Integrated high-temperature frequency-variable heat pump heating air conditioning system

An air-conditioning system, all-in-one technology, used in lighting and heating equipment, fluid circulation arrangements, compressors with multiple condensers, etc. It can reduce the pressure and temperature, ensure the condensation effect, and reduce the high temperature load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

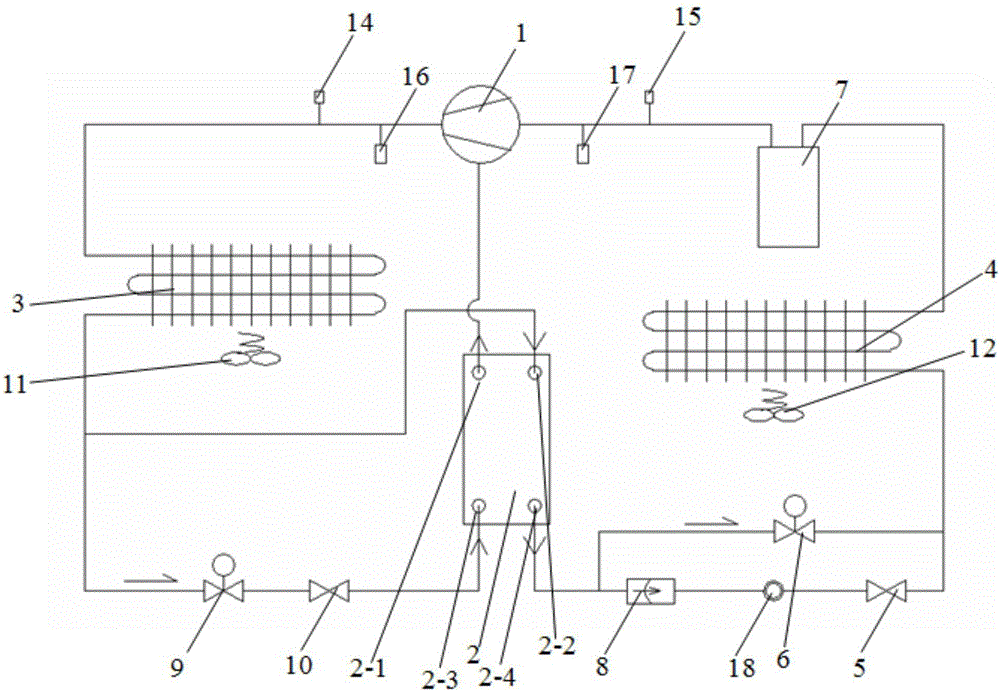

[0016] See attached figure 1 As shown, the integrated high temperature frequency conversion heat pump heating and air conditioning system includes frequency conversion intermediate air supply scroll compressor 1, plate heat exchanger 2, fin condenser 3, fin evaporator 4, main road thermal expansion valve 5, normally open Type solenoid valve 6, gas-liquid separator 7, dry filter 8, normally closed solenoid valve 9, branch thermal expansion valve 10, axial flow condensing fan 11, axial flow evaporating fan 12, pipeline 13, high pressure detection valve 14 , low-pressure detection valve 15, high-pressure pressure switch 16, low-pressure pressure switch 17, and sight glass 18; according to the flow direction of the refrigerant, through the pipeline 13, the frequency conversion intermediate air supply scroll compressor 1 and the fin The fin condenser 3 is connected, and the refrigerant is condensed through the fin condenser 3 to form a first circulation loop and a second circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com