A kind of mother-in-law mobile dust removal cover car and dust removal method for steelmaking environment

A mobile dust removal, mother-in-law technology, applied in the direction of dust removal, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of dust removal equipment that cannot be satisfied, and achieve prolonging the effective service life, high dust removal efficiency, and high transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

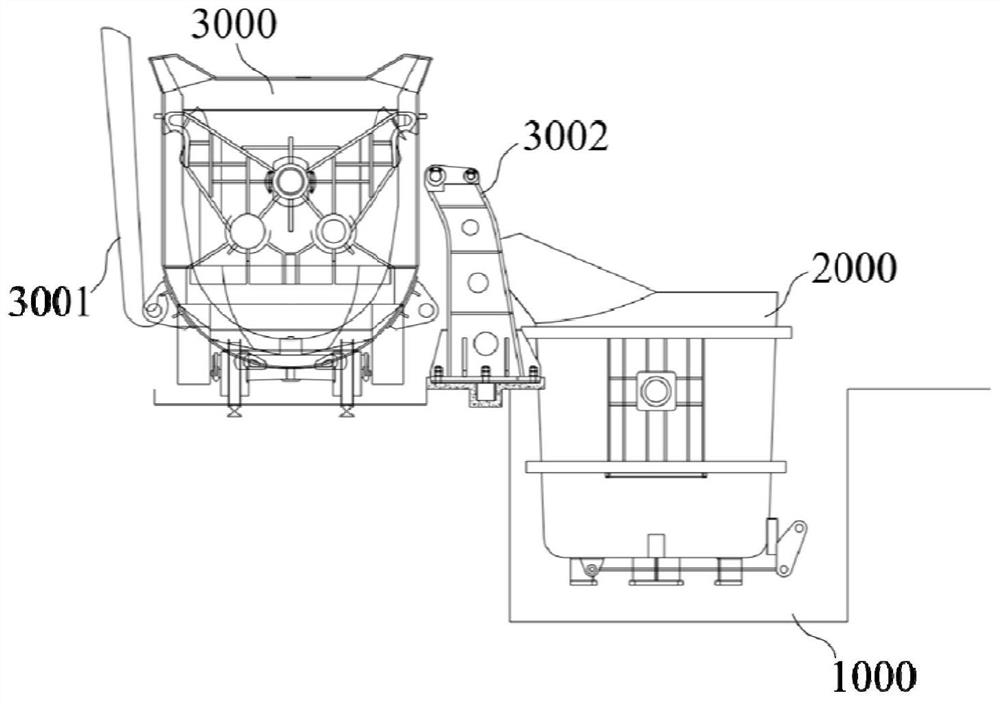

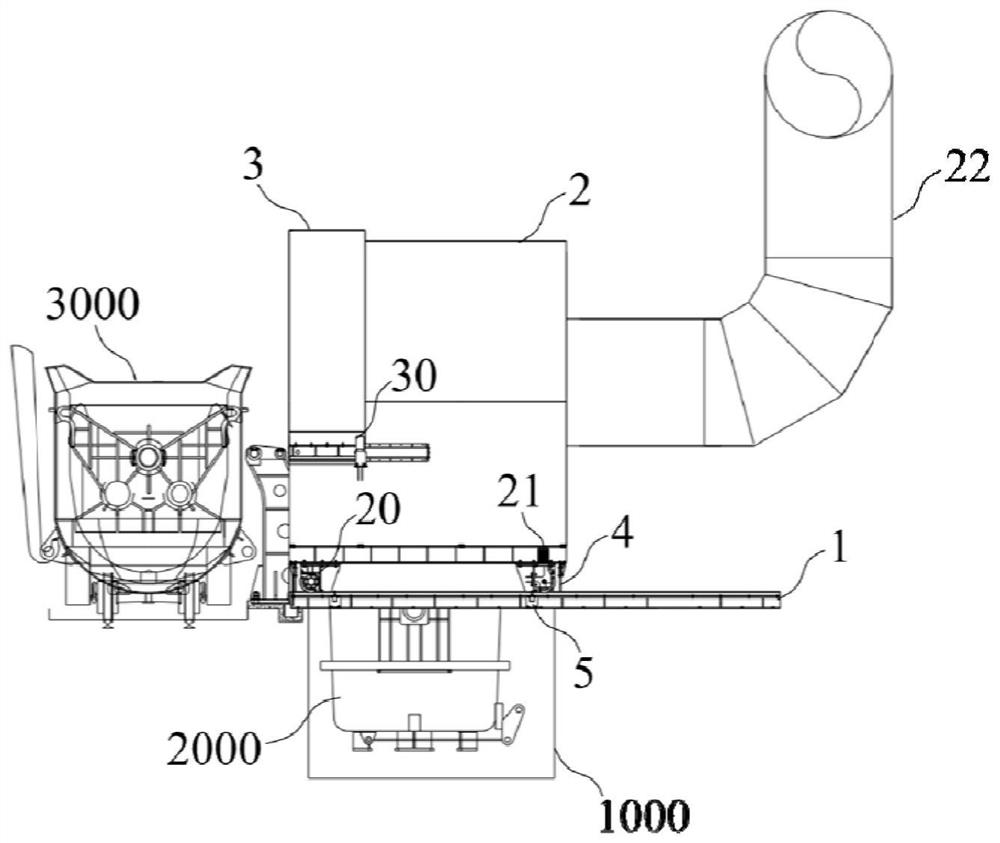

[0088] Such as figure 1 , figure 2 , image 3 As shown, the steelmaking environment of the present embodiment uses a mother-in-law mobile dust removal cover car, including,

[0089]The pit 1000, the first ladle 2000 placed in the pit 1000, the second ladle 3000 placed on the ground beside the pit 1000;

[0090] Guide rail 1, which is laid on the ground on both sides of the pit 1000;

[0091] The female dust removal cover vehicle 2 is movably connected to the guide rail 1 through the bottom roller 20, and reciprocates on the guide rail 1 driven by the first driving member 21;

[0092] Also includes:

[0093] The child dust removal cover 3 is a frame-shaped cover body, which is movably connected to the upper part of the mother dust removal cover car 2, and is driven by the second drive unit 30 to reciprocate along the direction of the second ladle 3000;

[0094] The cleaning unit 4 is fixedly connected to the bottom of the mother dust removal cover car 2, and cleans the su...

Embodiment 2

[0105] Such as figure 2 and image 3 As shown, the steel-making environment of this embodiment is further improved on the basis of Embodiment 1, and the guide rail 1 is laid along the direction toward the second ladle 3000 .

[0106] This embodiment is a preferred solution for the laying direction of the guide rail 1. The guide rail 1 is vertically arranged on the left and right sides of the pit 1000. Completed between the two guide rails 1, the top of the guide rail 1 does not pass through the second molten iron ladle 3000, there will be no direct dripping of molten iron, and it may only be splashed into the molten iron, which can be removed in time under the action of the cleaning unit 4 of the device. When the guide rail 1 is vertically arranged in the front and rear ends of the pit 1, although the movement and dust removal of the dust removal cover car can also be realized, when the second molten iron ladle 3000 is pouring molten iron or when it is reset, the bag The mo...

Embodiment 3

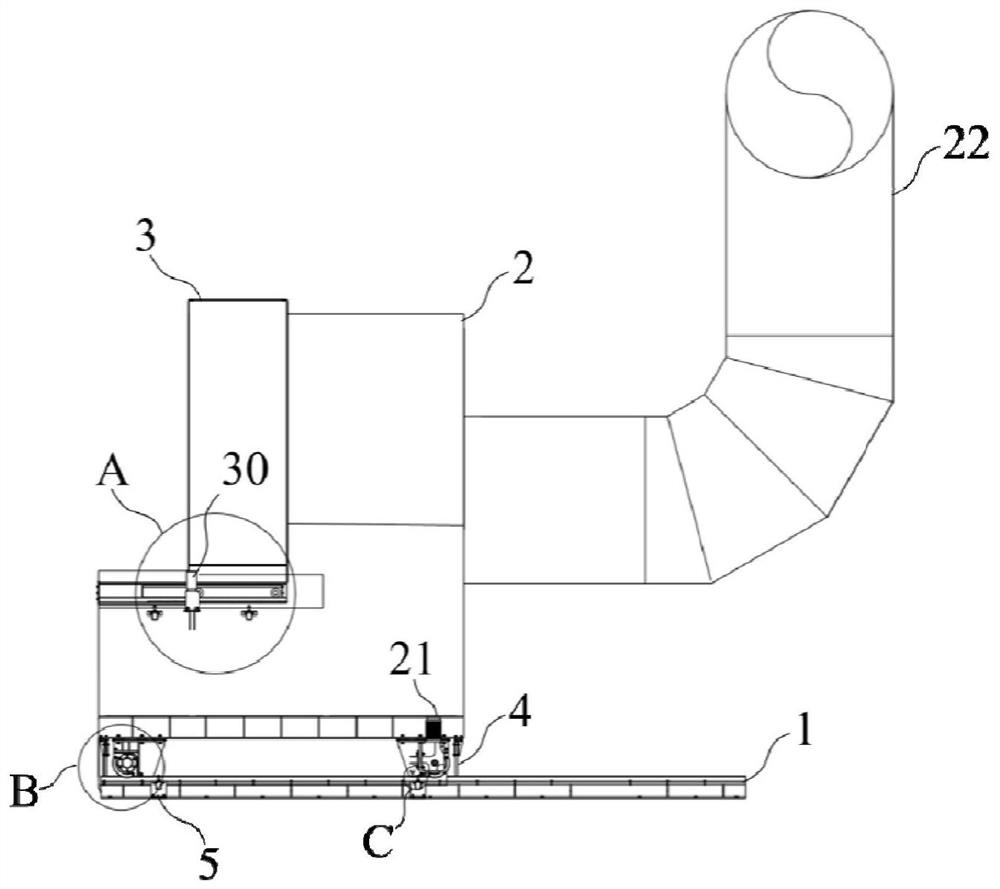

[0108] Such as Figure 4 and Figure 8 As shown, the steel-making environment of the present embodiment is further improved on the basis of embodiment 2, and the second drive unit 30 is arranged on both the mother dust removal hood 2 and the child dust removal hood 3. side, including:

[0109] The second driving member 300, which provides driving force;

[0110] The gear 301 is connected with the sub-dust cover 3 and connected with the second driving member 300 in transmission;

[0111] The rack 302 is horizontally fixed on both sides of the female dust removal hood vehicle 2, and the rack 302 is meshed with the gear 300.

[0112] In this embodiment, the second driving member 300 can be a component that can provide driving force such as a geared motor. Both sides of the dust removal cover vehicle 2 cover body, the gear 301 is fixedly connected with the bottom of the two sides of the dust removal cover 2 and the gear 301 is meshed with the rack 302, and the gear motor is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com