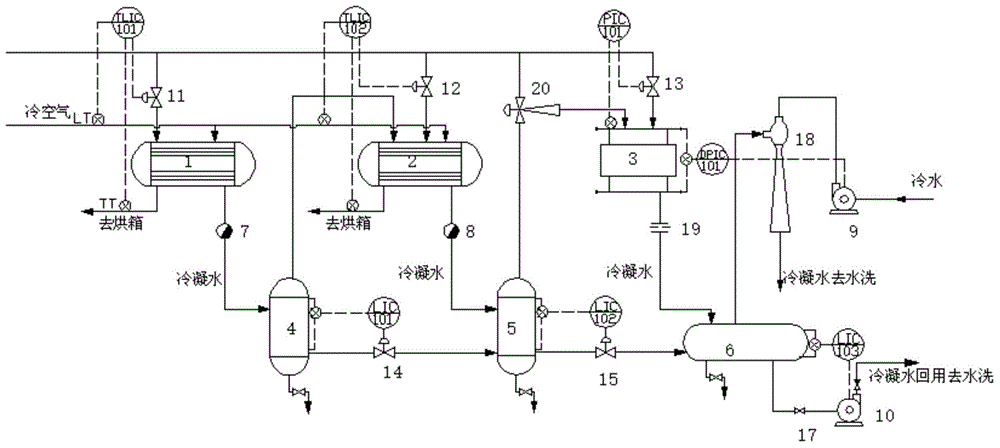

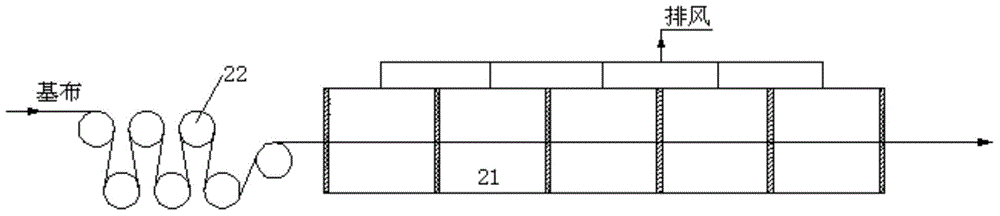

Control method and system for wet method leather manufacturing

ActiveCN104913624AImprove surface qualityRealize automated productionDrying gas arrangementsTextile/flexible product manufactureControl systemProcess engineering

The invention discloses a control method and a system for wet method leather manufacturing. By means of combination of hot air dying and drying-cylinder drying, base cloth is subjected to hot pressing and ironing at low temperature to improve surface quality of the base cloth; by means of three-section steam supply, trapezoidal utilization of energy is realized, fresh steam consumption is reduced while base cloth is dried, so that energy saving and consumption reduction are realized; the problem of safety in heating of conduction oil is solved by adoption of steam; by a multi-section heat supply control system, heat of steam condensate can be recycled completely, so that energy saving and consumption reduction are realized; owing to design of the control system, automatic production of a drying section is realized; in addition, adjustment of steam quantity according to operating conditions is realized so as to meet production requirements of different synthetic leather techniques.

Owner:SHAANXI UNIV OF SCI & TECH

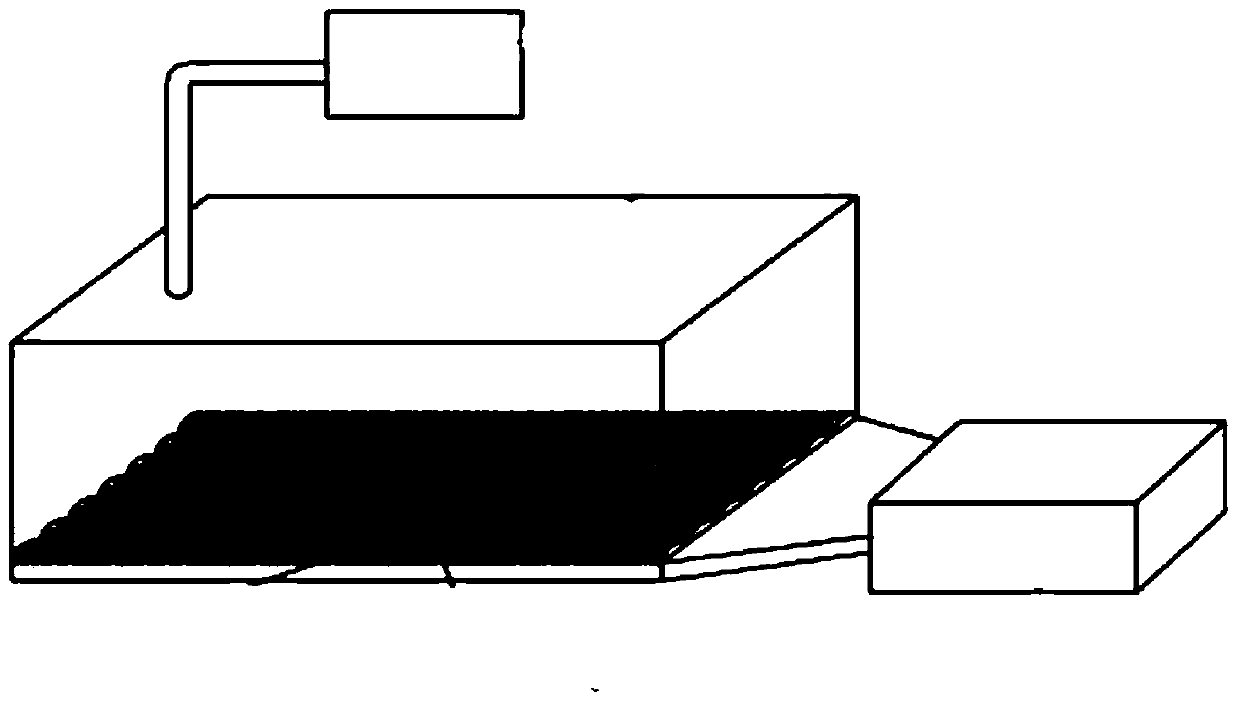

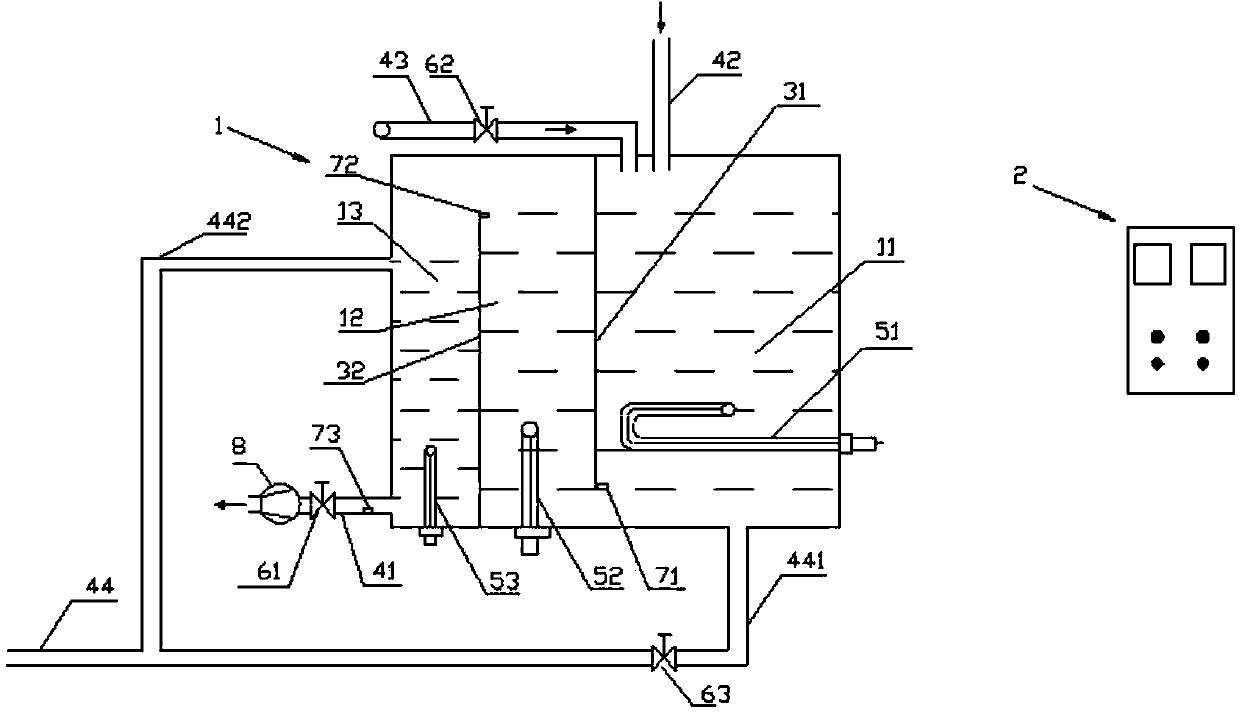

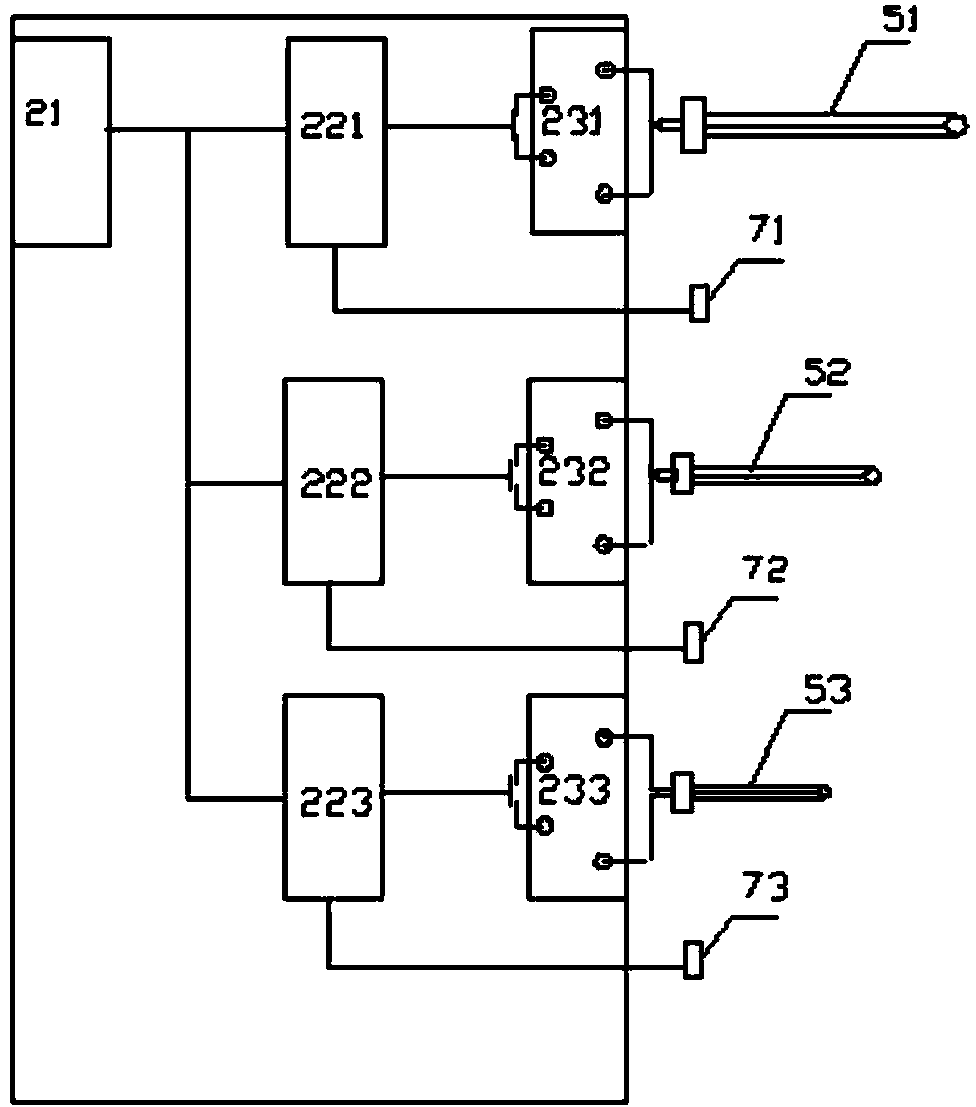

Three-stage temperature control cooling water tank

The invention relates to a three-stage temperature control cooling water tank. The three-stage temperature control cooling water tank comprises a tank body for containing cooling water, wherein the interior of the tank body is divided into a first tank body, a second tank body and a third tank body by a first partition plate and a second partition plate; a first heating device is mounted in the first tank body, a drain pipe is mounted at the bottom, and a water return pipe and a water replenishing pipe are mounted at the top; a second heating device is mounted in the second tank body; a third heating device is mounted in the third tank body, an overflow pipe is mounted at the upper part of the side wall of the third tank body, a water supply pipeline is mounted at the lower part, the drain pipe and the overflow pipe are connected with a drainage pipe, the bottom of the first tank body is communicated with the bottom of the second tank body, and the top of the second tank body is communicated with the top of the third tank body. The three-stage temperature control cooling water tank provided by the invention is designed against the temperature control range of the cooling water tank, which is required for the experiments, fully utilizes the characteristic of rich industrial water sources in a power plant, and directly uses a method of injecting water at normal temperature to cool the circulating cooling water; compared with the traditional cooling water tank, a compressor is omitted, so that the space is saved.

Owner:SHANDONG UNIV

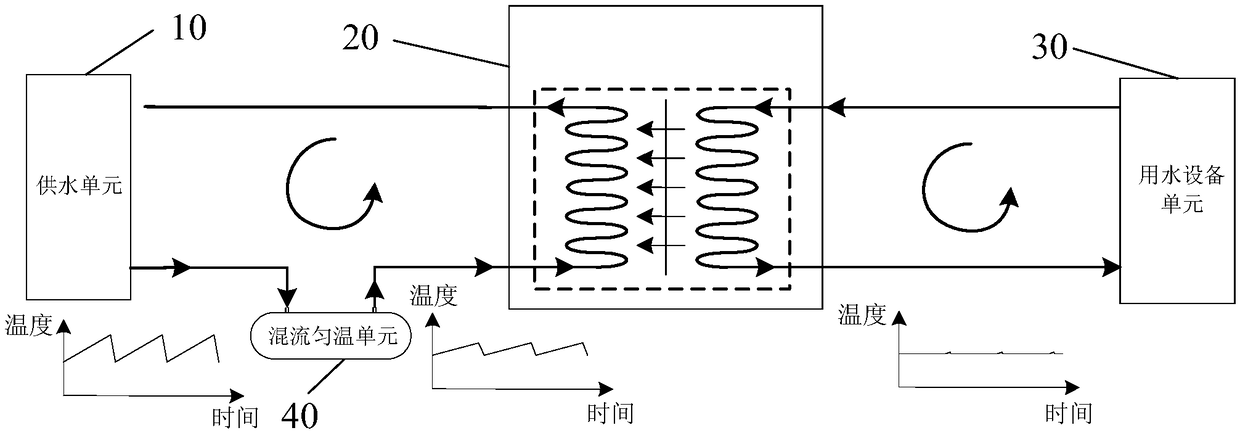

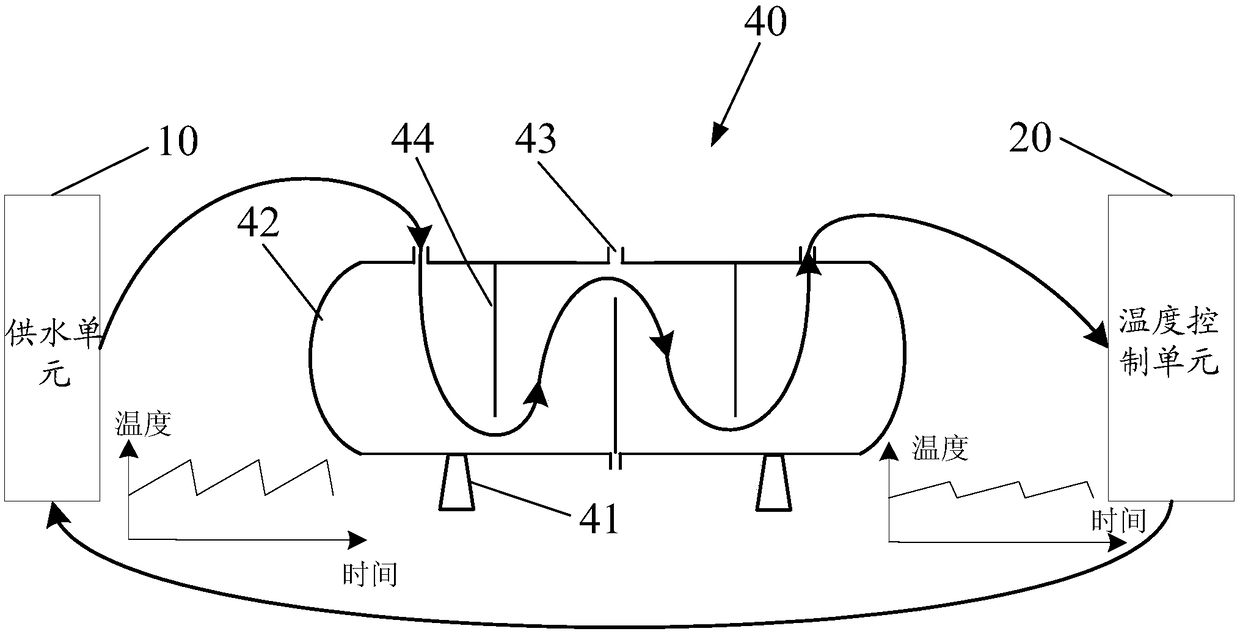

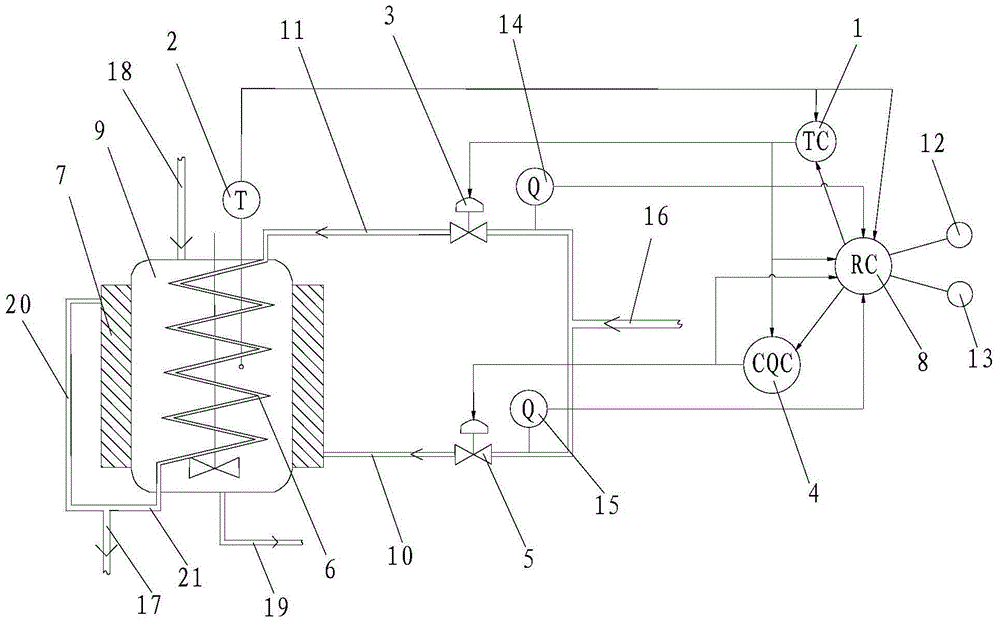

Device water supply temperature control apparatus and control method

ActiveCN108334124AAffect the heat transfer processGuaranteed temperature control accuracyTemperatue controlTemperature controlMixed flow

The invention relates to a device water supply temperature control apparatus and a control method. The apparatus comprises a water supply unit for providing cooling water; a temperature control unit for detecting the temperature of the cooling water provided by the water supply unit, and modulating the temperature according to the water demand of a water equipment unit to provide circuit water ofprecise temperature control for the water equipment unit; and a mixed flow temperature homogenizing unit disposed between the water supply unit and the temperature control unit for homogenizing the cooling water provided by the water supply unit. According to the invention, the influence of temperature sudden changes as an external disturbance factor on the heat exchange process of the temperaturecontrol unit is avoided by the connection of the mixed flow temperature homogenizing unit in the case that a facility system is not good enough, such that the temperature control precision of the temperature control unit is ensured to improve the adaptability of the temperature control unit to harsh facility conditions.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Temperature control system for unfreezing and heat preservation of biological product liquid medicine

ActiveCN106527528AFast temperature changeGuaranteed temperature control accuracyTemperatue controlEnergy industryPipingElectric heating

The invention discloses a temperature control system for the unfreezing and heat preservation of biological product liquid medicine, and the system comprises a water-bath heating module and an electric heating module, wherein the water-bath heating module comprises an industrial steam heating pipe, a freezing water pipe, a water supplement pipe, and a plate heat exchanger. The industrial steam heating pipe, the freezing water pipe and the water supplement pipe are respectively connected with the plate heat exchanger. The electric heating module comprises a heating tank and an electric heating pipe system, and the electric heating pipe system is connected with the heating tank. The interior of the heating tank is vertically and uniformly provided with a plurality of heating pipes. The water-bath heating module is used for achieving the quick rise of temperature, and improving the temperature response speed. A heat exchanger industrial steam pipe is connected with an industrial steam pneumatic angle valve, thereby achieving a purpose of stopping the industrial steam heating when the industrial steam is nearly heated to designed temperature. The freezing water pipe is used for achieving the cooling of the plate heat exchanger. During the approaching of the designed temperature, the electric heating module can effectively control the precision of temperature rise through controlling the number of heating tube switches in the heating tank and the heating time.

Owner:JILIN HONGZHAN FLUID TECH CO LTD

Cooling water tank allowing amount of returning water to be controlled

The invention relates to a cooling water tank allowing the amount of returning water to be controlled. The cooling water tank comprises a tank body holding cooling water; a first partition board and a second partition board are vertically arranged in the tank body and divide the tank body into a first tank body, a second tank body and a third tank body; a first heating device is mounted in the first tank body, a flow discharge pipe is mounted at the bottom, a water return pipe and a water replenishing pipe are mounted at the top, and a water drainage pipe and a fourth regulating valve are additionally arranged on the water return pipe; a second heating device is mounted in the second tank body; a third heating device is mounted in the third tank body, an overflow pipe is mounted at the upper part of the side wall of the third tank body, and a water supplying pipeline is mounted at the lower part; the flow discharge pipe and the overflow pipe are both connected with the water drainage pipe; the bottoms of the first tank body and the second tank body are communicated, and the tops of the second tank body and the third tank body are communicated. Compared with a traditional cooling water tank, the cooling water tank provided by the invention has the advantages that a compressor is canceled, and the space is saved; besides, the opening degree of the fourth regulating valve can be reduced, so that the flow rate of the cooling water which is subjected to heat exchange, is relatively high in temperature and returns to the tank body through the water return pipe can be controlled.

Owner:SHANDONG UNIV

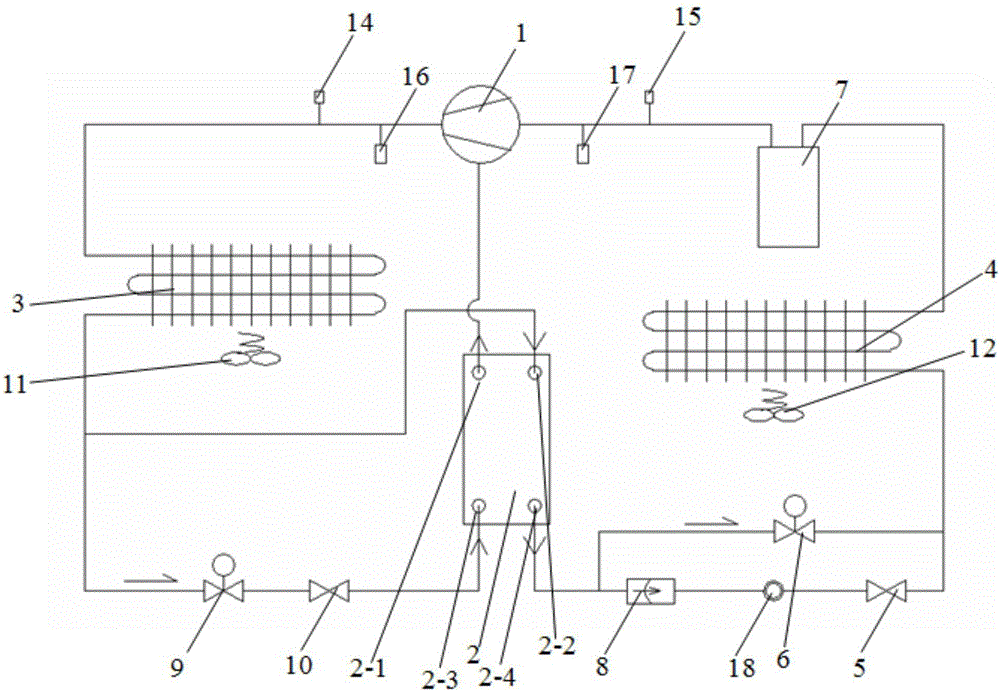

Integrated high-temperature frequency-variable heat pump heating air conditioning system

InactiveCN106091458AReduce high temperature loadTemperature controlMechanical apparatusCompression machines with several condensersTemperature controlVapor–liquid separator

The invention relates to an air conditioning system and particularly relates to an integrated high-temperature frequency-variable heat pump heating air conditioning system. The air conditioning system comprises a frequency-variable intermediate gas-supplementing scroll compressor, a plate type heat exchanger, a finned condenser, a finned evaporator, a main thermostatic expansion valve, a normally-opened electromagnetic valve, a gas-liquid separator, a drying filter, a normally-closed electromagnetic valve, a branch thermostatic expansion valve, an axial flow condensation fan, an axial flow evaporation fan, a pipeline, a high-pressure detection valve, a low-pressure detection valve, a high-pressure switch, a low-pressure switch and a liquid observing mirror. In order to overcome the disadvantages of the prior art, the integrated high-temperature frequency-variable heat pump heating air conditioning system is adopted; the compressor adopts a special frequency-variable intermediate gas-supplementing scroll compressor for a high-temperature heat pump; the displacement of the compressor is controlled by adjusting the operation frequency of the compressor, and the heating capacity on a condensation side is dynamically adjusted, so that the inner temperature of a curing barn is controlled, and the temperature control accuracy of the curing barn is ensured.

Owner:合肥海瑞弗机房设备有限公司

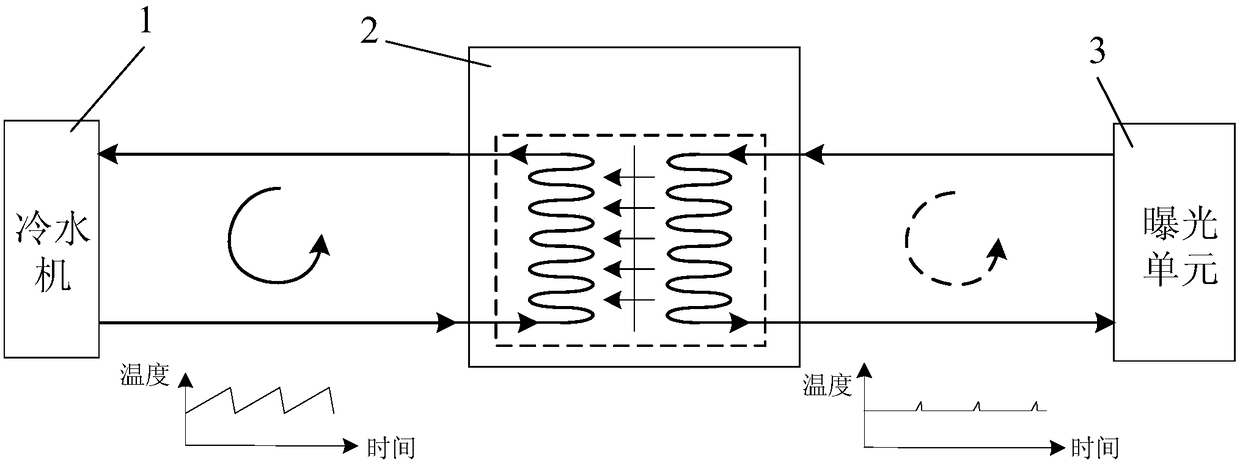

Temperature control method and device of immersion lithography machine

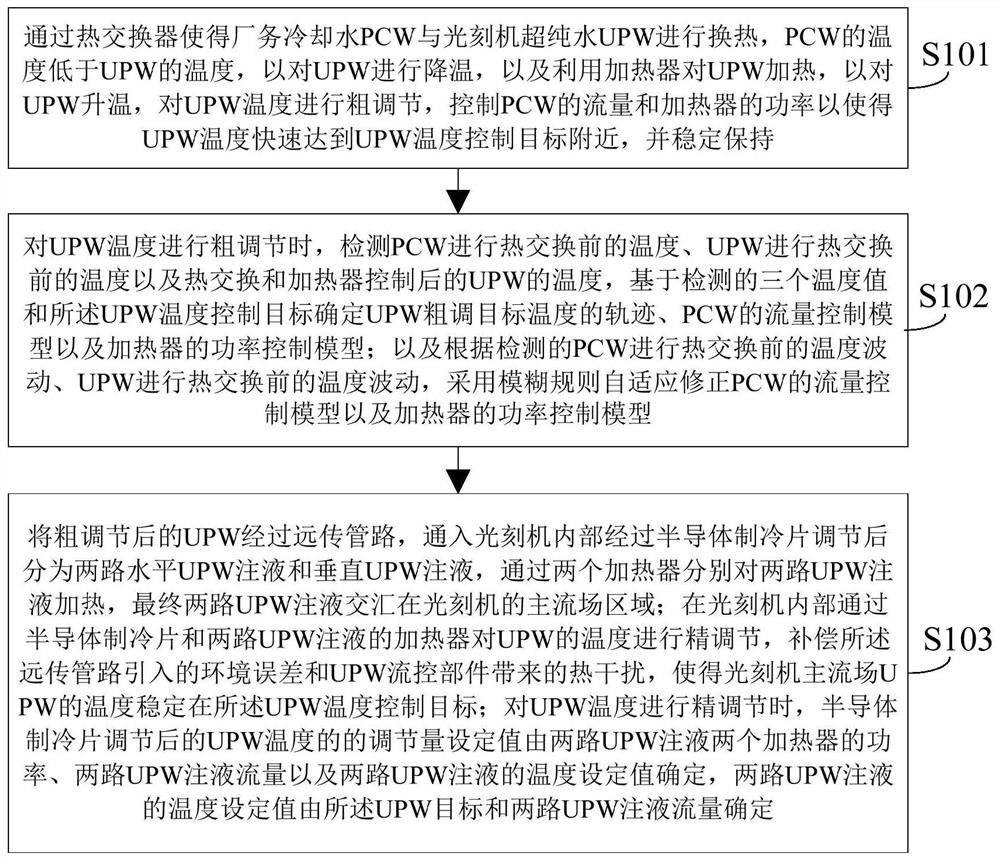

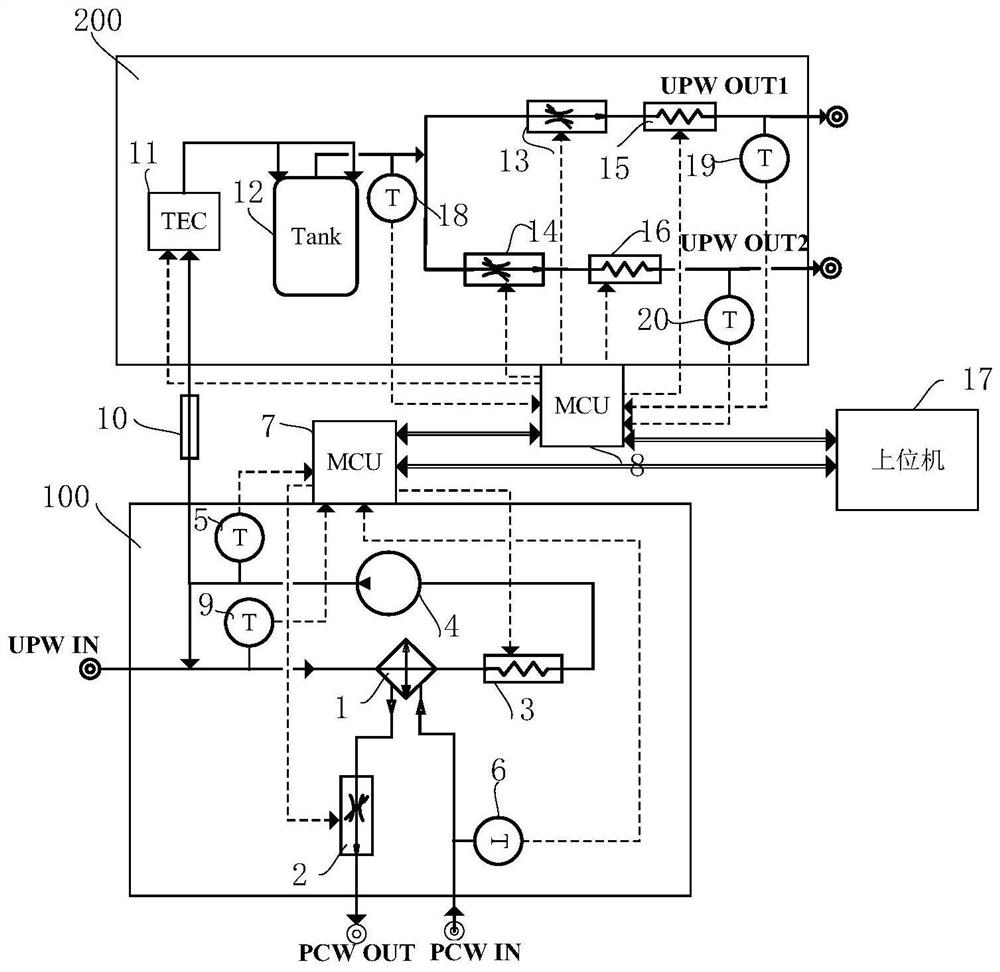

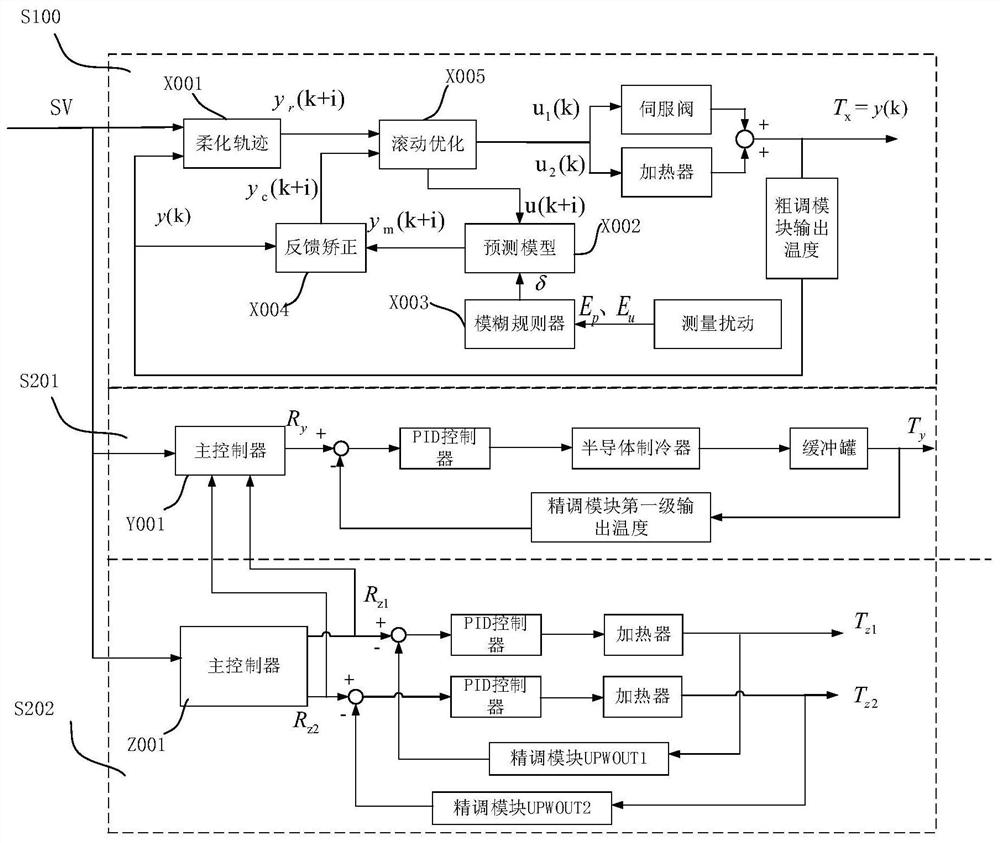

ActiveCN112445084AOvercome the effect of target temperatureGuaranteed temperature control accuracyTemperatue controlPhotomechanical exposure apparatusTemperature controlControl power

The invention provides a temperature control method and device for an immersion lithography machine, and the method comprises the steps: carrying out the heat exchange between a PCW and a lithographymachine UPW through a heat exchanger, heating the UPW through a heater, so as to heat the UPW, and carrying out the rough adjustment of the temperature of the UPW, determining a UPW temperature track,a PCW flow control model and a heater power control model based on the detected three temperature values and the UPW temperature control target; adaptively correcting a flow control model of the PCWand a power control model of the heater by adopting a fuzzy rule; introducing the coarsely adjusted UPW into a photoetching machine through a remote transmission pipeline, dividing the UPW into two paths of UPW injection liquid after being adjusted by a semiconductor chilling plate, and respectively heating the two paths of UPW injection liquid through two heaters; and when the UPW temperature isfinely adjusted, the adjustment amount of the refrigeration sheet is determined by the power of the two heaters for two paths of UPW liquid injection, the flow of the two paths of UPW liquid injectionand the temperature set values of the two paths of UPW liquid injection. According to the invention, the temperature control precision of the photoetching machine is improved.

Owner:WUHAN INTELLIGENT EQUIP IND INST CO LTD

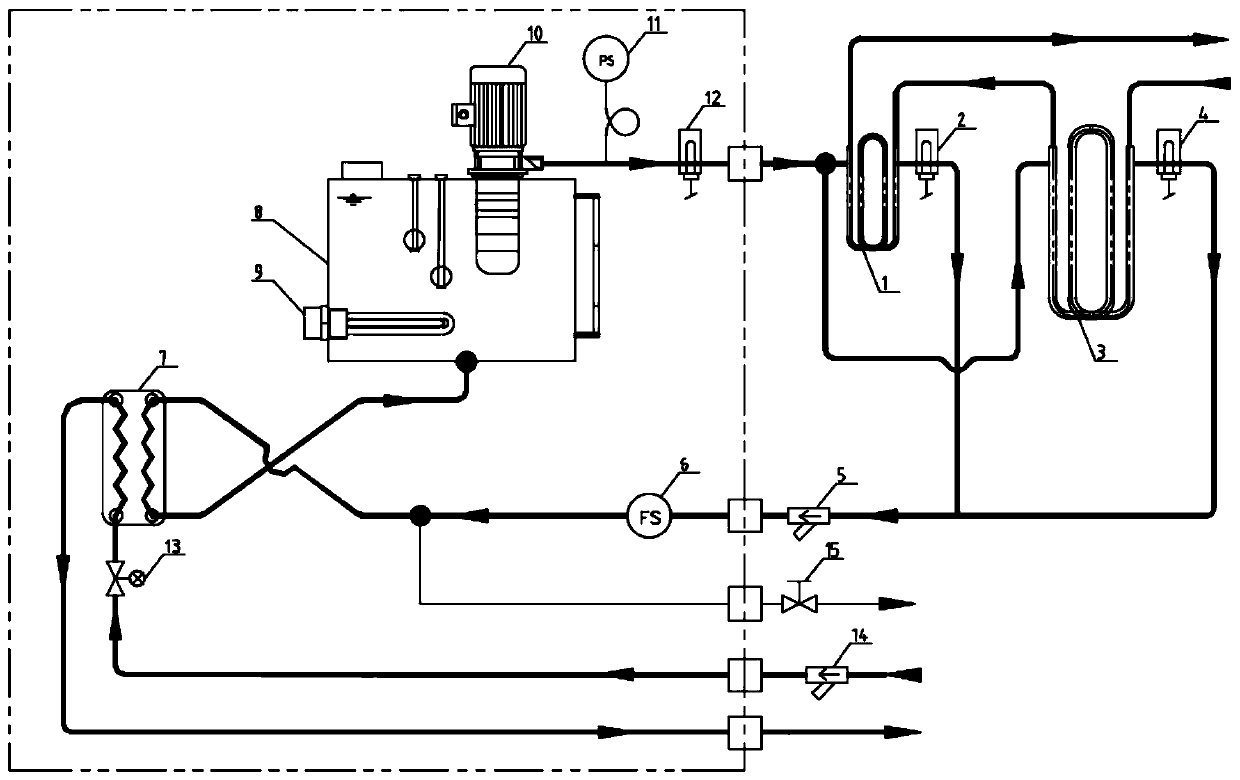

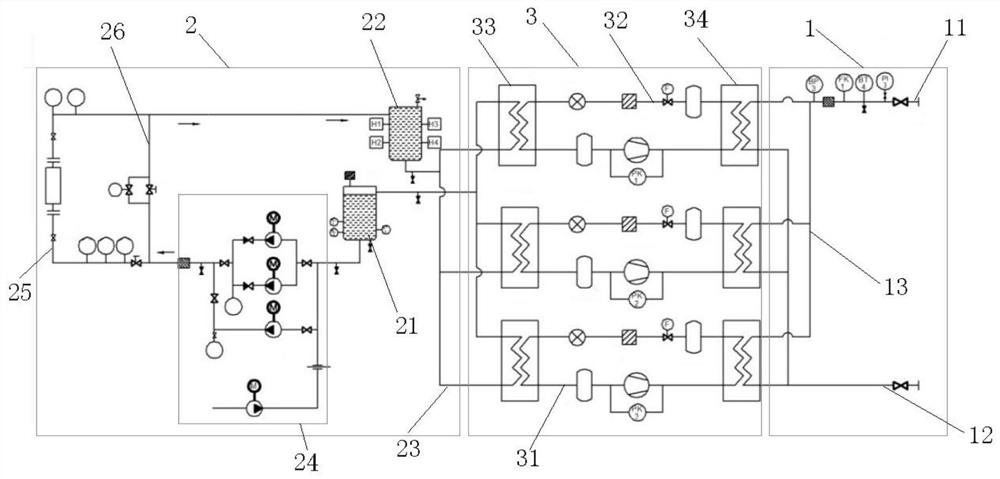

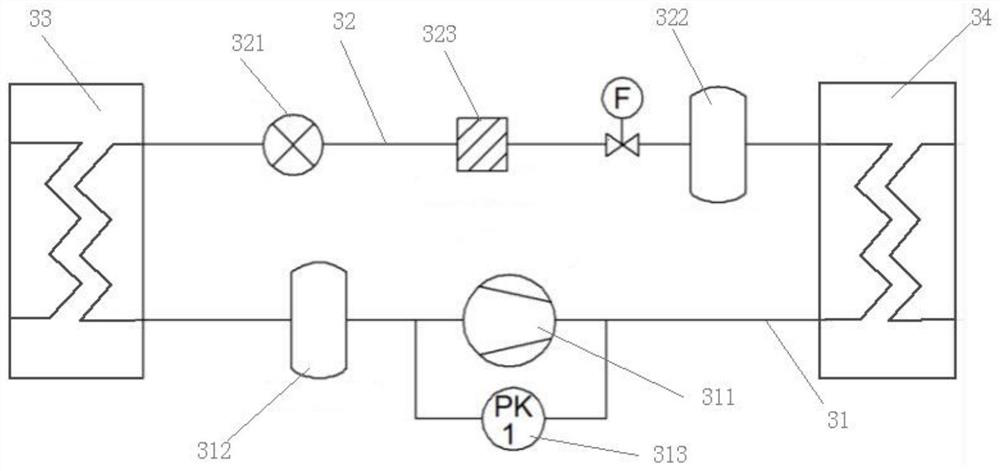

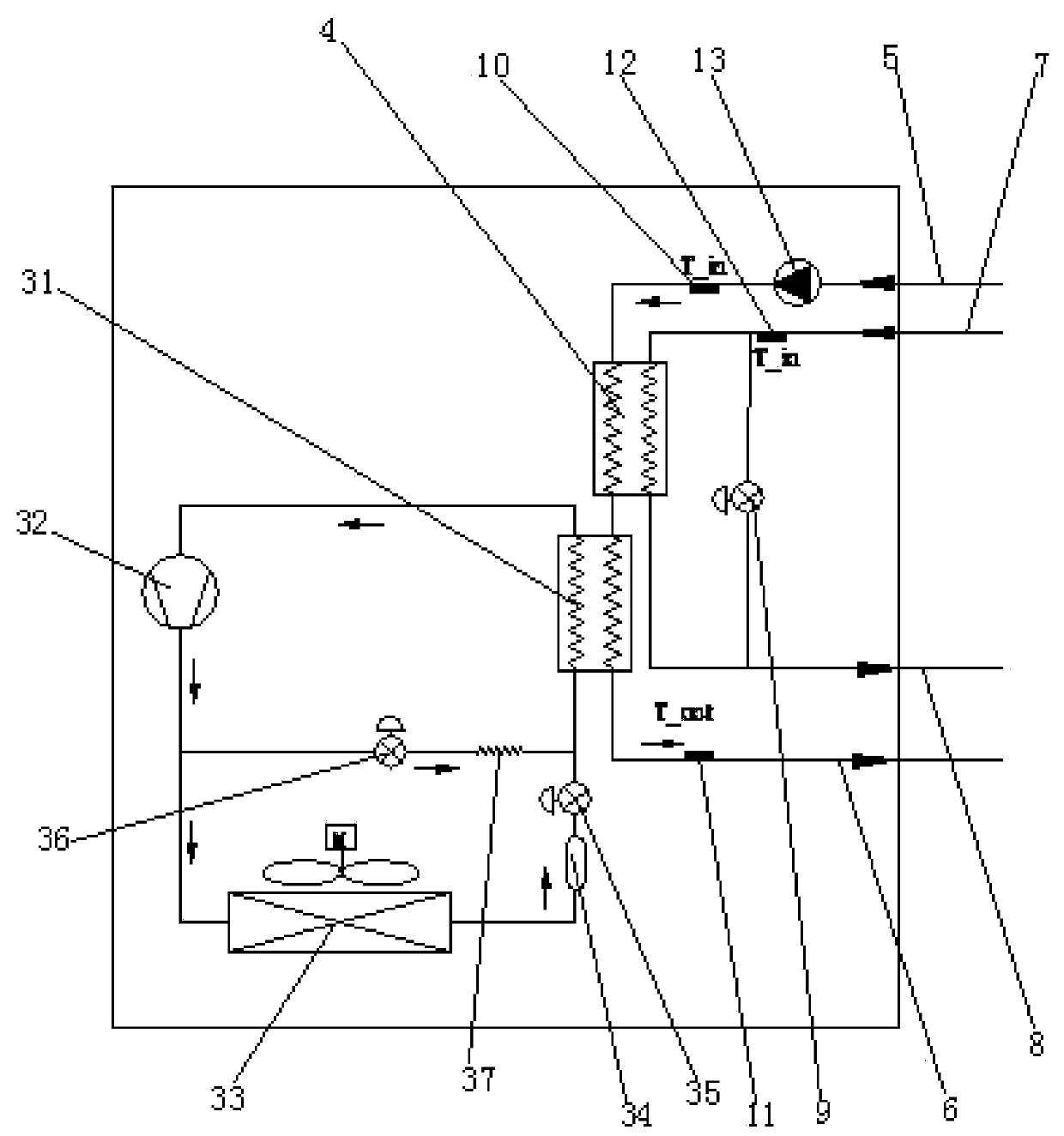

Two-stage heat-exchanging precise temperature control system

InactiveCN111322902AGuaranteed temperature control accuracyGuaranteed special needsHeat exchange apparatusTemperature controlWater flow

The invention discloses a two-stage heat-exchanging precise temperature control system. The two-stage heat-exchanging precise temperature control system comprises a primary-stage heat exchanger and asecondary-stage heat exchanger, wherein the primary-stage heat exchanger and the secondary-stage heat exchanger are connected in series in a first circulating fluid side and are connected in parallelin a second circulating fluid side; a first circulating fluid and a second circulating fluid are subjected to heat exchange in the primary-stage heat exchanger to be primarily adjusted, and are subjected to heat exchange in the secondary-stage heat exchanger to be finely adjusted; by adjusting a factory affair water flow regulating valve, the temperature precision of the second circulating fluid is controlled, thereby ensuring the accuracy of the first circulating fluid temperature control precision to be up to minus or plus 0.01 DEG C; and meanwhile, the two stages of heat exchangers are arranged separately, so that the universality is high, and the special requirements of the first circulating fluid is met.

Owner:PHST CORP

Large-temperature-zone refrigerating device for satellite normal-pressure thermal test

ActiveCN106091473ARealize temperature controlRapid coolingDomestic cooling apparatusStructural/machines measurementPressure stabilizationRoom temperature

The invention discloses a large-temperature-zone refrigerating device and method for a satellite normal-pressure thermal test. The large-temperature-zone refrigerating device for the satellite normal-pressure thermal test disclosed by the invention comprises a nitrogen system, a fan inside a box, a control device, a cascade refrigerating system, a normal-pressure thermal test box and a pressure-relief air interchanger, wherein the control device controls the nitrogen system, the fan inside the box and the cascade refrigerating system to realize refrigerating; and the control device controls the pressure-relief air interchanger to realize pressure stabilization and air interchanging in the normal-pressure thermal test box. The large-temperature-zone refrigerating device adopts a two-stage refrigerating system which is composed of a mixed refrigerant cascade refrigerating system and a nitrogen refrigerating system, can realize a large-temperature-zone working condition from (-) 120 DEG C to the room temperature, can select different refrigerating modes according to different temperature needs, and is stable and efficient.

Owner:SHANGHAI INST OF SATELLITE EQUIP

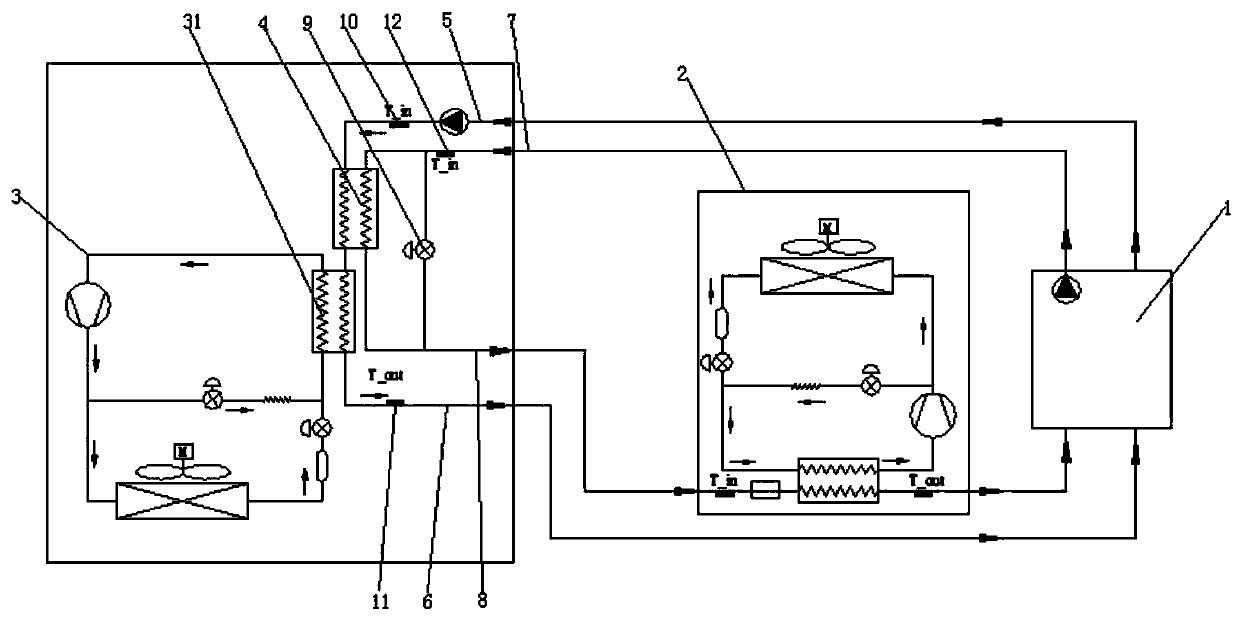

Cooling device

InactiveCN112762649AReduce loadHigh control precisionLighting and heating apparatusCooling fluid circulationThermodynamicsEngineering

The invention provides a cooling device, in particular to a temperature-controllable multipurpose cooling device used for testing and applied to cooling oil / cooling liquid and cooling water. The cooling device comprises a primary side loop, a second side loop and an intermediate loop. The primary side loop is connected with an external circulating device, circulating water with higher temperature is guided into the external circulating device, and circulating water with lower temperature is introduced. The secondary side loop is provided with a tested device and is used for cooling the tested device. The intermediate loop is connected with the primary side loop and the secondary side loop, the intermediate loop exchanges heat with the secondary side loop and absorbs heat of the secondary side loop, and meanwhile, the intermediate loop exchanges heat with the primary side loop and releases heat to the primary side loop. The circulating liquid in the secondary side loop adopts a mode of combining circulating water and circulating oil. According to the invention, through the cooperation of cooling water and cooling oil, the application temperature range is wide, and a simulation test is carried out on the tested device by simulating severe conditions.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

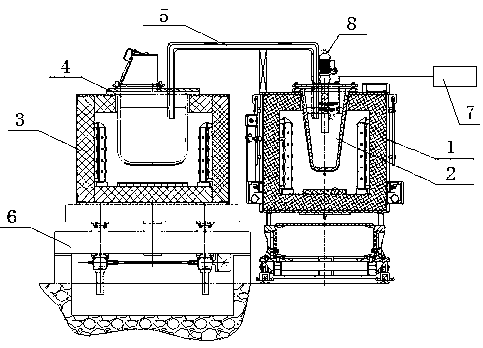

Heat-preserving furnace for magnesium alloy die casting

The invention relates to a heat-preserving furnace for magnesium alloy die casting. The furnace comprises a heat-preserving furnace body. A first crucible is arranged in the heat-preserving furnace body. The heat-preserving furnace for magnesium alloy die casting further comprises an electric heating furnace, a second crucible is arranged in the electric heating furnace, and the first crucible and the second crucible are communicated through a siphon pipe. The heat-preserving furnace utilizes the siphon principle to keep liquid level and temperature constant and greatly improves quality of magnesium alloy die casting pieces in an allowable range.

Owner:NANJING YUNHAI LIGHT METALS PRECISION MFG

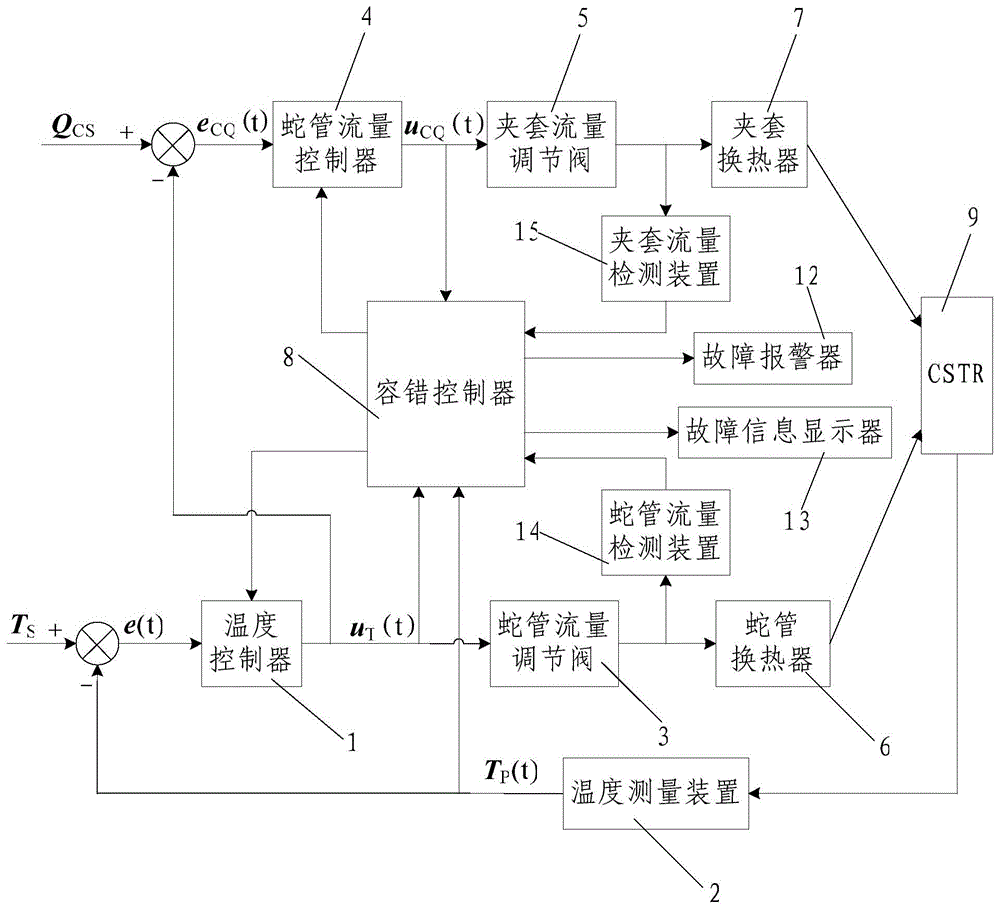

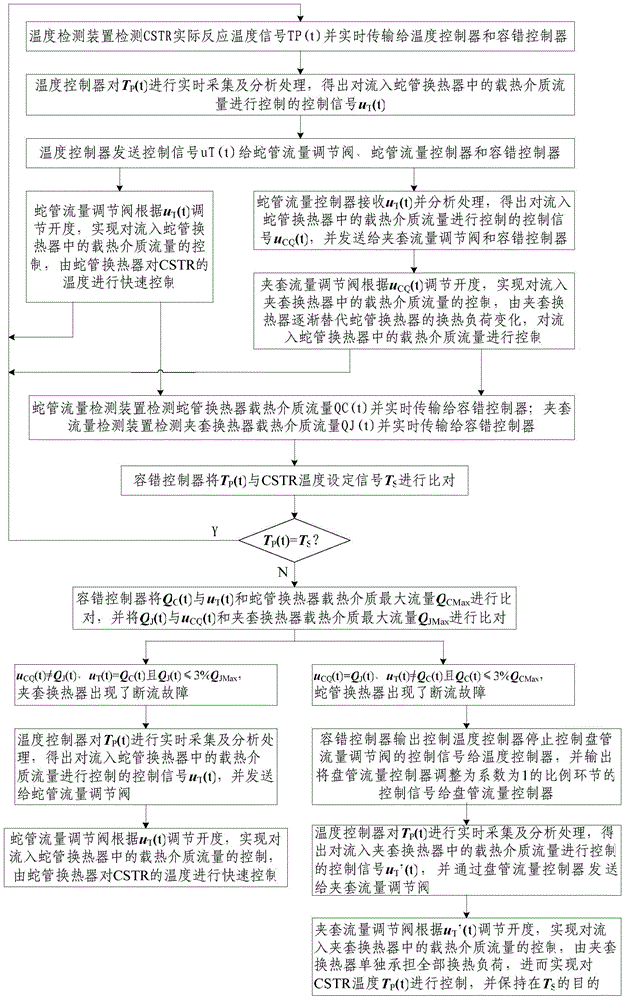

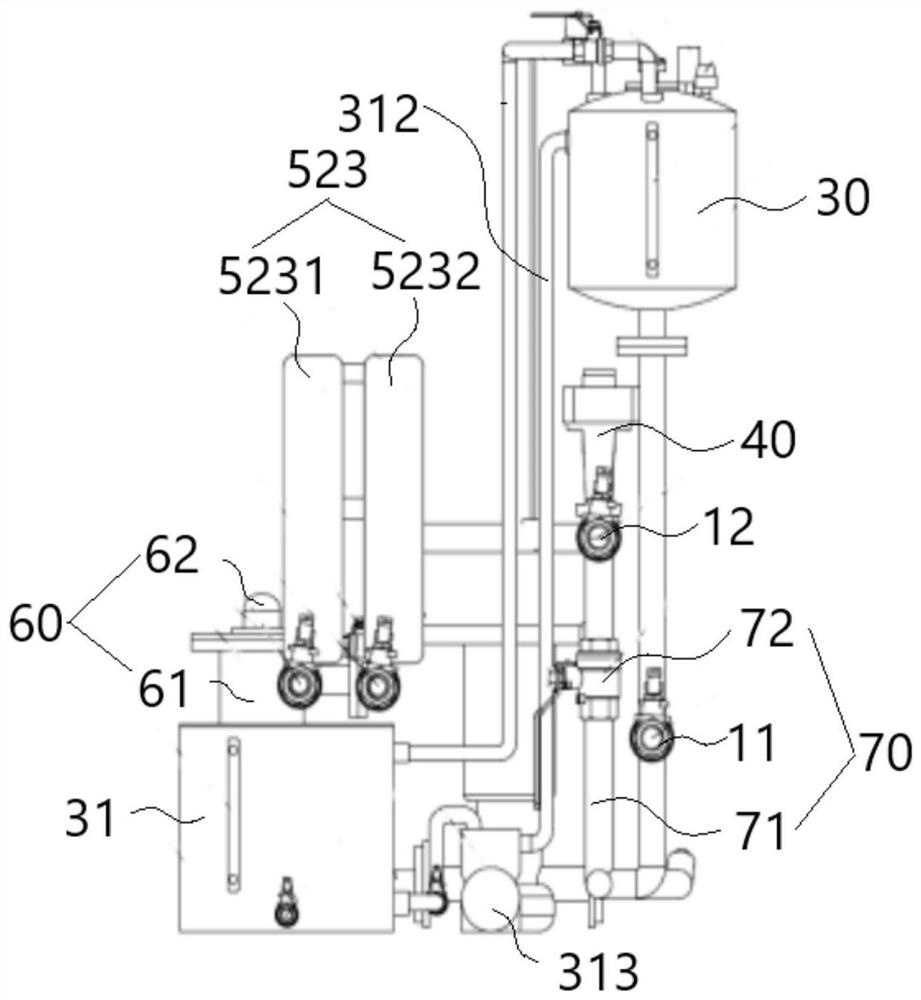

CSTR temperature fault-tolerant control system based on double heat exchangers and method thereof

InactiveCN104898728ASimple structureNovel and reasonable designTemperature control using electric meansEconomic benefitsEngineering

The invention discloses a CSTR temperature fault-tolerant control system based on double heat exchangers. The CSTR temperature fault-tolerant control system comprises a temperature controller and a coil pipe flow controller. The input end of the temperature controller is connected with a temperature detection device. A coil pipe flow regulating valve is connected with the output end of the temperature controller. A clamp sleeve flow regulating valve is connected with the output end of the coil pipe flow controller. The CSTR temperature fault-tolerant control system also comprises a fault-tolerant controller, a fault alerter and a fault information displayer. The input end of the fault-tolerant controller is connected with a coil pipe flow detection device and a clamp sleeve flow detection device. The temperature controller and the coil pipe flow controller are connected with the fault-tolerant controller. The temperature detection device is connected with the input end of the fault-tolerant controller. The invention also discloses a CSTR temperature fault-tolerant control method based on the double heat exchangers. The CSTR temperature fault-tolerant control system is high in control precision, high in heat exchange efficiency and low in heat-carrying medium consumption so that working safety and reliability of a CSTR are enhanced and economic benefit produced by reaction of the CSTR is enhanced.

Owner:XIAN UNIV OF SCI & TECH

Cooling liquid temperature control system

ActiveCN112727587ABroaden the heat transfer rangeIncreased heat transfer rangeCoolant flow controlMachines/enginesExpansion tankTemperature control

The invention relates to the technical field of engine performance testing, and provides a cooling liquid temperature control system, which is used in an engine testing experiment. A liquid outlet pipe and a liquid inlet pipe are arranged on an engine. The cooling liquid temperature control system comprises a pipeline pump, an expansion water tank, a proportional valve and a cooling liquid circulation system, wherein the cooling liquid circulation system comprises a first cooling liquid circulation system and a second cooling liquid circulation system which are arranged in parallel; the first cooling liquid circulation system is a first cooling liquid pipeline; and the second cooling liquid circulation system comprises a first pipeline, a second pipeline, at least two heat exchangers and an external cooling water circulation system connected to the two heat exchangers in series. According to the cooling liquid temperature control system provided by the invention, the two cooling liquid circulating systems are arranged in parallel, and the at least two heat exchangers are further connected in the second cooling liquid circulating system in parallel, so that the heat exchange range of the whole cooling liquid circulating system is widened, the utilization rate of the heat exchangers can be controlled by adjusting the proportional valve, and the temperature control precision is guaranteed.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

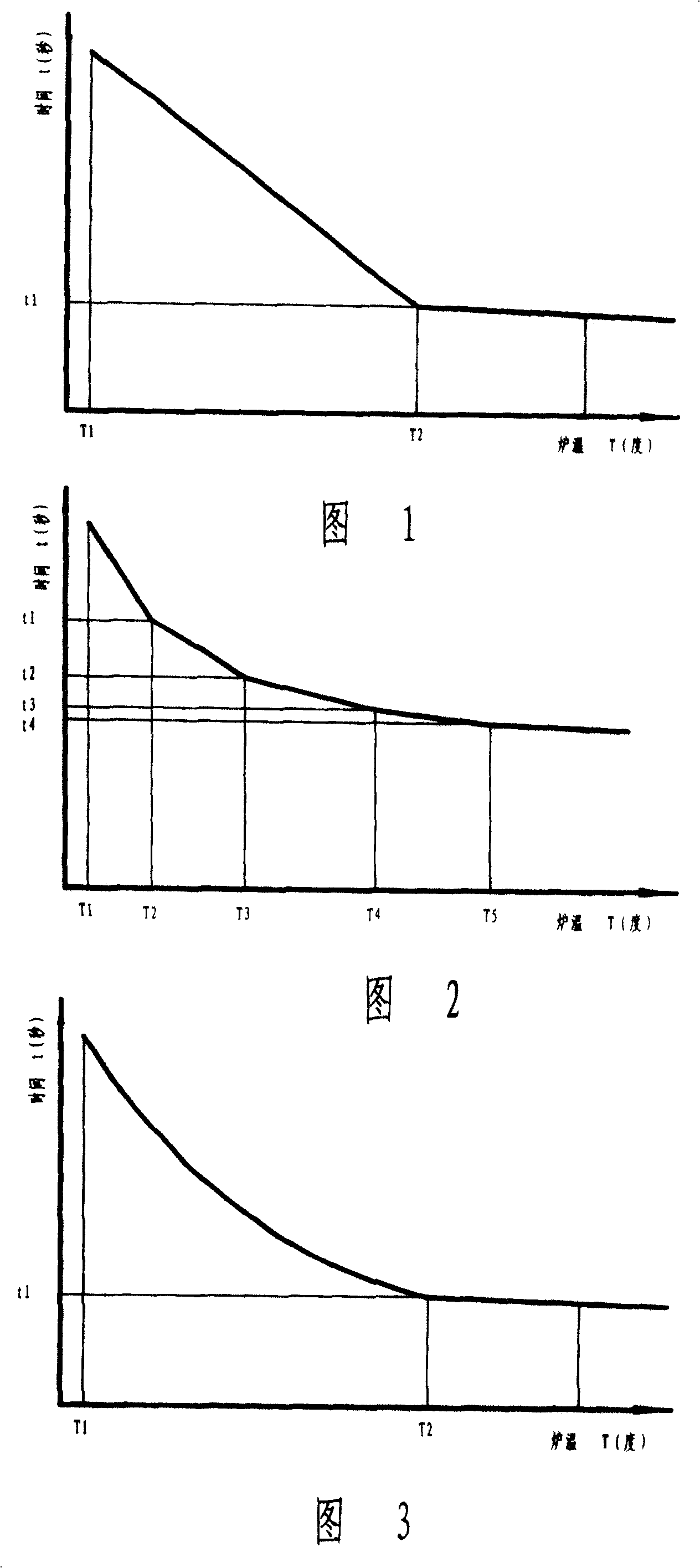

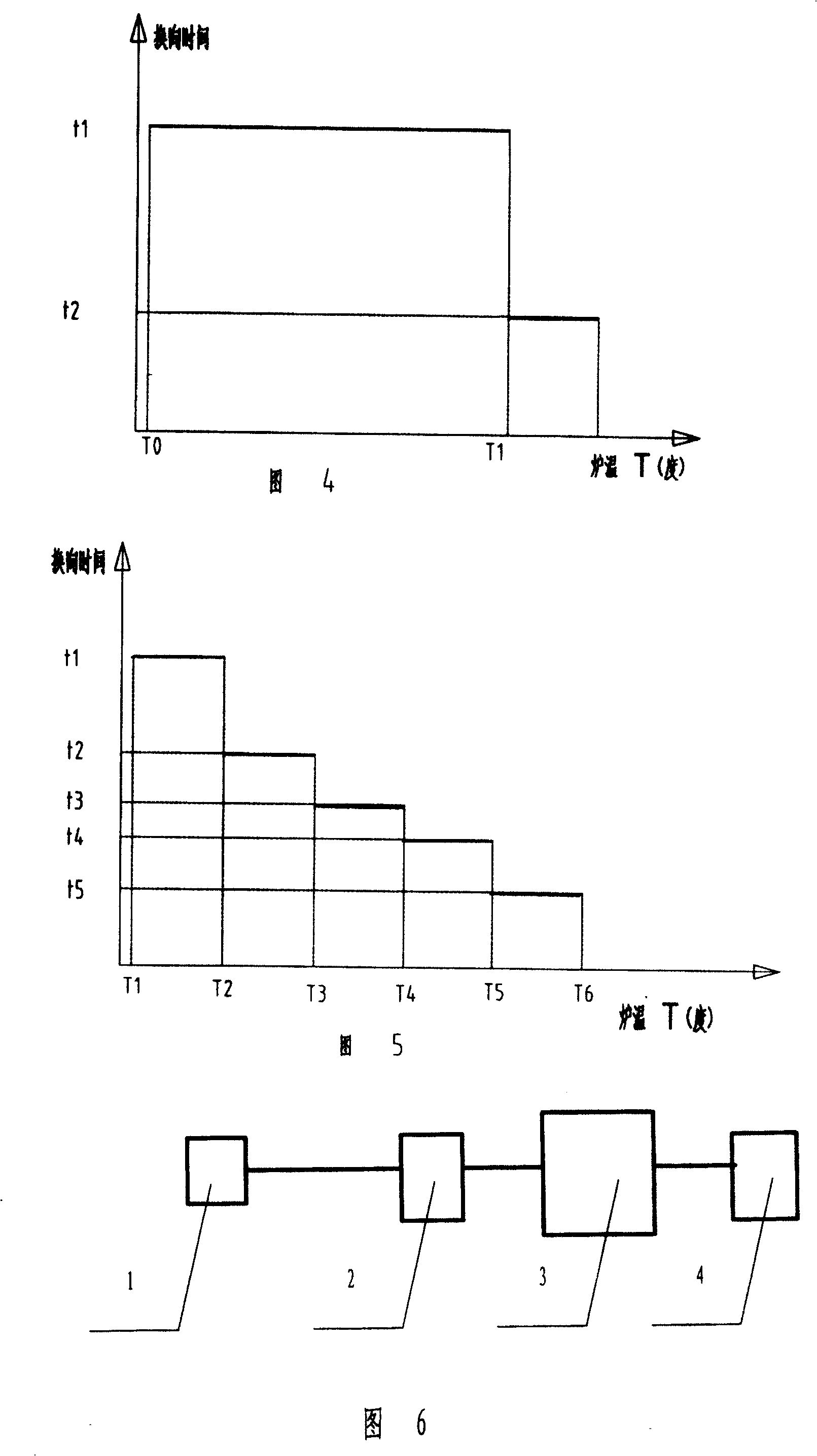

Inverting time control method for heat accumulation type burner

ActiveCN100447491CControl local overheatingControl burnCrucible furnacesIndirect carbon-dioxide mitigationFurnace temperatureTemperature control

The invention discloses a method for controlling the steering time in thermal-accumulated burner. The invention is characterized in that when the thermal-accumulated burner is ignited, the burning time of two nozzles are reduced stepped along the temperature increase of furnace. Compared with present technique, the invention can reduce the steering time along the optimized curvature according to the temperature increase of the furnace, to control the air and fuel temperatures, reduce the flame temperature, and improve the temperature-control accuracy. With the increase of furnace temperature, the steering time is reduced stepped, to improve the control accuracy from +-5 Deg. C to +-1 Deg. C to reach the control level of electric furnace. And at the high temperature, the invention can reduce the flame temperature to confirm the control accuracy. At the low temperature, the invention can improve the temperature of accumulator to improve the preheat temperatures of air and gas, to improve the heating efficiency. The invention can reduce the energy consumption.

Owner:CHONGQING AOKEQI TECH

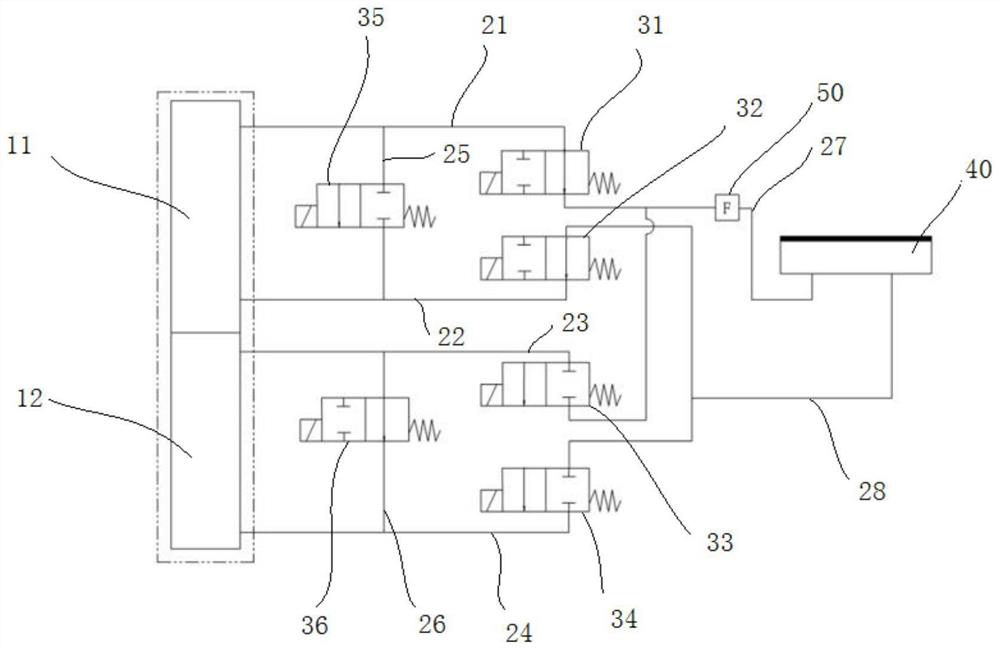

Temperature control device and method in semiconductor process device

PendingCN113013071AGuaranteed uptimeAvoid bleedingSemiconductor/solid-state device manufacturingTemperature controlProcess equipment

The invention provides a temperature control device and method in a semiconductor process device, and the temperature control device comprises a first temperature control source, a second temperature control source, a first output pipeline, a second output pipeline, a first backflow pipeline, a second backflow pipeline, a first short-circuit pipeline, a second short-circuit pipeline, and a controller. The output ports of the two temperature control sources are respectively communicated with the inlet of a chuck through the two output pipelines, and the backflow ports of the two temperature control sources are respectively communicated with the outlet of the chuck through two backflow pipelines; the output ports of the two temperature control sources are respectively communicated with the respective backflow ports through the two short-circuit pipelines; an on-off switch is arranged on each pipeline; the controller is used for sequentially connecting or disconnecting the multiple on-off switches and switching the connection of the chuck and the two temperature control sources, and the temperatures of the temperature control media in the two temperature control sources are different. According to the present invention, the temperature control range can be widened, the temperature control time can be shortened, and the problem of fluid mixing in the two temperature control sources can be effectively solved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

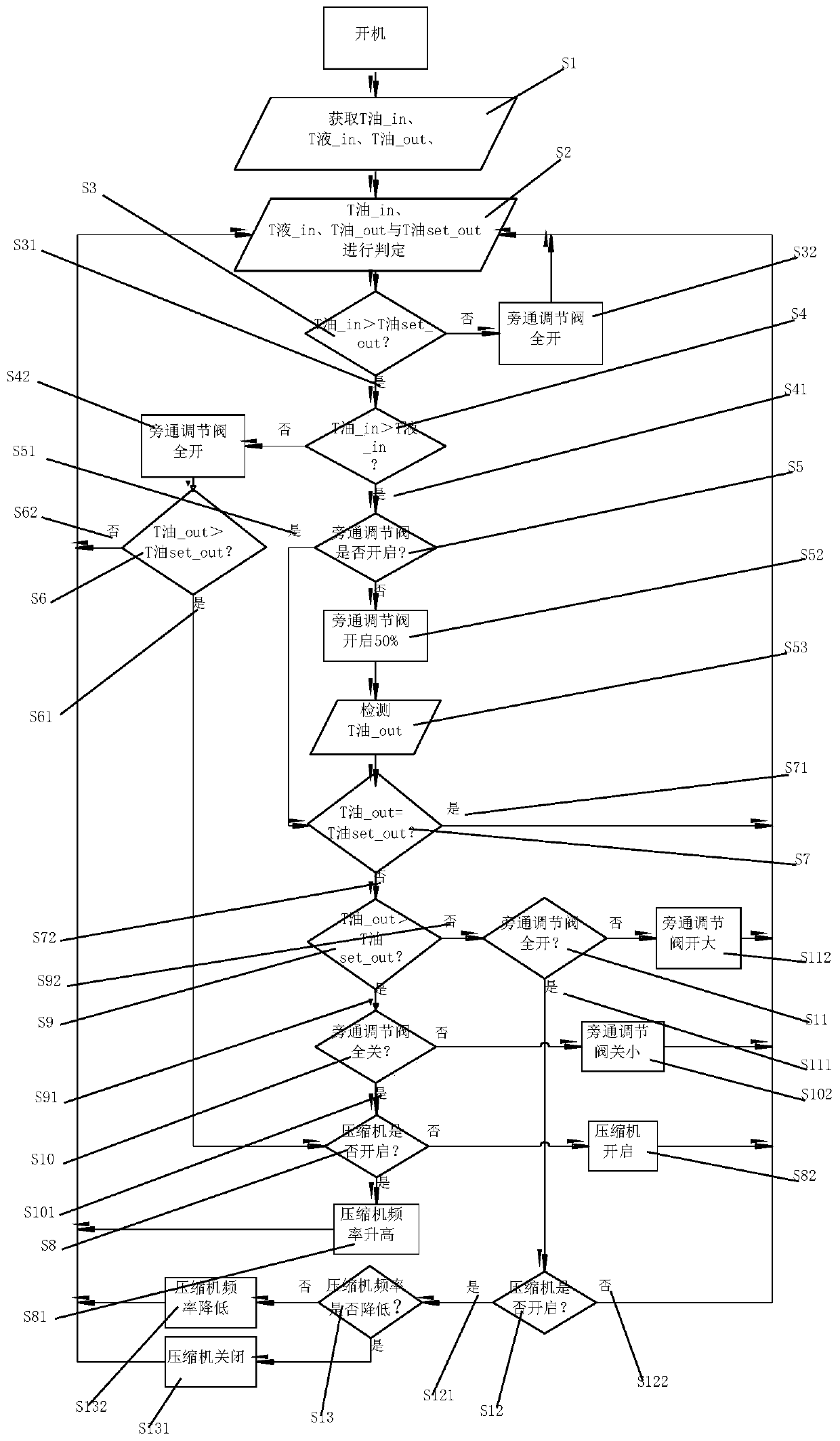

Spindle oil cooling system, spindle oil temperature control method and machine tool cooling machine system

ActiveCN110682156AReduce the temperatureIncrease profitMaintainance and safety accessoriesTemperature controlMachining system

The invention discloses a spindle oil cooling system. The system comprises a spindle oil cooling device, an oil inlet pipeline, an oil outlet pipeline, an oil inlet induction probe and an oil outlet induction probe. The spindle oil cooling device comprises an evaporator. The oil outlet end of the evaporator communicates with the oil outlet pipeline, and the spindle cooling device further comprisesan economizer, a liquid inlet pipeline, a liquid outlet pipeline, a bypass adjusting valve and a liquid inlet induction probe. The economizer is in heat exchange communication with the evaporator, the oil inlet end of the economizer communicates with the oil inlet pipeline, the liquid inlet pipeline communicates with the liquid inlet end of the economizer, the liquid outlet pipeline communicateswith the liquid outlet end of the economizer, the bypass adjusting valve is arranged between the liquid inlet pipeline and the liquid outlet pipeline, and the liquid inlet induction probe is arrangedon the liquid inlet pipeline. According to the spindle oil cooling system, waste heat of spindle oil can be recycled, and used for heating cutting liquid, electric heating of a cutting liquid coolingmachine is reduced, the aim of energy saving is achieved, meanwhile, temperature control precision of spindle oil can be ensured, the energy use rate is improved, and the invention further provides aspindle oil temperature control method and a machine tool cooling machine system with the spindle oil cooling system.

Owner:GREE ELECTRIC APPLIANCES INC

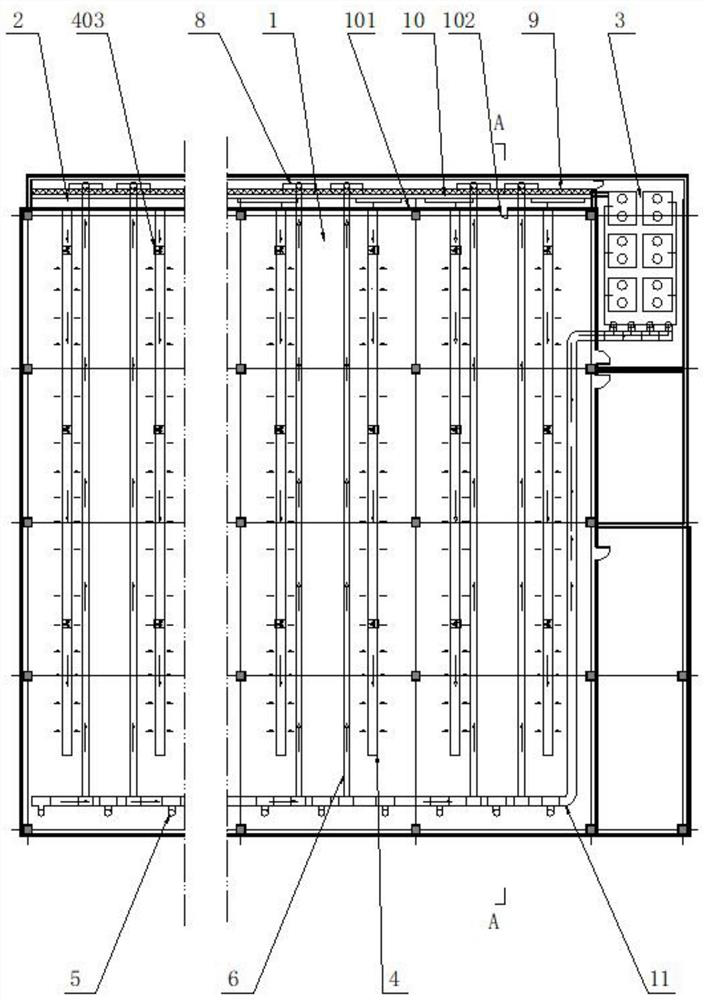

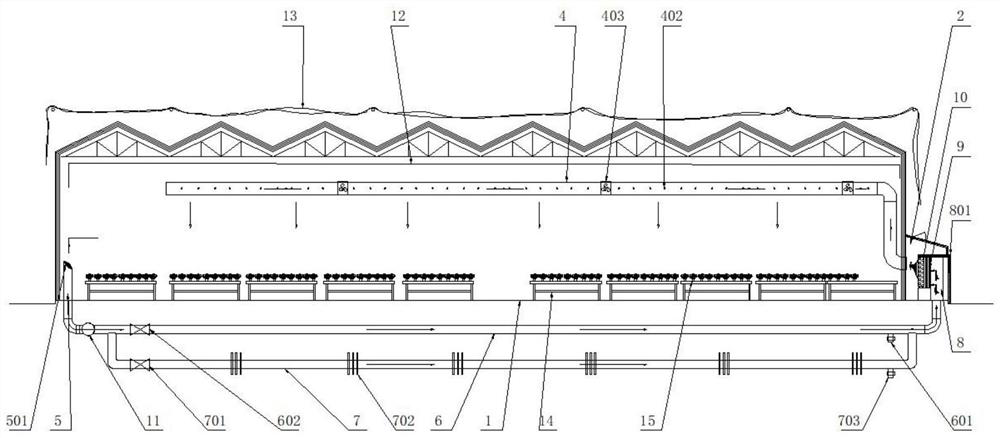

Circulating air temperature control greenhouse system and temperature control method thereof

PendingCN113692892AReduce occupancyAvoid occupyingClimate change adaptationGreenhouse cultivationTemperature controlGreenhouse

The invention discloses a circulating air temperature control greenhouse system which comprises a main greenhouse, a temperature adjusting chamber, an air return chamber, a wet curtain, an air conditioner coil pipe and a circulating pipeline, a support for placing potted plants is arranged in the main greenhouse, the temperature adjusting chamber is arranged below the outer side of a long side wall body of the main greenhouse, and the air return chamber is arranged in the temperature adjusting chamber; the circulating pipeline comprises a plurality of groups of circulating units arranged in parallel, each circulating unit comprises an air outlet pipe, a return air inlet pipe and a return air pipe, each air outlet pipe is arranged at the top of the main greenhouse, an air inducing fan and a plurality of air distribution holes for exhausting air re arranged in each air outlet pipe, and the root of each air outlet pipe communicates to the temperature adjusting chamber through a vertical air inducing pipe; and each air return inlet pipe is arranged in the main greenhouse and away from one end of the temperature adjusting chamber, the root of each air return inlet pipe communicates to the air return chamber through the air return pipe laid underground, and the wet curtain and the air conditioner coil pipe are arranged on an air outlet of the air return chamber. According to the circulating air temperature control greenhouse system and the temperature control method thereof, through the arrangement of the circulating pipeline, uniform flowing circulation of air in the greenhouse can be improved, and the controllability of the temperature in the greenhouse is good.

Owner:华乐种苗有限公司

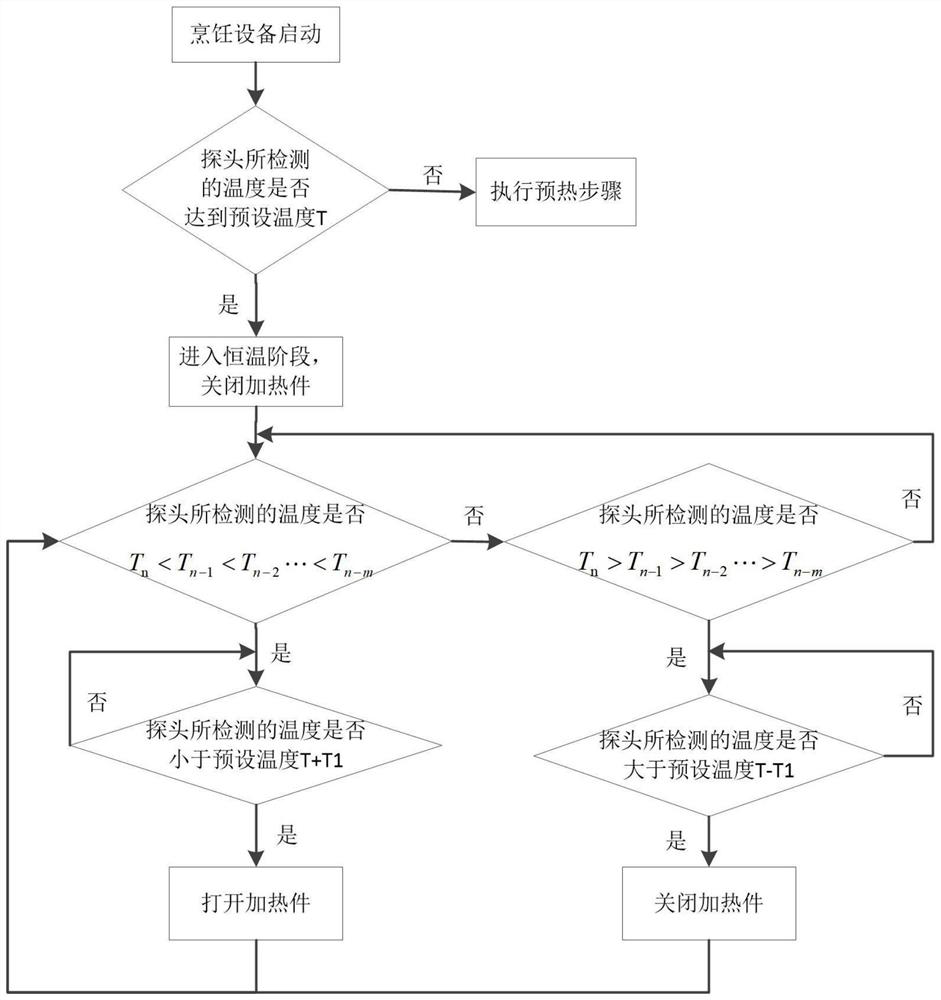

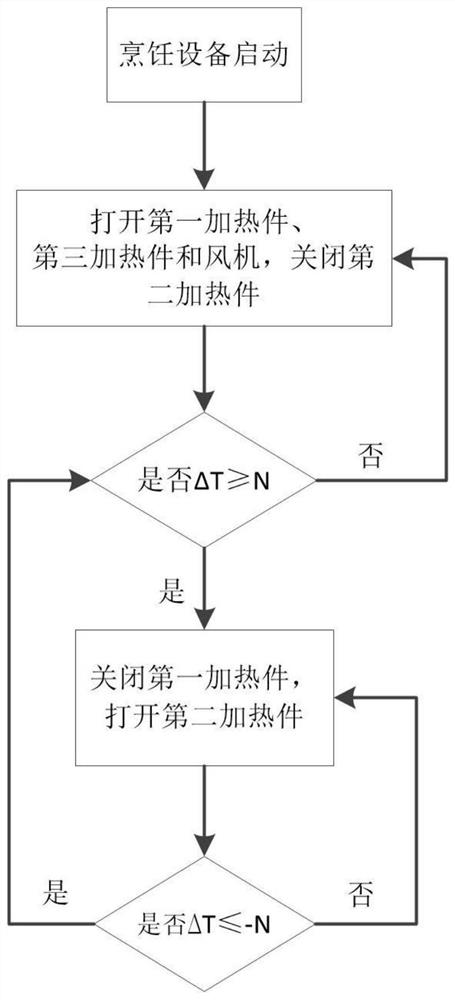

Temperature control method of cooking equipment and cooking equipment

ActiveCN113142980AGuaranteed accuracyGuaranteed heating frequencyTime-controlled ignitorsTemperature controlEngineering

The invention discloses a temperature control method of cooking equipment and the cooking equipment. The temperature control method comprises the following steps: S1, the cooking equipment is started; S2, whether the temperature detected by a probe used for detecting the temperature of a cooking cavity of the cooking equipment in the cooking equipment reaches a preset temperature T or not is judged, if the temperature detected by the probe reaches a preset value, S3 is executed, and if the temperature detected by the probe does not reach the preset value, the cooking equipment executes a preheating step; S3, the cooking cavity enters a constant-temperature stage, and the heating piece is closed; S4, the probe obtains multiple temperatures tn, tn-1, tn-2... tn-m at intervals of preset time, whether tn < tn-1 < tn-2... < tn-m or not is judged, if tn < tn-1 < tn-2... < tn-m, S5 is executed, and if tn < tn-1 < tn-2... < tn-m, S6 is executed; and S5, whether the temperature detected by the probe is smaller than the preset temperature T + T1 or not is judged, if the temperature detected by the probe is smaller than the preset temperature T + T1, the heating piece is turned on, and if the temperature detected by the probe is larger than or equal to the preset temperature T + T1, the S5 is executed repeatedly.

Owner:VATTI CORP LTD

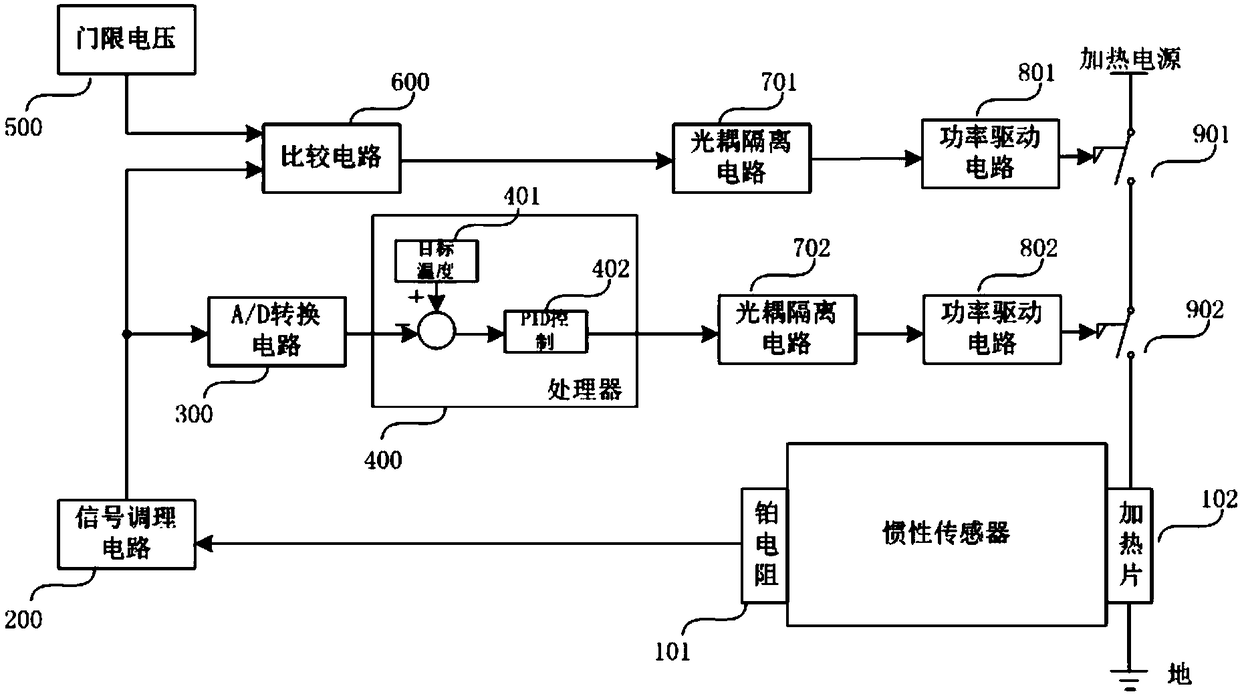

Highly reliable and safe temperature control circuit

InactiveCN109445490AImprove securityTemperature control does not affectTemperatue controlTemperature controlSignal conditioning circuits

The invention relates to a highly reliable and safe temperature control circuit which is characterized by comprising a platinum resistor, a signal conditioning circuit, a comparison circuit, a threshold voltage, a first heating switch, an A / D conversion circuit, a processor, a second heating switch and a heating sheet. The platinum resistor is fit to the surface of an inertia sensor in an inertiagroup, and used to collect the temperature of the inertial sensor; the signal conditioning circuit is connected with the platinum resistor; the first and second input ends of the comparison circuit are connected with the signal conditioning circuit and the threshold voltage respectively; the source of the first heating switch is connected with a heating power supply, and the gate of the first heating switch is connected with the output end of the comparison circuit; the A / D conversion circuit is connected with the signal conditioning circuit; the processor is connected with the A / D conversioncircuit; a target temperature is arranged in the processor and compared with a temperature digital signal; the second heating switch is an MOS type switch, the source of the second heating switch is connected with the drain of the first heating switch, and the gate of the second heating switch is connected with the processor; and the heating sheet is arranged in one side of the inertia sensor, andconnected with the drain of the second heating switch.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com