High-phosphorus hematite-limonite ore fluidized roasting system and method

A fluidized roasting and hematite technology, applied in the fields of metallurgy and mineral processing, to achieve the effects of high acid leaching removal rate, reduction of high temperature load, and optimization of energy balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

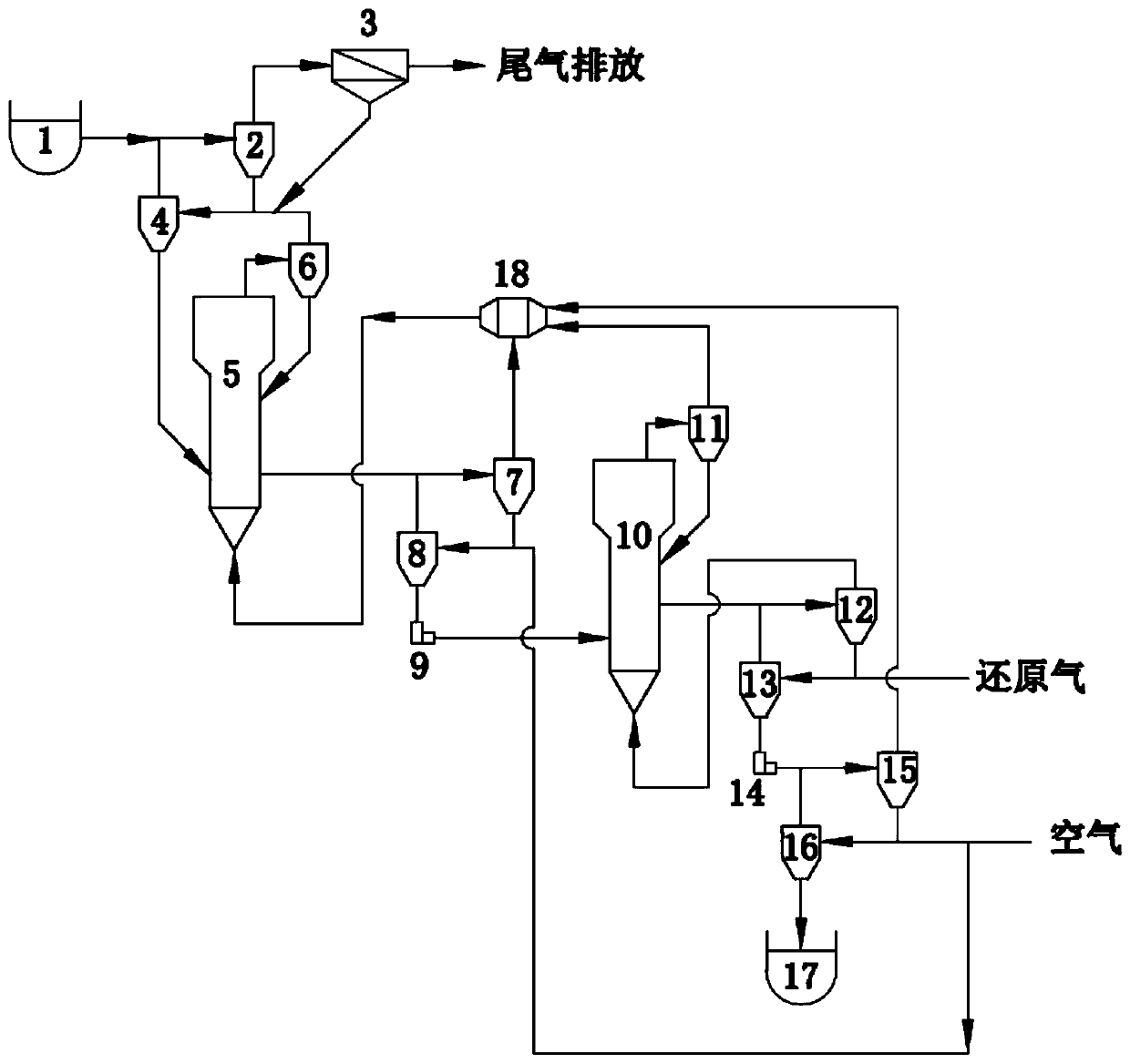

[0037] Such as figure 1 As shown, a high-phosphorus hematite fluidized roasting system includes a feed bin, a preheater, a fluidized oxidation roaster, an oxidation cooler, a burner, a fluidized magnetized roaster, and reducing gas cooling Generator, air cooler and discharge bin,

[0038] The preheater includes a multi-stage preheating cyclone and a bag filter 3, the fluidized oxidation roaster includes an oxidation roaster body 5 and an oxidation cyclone 6, and the oxidation cooler includes a two-stage oxidation cooling cyclone. And an oxidation discharge valve 9, the fluidized magnetized roaster includes a magnetized roaster body 10 and a magnetized cyclone separator 11, and the reducing gas cooler includes a two-stage reducing gas cooling cyclone and a cooling discharge valve 14. The air cooler includes a two-stage air cooling cyclone, of which,

[0039] The discharge port of the feed bin 1 is connected with the air inlet of the first-stage preheating cyclone 2, the top air ou...

Embodiment 2

[0054] The method for fluidized roasting of high-phosphorus hematite using the above-mentioned fluidized roasting system for high-phosphorus hematite is as follows:

[0055] The high-phosphorus hematite is stored in the feed bin and enters the preheater. In the multi-stage preheating cyclone, the ore powder and the fluidized oxidation roaster hot flue gas tail gas conduct gas-solid countercurrent heat exchange and increase the temperature. The heated hot ore The powder enters the body of the oxidation roaster, and undergoes phase modification of the phosphorus element under the condition of hot flue gas. The oxidized ore powder entrained by the airflow is gas-solid separated by the oxidation cyclone and then returned to the body of the oxidized roaster. The discharge port of the main body is discharged into the oxidation cooler. In the multi-stage oxidation cooling cyclone, the oxidized ore powder and room temperature cold air are cooled by gas-solid countercurrent cooling. The co...

Embodiment 3

[0058] The invention is used to process high-phosphorus hematite powder with an iron grade TFe of 47.7% and a phosphorus of 0.81%, with a particle size of 0.037-2mm, of which -0.074mm accounts for 50%. Hematite phase Fe 2 O 3 exist.

[0059] First, the fine ore enters the two-stage cyclone preheater from the silo to exchange heat with the tail gas of the oxidation furnace, and then enters the fluidized bed oxidation roaster at a temperature of 900 ℃ and the hot flue gas produced by the burner for 30 minutes. In the fluidized bed oxidation roaster, the phosphorus in the iron ore crystals reacts with the alkaline oxides in the minerals to form phosphorus oxides that are easily soluble in acid. After cooling by a multi-stage oxidation cooler, it enters the fluidized bed magnetized roasting furnace through the oxide ore discharge valve, and performs magnetization reduction roasting with the preheated producer gas at 525°C for 25 minutes. Producer gas composition is 20%CO+11%CO 2 +17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com