Inverting time control method for heat accumulation type burner

A technology of reversing time and combustion devices, which is applied in the direction of control of combustion, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve problems such as unbearable smoking equipment, complex industrial furnace structure, damage to furnace doors and other equipment, and achieve reduction Reduce energy consumption, improve temperature control accuracy, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

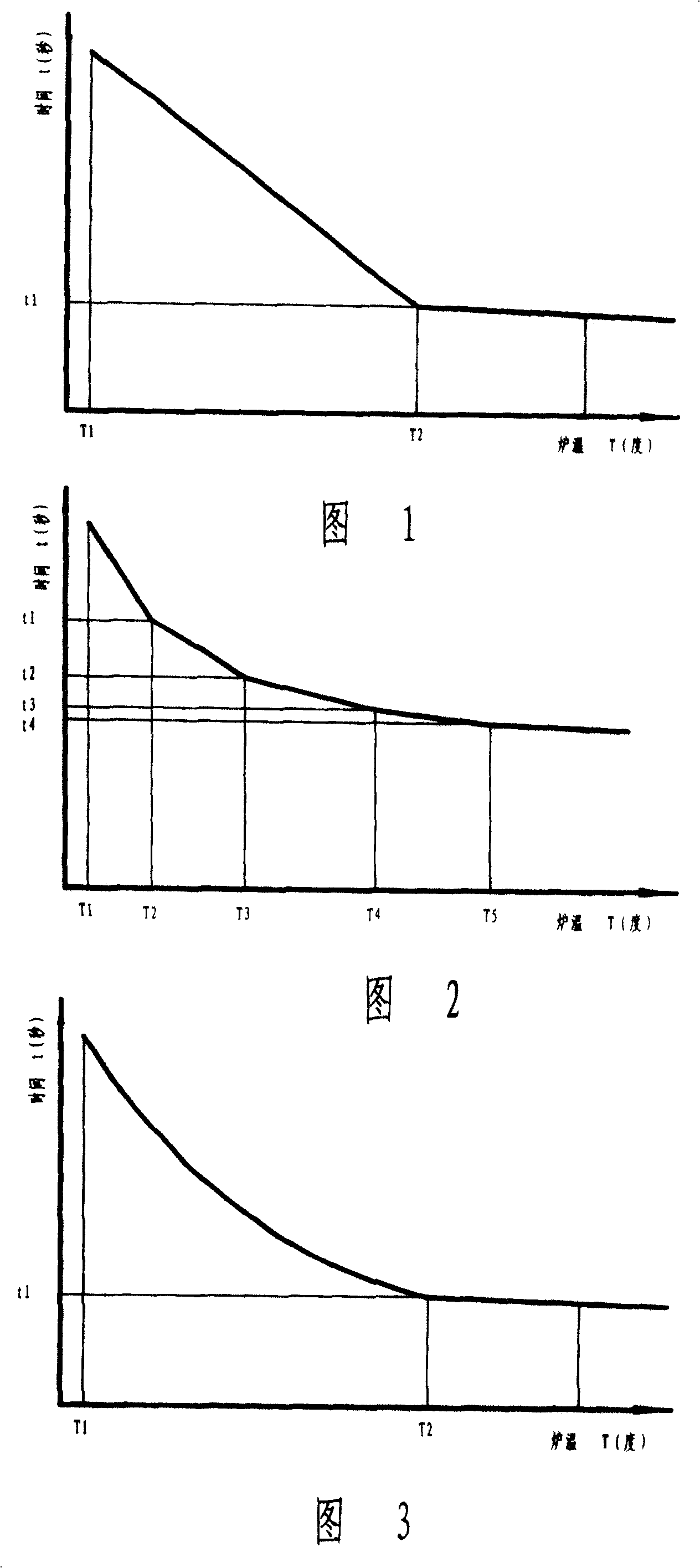

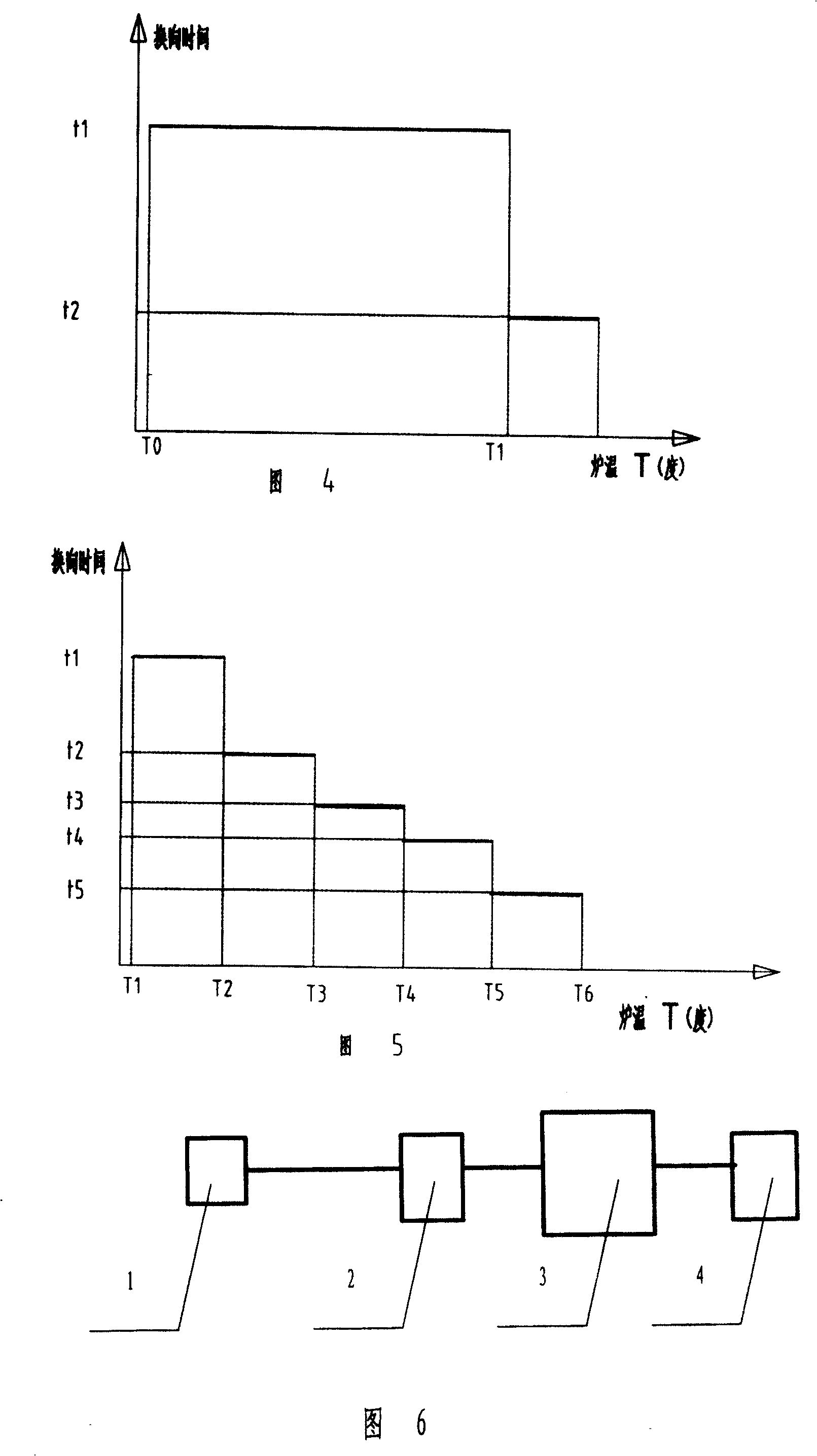

[0027] As shown in Figure 1, a schematic diagram of the relationship between the commutation time and the furnace temperature of the present invention, the commutation time when the two burners of the regenerative combustion device burn in turn, after the regenerative combustion device is ignited and burned, the two burners burn in turn As the temperature of the furnace increases, the commutation time is gradually shortened; when a certain set temperature is reached, the commutation time changes little and remains basically constant. Since the two burners burn in turn, in order to ensure the balance of combustion, the change of the reversing time should ensure the combustion cycle of the two burners, which is an even multiple of the combustion cycle of the two burners.

[0028] As shown in Figure 1, a schematic diagram of the first embodiment of the relationship between reversing time and furnace temperature of the present invention, the reversing time and furnace temperature are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com