Energy-saving and environment-friendly process device and method for treating organic solid waste through pulsed oxygen-enriched combustion

An organic solid waste, oxygen-enriched combustion technology, applied in the combustion method, combustion type, indirect carbon dioxide emission reduction, etc., can solve the problems of short service life of the combustion furnace and pollute the environment, and achieve the reduction of high temperature load, reduction of usage, and reduction of The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

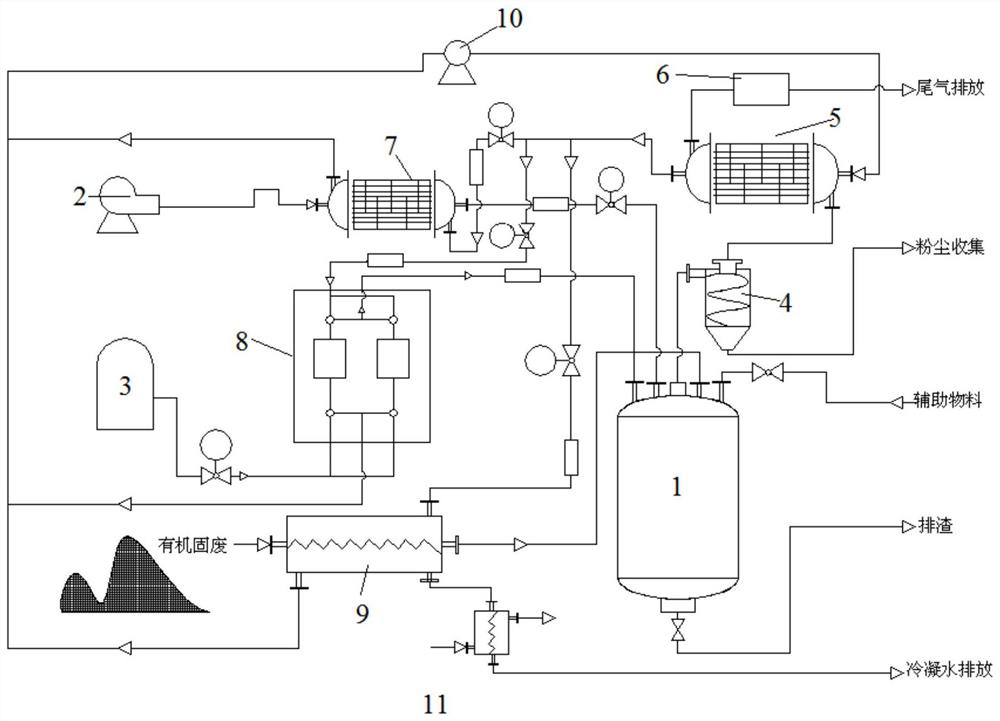

[0056] This embodiment provides an energy-saving and environment-friendly pulse oxygen-enriched combustion process device for treating organic solid waste. For its structure, see figure 1 As shown, it includes a combustion furnace 1, an air supply assembly, an oxygen supply assembly, a cyclone separator 4, a first heat exchanger 5 and an exhaust gas treatment assembly 6, wherein the air supply assembly, oxygen supply assembly and organic solid waste source The air inlet, the oxygen inlet and the organic solid waste inlet on the combustion furnace 1 are respectively connected through the air supply pipeline, the oxygen supply pipeline and the solid waste conveyor belt, and the exhaust gas outlet on the combustion furnace 1 is also connected to the cyclone separation 4, the first heat exchanger 5 and the tail gas treatment assembly 6, and the hot fluid outlet on the first heat exchanger 5 also leads to three preheating branches, which are respectively preheated or dried and sent ...

Embodiment 2

[0072] Compared with Example 1, most of them are the same, except some differences are as follows:

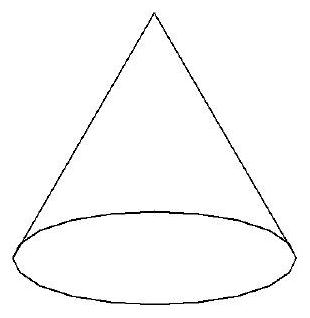

[0073] The inverted cone distributor in the combustion furnace 1 is made of No. 45 carbon steel, and it is distributed under the feed inlet in five layers. Each layer of the inverted cone distributor is arranged in a circle, and the upper and lower distributors are alternate Column arrangement. The length x width x height of the inverted cone distributor is 40cm x 40cm x 40cm.

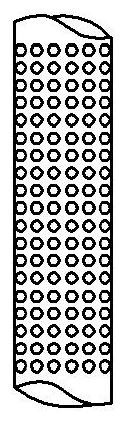

[0074] The air dispersing device and the oxygen dispersing device are multi-tube structures, and a porous structure is set at the gas outlet of the tubes. 500 holes are evenly distributed around the dispersing tubes, and each hole has a diameter of 2mm.

[0075] Use the above system for production, using an effective volume of 2m 3 The fluidized fluidized furnace carried out combustion test on tank bottom sludge with organic matter content of 90%, and detected the combustion effect. And in the specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com