Patents

Literature

77results about How to "Guaranteed condensation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

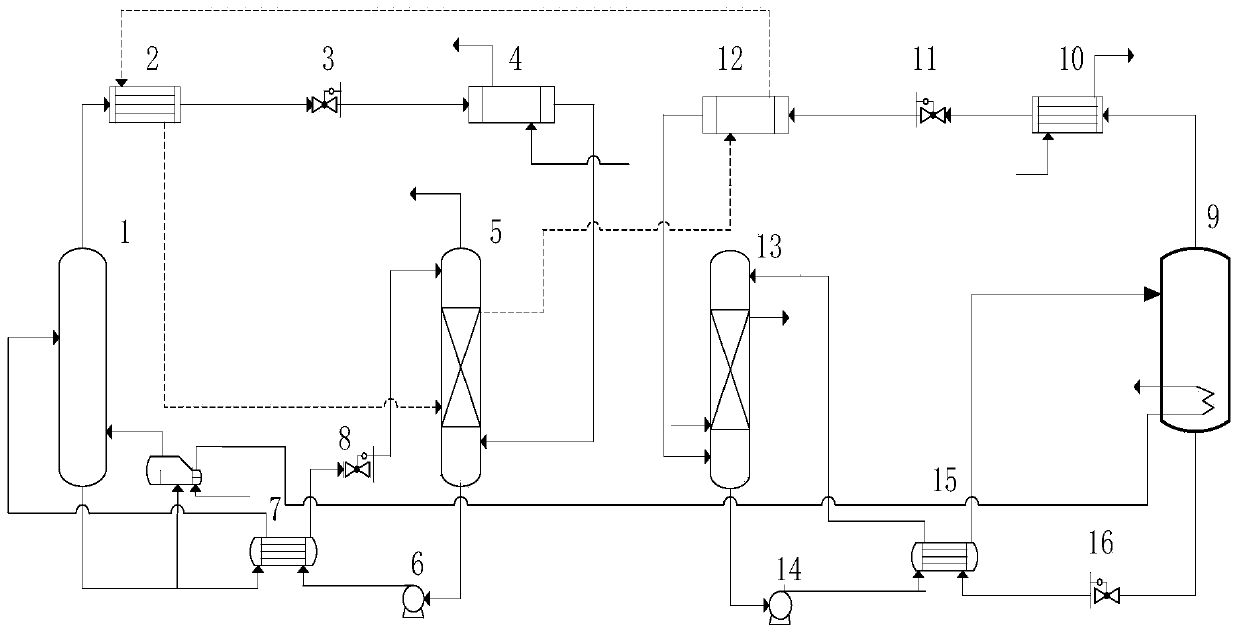

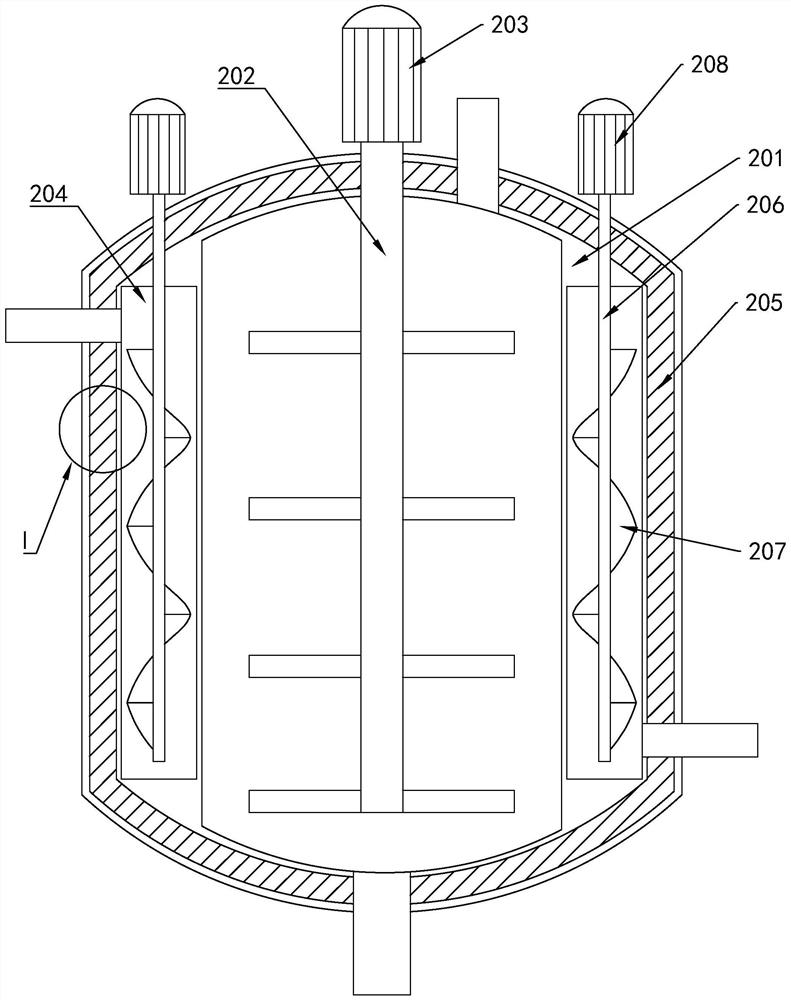

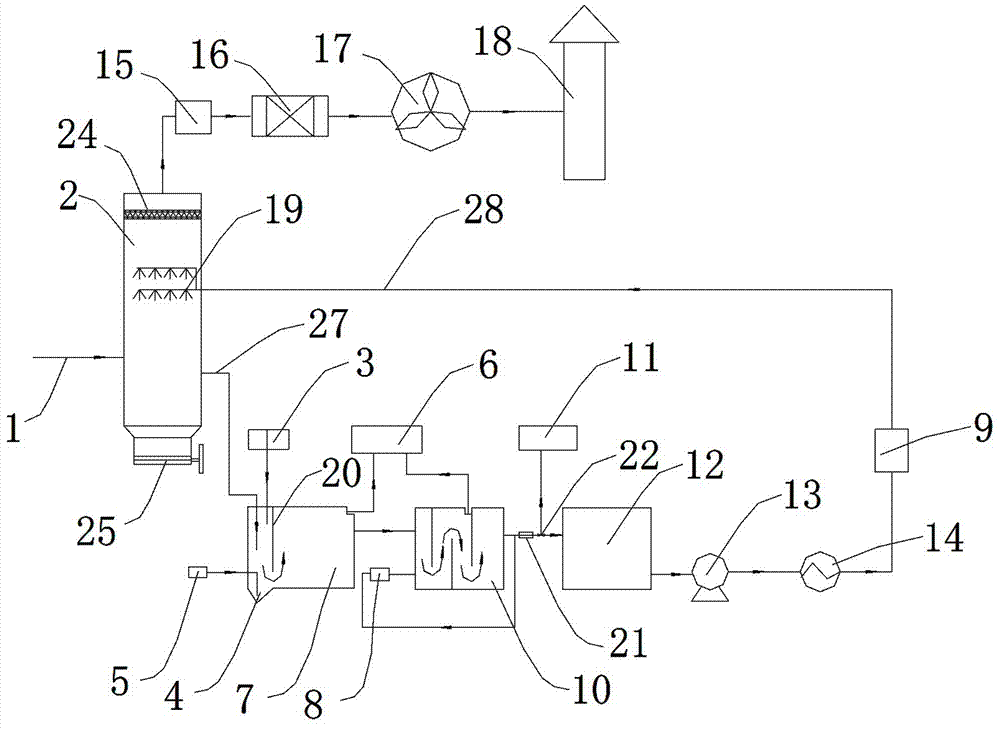

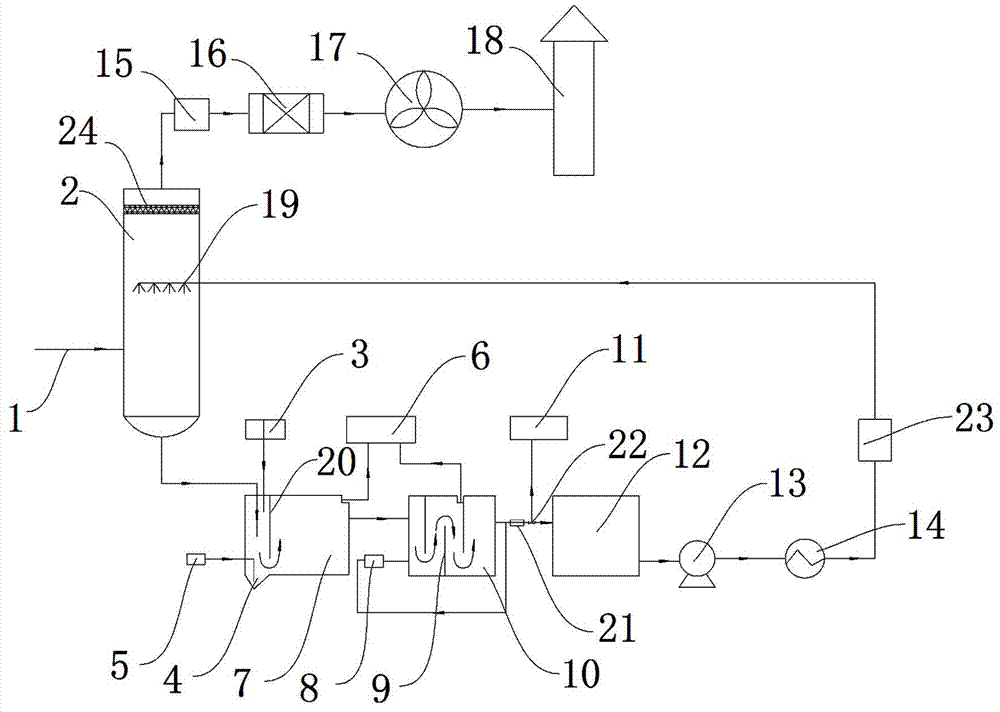

Ammonia and lithium bromide integrated absorption refrigeration device driven by heating medium water and method

ActiveCN103629854ALower operating temperatureLow operating pressureMechanical apparatusEnergy efficient heating/coolingEnergy gradientWater vapor

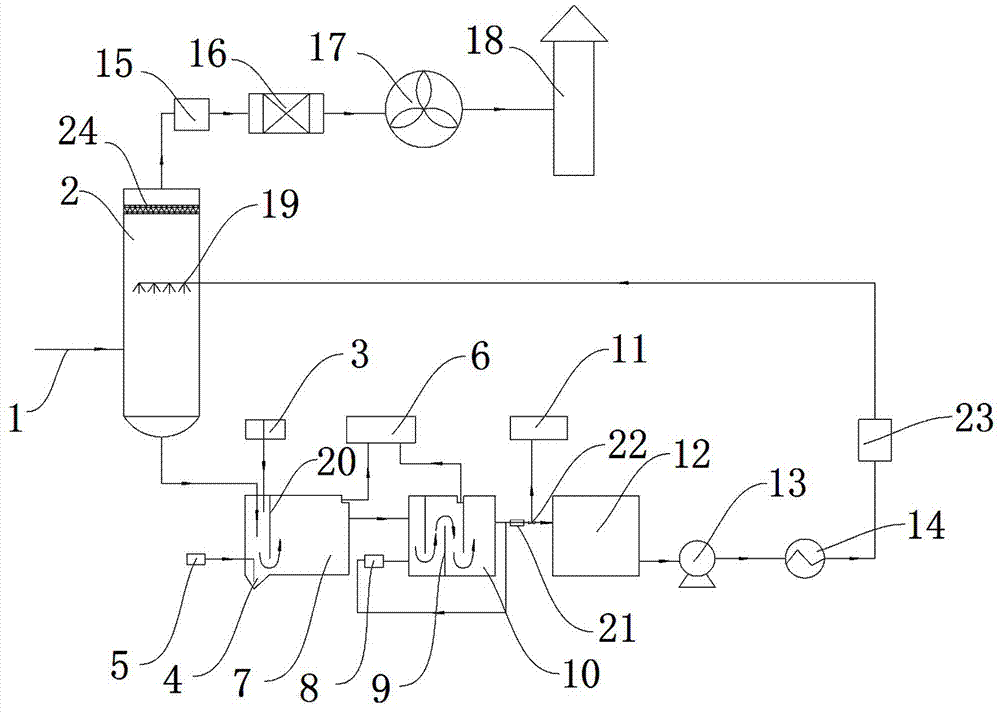

Provided are an ammonia and lithium bromide integrated absorption refrigeration device driven by heating medium water and a method. The device comprises an ammonia-water solution rectifying tower, an ammonia condenser, a liquid ammonia throttling valve, a liquid ammonia evaporator, a refrigerant ammonia absorber, an ammonia-water solution heat exchanger, an ammonia-water solution circulating pump, an ammonia-water solution reducing valve, a lithium bromide solution generator, a water vapor condenser, a water throttling valve, a water evaporator, a refrigerant water vapor absorber, a lithium bromide solution heat exchanger, a lithium bromide solution circulating pump and a lithium bromide solution reducing valve. An ammonia absorption refrigeration system and a lithium bromide absorption refrigeration system are integrated through heating medium water and chilled water energy flows. The process includes the steps that according to an energy gradient utilization principle, the heating medium water drives ammonia absorption refrigeration at first and then sequentially drives lithium bromide absorption refrigeration. Chilled water made through the lithium bromide absorption refrigeration system is used for cooling the generator (an ammonia-water solution rectifying overhead condenser) and the absorber of the ammonia absorption refrigeration system in a series level mode, and therefore the ammonia absorption refrigeration process is intensified.

Owner:DALIAN UNIV OF TECH

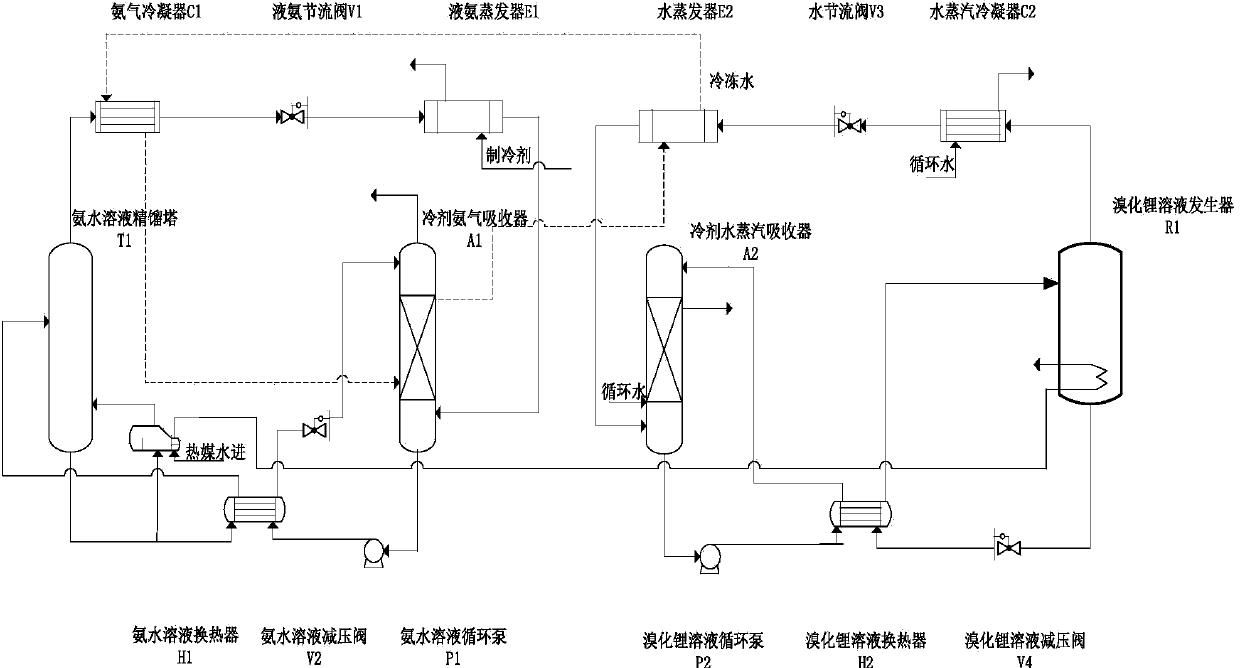

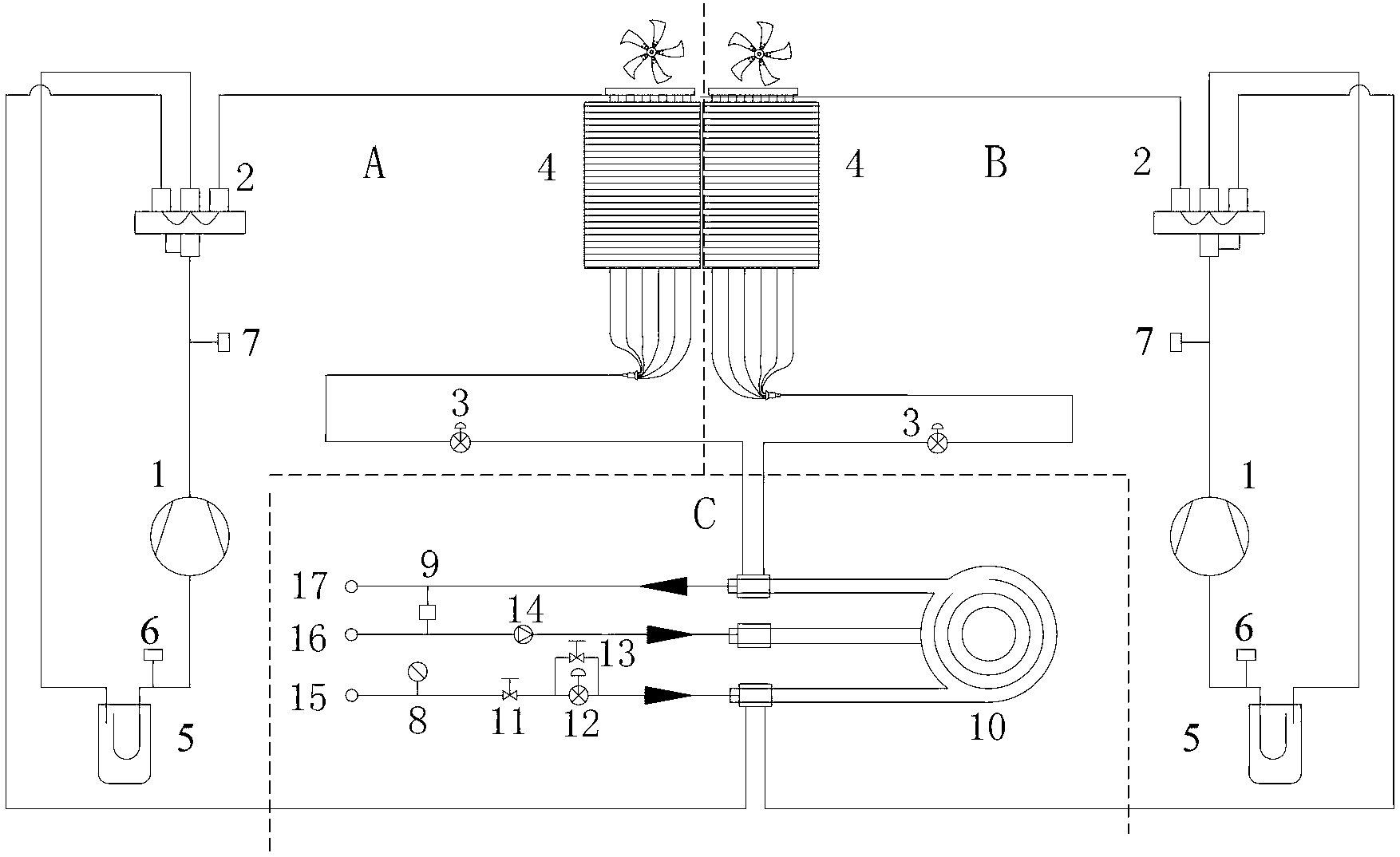

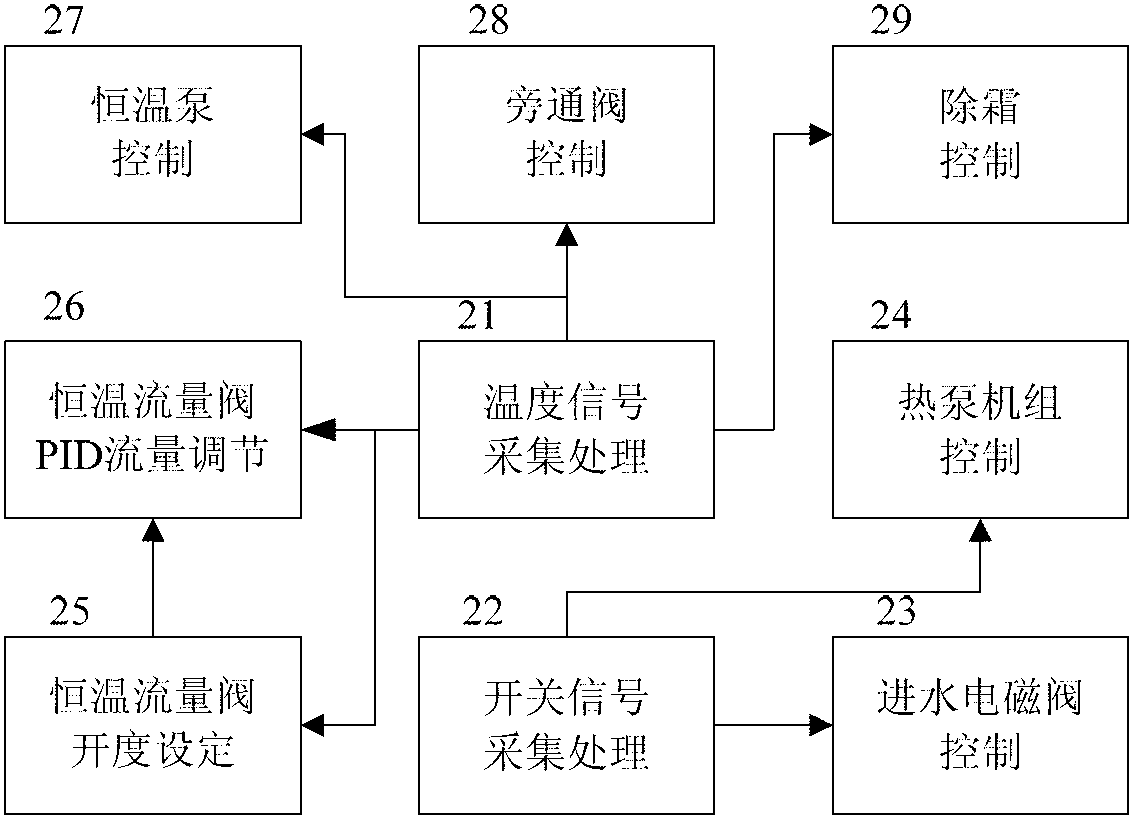

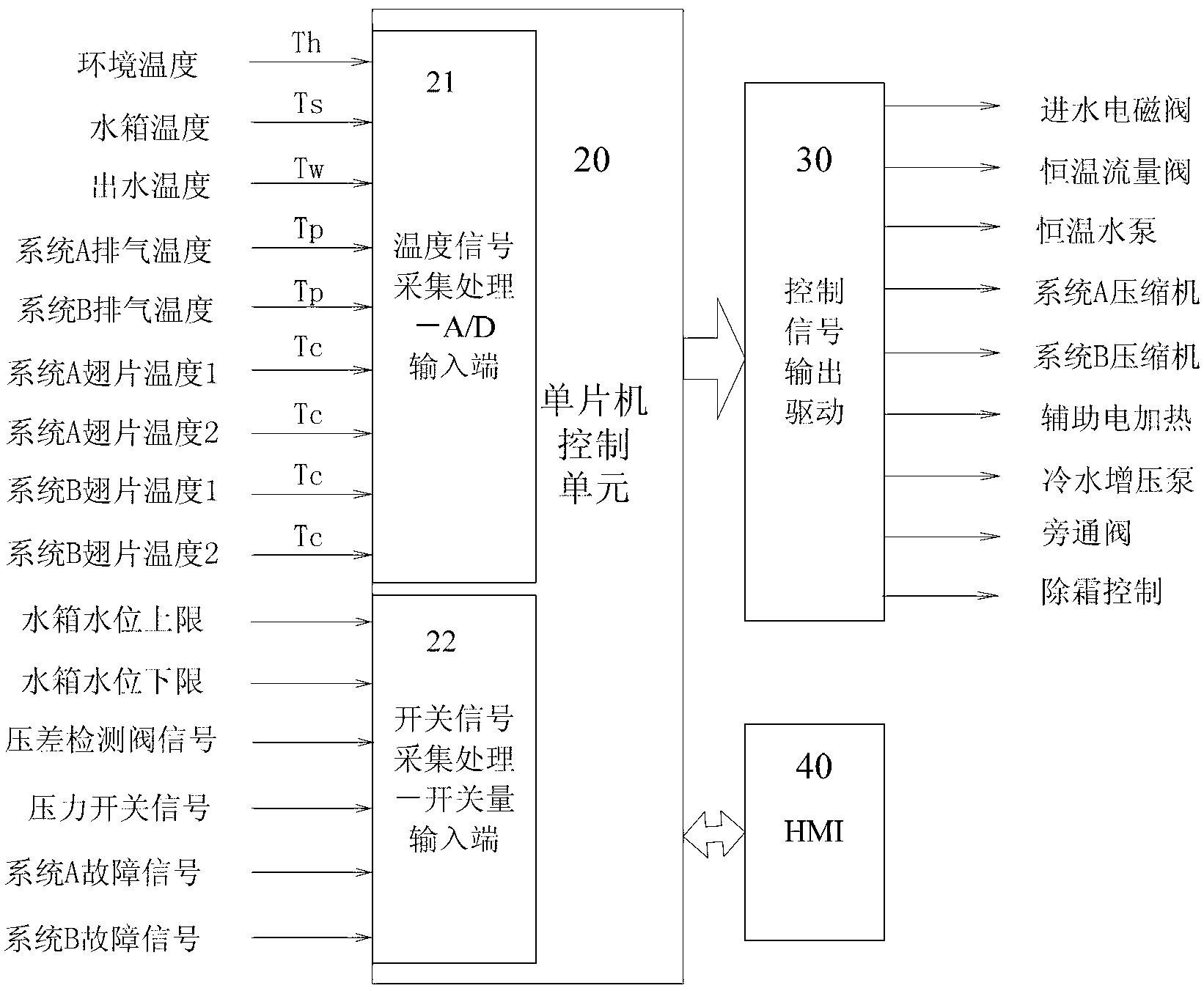

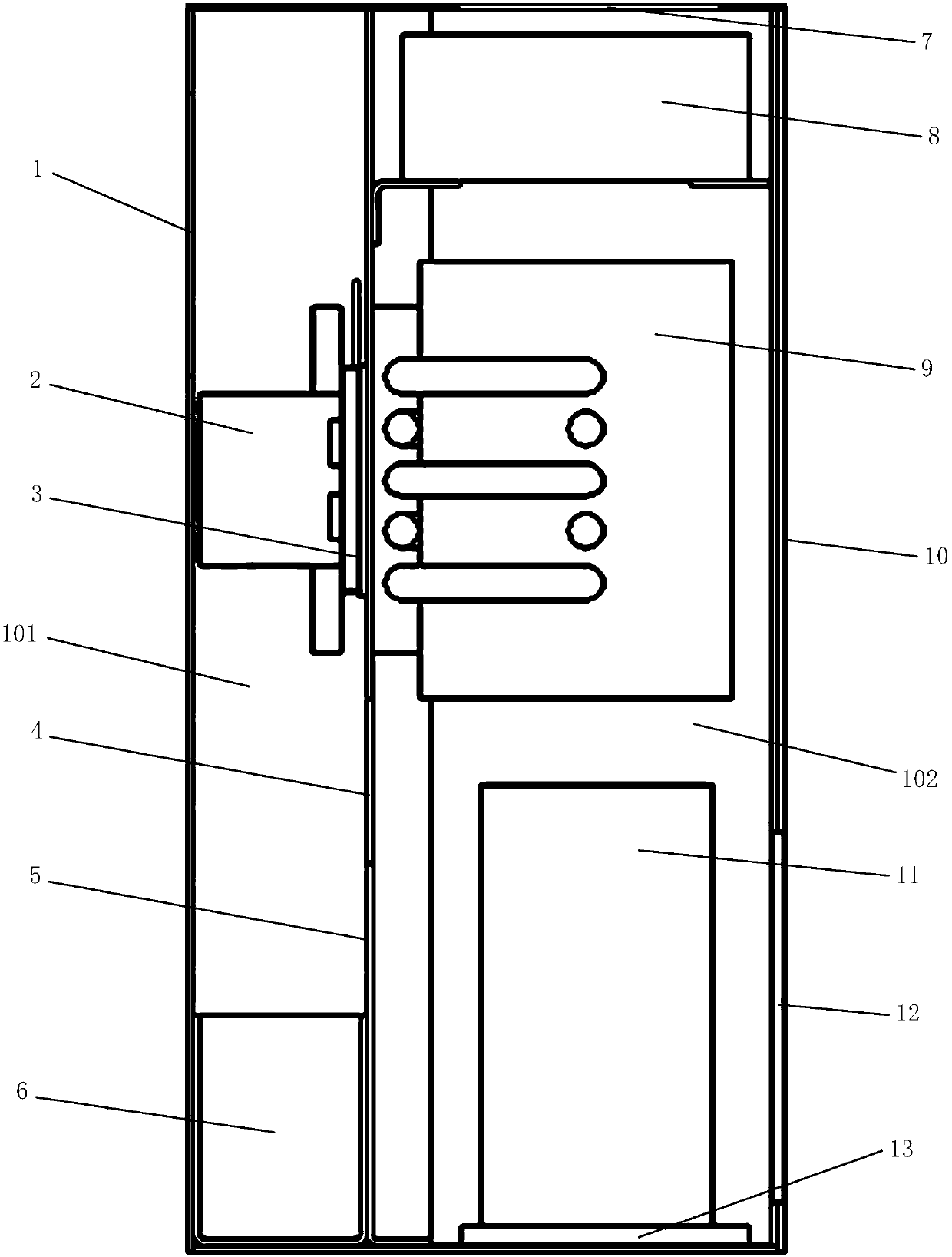

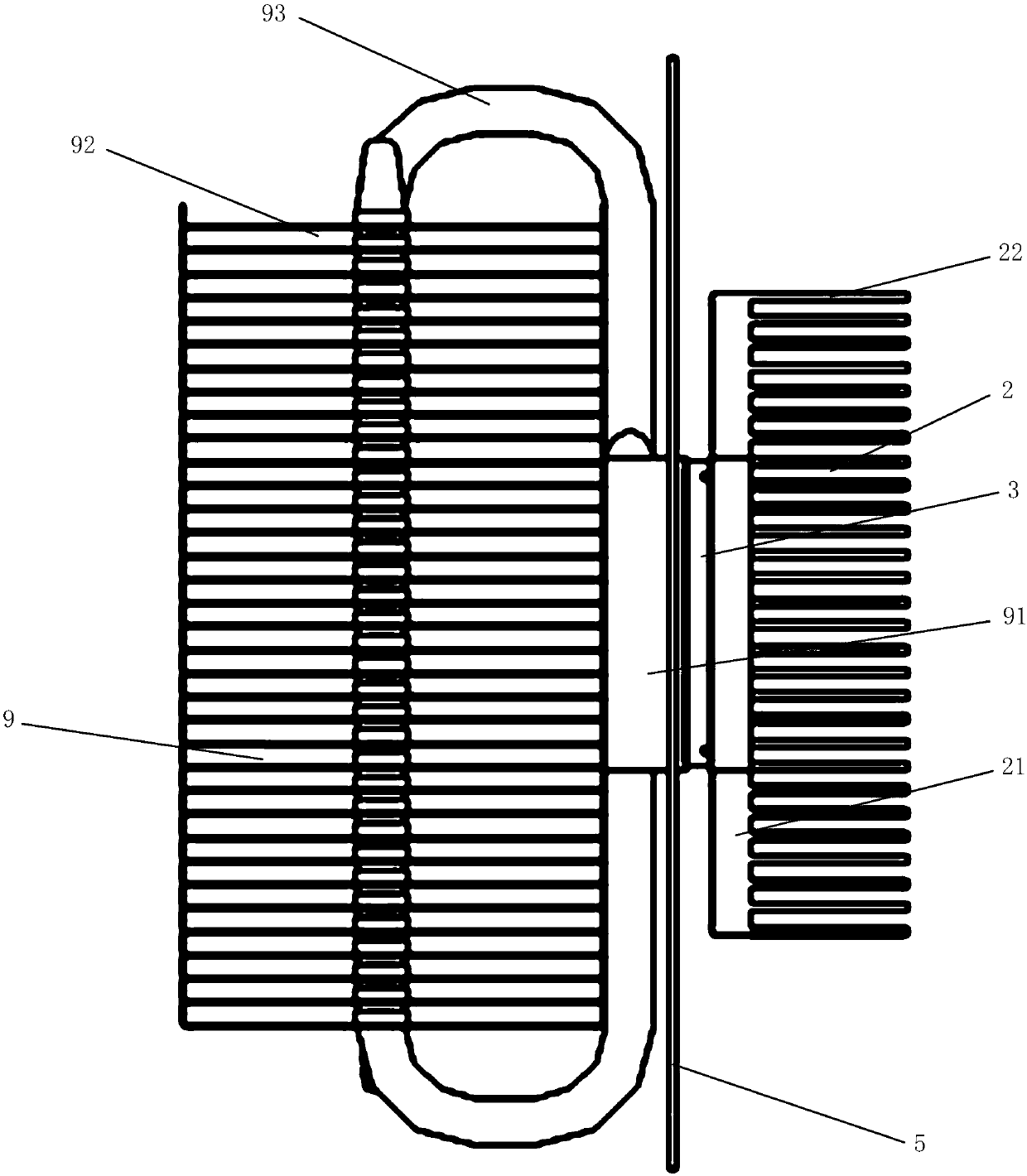

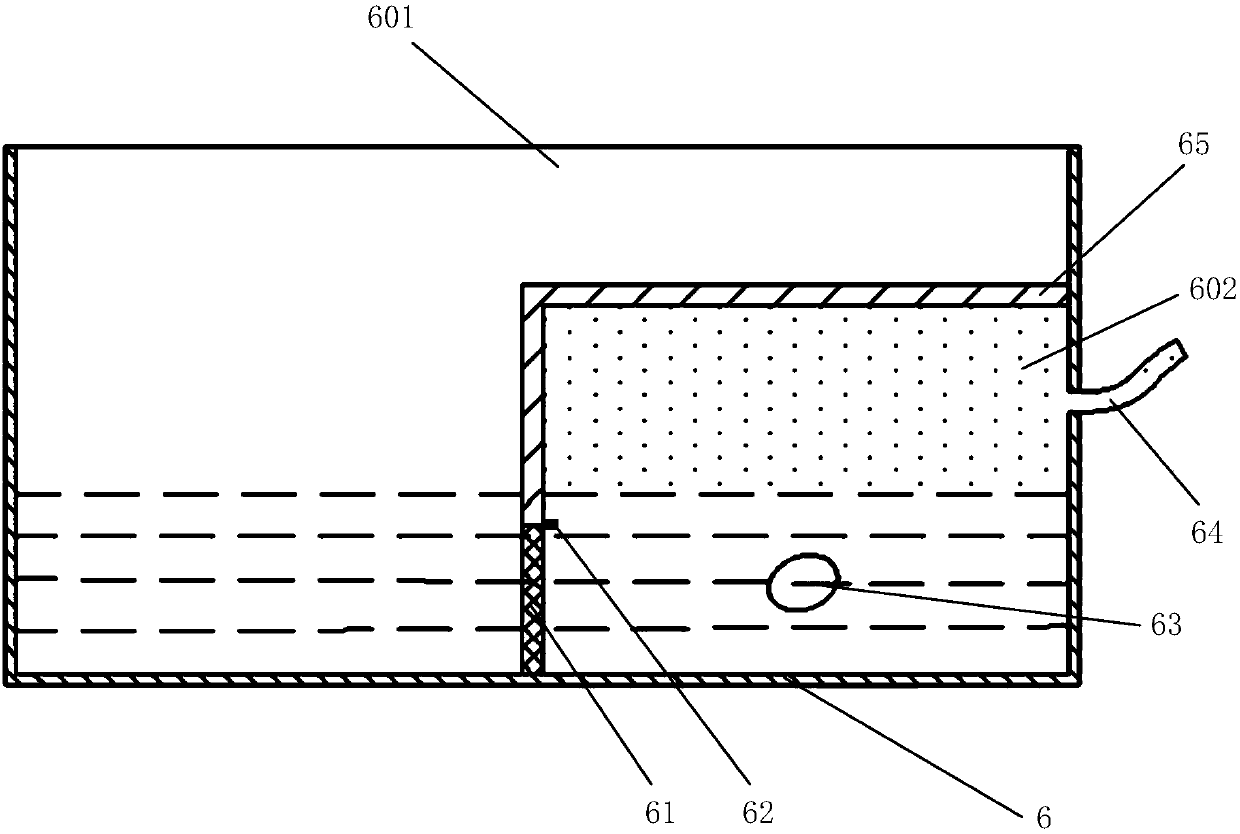

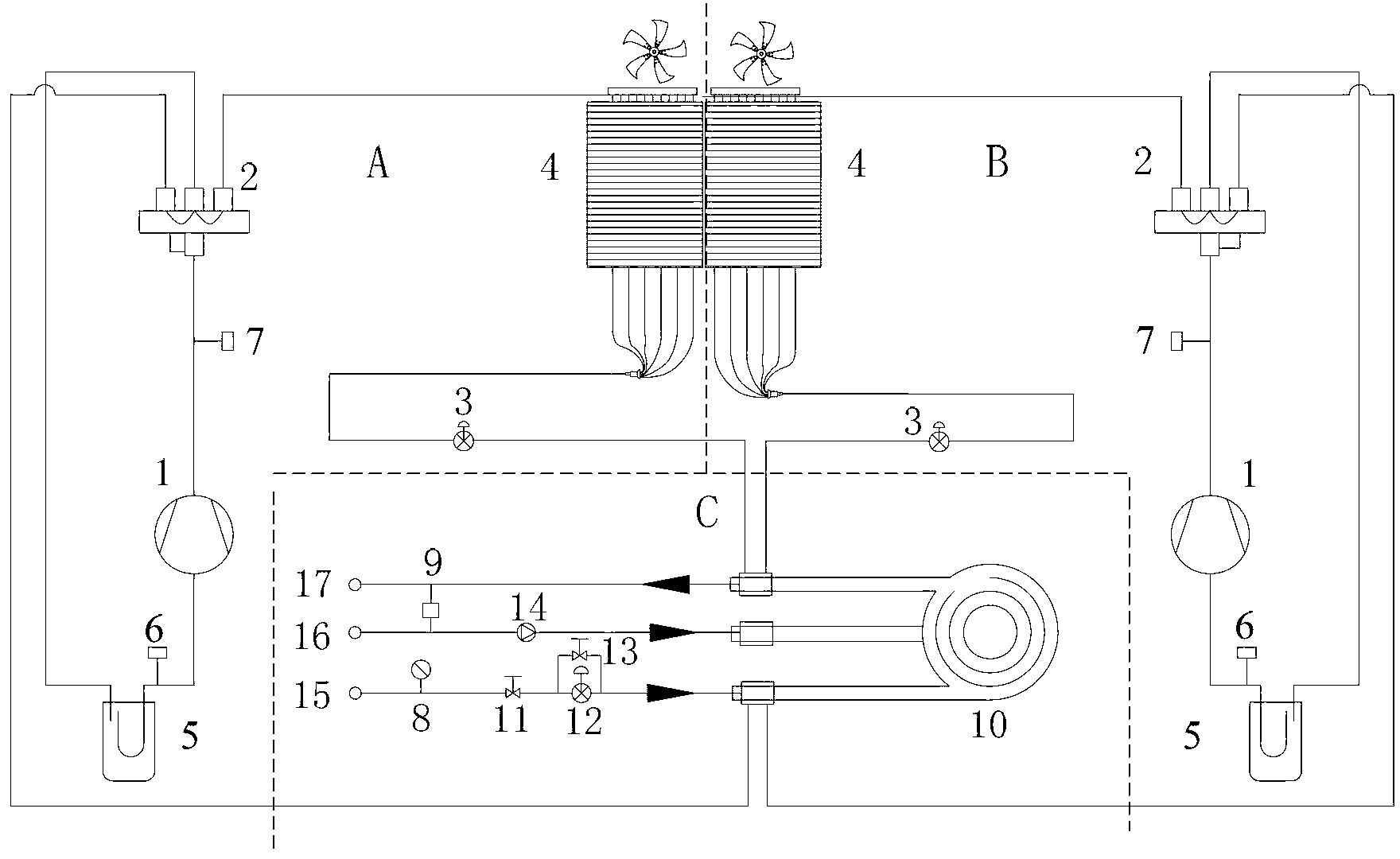

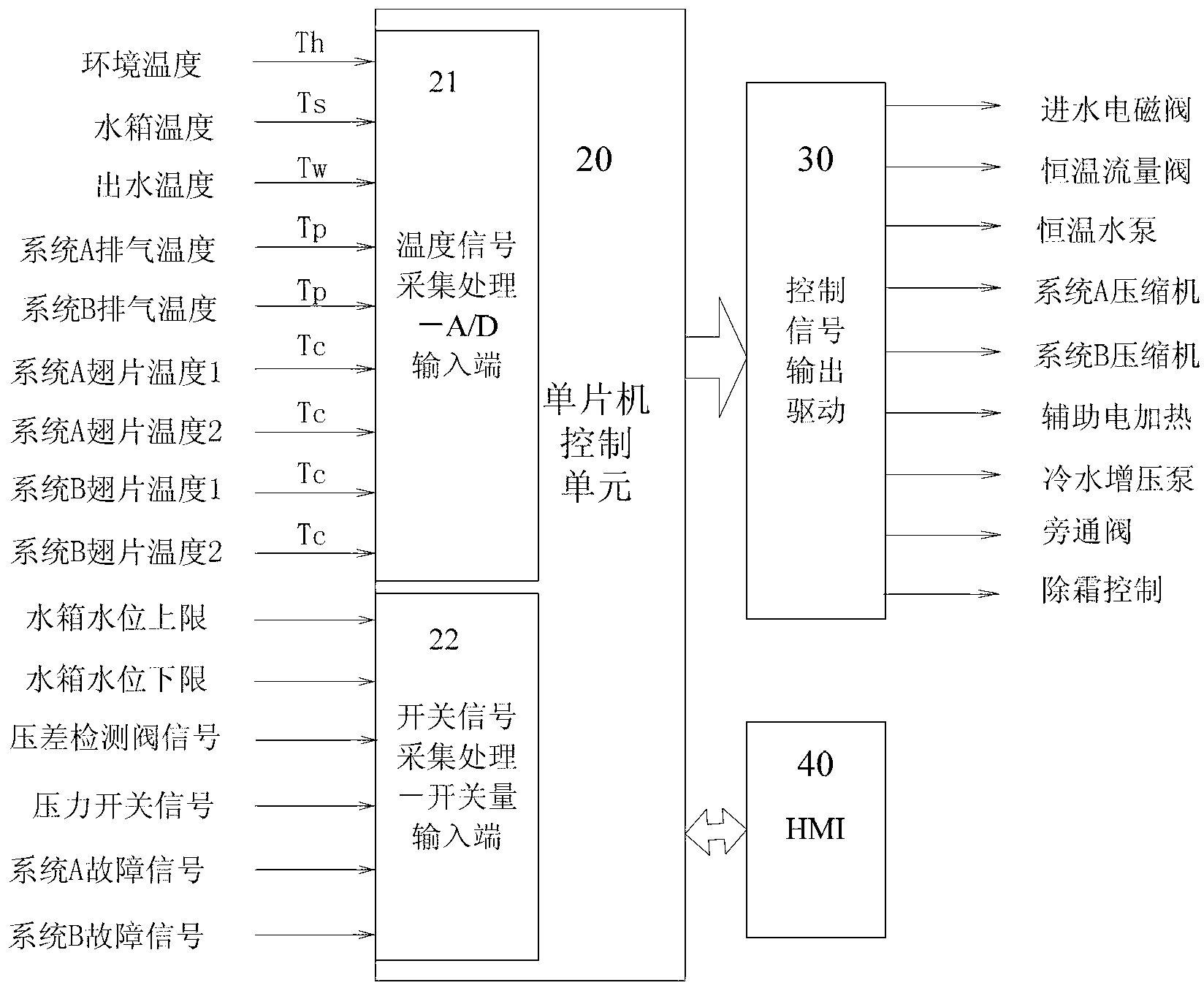

Constant temperature flow control method for heat pump water heater and double-system unit using same

The invention discloses a constant temperature flow control method for a heat pump water heater and a double-system unit using the same, relates to a fluid heater utilizing a heat pump and a control method thereof, and particularly relates to a constant temperature flow control method for the heat pump water heater and a double-system primary heating type heat pump water heater unit using the method. The double-system primary heating type hot pump water heater unit comprises a heat pump system A, a heat pump system B, a water supply heating system C and a constant temperature flow control device, wherein PID regulation on water flow is performed according to outlet water temperature; an outlet water temperature set value is set as a target value, and the opening of a constant temperature flow valve is controlled according to a checking value of the outlet water temperature so as to adjust the water flow; when the temperature of a water box is low, a constant temperature water pump and a compressor are started, and the unit operates at constant temperature; when inlet water temperature is too high, a bypass-valve is opened; and one system in a double-system generates a fault and stops operation, the outlet water set temperature is down-adjusted, the water flow of a heat pump unit is guaranteed, and the condensation effect and heating capacity and energy efficiency of the unit are improved, so that the other system without the fault is safely and stably operated in an efficient manner.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

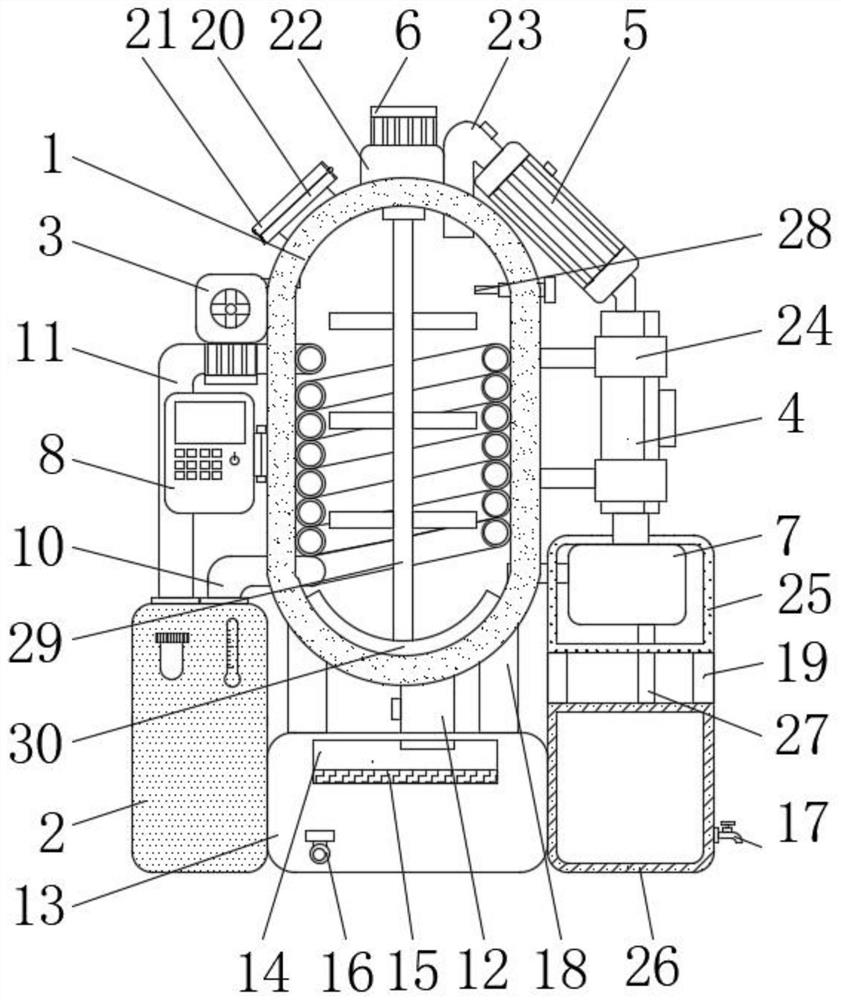

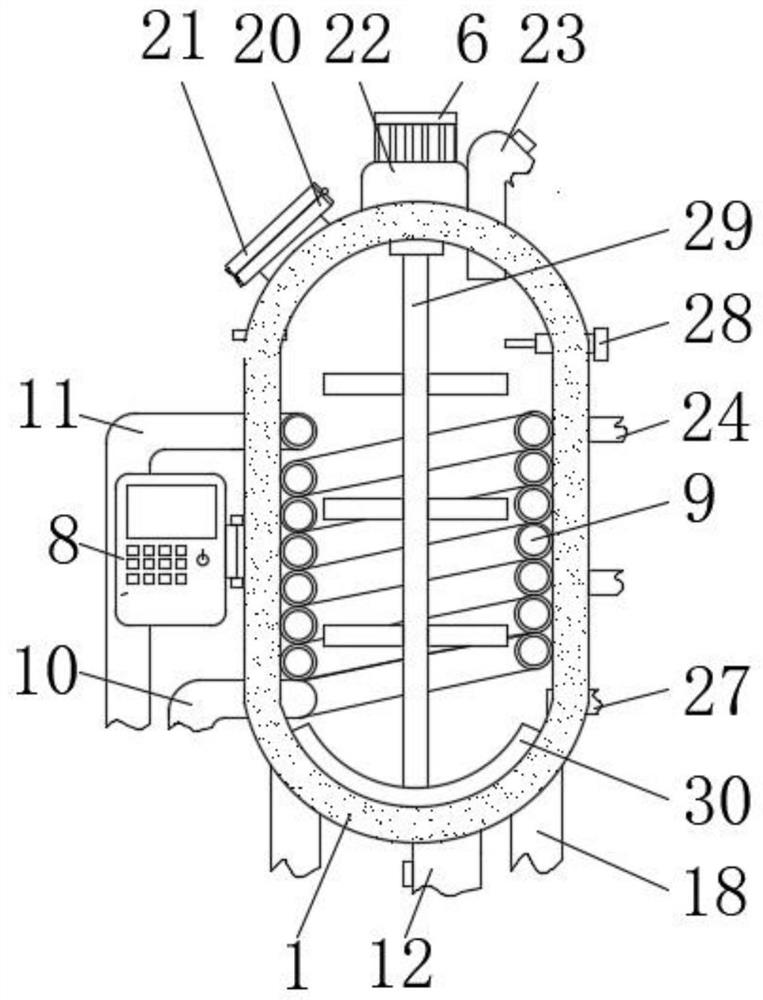

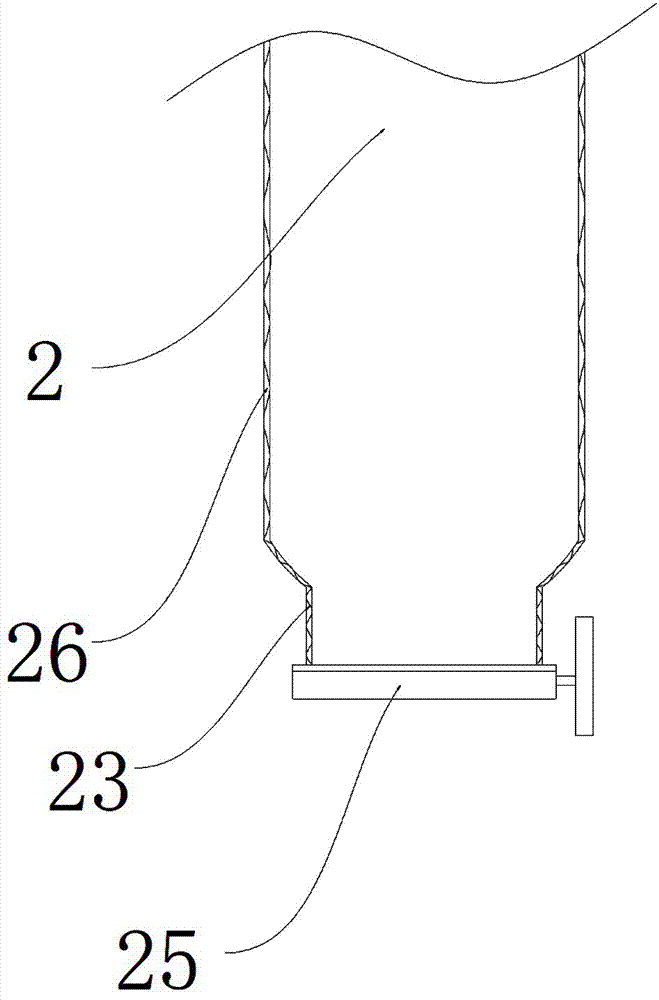

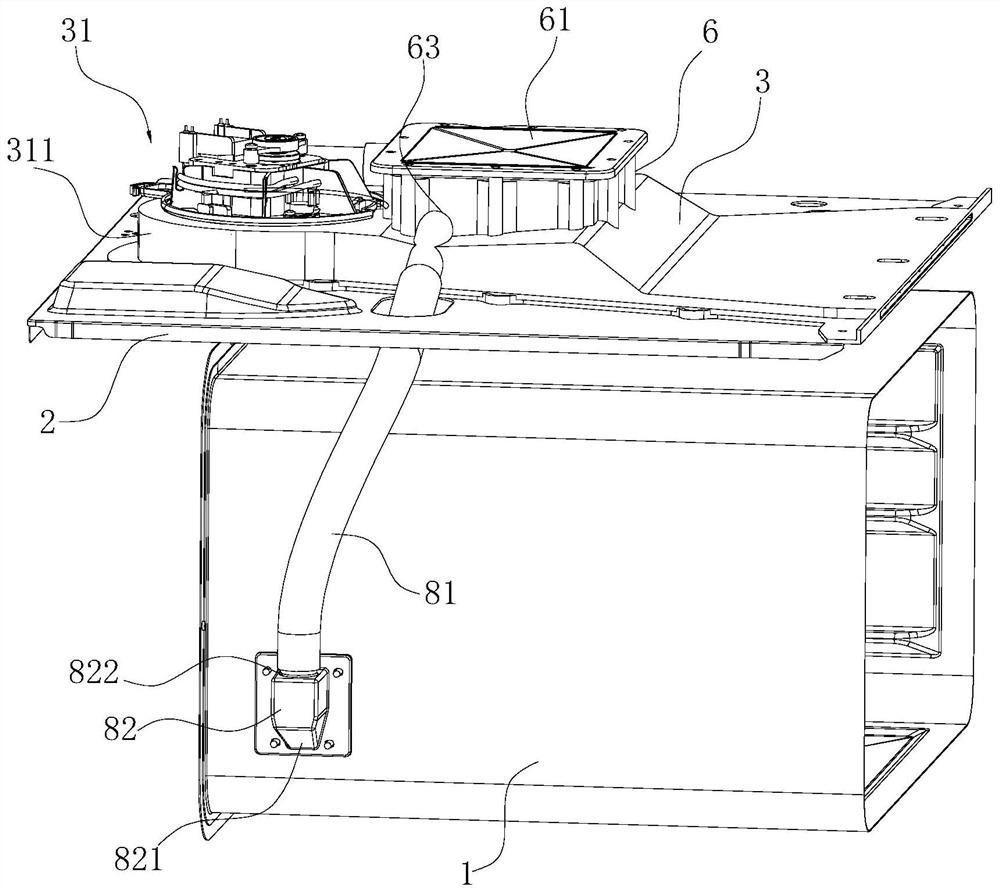

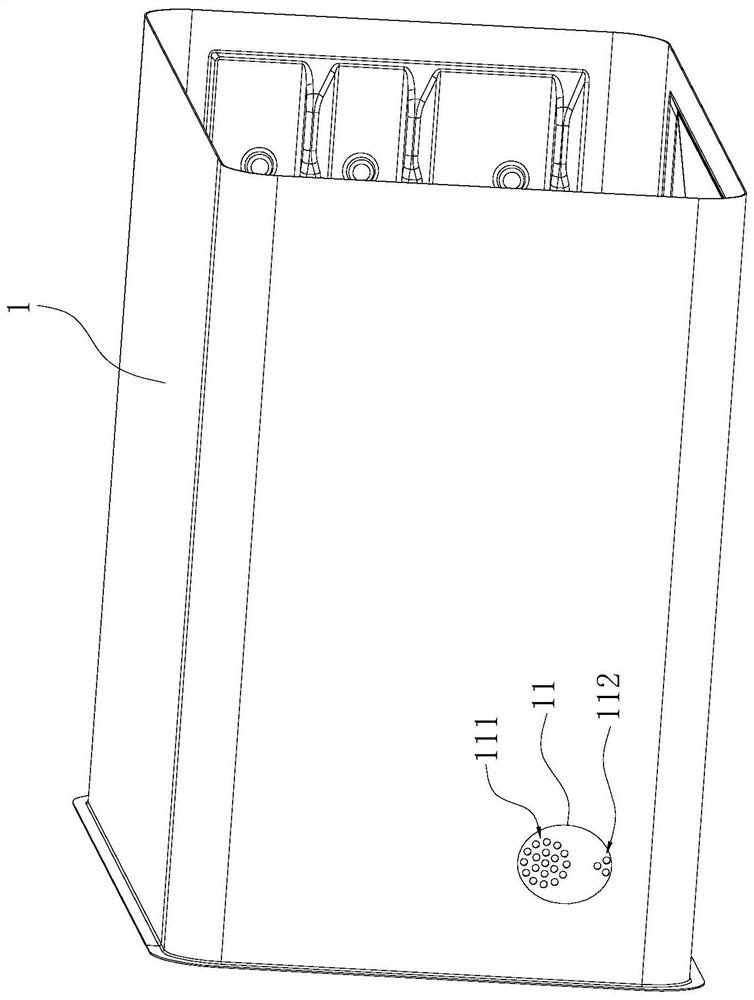

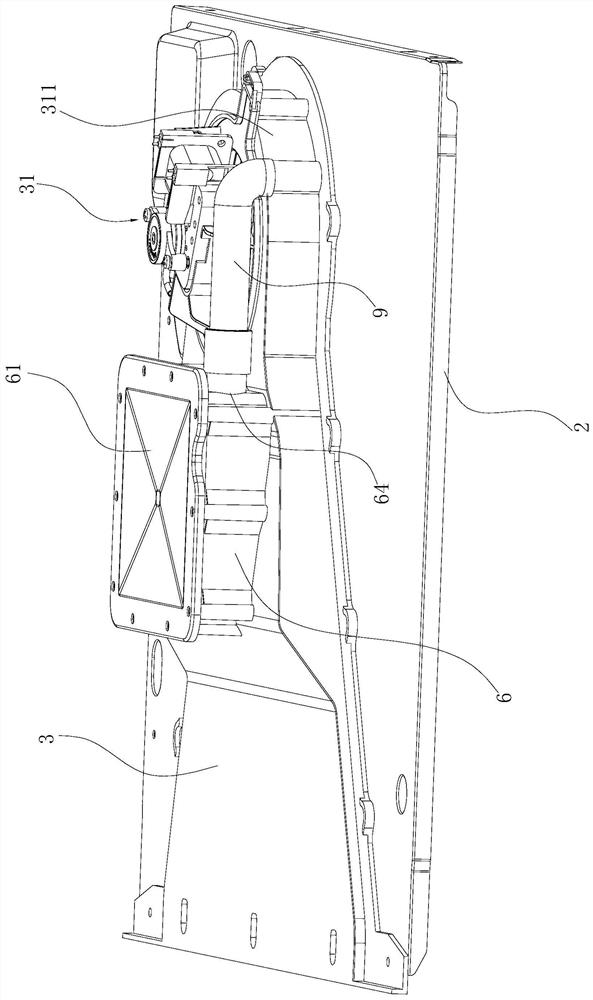

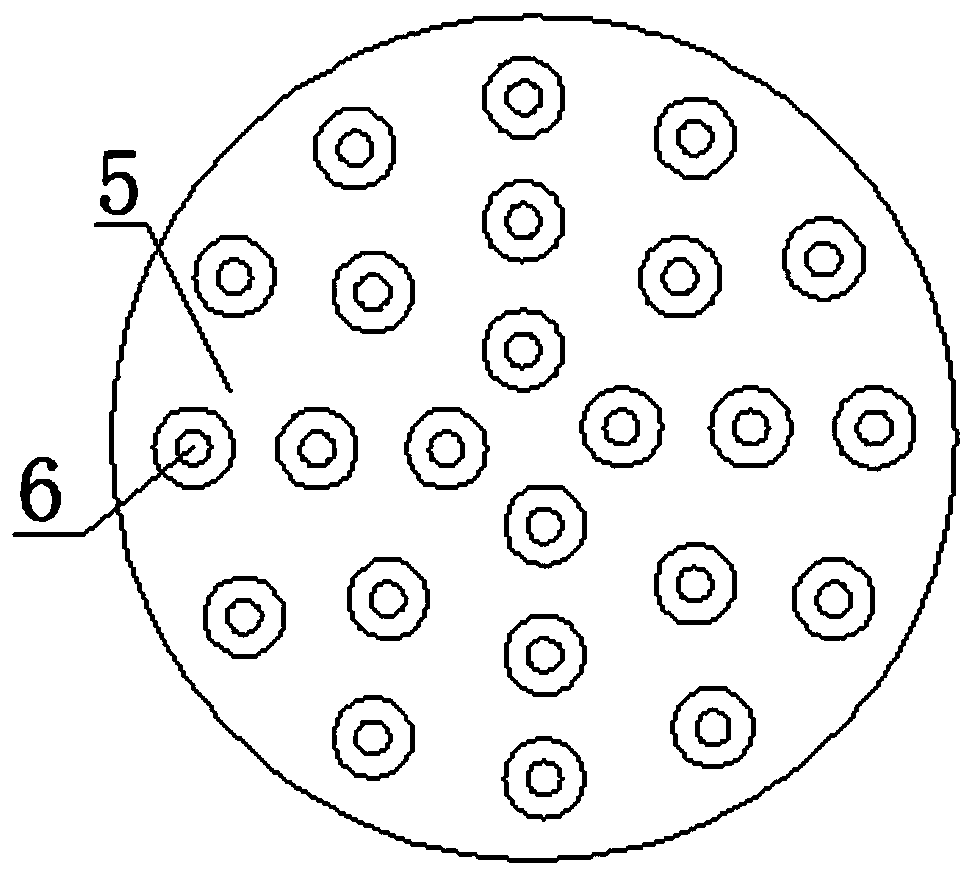

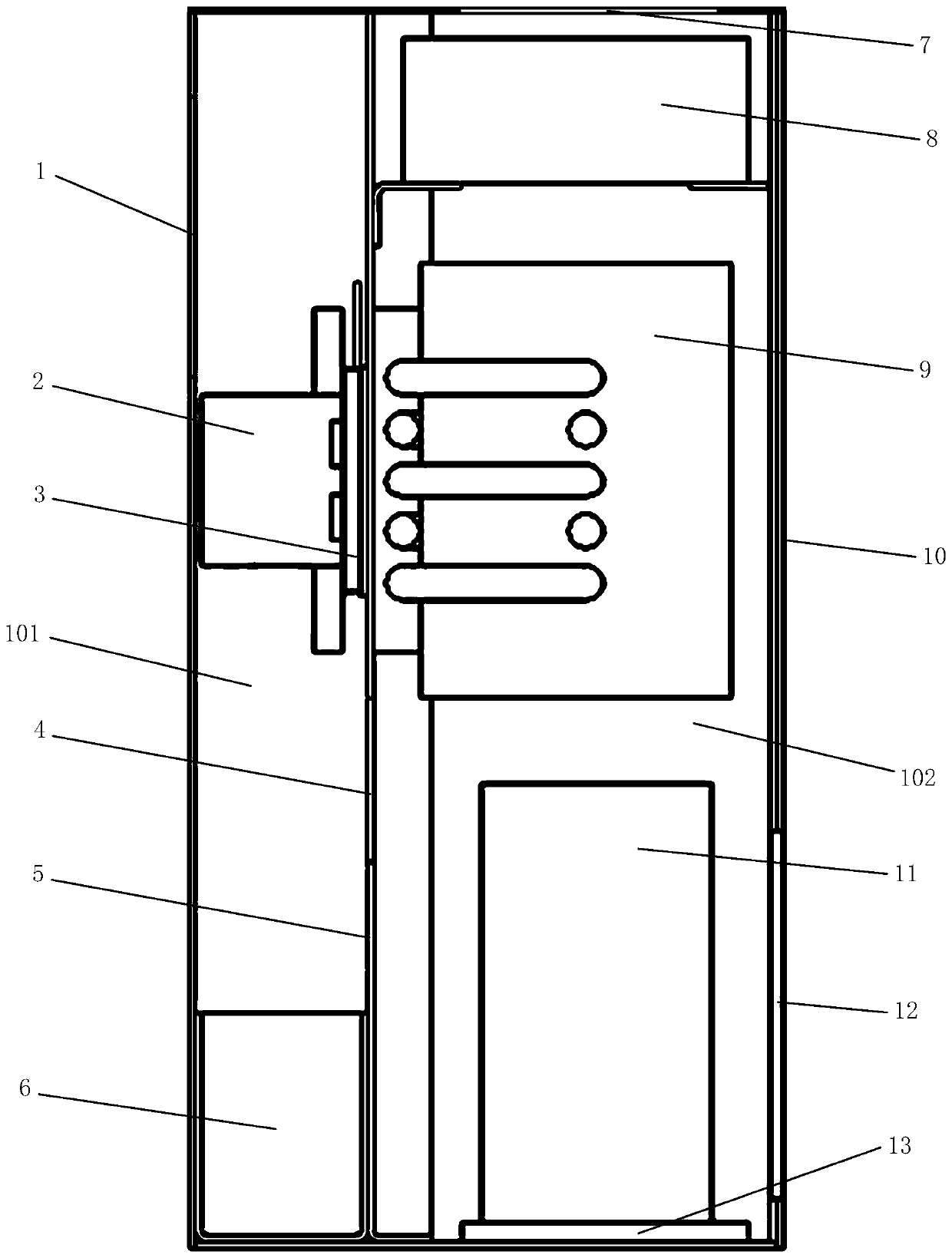

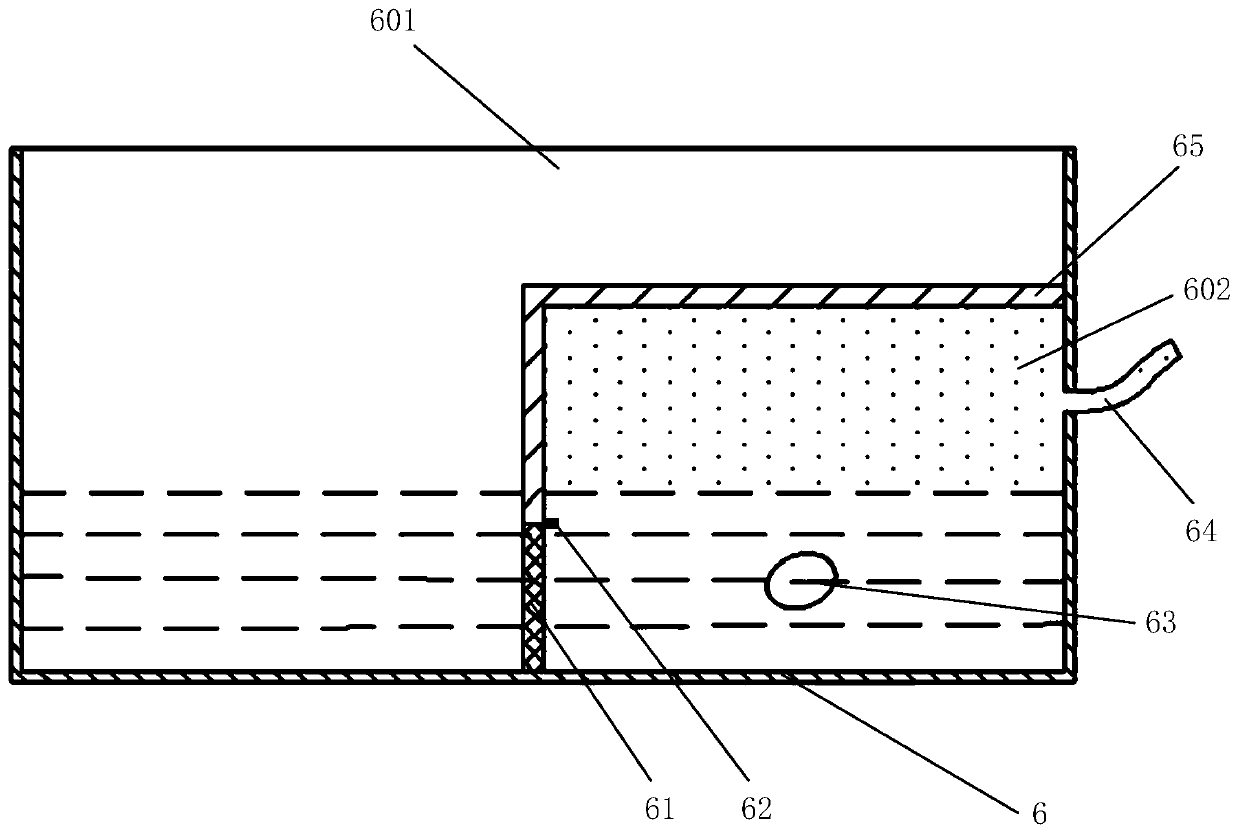

Semiconductor dehumidification device

ActiveCN107785783AImprove dehumidification efficiencyGuaranteed condensation effectSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringRefrigeration

The invention discloses a semiconductor dehumidification device. The device comprises a cold-side radiator, a semiconductor refrigeration sheet, a partition plate, a water tank, a fan, a hot-side radiator and a shell; the partition plate dives the shell from a horizontal direction into a condensation zone and a heat dissipation zone; and the condensation zone and the heat dissipation zone are communicated with each other through ventilation holes formed in the partition plate; an air inlet located in the condensation zone is formed in the upper part of the shell; an air outlet located in the heat dissipation zone is formed in the top of the shell; the semiconductor refrigeration sheet is arranged in the partition plate; the cold end of the semiconductor refrigeration sheet is connected with the cold-end radiator; the hot end of the semiconductor refrigeration sheet is connected with the hot-end radiator; the cold-end radiator and the hot-end radiator are fixed at two sides of the partition plate; the fan is located between the upper part of the hot-end radiator and the air outlet; the water tank is disposed below the cold-end radiator; and an atomization and water draining device is disposed in the water tank. With the semiconductor dehumidification device of the invention, the technical problems of low dehumidification efficiency, complicated structure and difficulty in waterdrainage of an existing semiconductor dehumidification device can be solved. The semiconductor dehumidification device of the invention has the advantages of high dehumidification efficiency and simple structure, and can realize intelligent water drainage.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

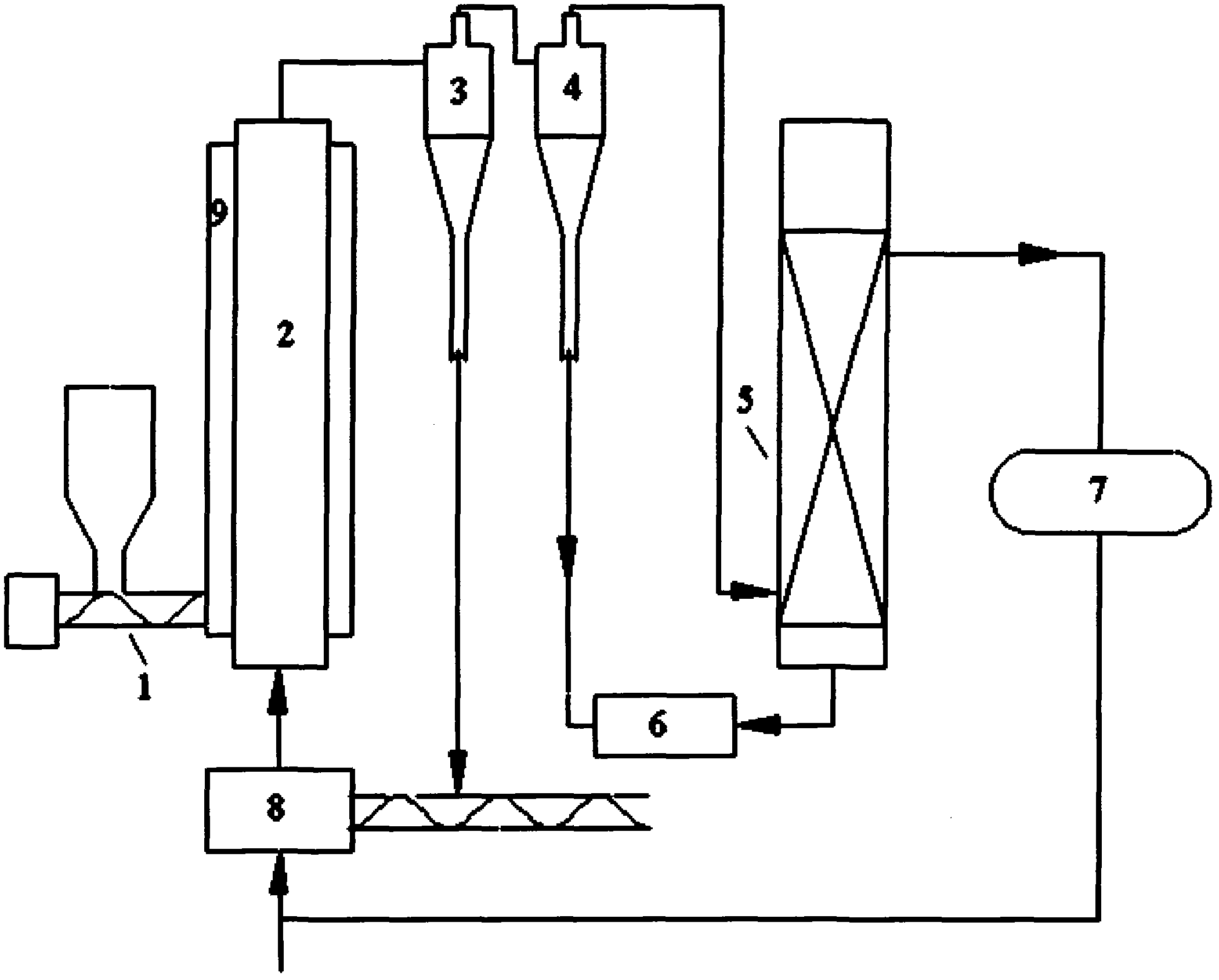

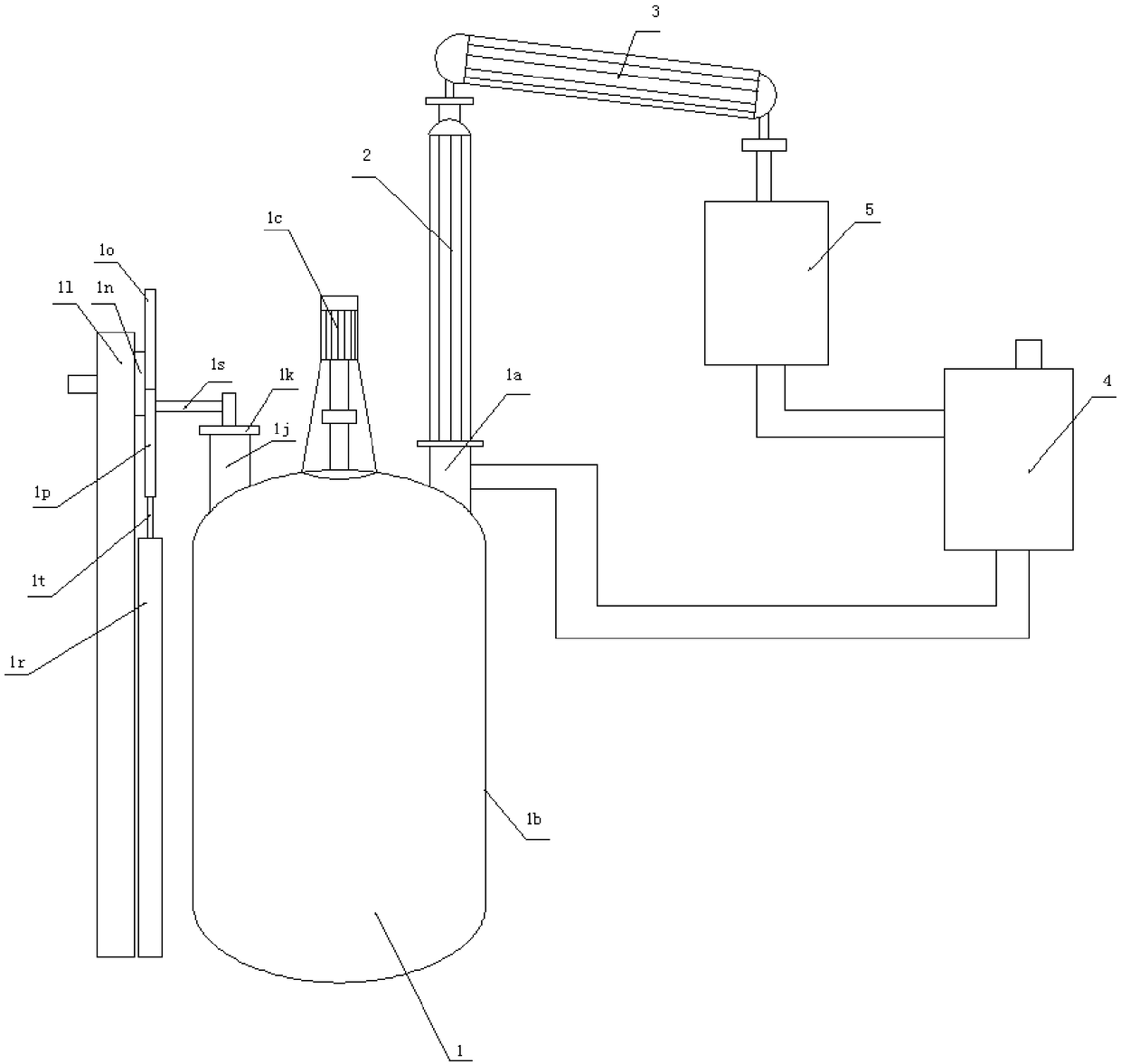

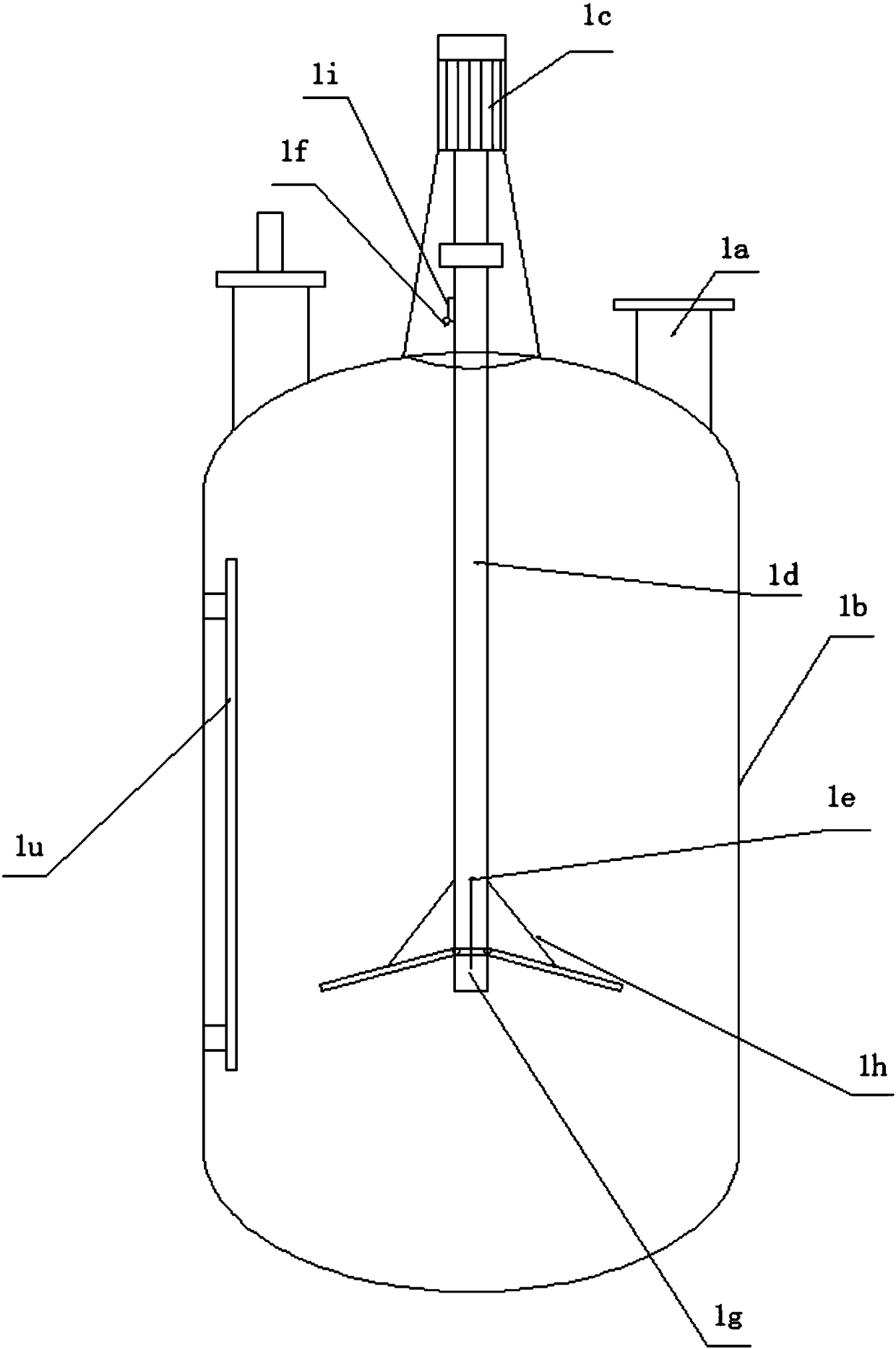

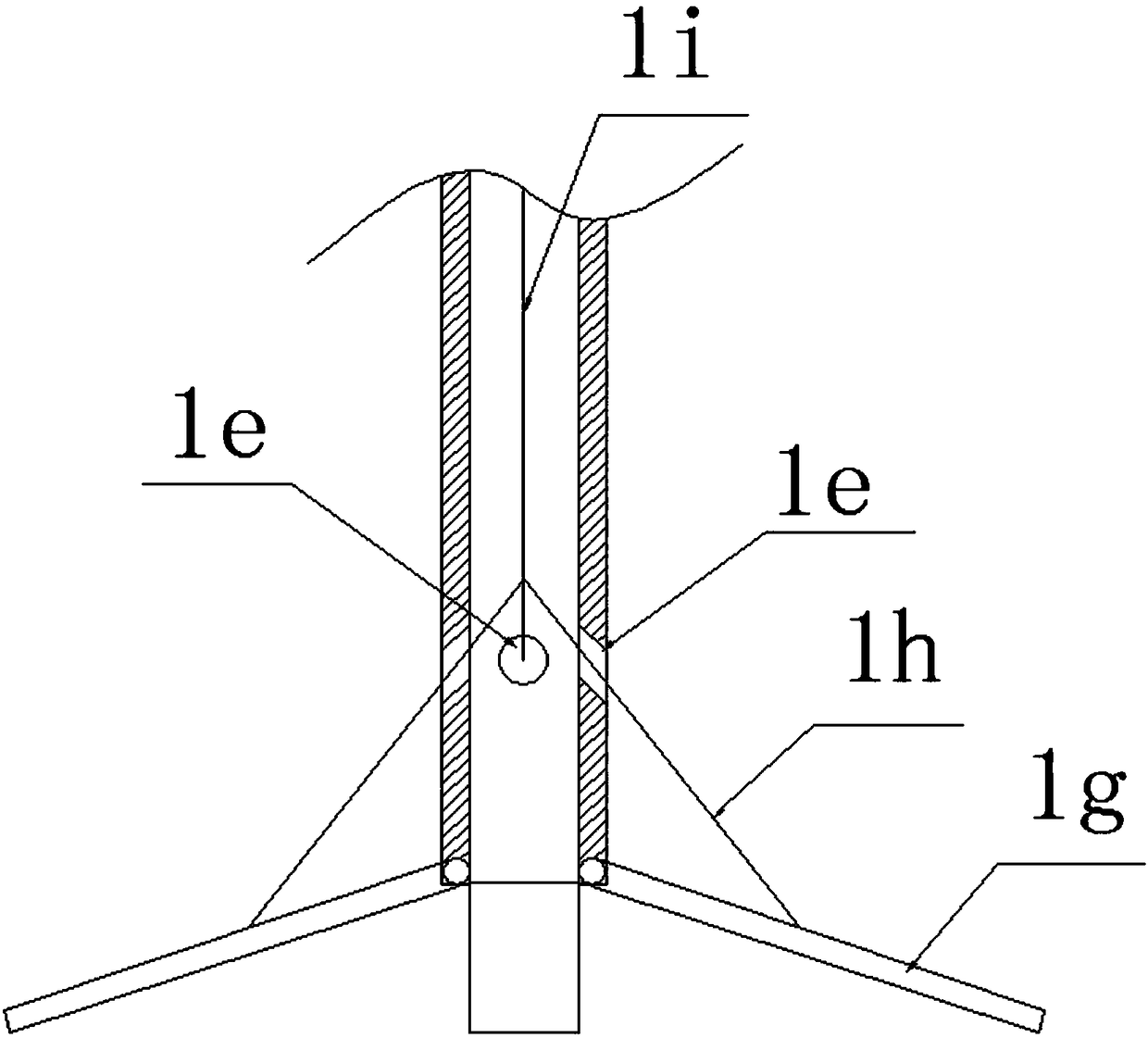

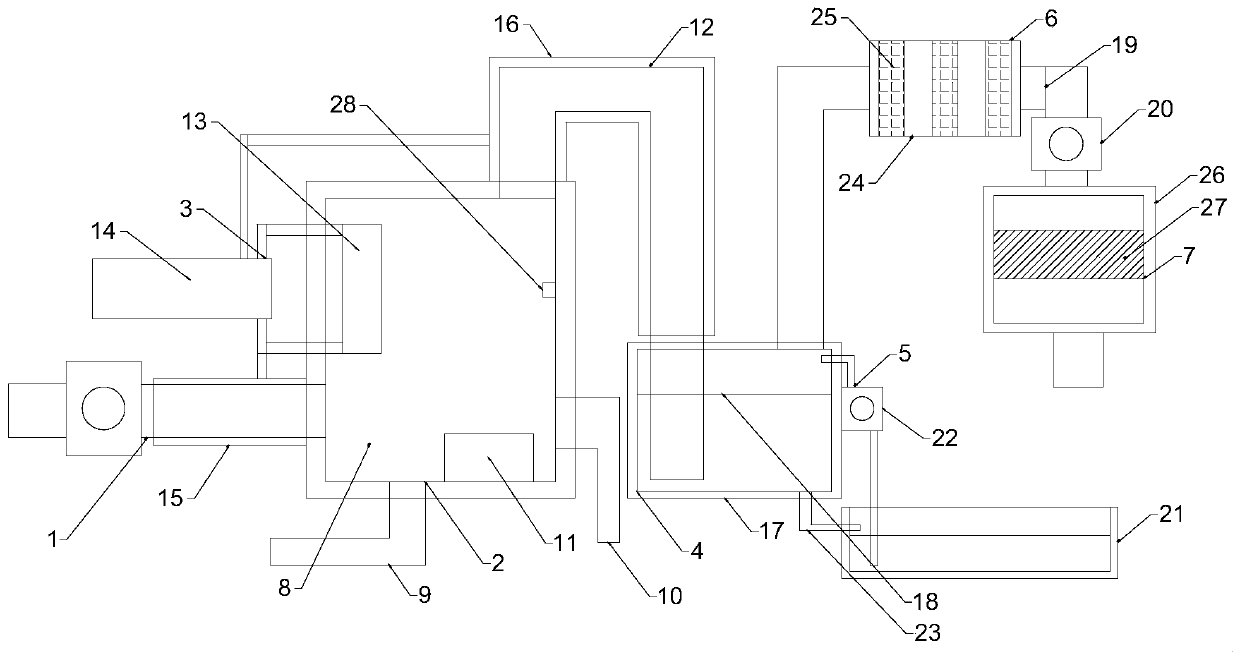

Pyrolytic process and device capable of directly transforming straws into petrol and diesel

InactiveCN102031131AIncrease moisture contentLow calorific valueBiofuelsWaste based fuelInternal combustion engineBiochar

The invention relates to pyrolytic process and device capable of directly transforming straws into petrol and diesel. The core process of the invention adopts a certain proportion of waste plastics as an additive to assist the pyrolysis of the crop straws, which efficiently reduces the pyrolytic temperature, and enhances the quality of pyrolysis oil (same with the quality of petrol and diesel). The invention relates to a novel pyrolytic system which adopts a self-heating efficient air-solid separation and direct condensation technology, can completely transform biomass materials into the high-quality biomass petrol and diesel (the productivity of which is about 50%). The biomass petrol and the biomass diesel can be directly used on a combustion motor for burning, and can efficiently reduce the motor vehicle exhaust. Biochar (the output of which is about 30%) obtained after the pyrolysis and combustible gases (the output of which is about 20%) can be used as heat sources for the pyrolysis, and the rest part can be used for combustion and electricity generation, and can be merged into commercial power grids to obtain extra economic benefits.

Owner:HENAN ZHONGBU NEW ENERGY

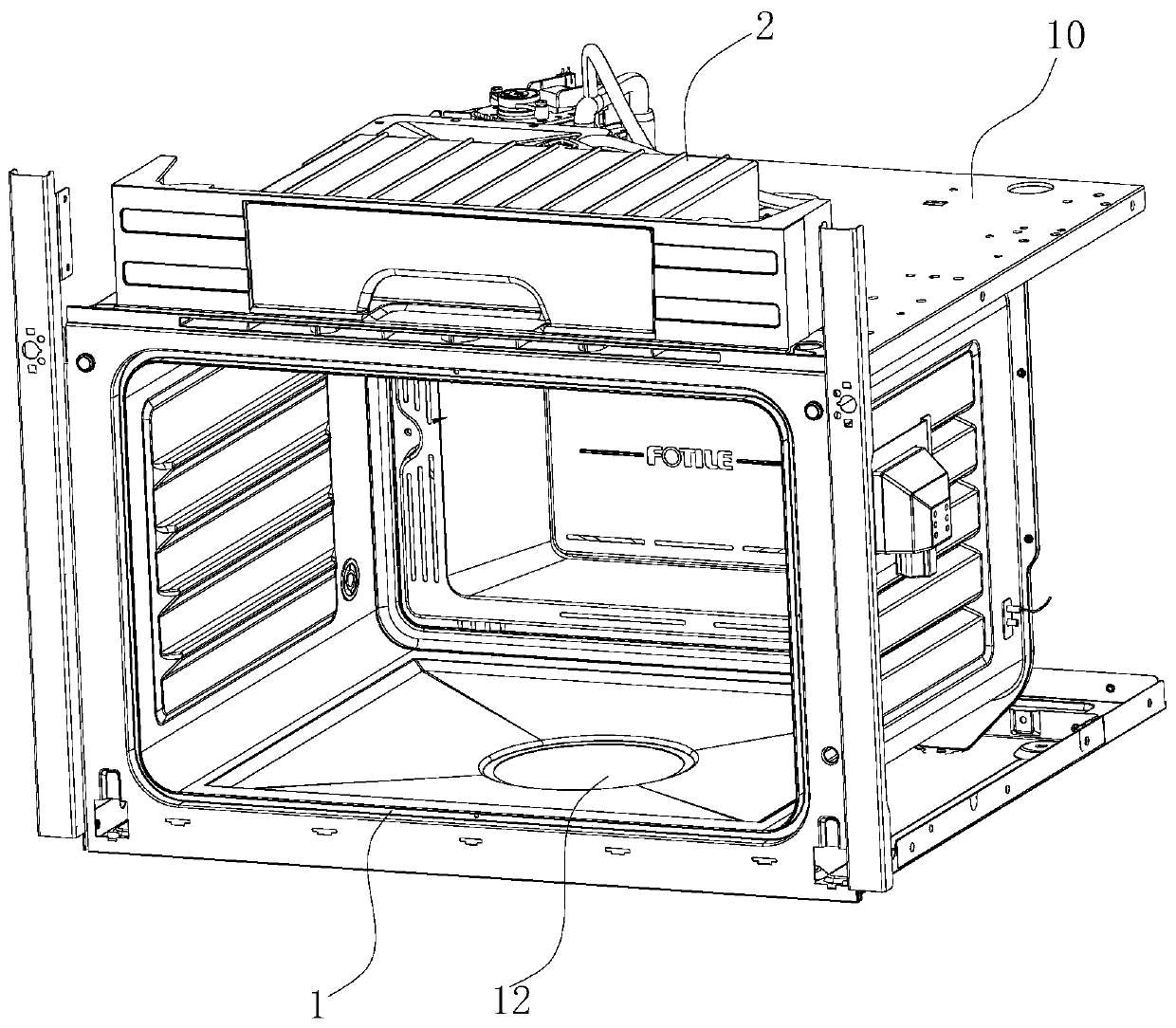

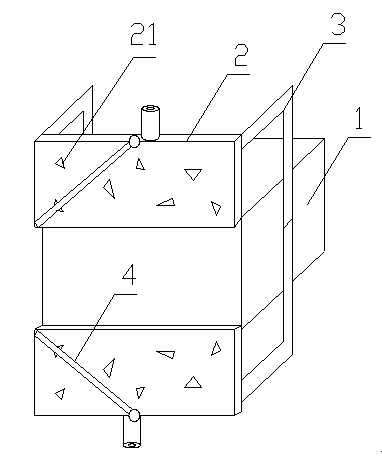

Steam low-displacement steam box

ActiveCN111557587AAchieve condensationShorten warm-up timeSteam cooking vesselsThermodynamicsInlet valve

The invention relates to a low-displacement steam box. The low-displacement steam box comprises an inner container, a water tank and an exhaust channel, and an exhaust port and a water inlet are formed in the side wall of the inner container. The water tank is provided with a water outlet connector and a water return connector. The low-displacement steam box also comprises a water inlet pipeline and an exhaust pipeline. The water inlet pipeline and the exhaust pipeline are adjacent to each other. One end of the water inlet pipeline is communicated with the water outlet interface. The other endof the exhaust pipeline is provided with a first water inlet branch and a second water inlet branch, a water inlet valve is arranged on the first water inlet branch, a water return valve is arrangedon the second water inlet branch, one end of the exhaust pipeline is communicated with the water return connector, the other end of the exhaust pipeline is communicated with an air inlet of the exhaust channel, and water in the water inlet pipeline can exchange heat with steam in the exhaust pipeline. Compared with the prior art, the amount of discharged steam can be reduced, the use experience ofa user is improved, meanwhile, the water in the water inlet pipeline can be preheated through the steam, and therefore the preheating time of the steam box is shortened, the time for heating water through a heating disc to generate steam is shortened, and the energy consumption of the steam box is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

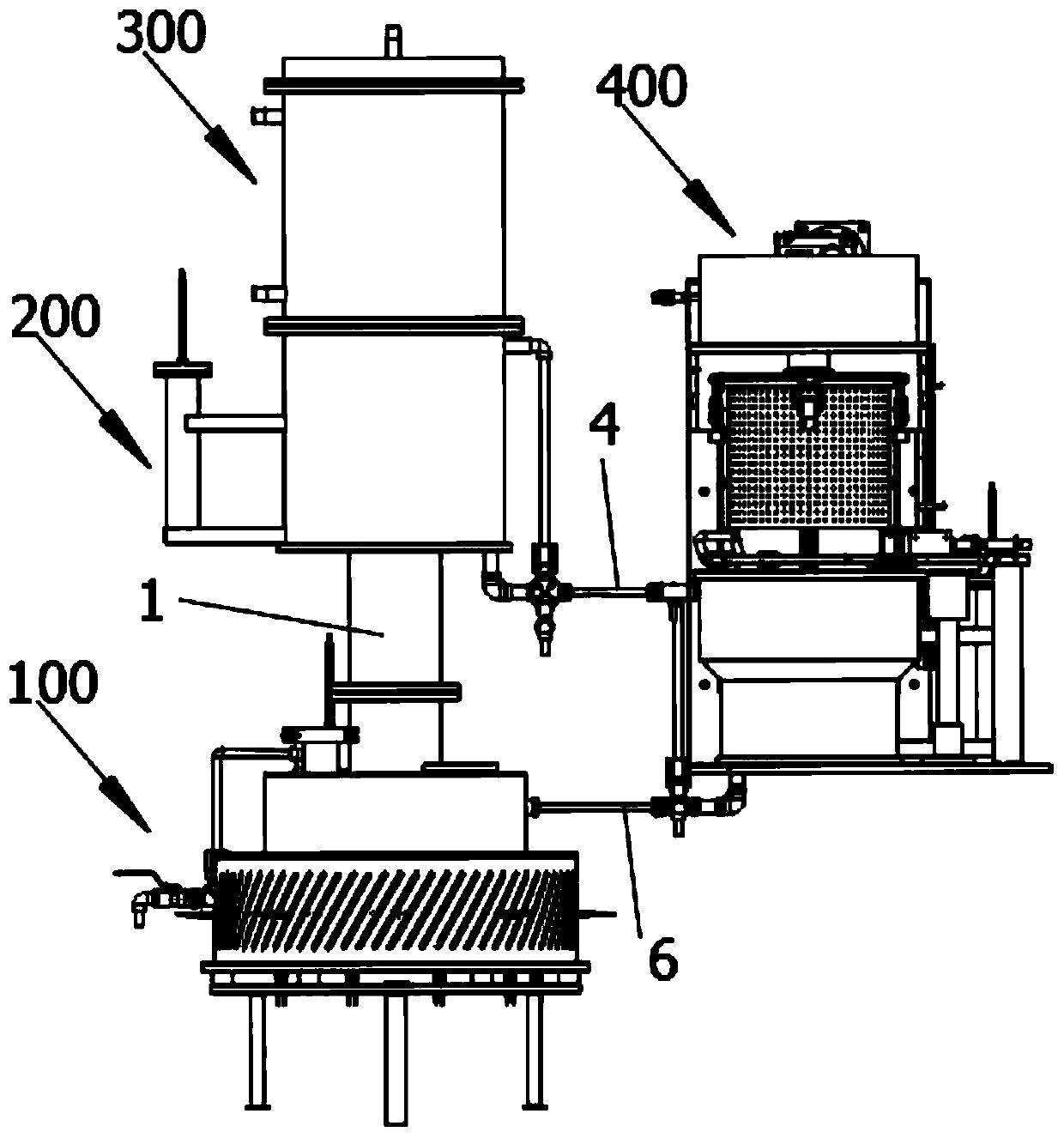

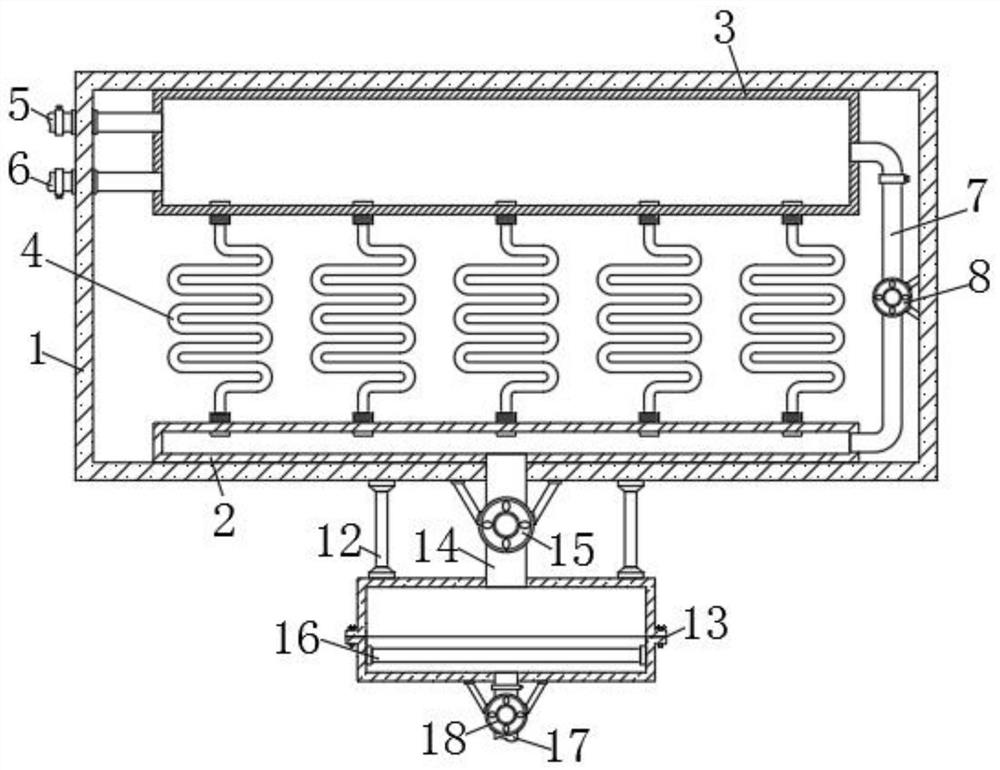

Rapid distillation equipment for rose essential oil extraction

InactiveCN111763571AImprove extraction efficiencyGuaranteed condensation effectEssential-oils/perfumesThermodynamicsProcess engineering

The invention discloses rapid distillation equipment for rose essential oil extraction, and belongs to the technical field of rose essential oil extraction. The rapid distillation equipment comprisesa distillation retort, wherein the lower surface of the distillation retort is fixedly connected with the upper surface of a cleaning box through a support, and the left and right side surfaces of thecleaning box are fixedly connected with the opposite surfaces of a steam generator and a storage box respectively. According to the rapid distillation equipment for rose essential oil extraction, thedistillation retort, a condensing coil, a semiconductor chilling plate and oil-water separation equipment are arranged; liquid formed by mixing water and a solution enters the condensing coil througha first air guide pipe; then the internal temperature of the condensing coil is kept low under the action of the semiconductor chilling plate; residual steam is condensed, then the condensed liquid enters the oil-water separation equipment, the mode that the residual steam can be further condensed is not affected by the external environment temperature, the condensation effect and speed are guaranteed, the oil extraction efficiency is relatively improved, and the preparation time is saved to a certain degree.

Owner:湖北瑞晟生物有限责任公司

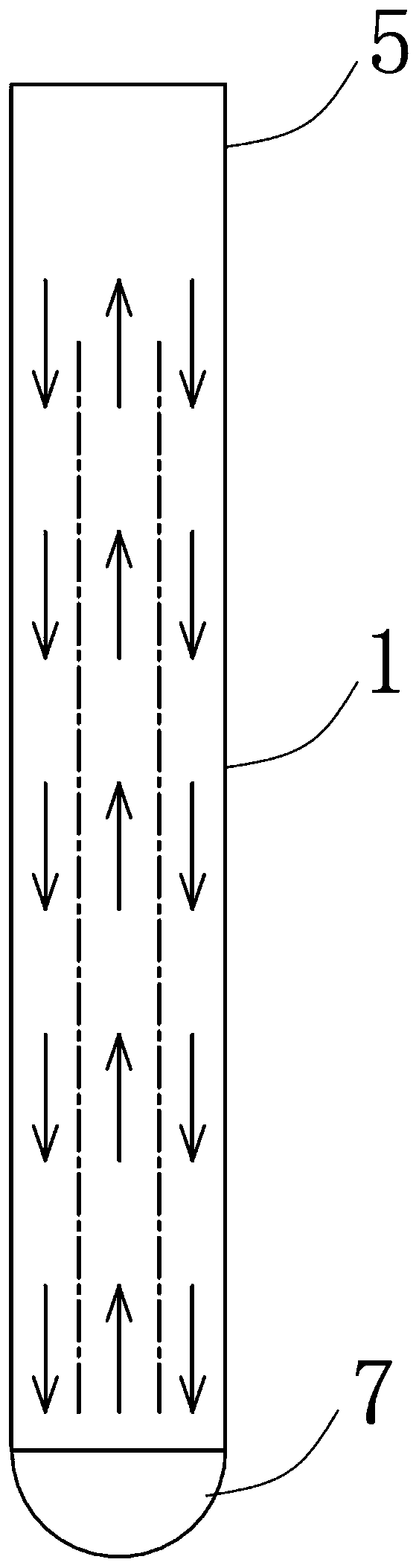

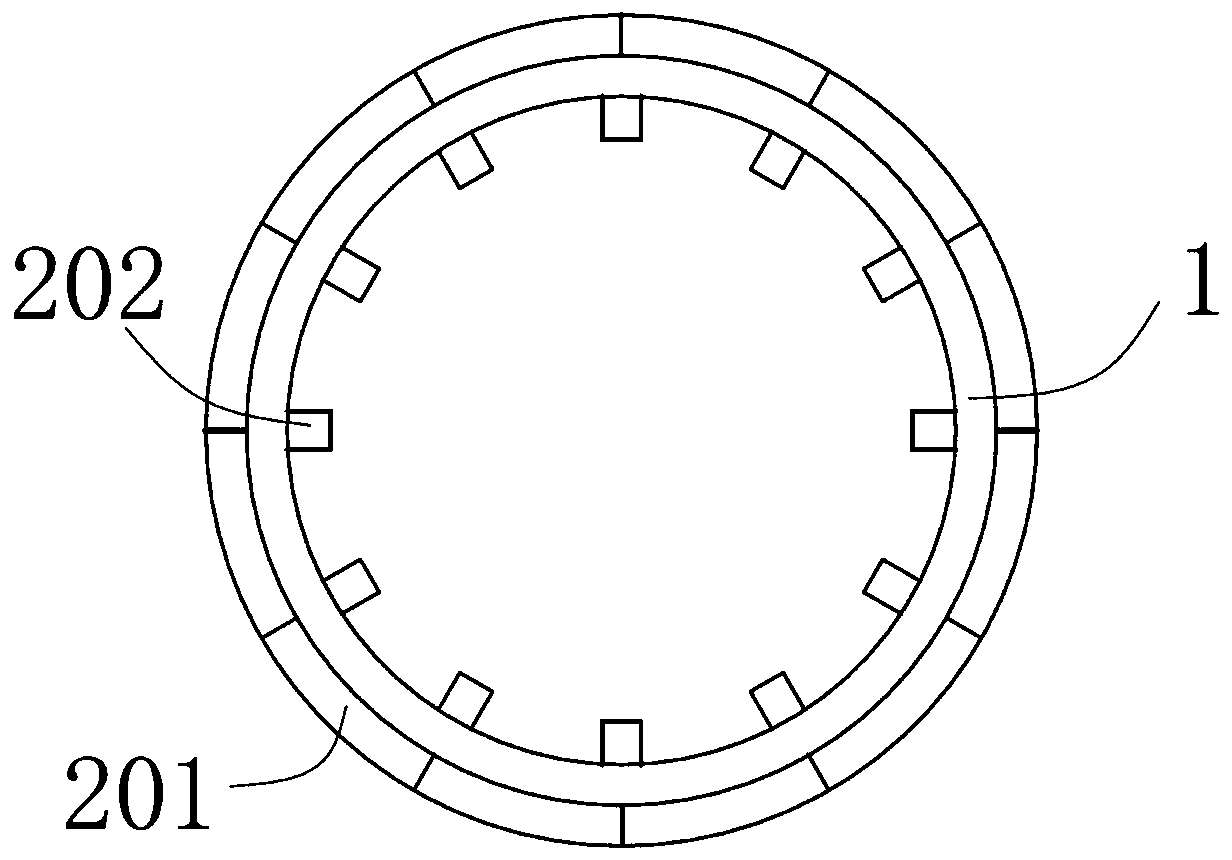

In-situ geothermal power generation system

PendingCN111207047AReduce lossImprove power generation efficiencyGeothermal energy generationMachines/enginesThermodynamicsMechanical engineering

The invention provides an in-situ geothermal power generation system. The system comprises a heat pipe, a thermoelectric temperature difference power generation device and a magnetic levitation powergeneration device. The upper end of the heat pipe extends to the earth's surface or a water body. The lower end of the heat pipe is located at a geothermal source. A circulating cavity is formed in the heat pipe. A circulating working medium is arranged in the circulating cavity. The thermoelectric temperature difference power generation device is located at the lower end of the heat pipe. The magnetic levitation power generation device is located in the middle of the heat pipe. The thermoelectric temperature difference power generation device and the magnetic levitation power generation device output electric energy outwards through electric energy output ports correspondingly. According to the system provided by the invention, the heat pipe is directly buried deep underground, the heat pipe is located at the geothermal source, on the one hand, the thermoelectric temperature difference power generation device located on the lower segment of the heat pipe can directly convert geothermal energy into electric energy, on the other hand, a formed upward gaseous working medium drives the magnetic levitation power generation device in the middle of the heat pipe when the circulating working medium becomes the gaseous working medium during phase changing, geothermal energy is converted into mechanical energy which is then converted into electric energy, and the system has the advantages of geothermal in-situ power generation, low energy loss, high power generation efficiency and the like.

Owner:SHENZHEN UNIV +2

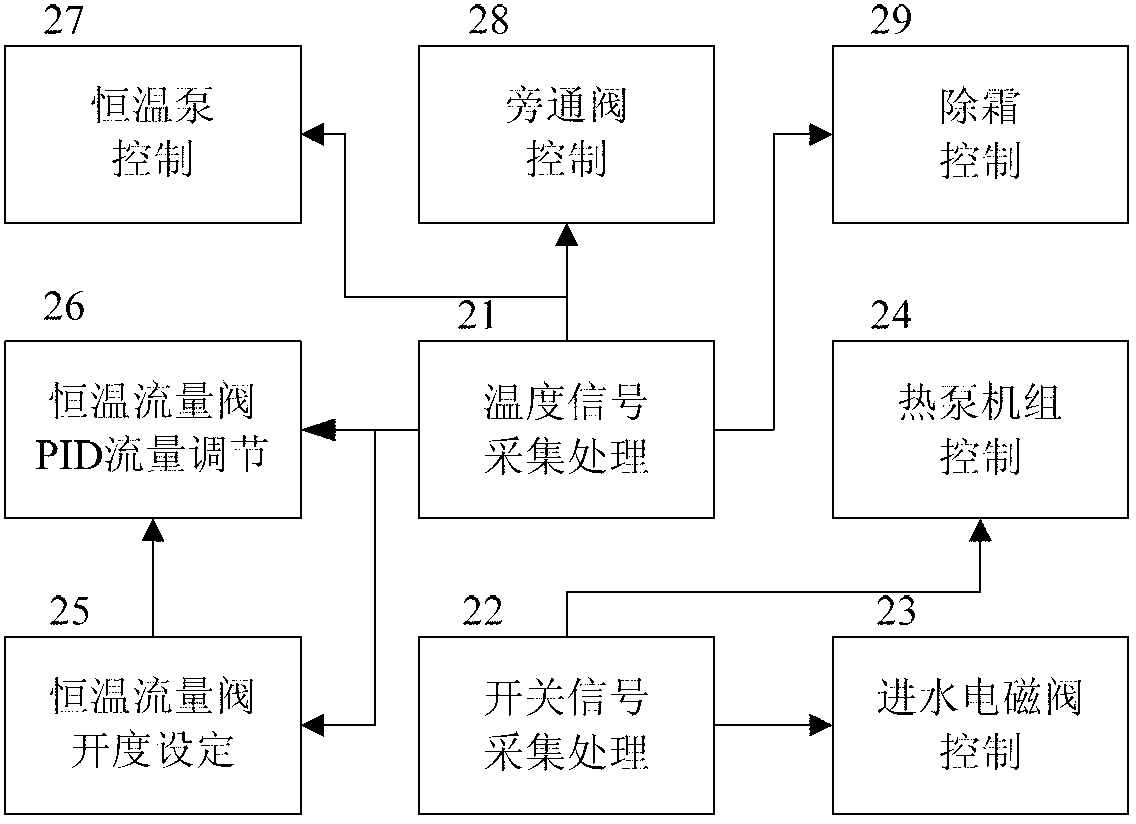

Thermostatic flow regulating device of single-heating type heat-pump water heating unit and control method of thermostatic flow regulating device

The invention discloses a thermostatic flow regulating device of a single-heating type heat-pump water heating unit and a control method of the thermostatic flow regulating device, relates to a control device for utilizing a fluid heater of a heat pump, in particular to a thermostatic flow regulating device for a dual-system single-heating type heat-pump water heating unit and a control method of the thermostatic flow regulating device. The thermostatic flow regulating device comprises a single chip microcomputer control unit, a temperature-sensing element, a switching signal element and a control signal output driving unit. The single chip microcomputer control unit is connected to a compressor, a water inlet electromagnetic valve, a thermostatic flow valve, a by-pass valve and a thermostatic water pump of the dual-system single-heating type heat-pump water heating unit through the control signal output driving unit. An outlet temperature set value is taken as a target value, opening of the thermostatic flow valve is controlled according to an outlet water temperature measured value, and water flow is regulated; when water tank temperature is low, the unit runs thermostatically; when inlet water temperature is over-high, the by-pass valve is turned on; when one of dual systems is faulted to stop running, outlet water set temperature is lowered so as to guarantee the other non-fault system to be capable of running efficiently, safely and stably.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

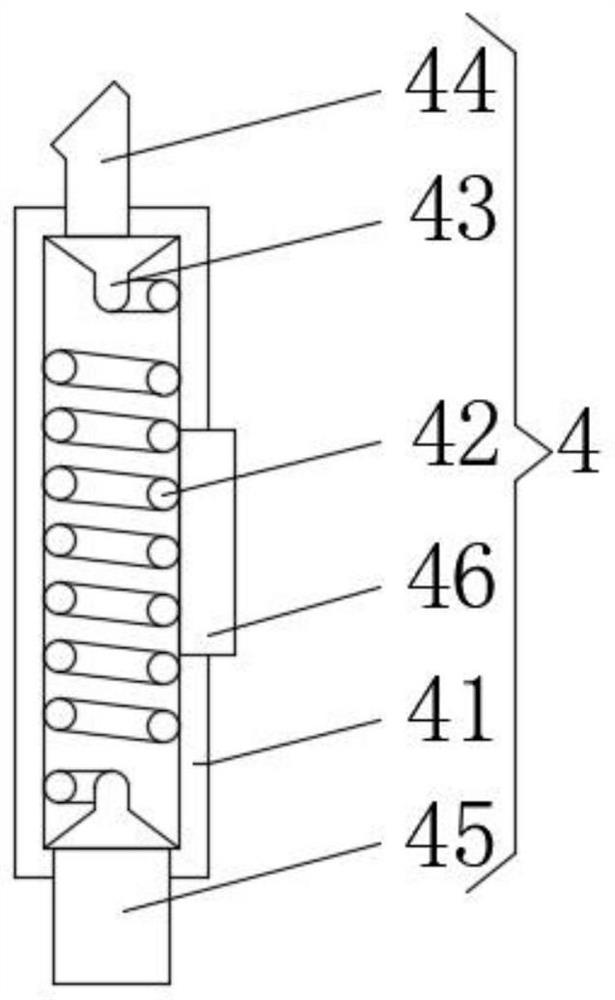

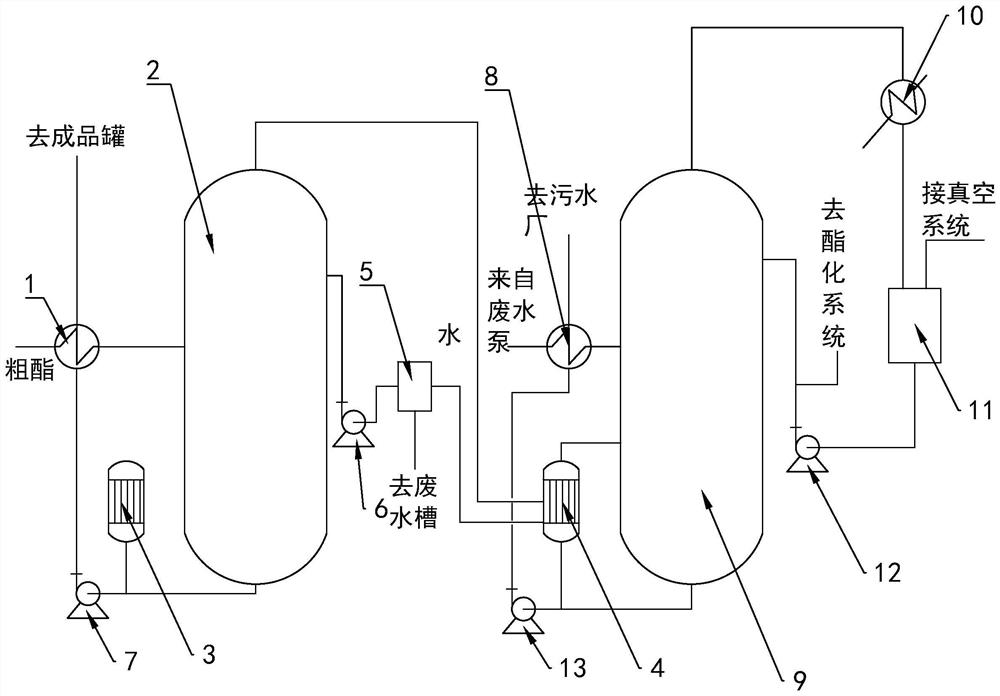

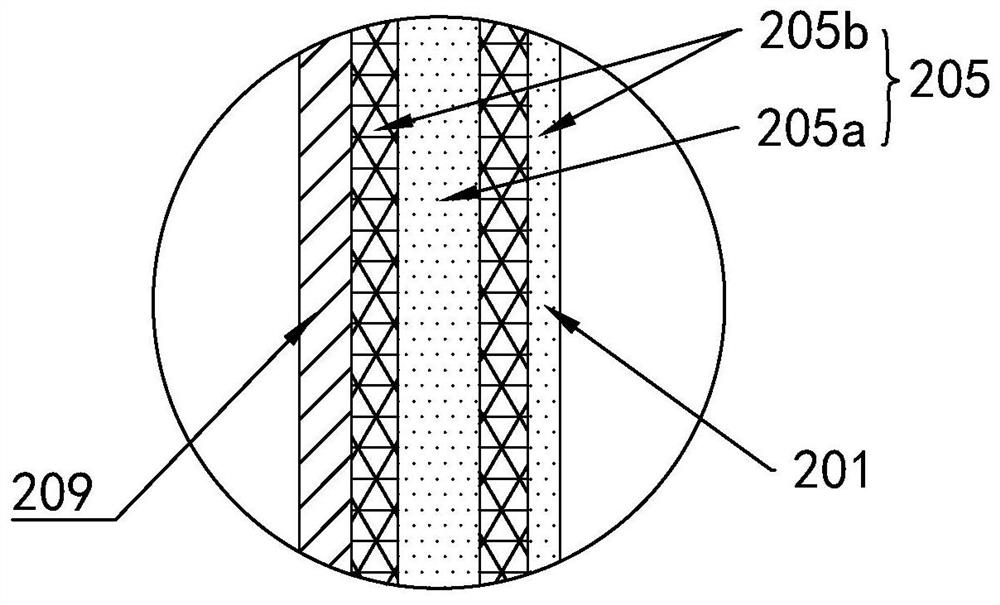

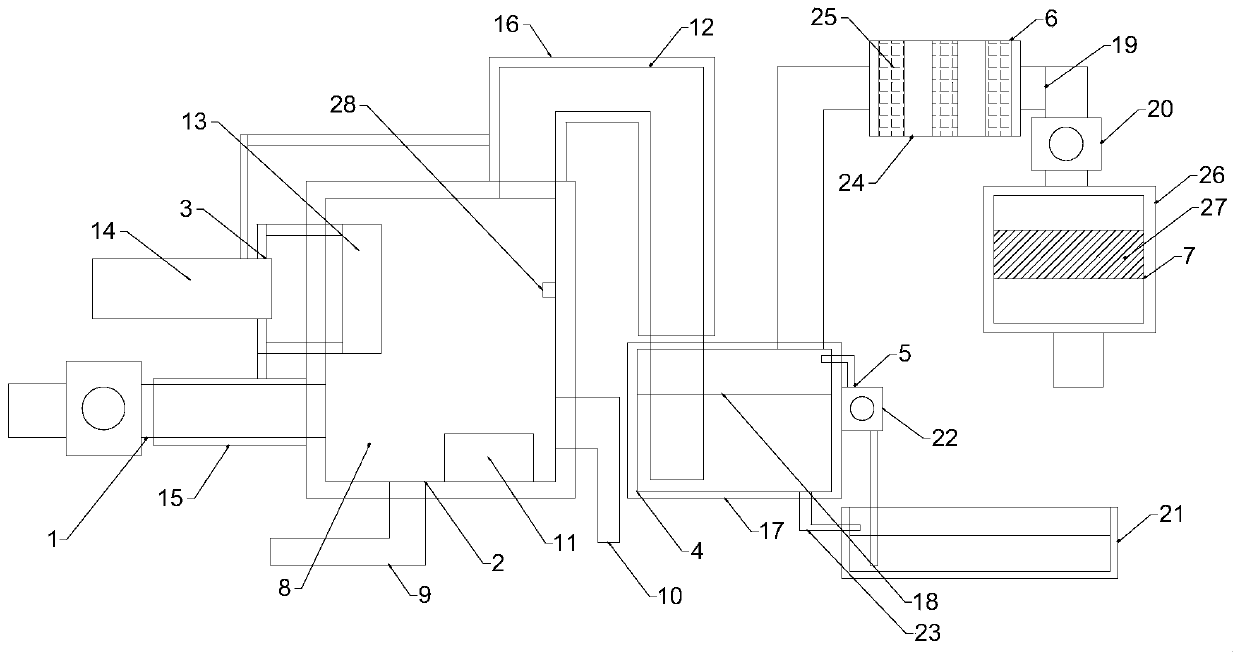

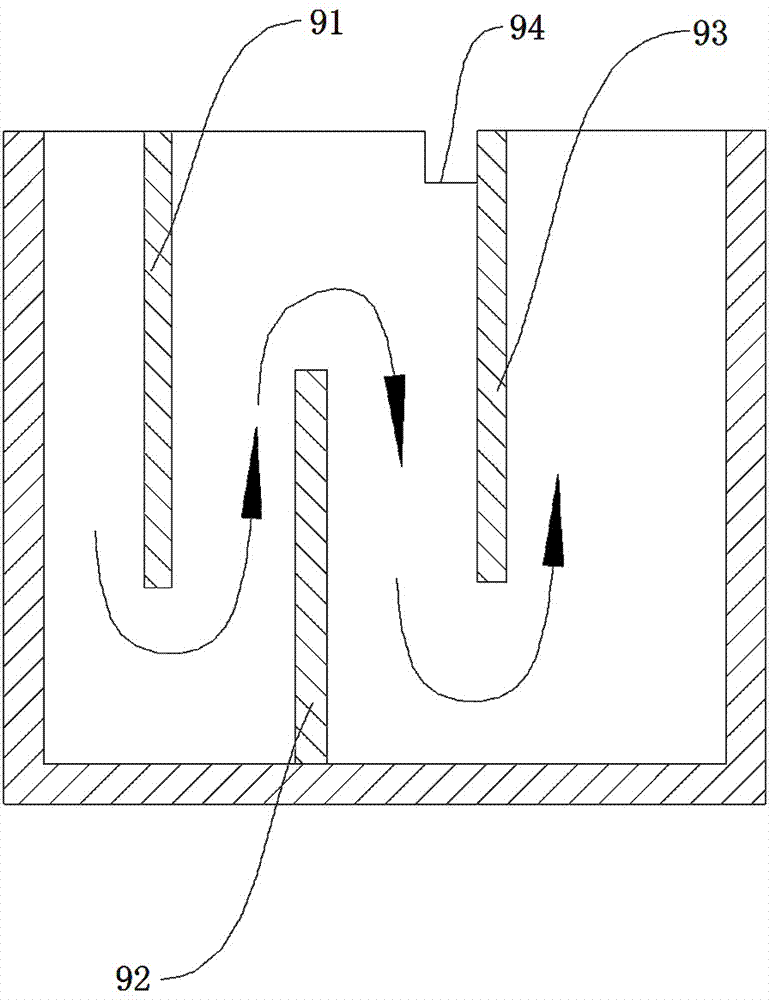

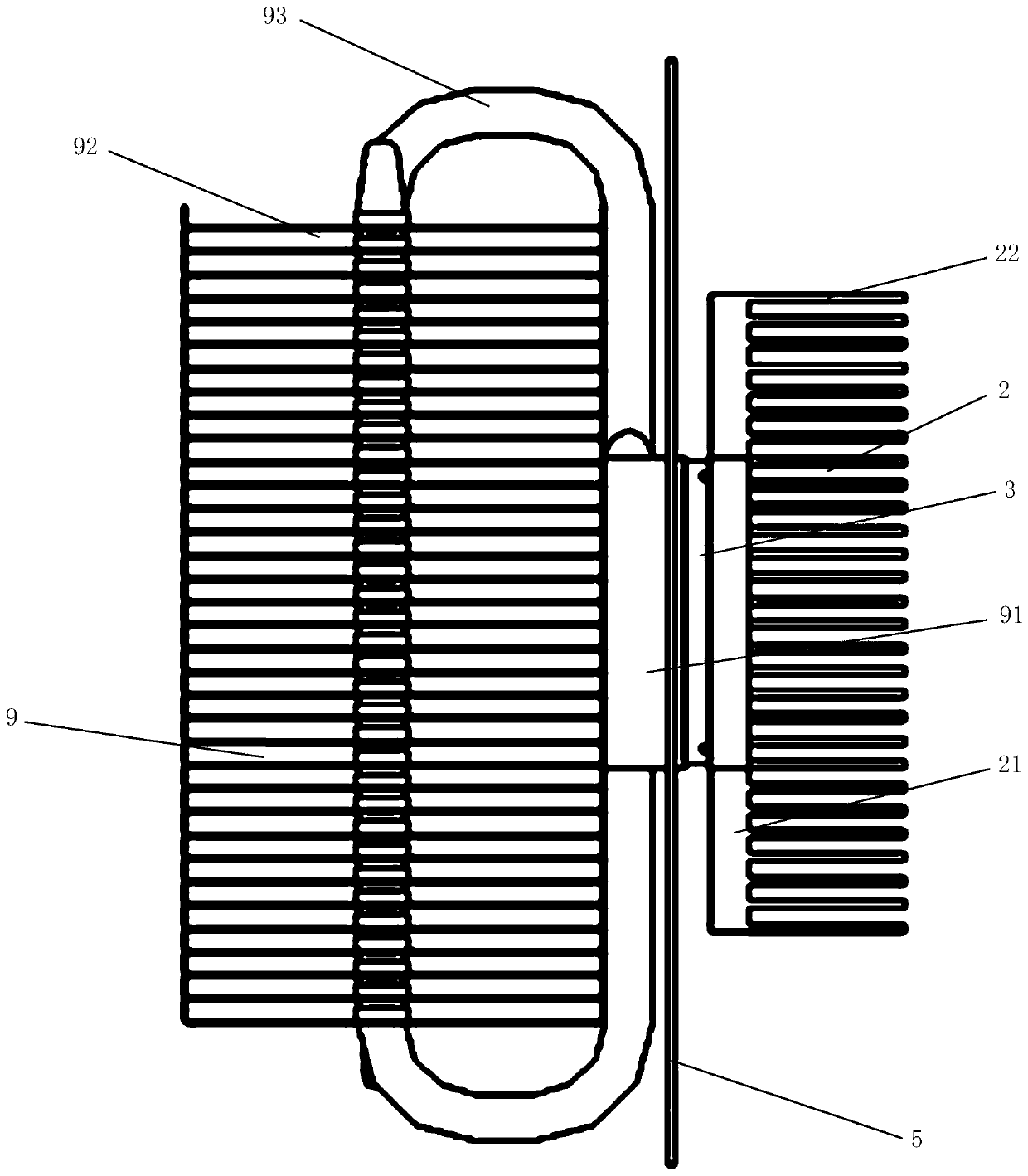

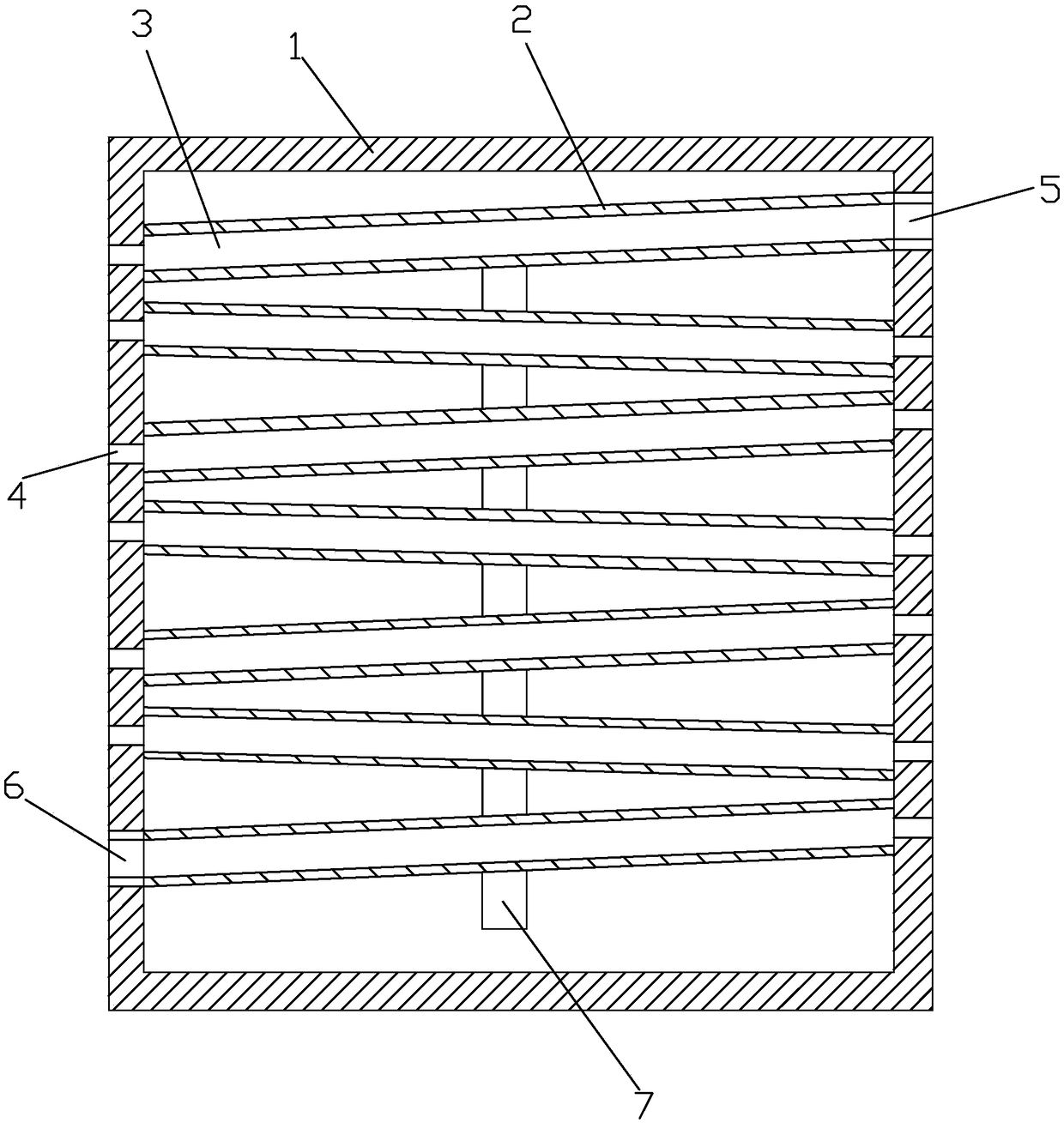

Resin production system

ActiveCN108079929AExtended condensation pathGuaranteed condensation effectChemical industryVapor condensationEnvironmental resistanceClosed loop

The invention provides a resin production system, comprising a polymerization reaction kettle, a vertical condenser, a horizontal condenser and a buffer recovery tank, wherein the polymerization reaction kettle is provided with a feeding hole and a gas outlet hole; the gas outlet hole is communicated with a tube pass entrance of the vertical condenser, a tube pass exit of the vertical condenser iscommunicated with a tube pass entrance of the horizontal condenser, a tube pass exit of the horizontal condenser is communicated with an inlet of the buffer recovery tank, and an outlet of the bufferrecovery tank is communicated with the gas outlet hole. The resin production system is provided with the vertical condenser and the horizontal condenser which are cooperatively used, thus guaranteeing the condensation effect of ethyl acetate gas; the buffer recovery tank is arranged, and the whole system is enabled to form a closed loop, so that the system is not limited by the high temperature vaporization of ethyl acetate, the cooling time is shortened, the system power consumption and energy consumption are reduced, the machine abrasion is reduced, and the production cost is further lowered; furthermore, part of the uncondensed ethyl acetate gas is recovered by means of the buffer recovery tank and is not discharged into the atmosphere, so that the pressure for environmental protectionis reduced.

Owner:四川普思瑞新材料有限公司

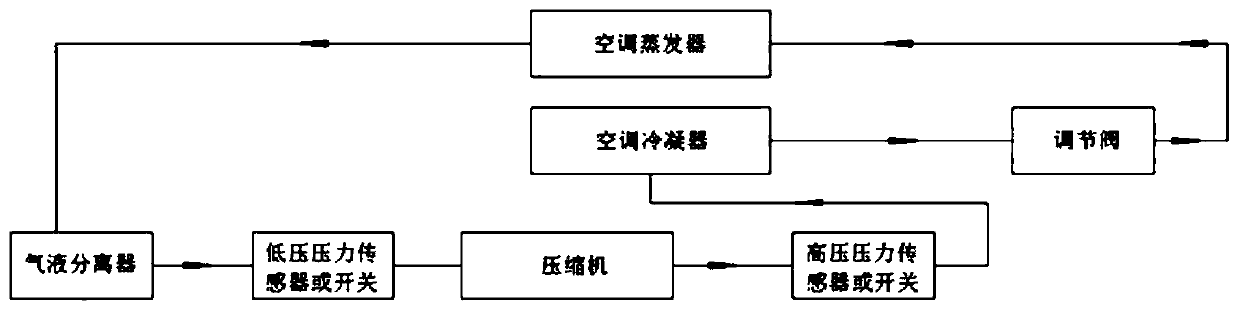

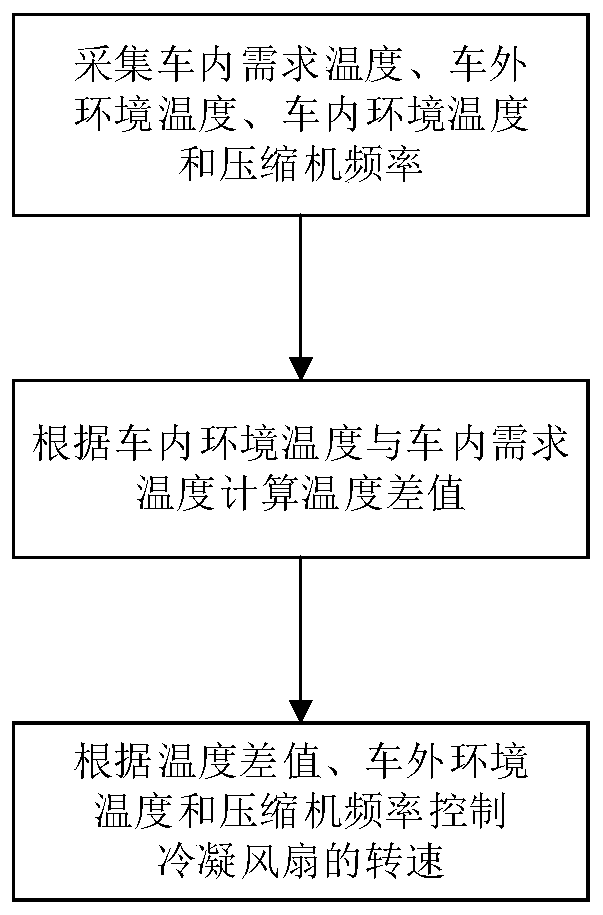

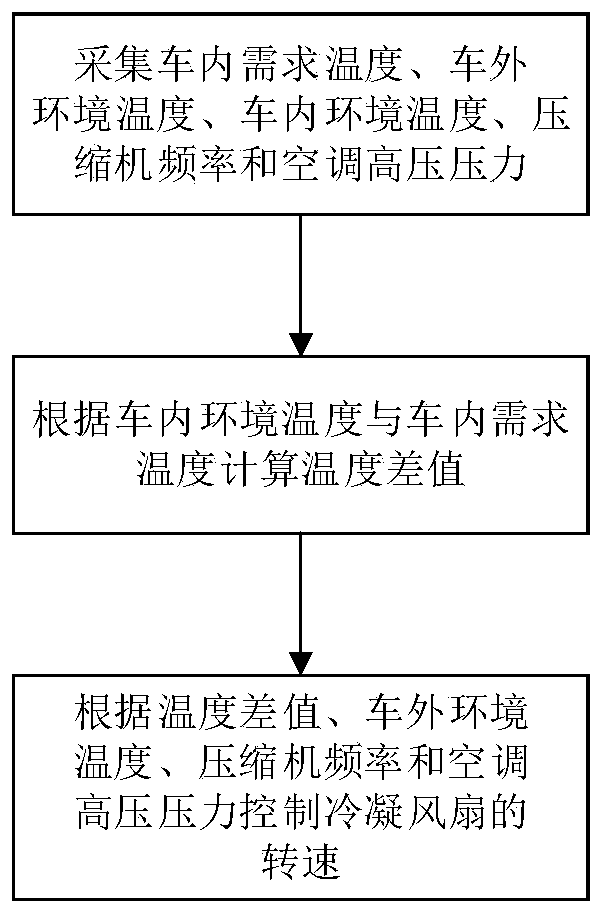

Method and device for calculating rotating speed of condenser fan in automotive air conditioning system

ActiveCN111486120AReduce operating energy consumptionIncreased operating lifeAir-treating devicesVehicle heating/cooling devicesThermodynamicsMechanical engineering

The invention relates to a method and device for calculating a rotating speed of a condenser fan in an automotive air conditioning system. The method comprises the following steps of collecting at least an inside required temperature, an outside environment temperature, an inside environment temperature and a compressor frequency; and calculating a temperature difference according to the inside environment temperature and the inside required temperature, and controlling the rotating speed of the condenser fan at least according to the temperature difference, the outside environment temperatureand the compressor frequency, wherein the rotating speed of the condenser fan is positively correlated with the temperature difference, the outside environment temperature and the compressor frequency. The invention adjusts the rotating speed of the condenser fan according to the compressor frequency. When the compressor frequency is high, the rotating speed of the condenser fan is increased correspondingly to ensure the condensing effect. When the compressor frequency is low, the rotating speed of the condenser fan is reduced accordingly to save the operating energy consumption of the condenser fan and increase the operating life of the condenser fan while ensuring the condensing effect. Since the working condition of the compressor is fully considered, the control reliability of the condensing effect is effectively improved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

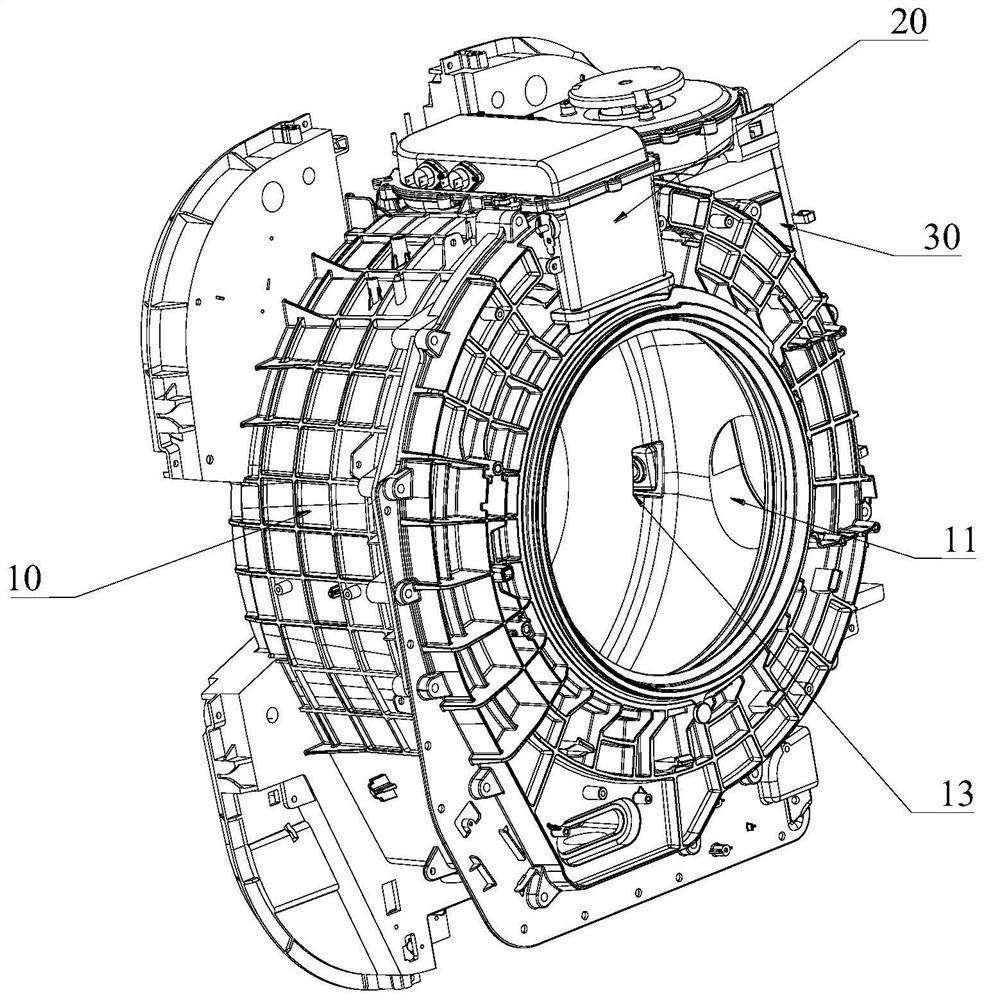

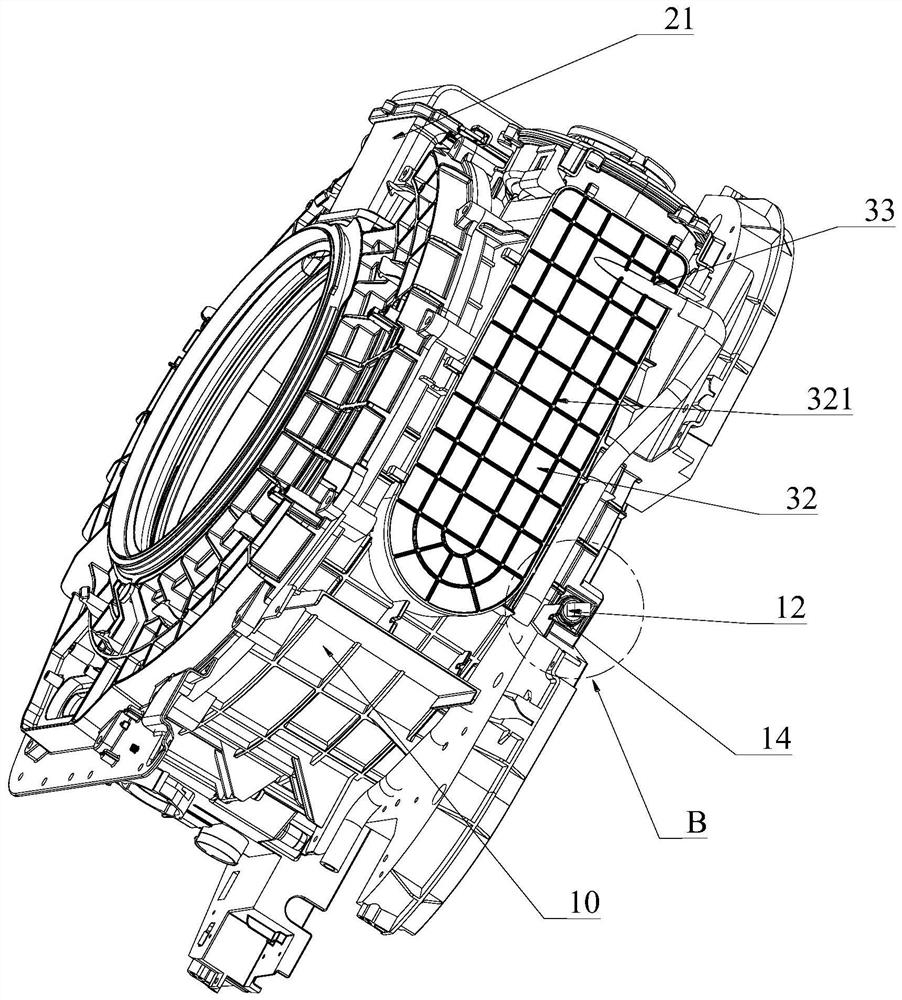

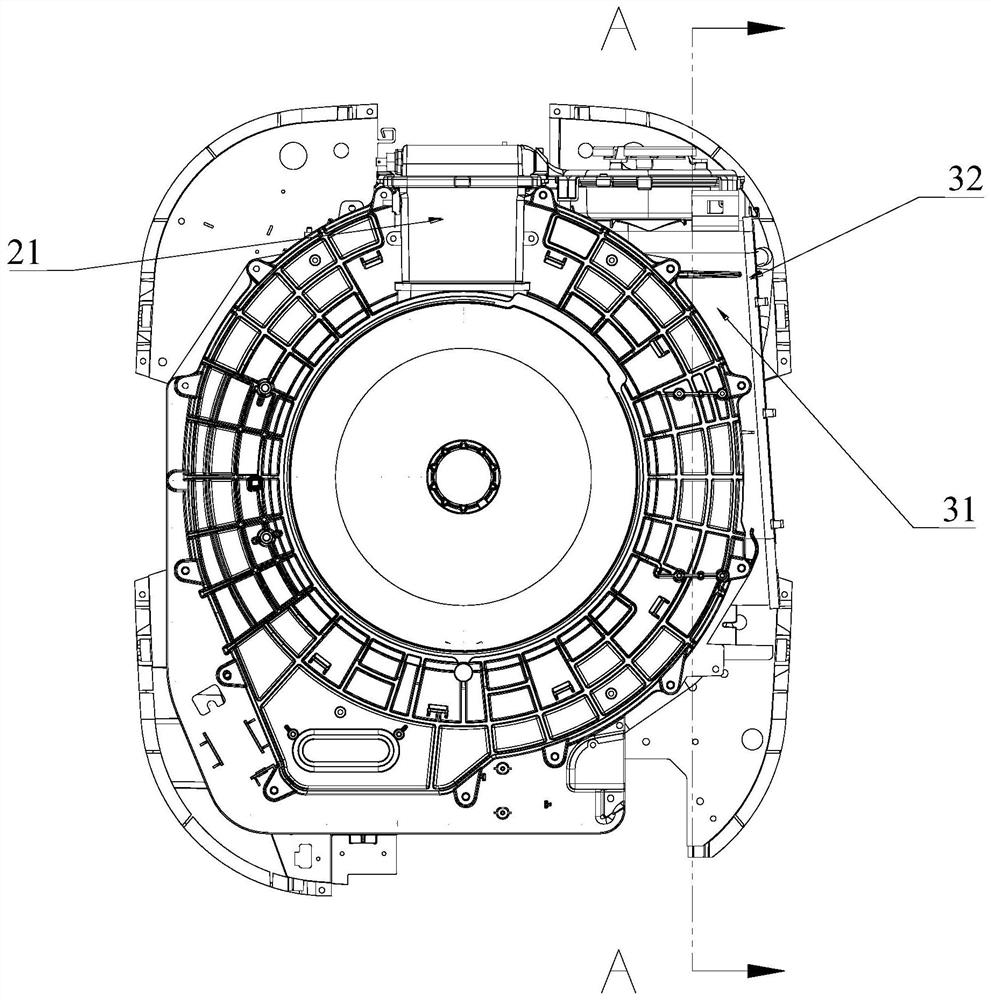

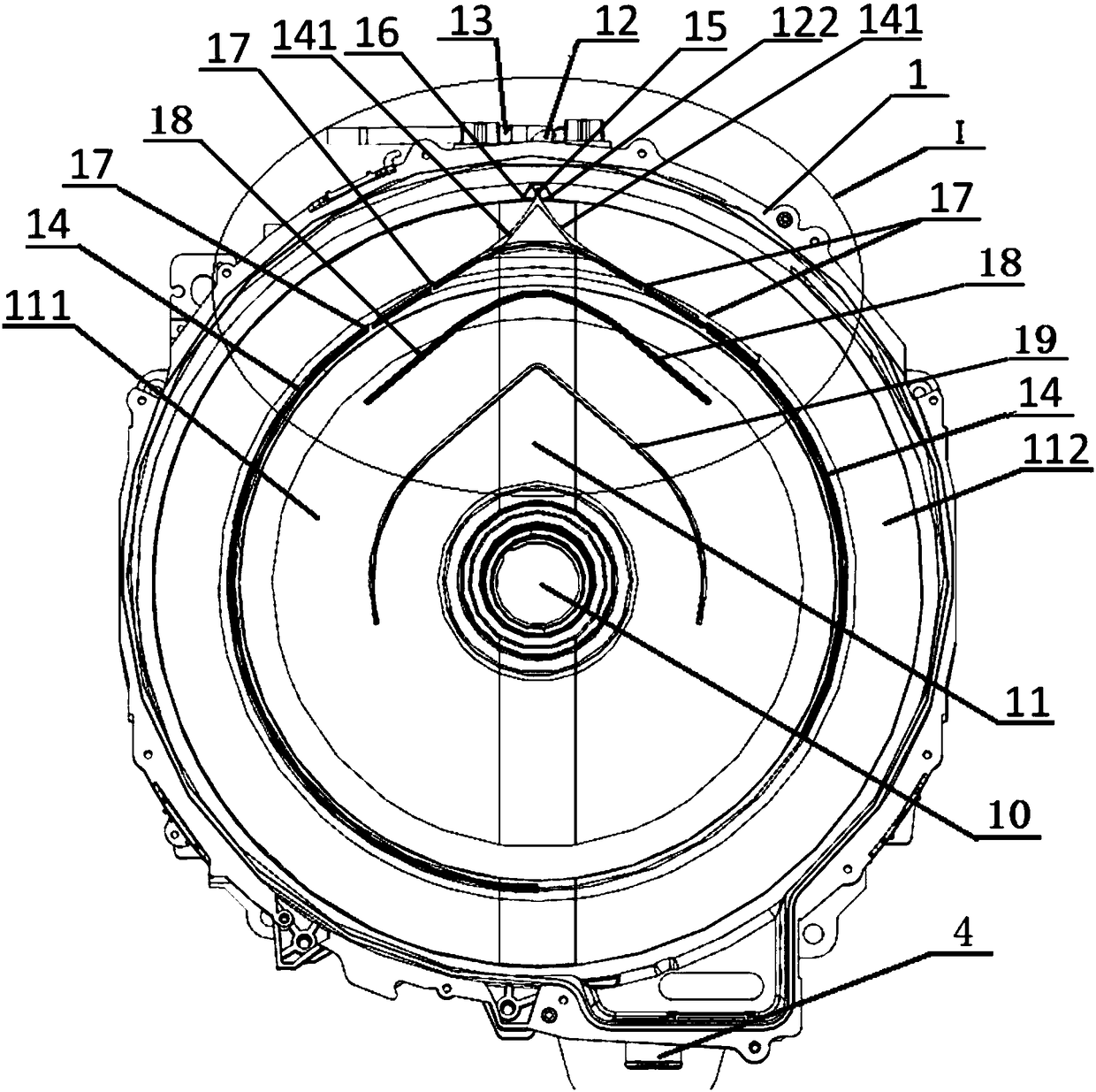

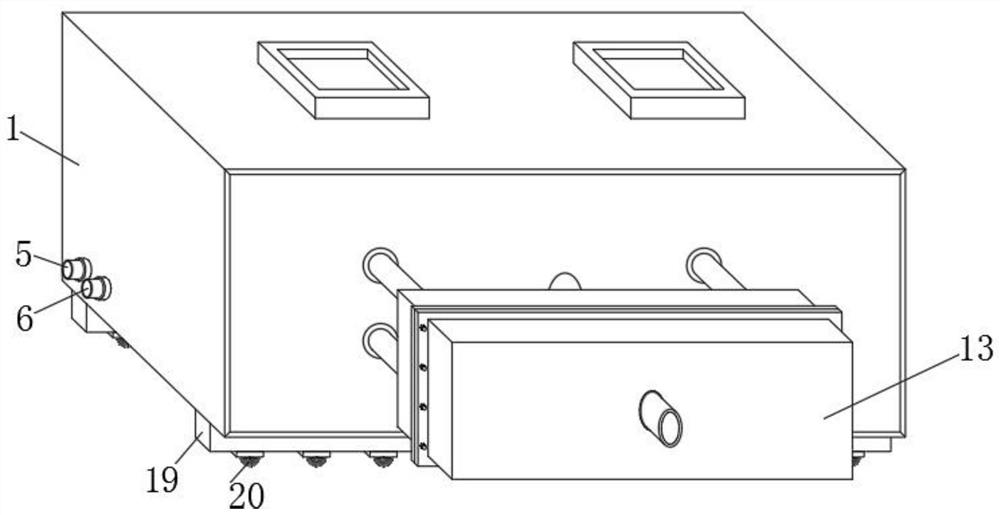

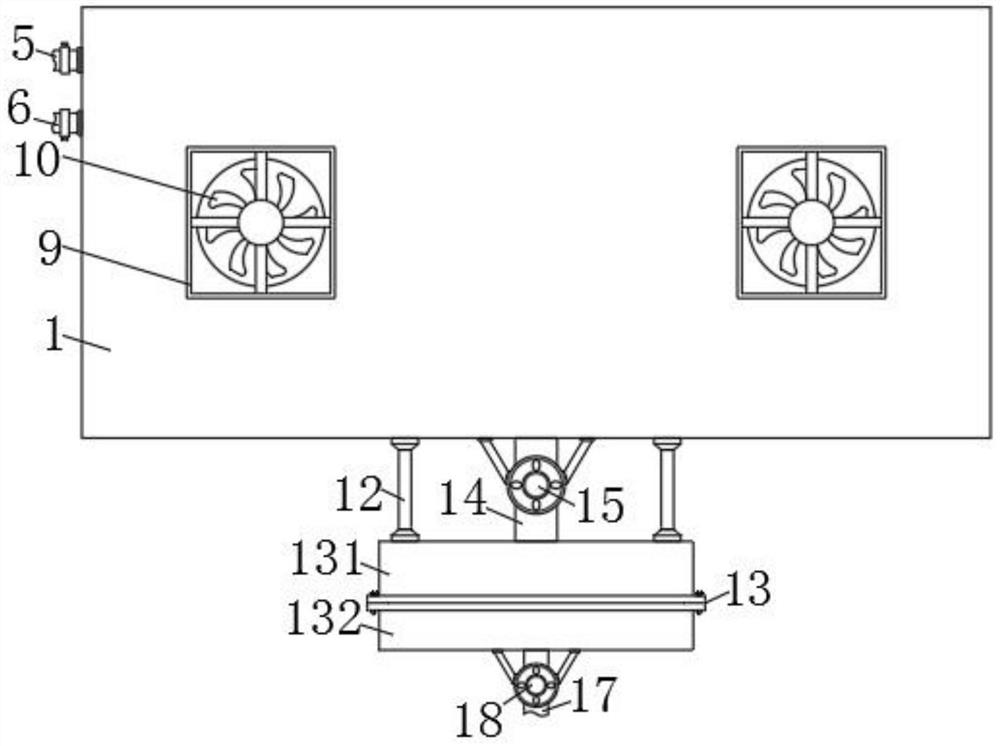

Clothes treatment equipment and control method thereof

PendingCN113265861AThe temperature is accurately knownGuaranteed condensation effectTextiles and paperLaundry driersTemperature controlProcess engineering

The invention discloses clothes treatment equipment and a control method thereof. The clothes treatment equipment comprises a clothes treatment barrel and a drying device; the clothes treatment barrel is provided with an air outlet; one end of the drying device communicates with the air outlet, and the other end of the drying device communicates with the interior of the clothes treatment barrel; a first temperature detection unit is arranged at the position, close to the air outlet, in the clothes treatment barrel; and a controller controls the flow of refrigerants in the drying device according to the temperature, detected by the first temperature detection unit, of the humid and hot air at the air outlet. The temperature detection unit for detecting the temperature of the humid and hot air is arranged at the air outlet, and the flow of the refrigerant can be adjusted according to the temperature of the humid and hot air, so that the drying parameters are more accurate, and the drying performance can be better controlled.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

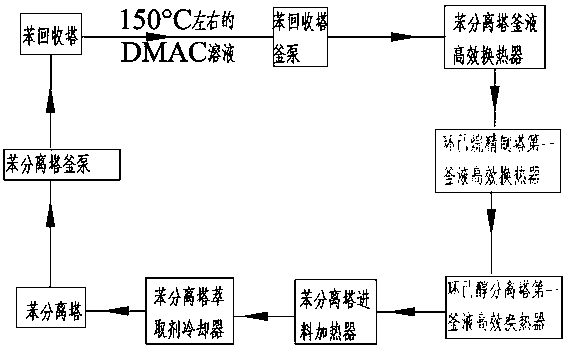

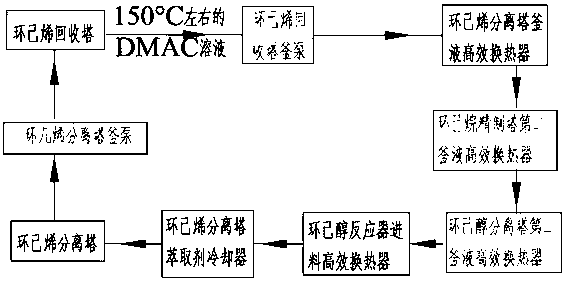

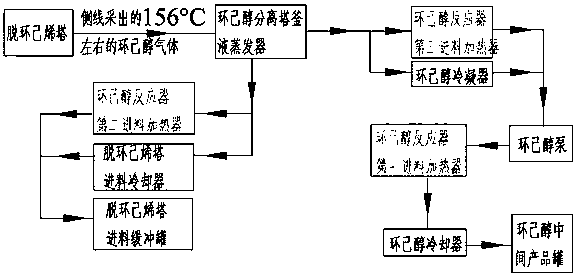

Novel heat energy utilization system and novel heat energy utilization method for cyclohexanol production

PendingCN108530264AReduce consumptionReduce usageChemical industryDistillation purification/separationProcess engineeringElectric energy

The invention discloses a novel heat energy utilization system and a novel heat energy utilization method for cyclohexanol production. The novel heat energy utilization system comprises a benzene recovery tower heat energy utilization unit, a cyclohexene recovery tower heat energy utilization unit, a cyclohexene removal tower heat energy utilization unit and a cyclohexane refining tower heat energy utilization unit. The novel heat energy utilization system and the novel heat energy utilization method for cyclohexanol production have the advantages that the process heat in the system can be utilized and recovered to the maximum limit, the consumption of boiler steam is reduced, simultaneously the usage amount of industrial circulating water is reduced, and the consumption of circulating water and the consumption of electric energy are reduced. The novel heat energy utilization system for cyclohexanol production has the characteristics that according to the level of the energy of each device for cyclohexanol production, reasonable heat recovery ways and heat exchange devices are designed, and energy saving and consumption reduction are realized to the maximum limit. By adopting the processes and the devices disclosed by the invention, the consumption of the steam for per ton of cyclohexanol can be reduced by 2.0-2.5 tons, the usage amount of the circulating water can be reduced by 200-250 tons, and the production cost can be reduced by 350-425 yuan / ton.

Owner:李洪震

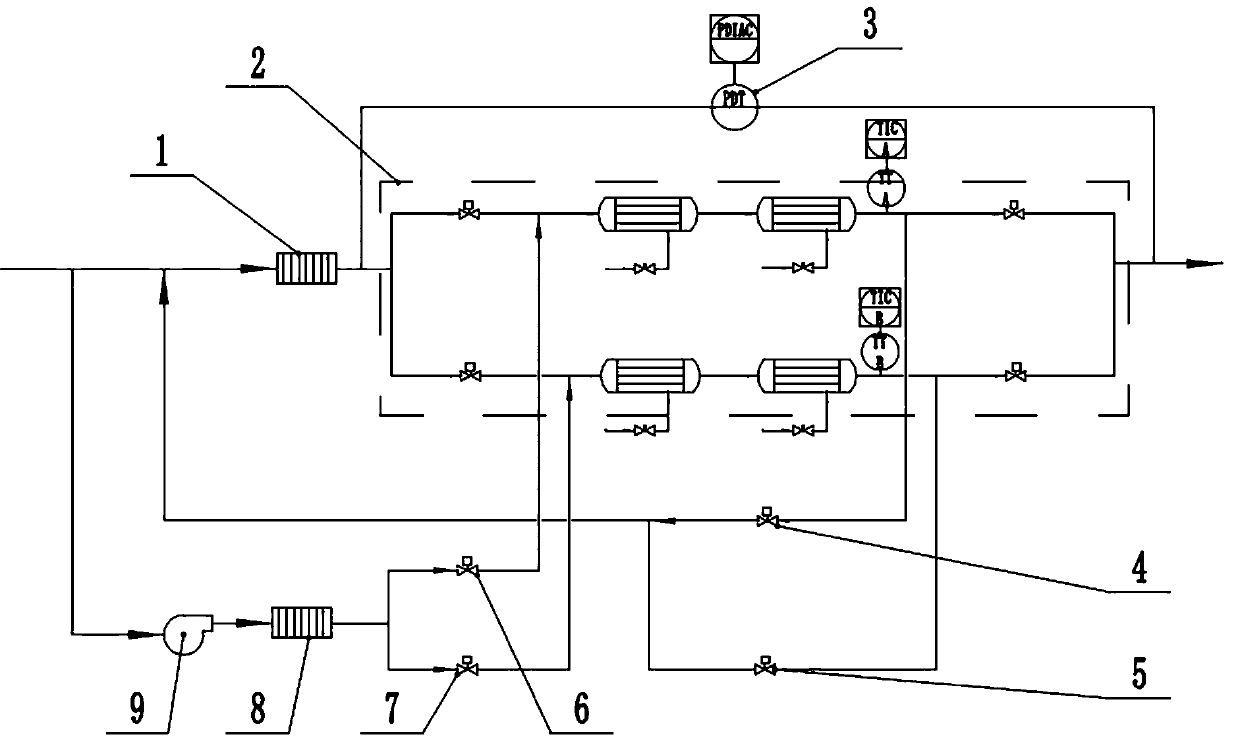

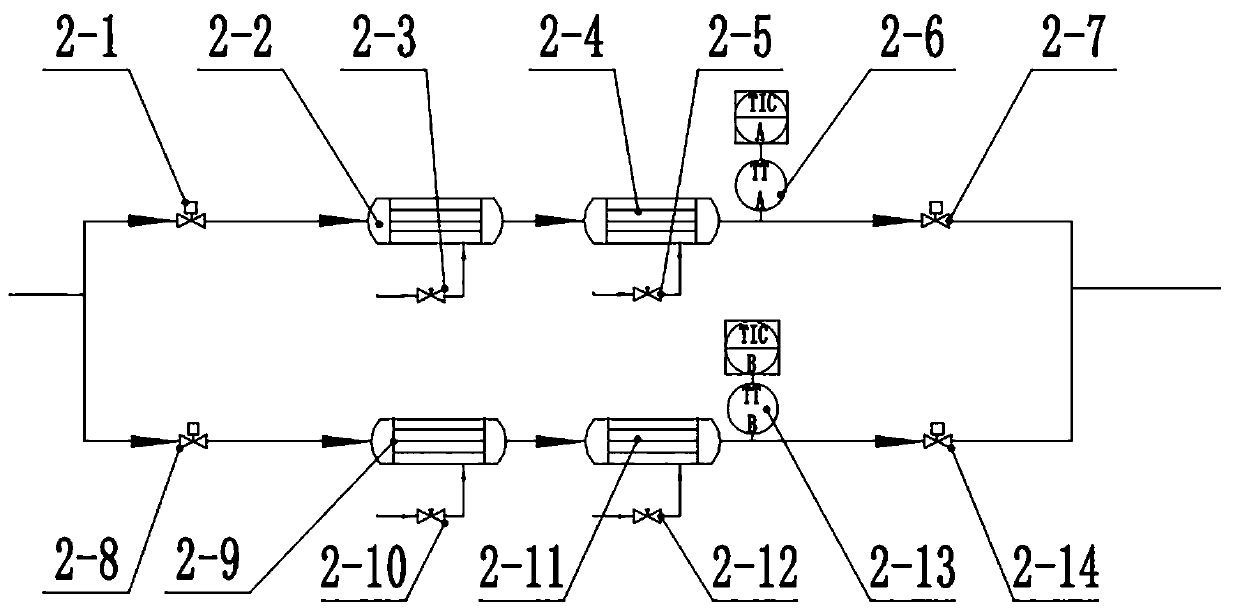

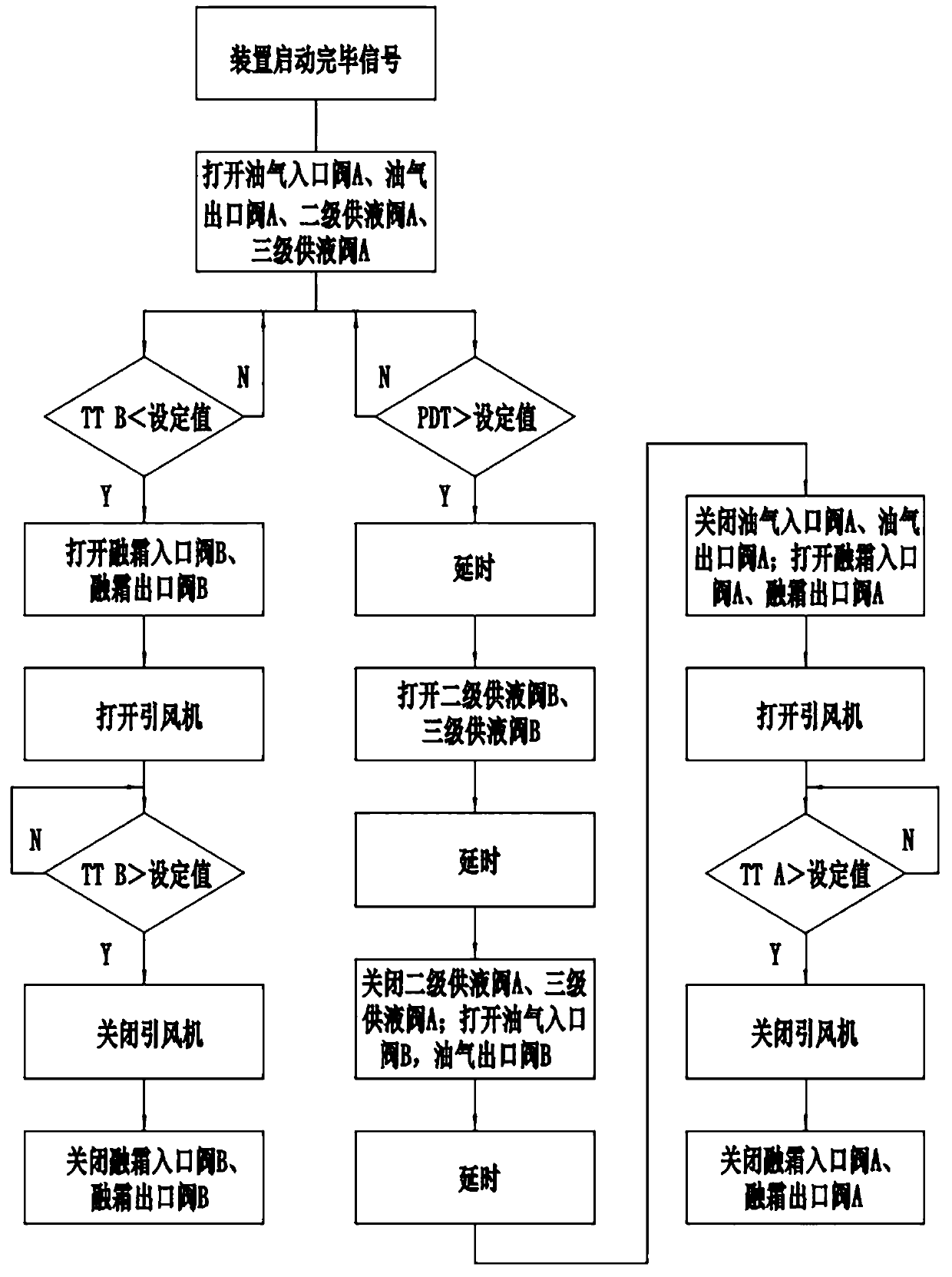

Oil gas defrosting system and method for condensation method oil-gas recovery device

ActiveCN111530117AFast defrostingEffective defrostingDispersed particle separationVapor condensationOutlet Port ValveInlet valve

The invention discloses an oil gas defrosting system and method for a condensation method oil gas recovery device. The oil gas recovery device comprises an oil gas inlet and an oil gas outlet and further comprises a heat exchange module installed between the oil gas inlet and the oil gas outlet and used for condensing oil gas, and the defrosting system comprises a heat exchange branch A and a heatexchange branch B which are arranged in the heat exchange module and connected in parallel. The oil gas defrosting system further comprises an induced draft fan, a heat exchanger, a defrosting inletvalve A, a defrosting inlet valve B, a defrosting outlet valve A and a defrosting outlet valve B. By means of branch switching, frosting of the heat exchanger is avoided, and normal operation of the recovery device is guaranteed.

Owner:山东冰轮海卓氢能技术研究院有限公司 +1

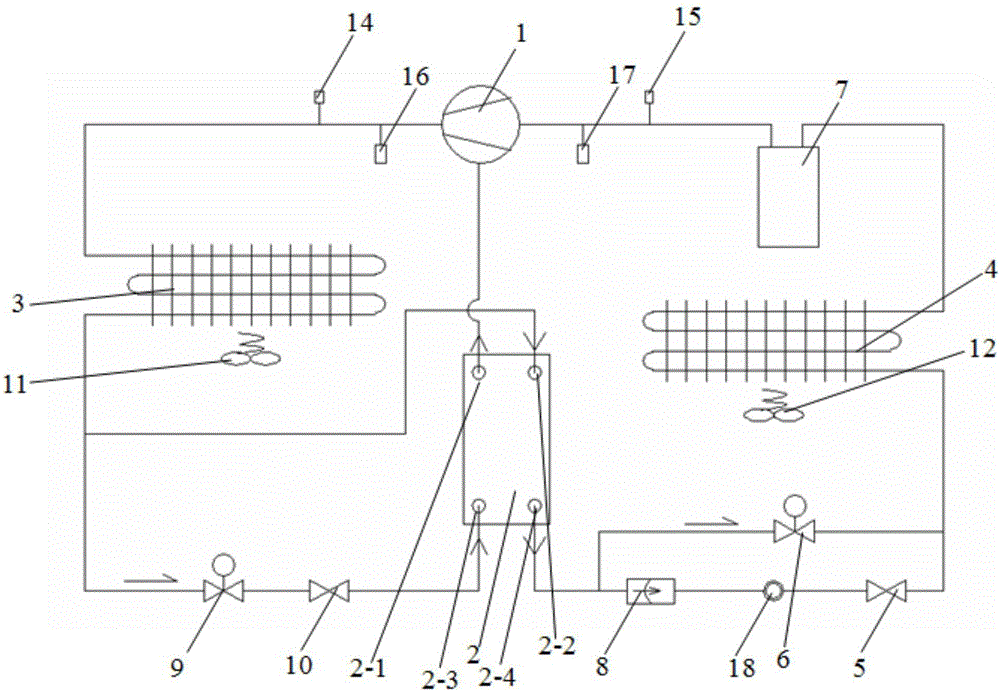

Integrated high-temperature frequency-variable heat pump heating air conditioning system

InactiveCN106091458AReduce high temperature loadTemperature controlMechanical apparatusCompression machines with several condensersTemperature controlVapor–liquid separator

The invention relates to an air conditioning system and particularly relates to an integrated high-temperature frequency-variable heat pump heating air conditioning system. The air conditioning system comprises a frequency-variable intermediate gas-supplementing scroll compressor, a plate type heat exchanger, a finned condenser, a finned evaporator, a main thermostatic expansion valve, a normally-opened electromagnetic valve, a gas-liquid separator, a drying filter, a normally-closed electromagnetic valve, a branch thermostatic expansion valve, an axial flow condensation fan, an axial flow evaporation fan, a pipeline, a high-pressure detection valve, a low-pressure detection valve, a high-pressure switch, a low-pressure switch and a liquid observing mirror. In order to overcome the disadvantages of the prior art, the integrated high-temperature frequency-variable heat pump heating air conditioning system is adopted; the compressor adopts a special frequency-variable intermediate gas-supplementing scroll compressor for a high-temperature heat pump; the displacement of the compressor is controlled by adjusting the operation frequency of the compressor, and the heating capacity on a condensation side is dynamically adjusted, so that the inner temperature of a curing barn is controlled, and the temperature control accuracy of the curing barn is ensured.

Owner:合肥海瑞弗机房设备有限公司

Equipment and method for rectifying and separating azeotrope of ethyl acetate and ethanol

PendingCN112358397AGuaranteed StrengthLow costOrganic compound preparationCarboxylic acid esters separation/purificationRefluxReboiler

The invention discloses equipment for rectifying and separating an azeotrope of ethyl acetate and ethanol. The equipment comprises a condenser I, a distillation kettle, a reboiler I, a reboiler II, aphase splitter, a pump I, a pump II, a condenser II, a recovery tower, a condenser III, a reflux tank, a pump III and a pump IV, wherein each of the condenser I, the condenser II and the condenser IIIcomprises a condenser body with a feeding pipe, a discharging pipe, a water inlet pipe, a water outlet pipe, a condensation cavity and a condensation pipe, the condensation pipe is of a double-layerpipe structure and comprises an inner pipe and an outer supporting pipe, the outer supporting pipe is arranged on the outer side of the inner pipe in a sleeving mode, a plurality of condensation wingsevenly distributed along the circumference are integrally formed on the outer side wall of the inner pipe, and wrapping parts wrapping the condensation wings are arranged on the outer supporting pipe.

Owner:浙江台州市联创环保科技股份有限公司

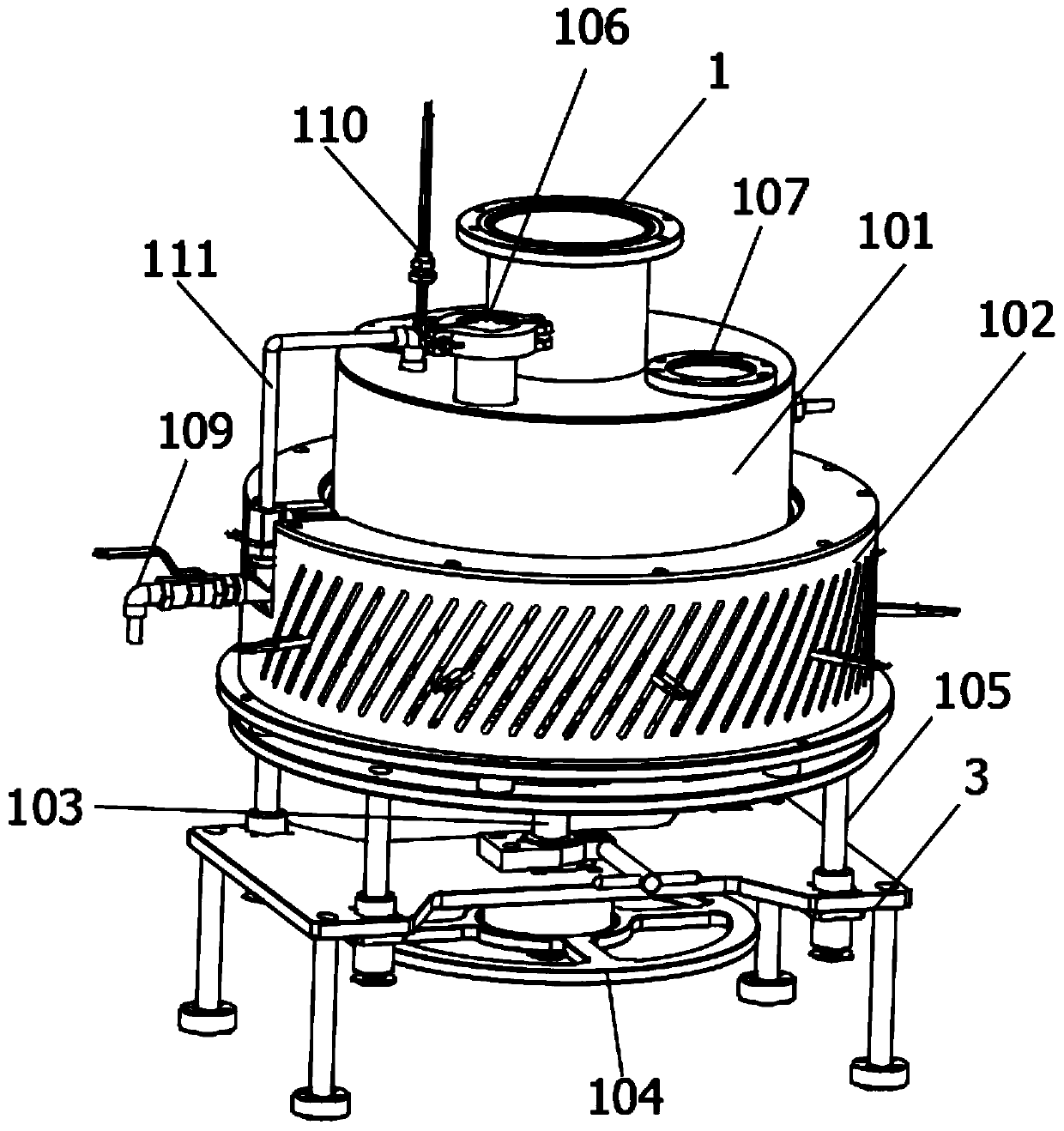

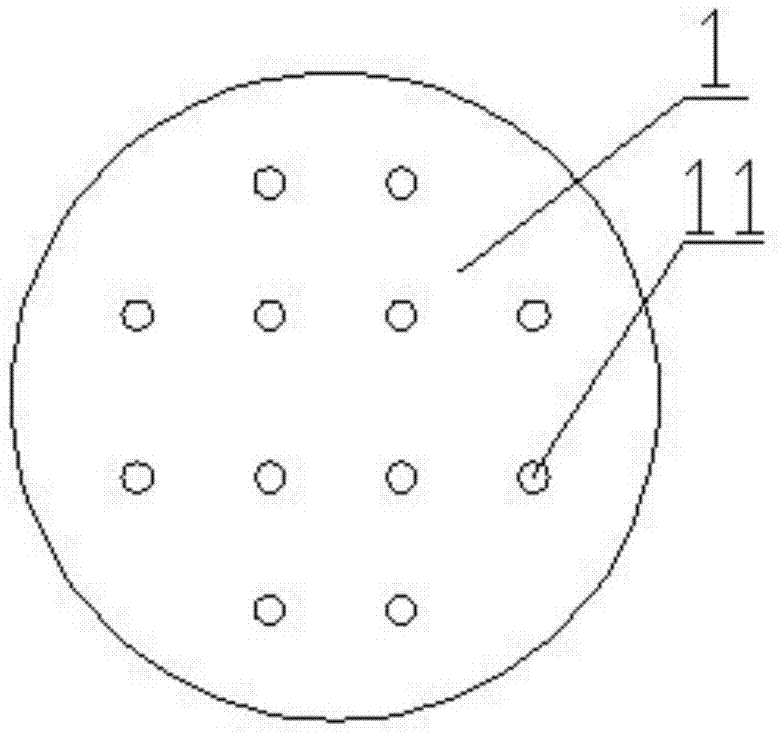

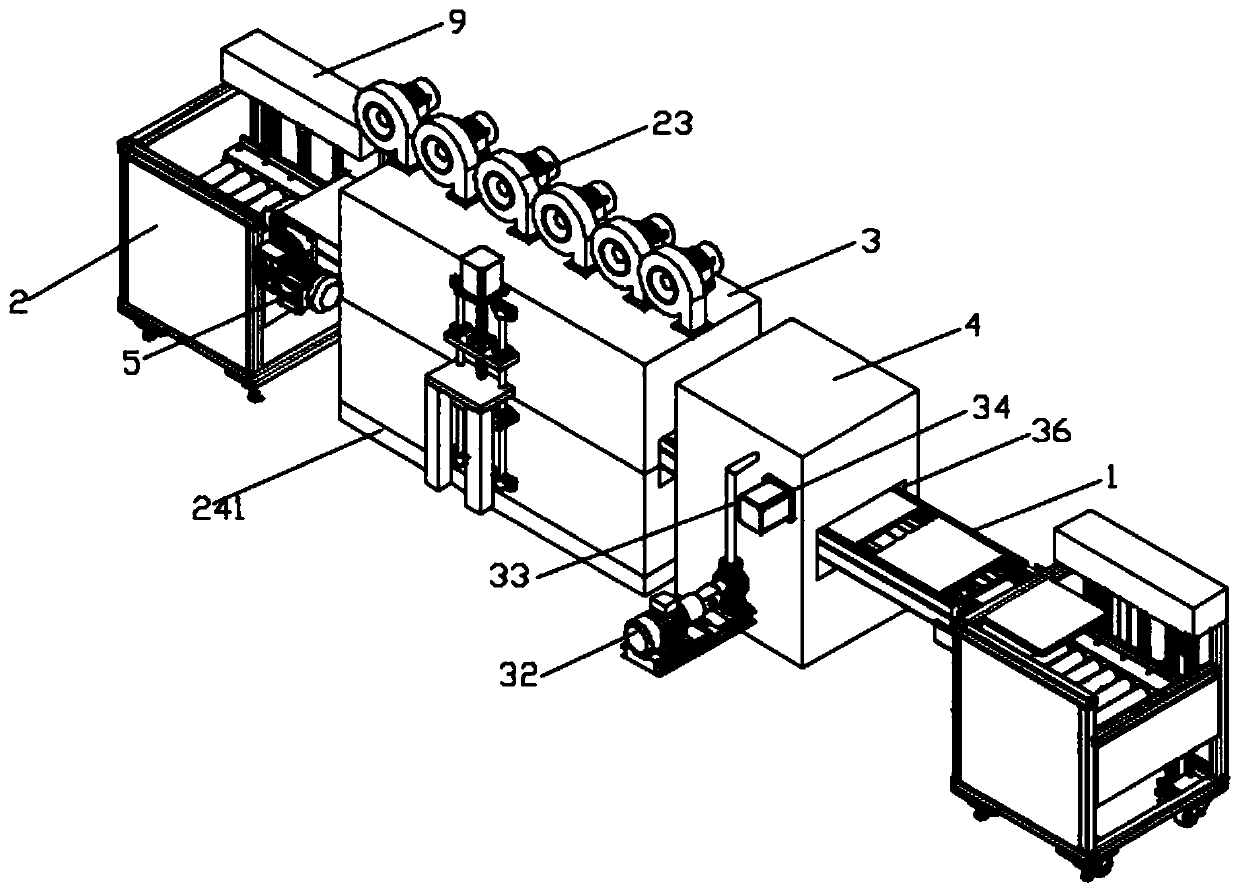

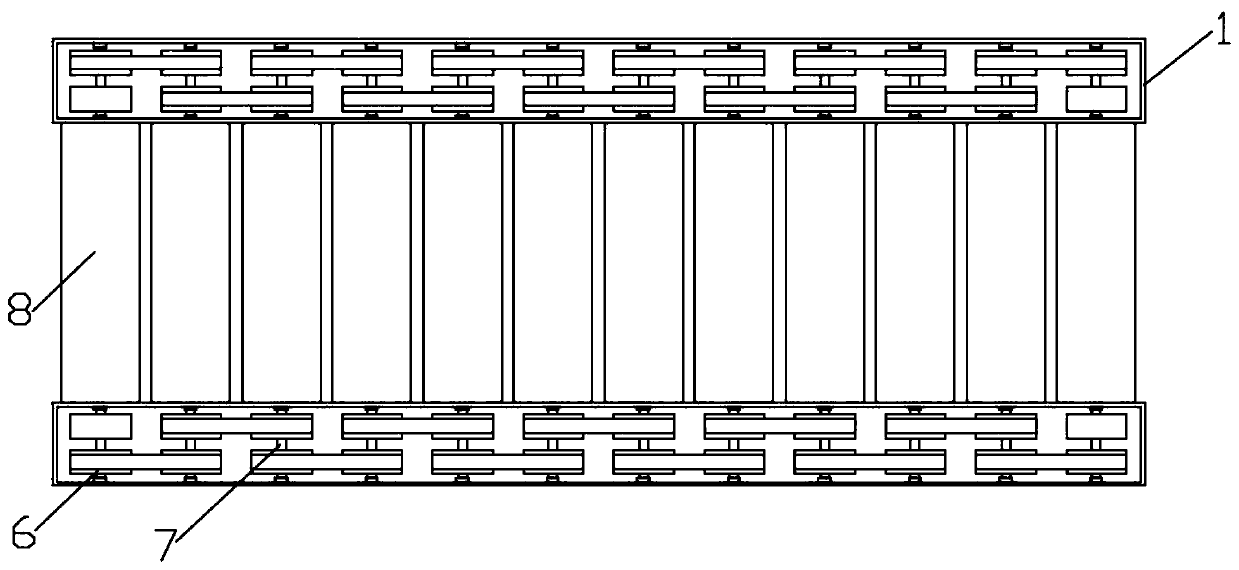

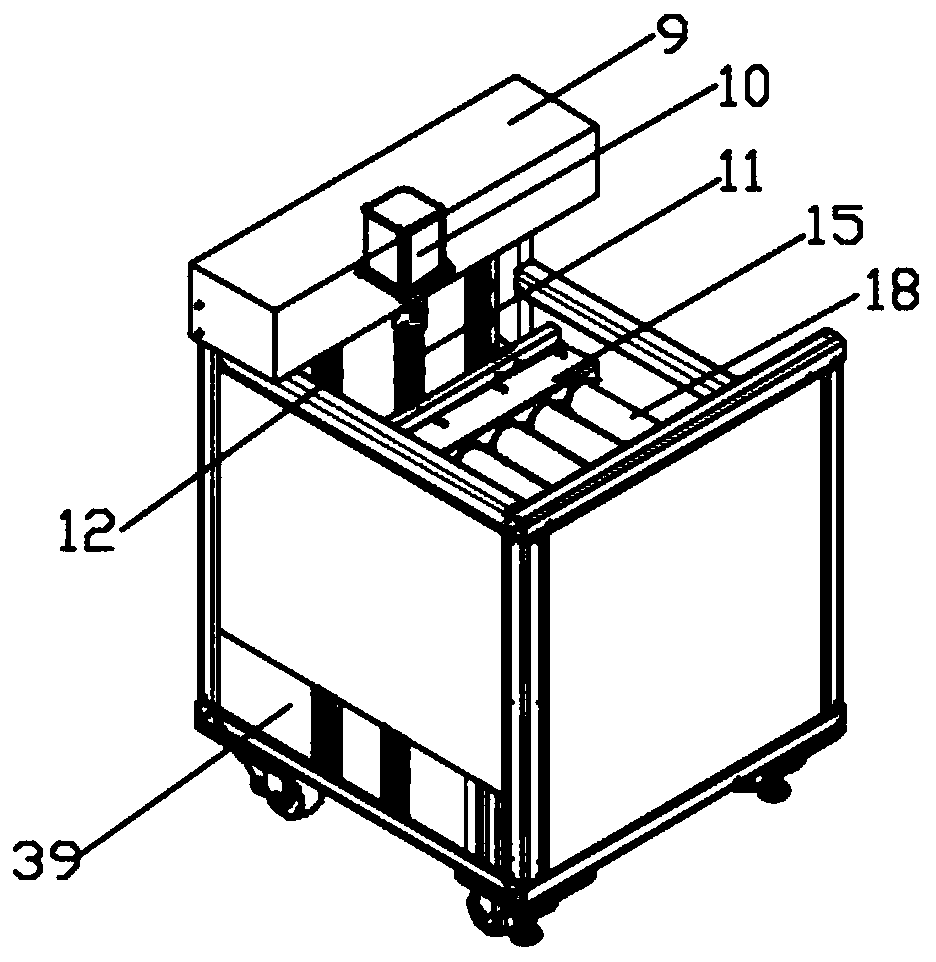

High-efficiency core cleaning machine

PendingCN110274811AQuick washGuaranteed condensation effectPreparing sample for investigationEngineeringOil storage

The invention discloses a high-efficiency core cleaning machine. The high-efficiency core cleaning machine comprises an evaporation component, a liquid collection component, a condensing component and an oil washing component; the evaporation component comprises an oil storage chamber and a heating module used for heating the oil storage chamber; the liquid collection component comprises a liquid collection chamber, wherein the liquid collection chamber is communicated with the oil storage chamber through a steam pipeline; the condensing component comprises a condensation chamber, wherein the condensation chamber is communicated with the liquid collection chamber; the oil washing component comprises a rock core basket used for containing a rock core, a first lifting mechanism for driving the rock core basket to ascend and descend, a rotating mechanism for driving the rock core basket to rotate and an oil washing chamber used for containing the rock core basket; the condensation chamber is communicated with the oil washing chamber; and the oil washing chamber is communicated with the oil storage chamber. The method disclosed by the invention is suitable for realizing the rapid cleaning of rock cores in large batches, and has high oil washing efficiency; and organic solvents can be recycled, and therefore, resources are saved, and environmental pollution is avoided.

Owner:KUNSHAN HRHA ELECTRONICS TECH

Waste gas recovery device for normal butane production

InactiveCN111156530AImprove processing qualityEasy to handleDispersed particle separationVapor condensationCombustion chamberThermodynamics

The invention belongs to the technical field of waste gas treatment equipment, and particularly relates to a waste gas recovery device for normal butane production. The waste gas recovery device for normal butane production comprises a gas inlet pipeline, a combustion device, a heat exchange device, a condensation device, a circulating device, a drying device and a filtering device, wherein the combustion device comprises a combustion chamber; the gas inlet pipe is arranged on one side of the combustion chamber; a fuel supply device and an oxygen supply device are arranged on the combustion chamber; the combustion device is arranged in the combustion chamber; a gas outlet pipeline is arranged at the top end of the combustion chamber and is connected with the condensation device; the heat exchange device is arranged on the gas inlet pipeline, the combustion chamber and the gas outlet pipeline; the circulating device is arranged on the condensation device; the condensation device is connected with the drying device; and the drying device is connected with the filtering device. The waste gas recovery device for normal butane production provided by the invention can be used for effectively purifying waste gas and utilizing energy at the same time so as to be energy-saving and environmental-friendly.

Owner:ANHUI HAIDE PETROCHEM

Tail gas treatment device of high-temperature sintering furnace for graphite production

InactiveCN107998810AMeets industry standardsAvoid recycling multiple timesUsing liquid separation agentMultistage water/sewage treatmentOil and greaseWater circulation

The invention discloses a tail gas treatment device of a high-temperature sintering furnace for graphite production. The tail gas treatment device comprises a spraying tower, a gas inlet pipe for fluegas to enter is arranged on the spraying tower, a blanking device is arranged at the bottom of the spraying device, a liquid outlet pipe for discharging cooling liquid and a liquid spraying pipe forconveying the cooling liquid are arranged on the side wall of the spraying tower, the liquid outlet pipe is positioned under the liquid spraying pipe, and a heating device for heating the inner side wall of the spraying tower is also arranged on the spraying tower. The tail gas treatment device disclosed by the invention has the benefits that the zero pollution discharge is realized, grease, floating oil and waste gas can be effectively treated, the energy consumption is low, and the efficiency is high; tail gas in the whole sintering furnace is treated by adopting a physical method, so that the use of chemical materials is reduced. Therefore, the treatment mode can be used for a long term, and the tail gas treatment cost is reduced; through a water circulation treatment device, the condensing effect of an aqueous solution is ensured, and water recycling is realized.

Owner:成都纽扣互动科技有限公司

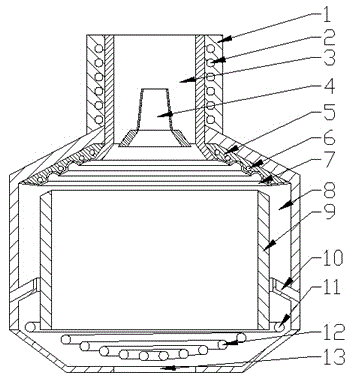

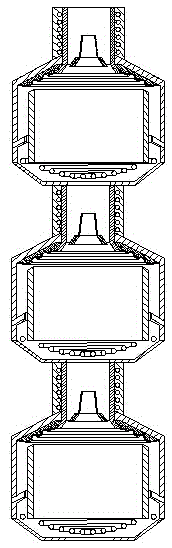

High-efficiency fractionator

InactiveCN104667557AHigh fractionation rateRelatively smallFractional distillationBiochemical engineeringFractionation

The invention relates to a high-efficiency fractionator. The high-efficiency fractionator comprises a plurality of fractionation tank bodies which are communicated with one another, wherein each fractionation tank body comprises a cylindrical shell with two sealed ends; an exhausting pipe is fixedly arranged at the top of each shell; the bottom of the shell is provided with a gas inlet; a heating assembly is arranged at the bottom of the shell; each fractionation tank body is communicated with the gas inlet in the bottom of an adjacent fractionation tank body; a fractionation assembly is arranged in each exhausting pipe and comprises a trumpet-shaped flow guide nozzle with openings in the two ends; an annular condenser is arranged at the closed end of the top of each shell; each condenser comprises a trumpet-shaped condensation surface; a cylindrical separation plate is further arranged in each shell; the axis of each separation plate and the axis of the corresponding cylindrical shell are coaxial; a plurality of liquid discharging grooves are further formed in the middle position of each separation plate; one end of each liquid discharging groove is fixed on the outer wall of the corresponding separation plate; and the other end of each liquid discharging groove penetrates through the inner wall of the corresponding shell and stretches outwards, and the side wall at one side of each liquid discharging groove is in an opening shape.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

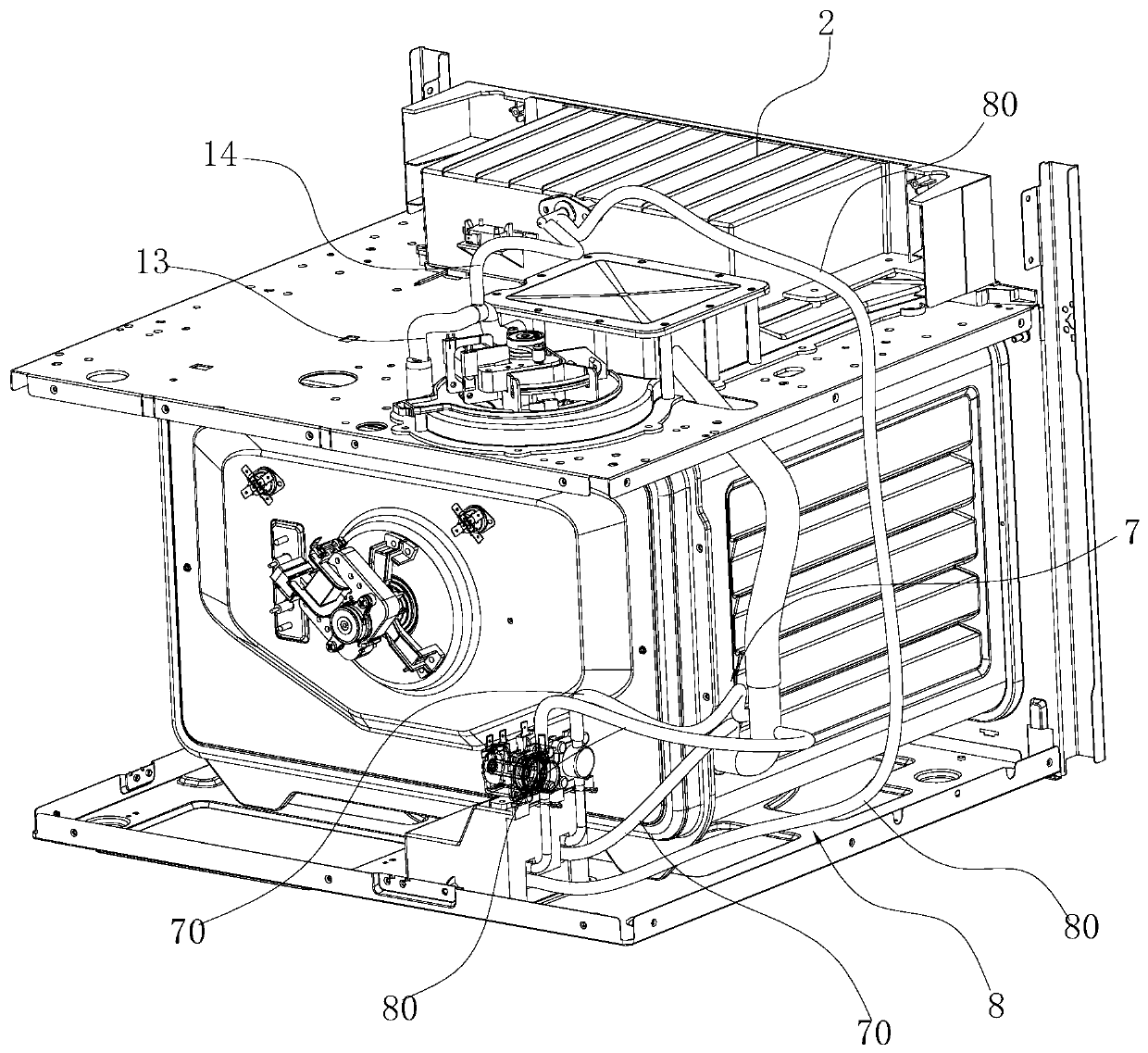

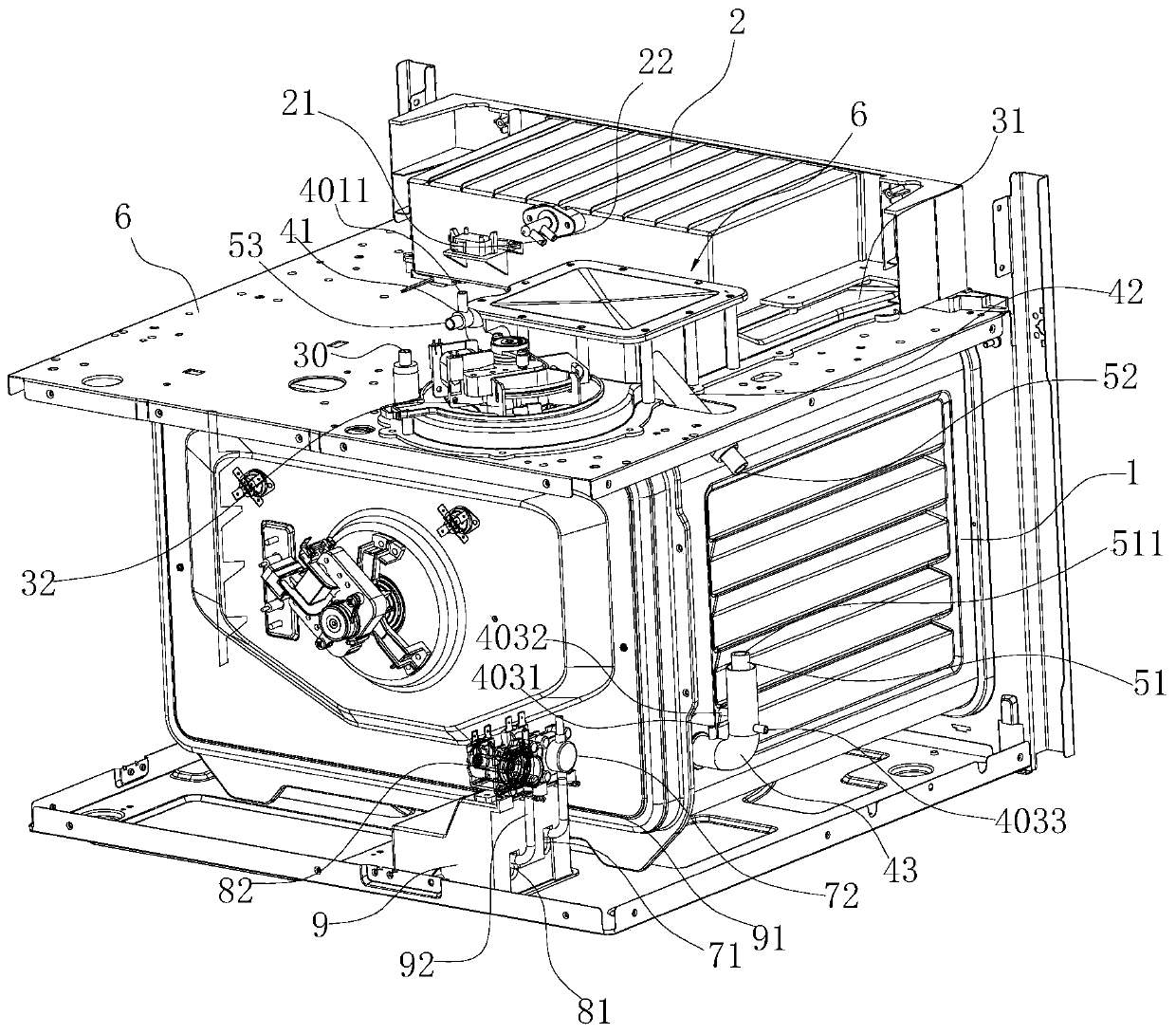

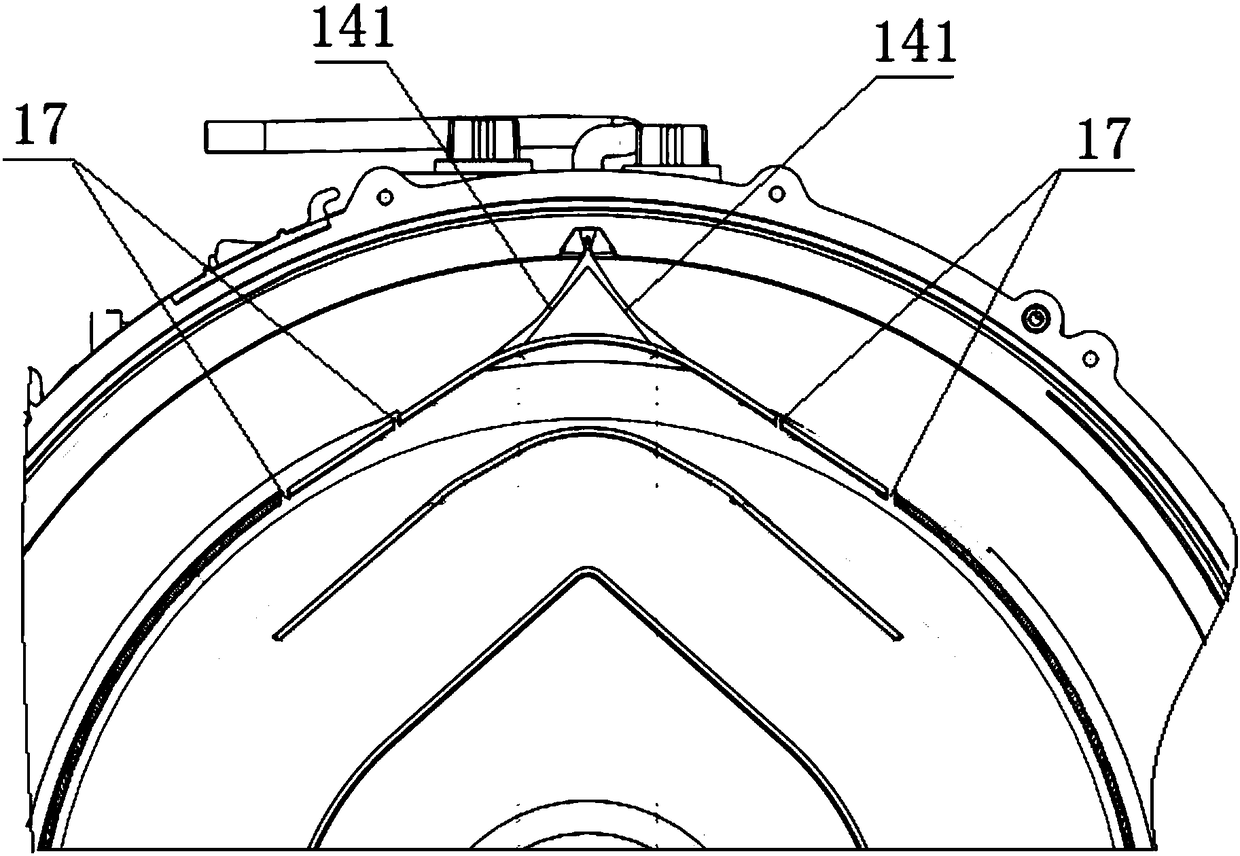

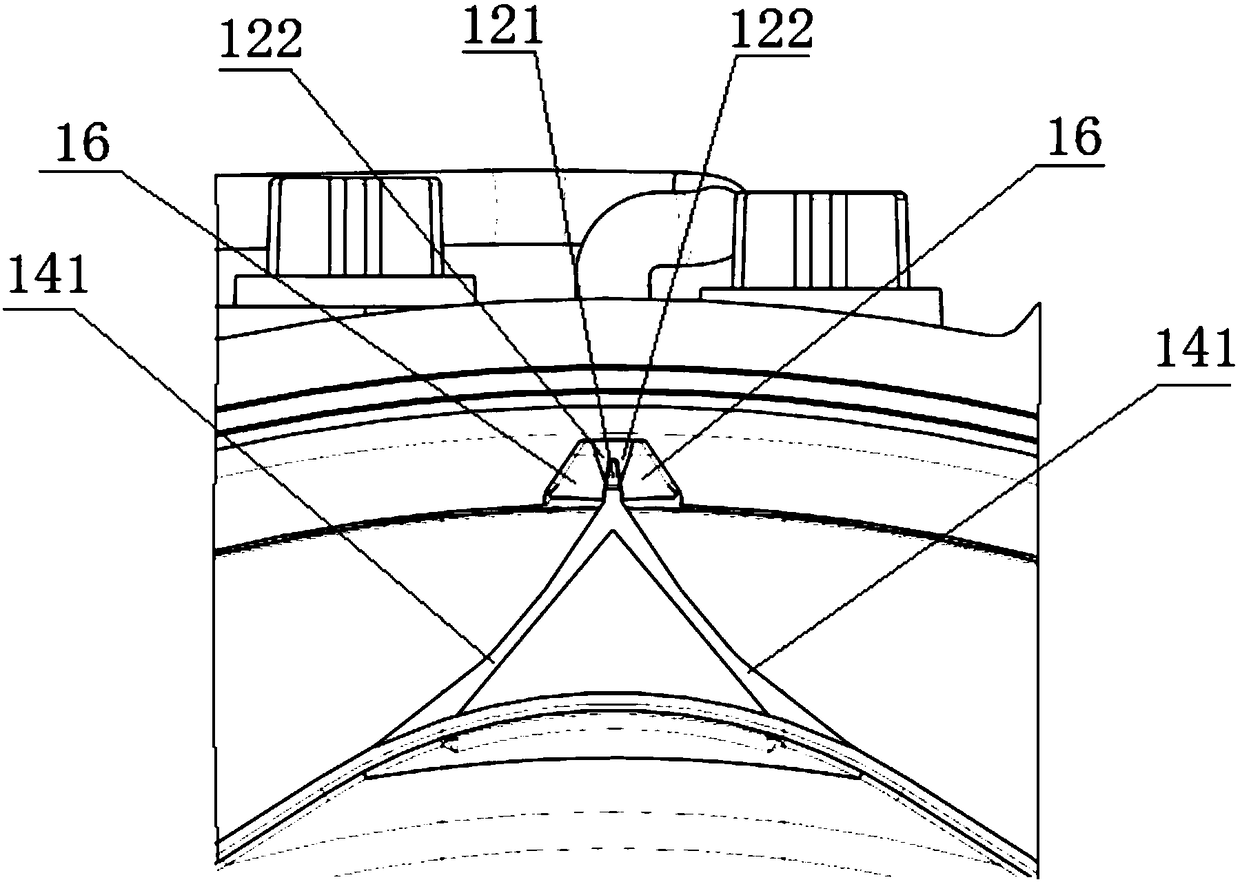

Steaming exhaust structure and electric steam box with same

PendingCN112754271AImprove condensation effectGuaranteed exhaust efficiencySteam cooking vesselsThermodynamicsMechanical engineering

The invention relates to a steaming exhaust structure and an electric steam box with same; the steaming exhaust structure comprises an inner container and a heat dissipation channel, a condensation cavity is formed above the heat dissipation channel, a steam inlet of the condensation cavity is in fluid communication with a steam exhaust port of the inner container, the top wall of the condensation cavity is a first heat dissipation plate, the bottom wall of the condensation cavity is a second heat dissipation plate, and the second heat dissipation plate and the top wall of the heat dissipation channel are shared. A partition plate is transversely arranged in the heat dissipation channel in the direction from the air inlet to the air outlet of the heat dissipation channel and divides the heat dissipation channel into a first air channel and a second air channel in the vertical direction, and the second heat dissipation plate is located in the first air channel. Through the arrangement of the double heat dissipation plates, the condensation effect on high-temperature steam entering the condensation cavity can be improved. Besides, heat, transmitted to the second heat dissipation plate, of steam in the condensation cavity can be taken away through the first air channel, so that the second heat dissipation plate can be kept at a low temperature, the continuous condensation effect of the second heat dissipation plate on the steam can be guaranteed, and the overall condensation effect of the condensation cavity on the steam is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

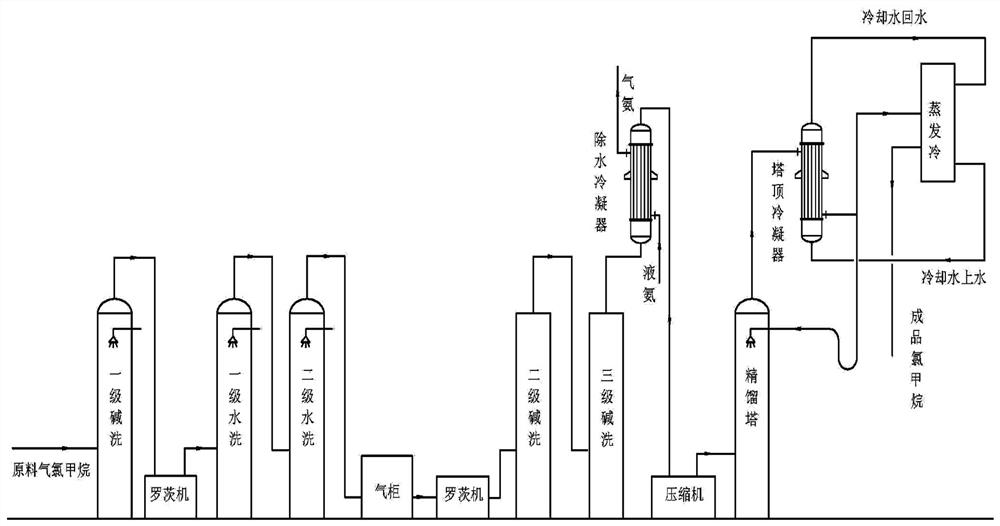

Method for recovering byproduct chloromethane in maltol production

InactiveCN111646878AHigh purity of finished productLow costHalogenated hydrocarbon separation/purificationSide productHydrogen chloride

The invention relates to a method for recovering byproduct chloromethane in maltol production. After the chlorination reaction in maltol production is finished, chlorination liquid is subjected to hydrolysis reaction to generate methyl maltol and ethyl maltol, and chloromethane gas containing water, hydrogen chloride, methanol and other organic impurities is generated as a byproduct. According tothe method, the byproduct chloromethane is subjected to alkali washing, water washing and alkali washing again, after compression, rectification and cooling are carried out to obtain liquid chloromethane, thus reducing the impurity content in chloromethane, and reaching the purposes of impurity removing and purifying, meanwhile, chloromethane is also a maltol production raw material, and recyclingis achieved.

Owner:ANHUI JINGHE IND

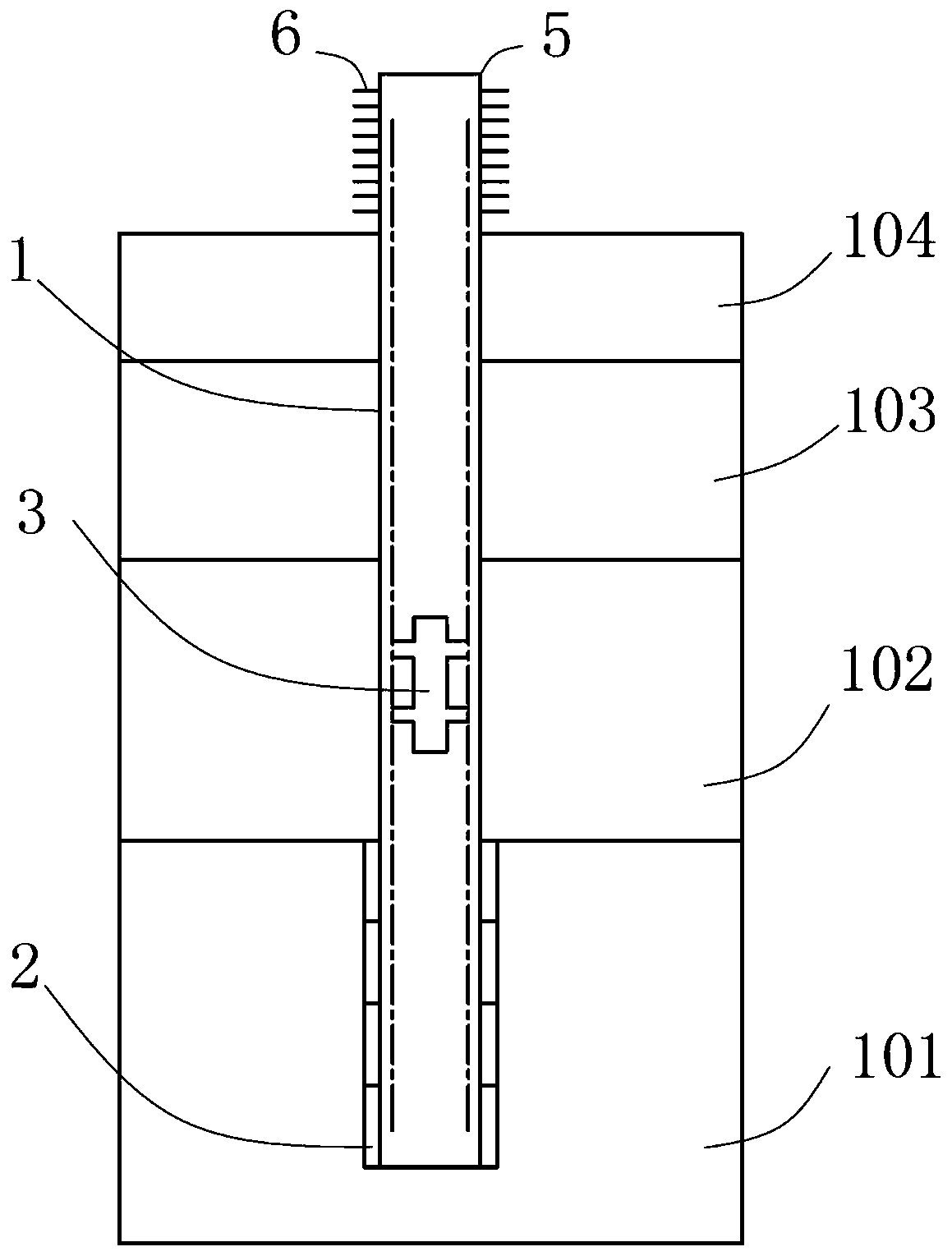

Baijiu condenser

The invention provides a baijiu condenser. The baijiu condenser comprises a shell, a condensing cavity in the shell, a condensate water inlet arranged at the lower part of the side wall of the shell, a condensate water outlet in the upper part of the side wall of the shell, a steam buffer cavity at the upper end of the shell, an air inlet pipe on the top of the steam buffer cavity, a wine liquid accommodating cavity at the lower end of the shell, a wine outlet pipe on the bottom of the wine liquid accommodating cavity, a plurality of condensing pipes arranged in the condensing cavity in parallel, and an upper tube plate and a lower tube plate which are connected with the condensing pipes. For the baijiu condenser, the upper parts and the lower parts of the condensing pipes are straight pipes, the middles of the condensing pipes are spiral pipes, the upper tube plate and the lower tube plate are detachably connected to the upper part and the lower part of the shell, and the wine liquid accommodating cavity is detachably connected to the lower end of the shell. The baijiu condenser provided by the invention is convenient to clean, is energy-saving and environmentally friendly, and is good in condensing effect, the storage of flavor substances in the wine liquid is facilitated, and thus the quality of the wine is improved.

Owner:HEBEI GUXIANGYANG WINE CO LTD

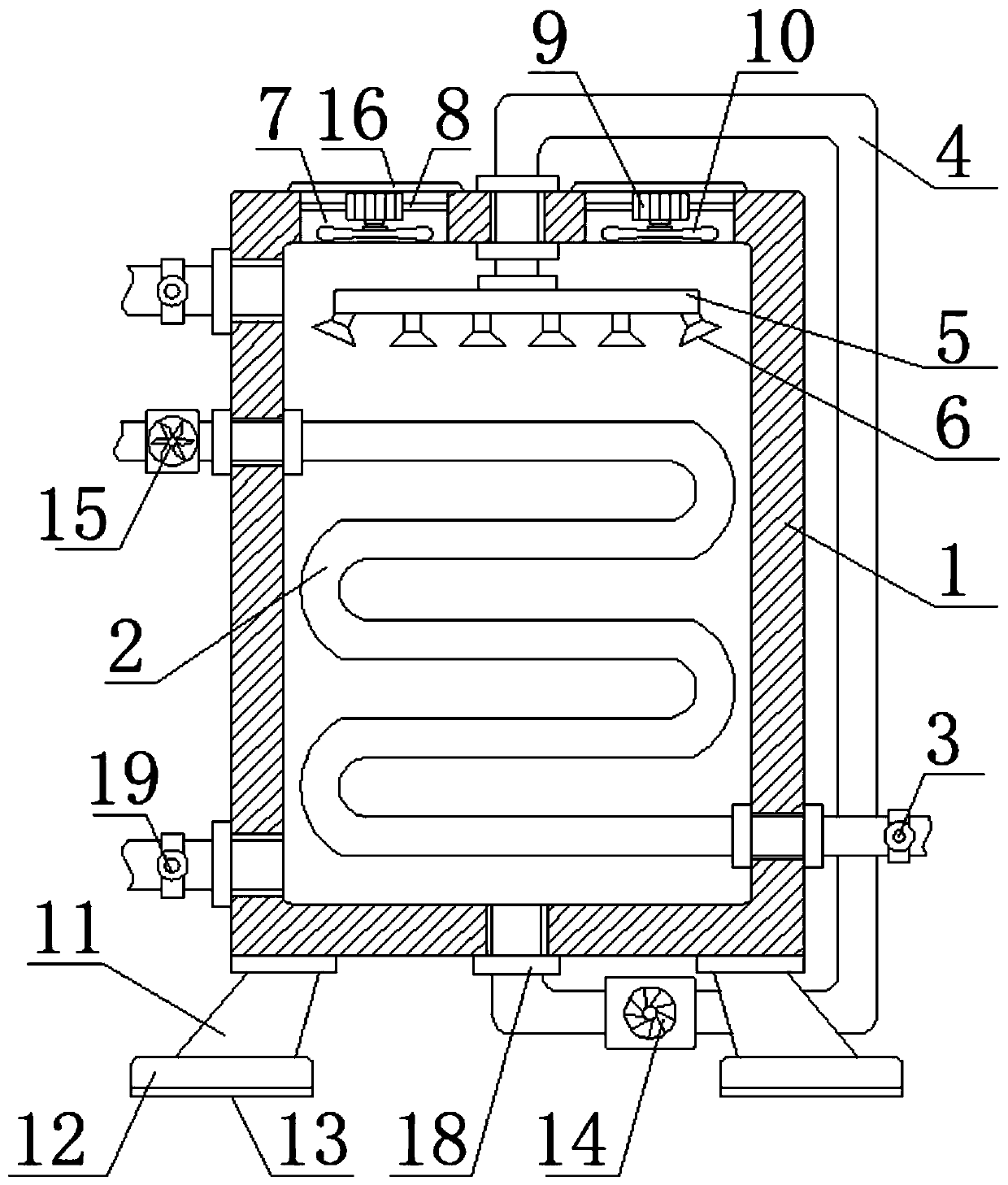

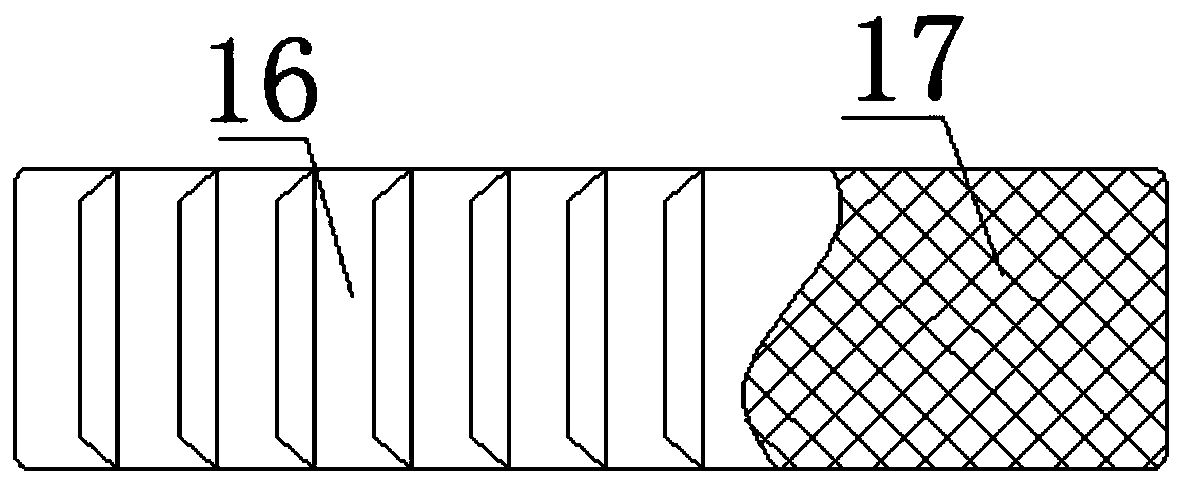

Sintering device for photovoltaic panel processing and working method thereof

ActiveCN110873535AEasy to unloadHigh degree of automationIncreasing energy efficiencyHandling discharged materialPhysicsElectric machinery

The invention discloses a sintering device for photovoltaic panel processing and a working method thereof. The sintering device comprises a conveying frame, wherein lifting frames are symmetrically arranged at the two ends of the conveying frame, four upright rails are symmetrically mounted on the two sides of the two lifting frames, first screw rods are arranged between every two adjacent uprightrails, connecting sliding blocks are arranged on the surfaces of the upright rails in a sliding mode, and the four connecting sliding blocks are symmetrically connected to the two sides of two side shells. According to the device, a condensation circulating water pump discharges condensed water into a spraying pipe through a water outlet pipe, the spraying pipe performs water cooling on the photovoltaic panel, the photovoltaic panel subjected to water cooling is continuously transferred to the position below a rolling brush, an output shaft of a fifth motor drives the rolling brush to removethe condensed water on the surface of the photovoltaic panel, the removed condensed water falls into the bottom of an inner cavity of a cooling box, and enters a water pumping pipe through guiding ofa guide plate and enters the condensation circulating water pump after being filtered by a filter element, and the filtered condensed water is condensed by the condensation circulating water pump andthen is discharged into the spraying pipe through the water outlet pipe for water cooling treatment on subsequent photovoltaic panels.

Owner:江苏宇辉光伏科技有限公司

Phosphorus oxychloride condensation recovery device

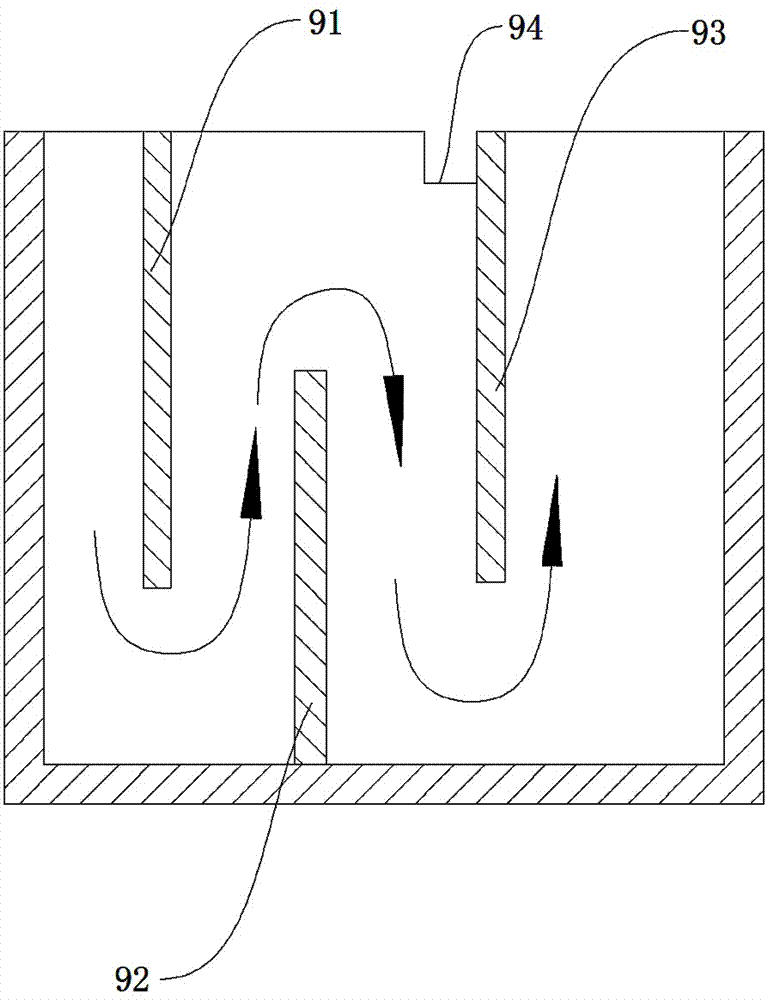

InactiveCN111544919ASlow down the flowIncrease condensation distancePhosphorus halides/oxyhalidesVapor condensationChemical synthesisEngineering

The invention belongs to the technical field of chemical synthesis equipment, and specifically, relates to a phosphorus oxychloride condensation recovery device. The phosphorus oxychloride condensation recovery device comprises a condensation tank; a condensation pipe is arranged in the condensation tank; a phosphorus oxychloride inlet end of the condensation pipe penetrates through the top of theinner wall of one side of the condensation tank and extends outwards; the phosphorus oxychloride outlet end of the condensation pipe penetrates through the bottom of the inner wall of the other sideof the condensation tank and extends outwards; a first control valve is mounted at the extending end of the condensation pipe; a cooling medium is arranged in the condensation tank; one side of the condensation tank is fixedly communicated with a cooling medium inlet and a cooling medium outlet; the bottom of the condensation tank is fixedly communicated with a circulating pipe; the other end of the circulation pipe penetrates through the top of the condensing tank and extends inward, and the extended end of the circulation pipe is fixedly communicated with a spray tray. According to the phosphorus oxychloride condensation recovery device, through the arrangement of the rotary condensation pipe, a cooling medium and a cooling fan, phosphorus oxychloride gas in the condensation pipe can befully cooled, and the condensation effect is effectively guaranteed.

Owner:宿州汉泰化工有限公司

Device for treating high-temperature tail gas of graphite production

InactiveCN107998839AMeets industry standardsAvoid recycling multiple timesCombination devicesWater treatment parameter controlGraphiteWater circulation

The invention discloses a device for treating high-temperature tail gas of graphite production. A gas inlet pipe is arranged on a spraying tower; a water circulation treatment device comprises a settling pond, an air flotation pond, a primary recovering pond, a clean water pond, a spraying pump and a spraying pipe; the water outlet end of the spraying tower is communicated with the water inlet endof the settling pond; a flocculating tank for adding a flocculating agent into the settling pond is arranged on one side of the settling pond; the first outlet of the settling pond is communicated with the primary recovering pond; the second outlet of the settling pond is communicated with the air flotation pond; the first outlet of the air flotation pond is communicated with the primary recovering pond; the second outlet of the air flotation pond is communicated with the clean water pond; and the water inlet of the spraying pump is communicated with the clean water pond. The device for treating high-temperature tail gas of graphite production has the following beneficial effects: the device can treat the high-temperature tail gas with complex and changeable components in the production process of the graphite, so the universality of the device is improved and the device is not constrained by the raw materials; furthermore, the whole treatment process is physical treatment and condensate water can be recycled, so that the treatment device is energy-saving and environment-friendly.

Owner:成都纽扣互动科技有限公司

A semiconductor dehumidifier

ActiveCN107785783BImprove dehumidification efficiencyGuaranteed condensation effectSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringRefrigeration

The invention discloses a semiconductor dehumidification device. The device comprises a cold-side radiator, a semiconductor refrigeration sheet, a partition plate, a water tank, a fan, a hot-side radiator and a shell; the partition plate dives the shell from a horizontal direction into a condensation zone and a heat dissipation zone; and the condensation zone and the heat dissipation zone are communicated with each other through ventilation holes formed in the partition plate; an air inlet located in the condensation zone is formed in the upper part of the shell; an air outlet located in the heat dissipation zone is formed in the top of the shell; the semiconductor refrigeration sheet is arranged in the partition plate; the cold end of the semiconductor refrigeration sheet is connected with the cold-end radiator; the hot end of the semiconductor refrigeration sheet is connected with the hot-end radiator; the cold-end radiator and the hot-end radiator are fixed at two sides of the partition plate; the fan is located between the upper part of the hot-end radiator and the air outlet; the water tank is disposed below the cold-end radiator; and an atomization and water draining device is disposed in the water tank. With the semiconductor dehumidification device of the invention, the technical problems of low dehumidification efficiency, complicated structure and difficulty in waterdrainage of an existing semiconductor dehumidification device can be solved. The semiconductor dehumidification device of the invention has the advantages of high dehumidification efficiency and simple structure, and can realize intelligent water drainage.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

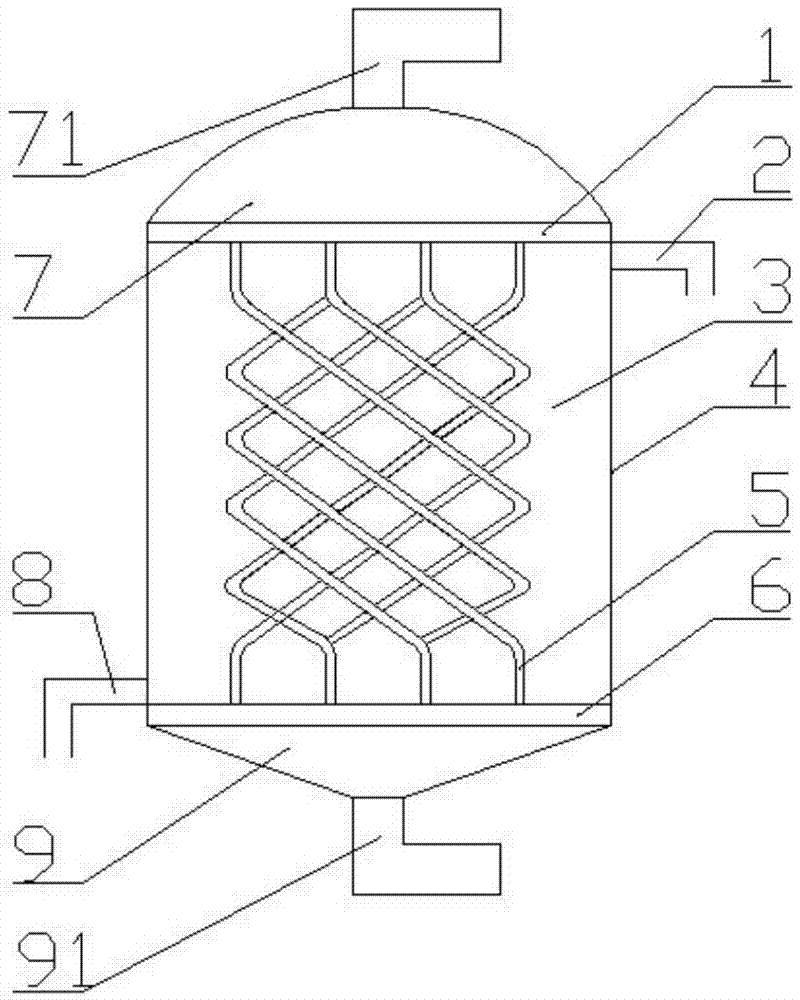

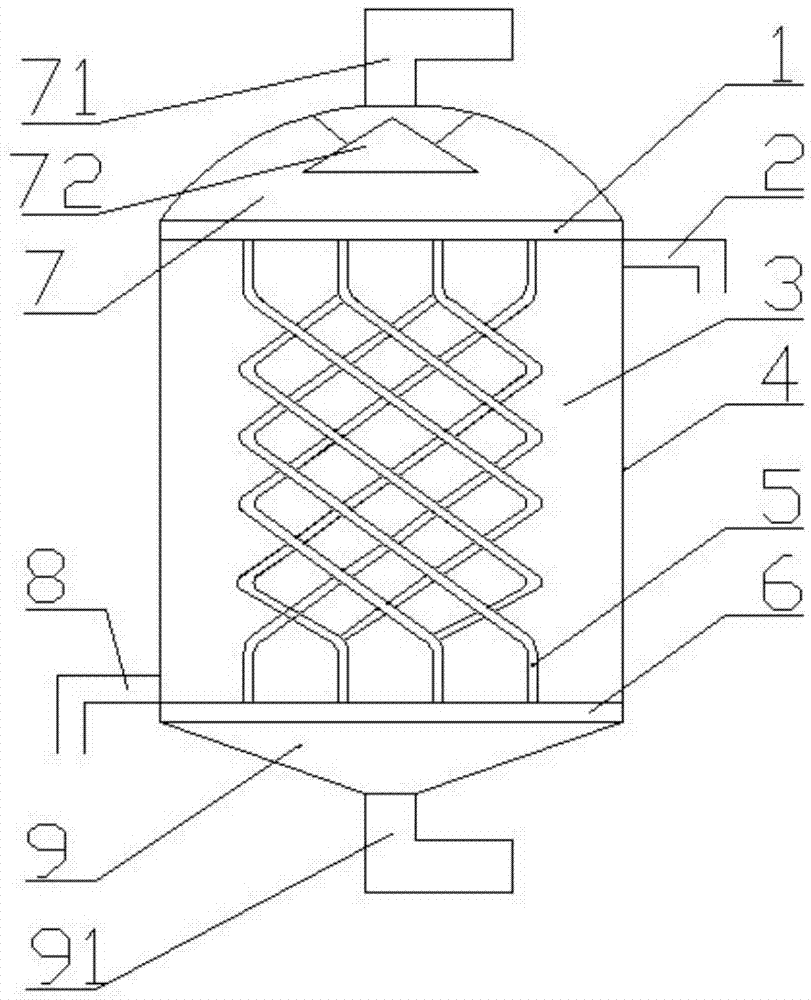

Efficient condenser

InactiveCN108088128ASpeed up circulationImprove condensation efficiencyEvaporators/condensersStationary tubular conduit assembliesEngineeringRefrigeration

The invention discloses an efficient condenser, and relates to the technical field of refrigeration. The efficient condenser comprises an outer shell body, and further comprises multiple inner shellswhich are uniformly distributed inside the outer shell; two side surfaces of the inner shells are open and are connected with the outer shell to form refrigerating chambers; heat dissipation holes areformed in the position, on opened positions, of the outer shell, and one-way breathable films cover the heat dissipation holes; refrigerants are arranged in the refrigeration chambers; the outer surfaces of the inner shells are tightly attached to the inner surface of the outer shell, inner grooves are formed in the outer surfaces of the inner shells, outer grooves are formed in the inner surfaceof the outer shell, wherein the inner grooves and the outer grooves form a condensation channel, and the condensation channel sequentially passes through the outer surfaces of the inner shells; and acondensation inlet and a condensation outlet are formed in the shell, and the condensation inlet communicates with one end of the condensation channel, and the condensation outlet communicates with the other end of the condensation channel. According to the efficient condenser, the condensation channel of a heat source is formed by utilizing the outer shell and the inner shell, a pipe body whichis used for circulating the heat source arranged in the outer shell is omitted, so that heat of the heat source is directly transmitted to the outer shell instead of being transmitted to the outer shell through the pipe body firstly, and therefore heat dissipation is faster, and the condensation efficiency is improved.

Owner:博维恩冷冻科技(苏州)有限公司

Condenser of vacuum freeze drier

InactiveCN103423971AGuaranteed condensation effectEasy to scrape offDrying solid materials without heatEvaporators/condensersEngineeringElectrical and Electronics engineering

The invention relates to the field of freeze-drying equipment, in particular to a condenser of a vacuum freeze drier. The condenser of the vacuum freeze drier comprises a condenser body, a plurality of metal absorption plates and an absorption plate replacing mechanism. At least one of the metal absorption plates is in contact connection with the condenser body. The absorption plate replacing mechanism is connected with the metal absorption plates. The metal absorption plates are replaceable; thick ice layers can be absorbed on the metal absorption plates, so that a condensing effect can be guaranteed by means of replacing with other metal absorption plates when the condensing effect is poor. Bumps suitable for adhering of water vapor are formed on the metal absorption plates, so that water vapor condensing is facilitated better. By means of arranging scraping rods, water layers on the metal absorption plates can be scraped, so that the metal absorption plates are prepared to be replaced. When the metal absorption plate replacing mechanism moves to a corresponding limited point, movement is interrupted, and the interruption can shake off an appropriate amount of ice layers so as to facilitate subsequent scraping works.

Owner:JIANGSU RUNHUA FROZEN FOODS

Washing and drying integrated machine with rolling drum

PendingCN108951051ANot easy to splashNot easy to get wetOther washing machinesTextiles and paperWater flowEngineering

The invention discloses a washing and drying integrated machine with a rolling drum. The machine includes a water containing barrel, the rolling drum and a cooling water supply device. The cooling water supply device supplies cooling water to the bottom wall surface of the water containing barrel through a cooling water inlet passage in order to form a condensing surface on the bottom wall surfaceof the water containing barrel, an outlet end of the cooling water inlet passage is formed in the upper portion of the bottom wall surface of the water containing barrel, and a diversion component for diverting cooling water flowing inward is arranged at the outlet end of the cooling water inlet passage; the outlet end is divided by the diversion component into two diversion outlets, and the cooling water is diverted by the diversion component and flows to the bottom wall surface of the water containing barrel through the diversion outlets. The washing and drying integrated machine is concisein structure, capable of preventing splashing of water and saving space and stable in condensation water path.

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

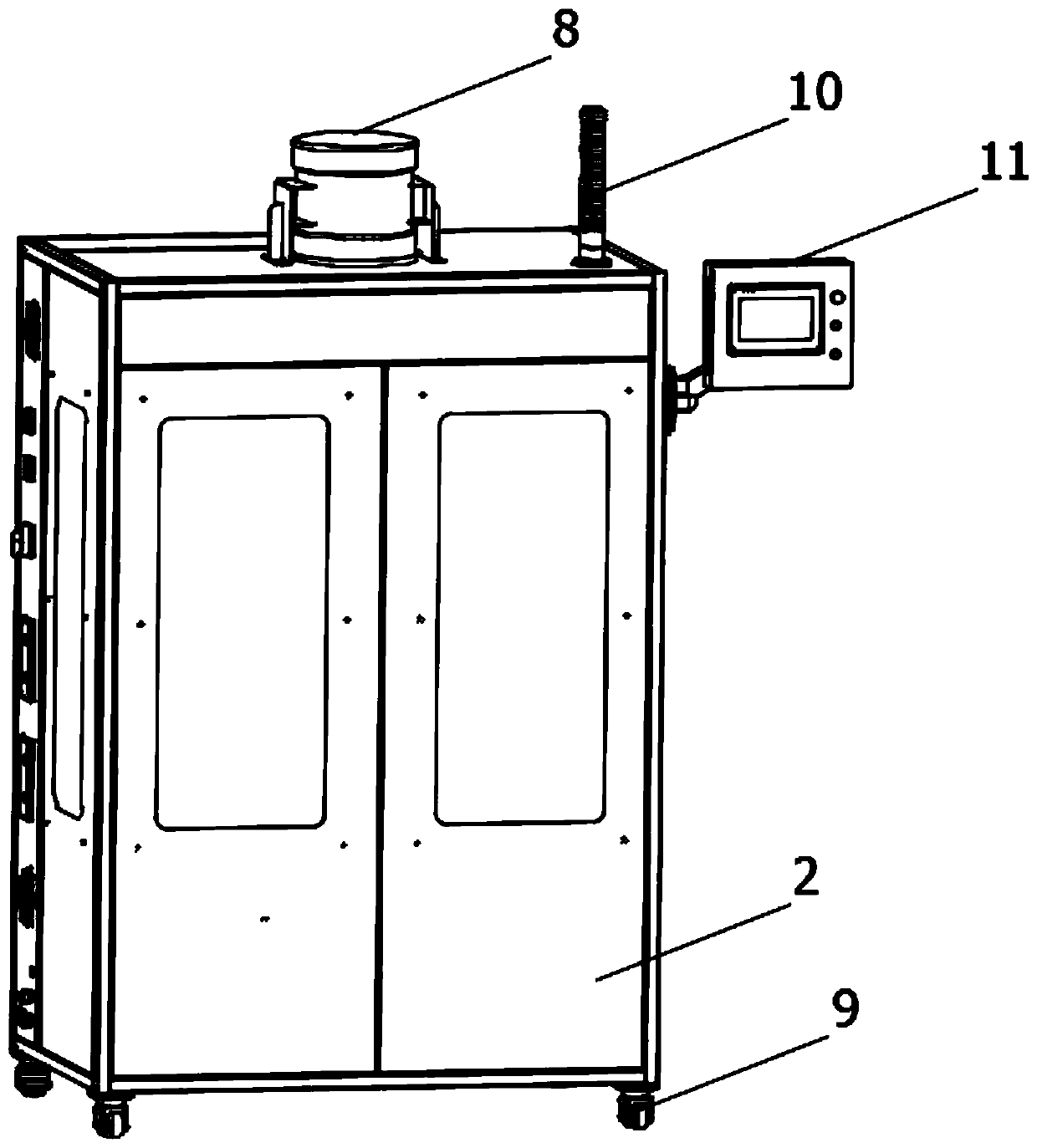

Water control type efficient energy-saving water conditioner for insect breeding and using method thereof

ActiveCN112197377AReduce usageGuaranteed cooling effectMechanical apparatusSpace heating and ventilation safety systemsWater storageWater resources

The invention discloses a water control type efficient energy-saving water conditioner for insect breeding. The water control type efficient energy-saving water conditioner comprises a main box body.A mounting box body and a water storage box body are fixedly mounted on the inner bottom wall of the main box body, and connecting pipes which are uniformly distributed fixedly communicate with the position between the mounting box body and the water storage box body. A drainage pipe and a liquid inlet pipe fixedly communicate with the inner side wall of the water storage box body, and a circulating water pipe fixedly communicates with the position between the inner side wall of the water storage box body and the inner side wall of the mounting box body. A first pressure pump is arranged in the middle of the circulating water pipe, and the side face of the first pressure pump is fixedly connected with the inner side wall of the main box body through a support. Two symmetrical mounting pipes fixedly communicate with the inner top wall of the main box body, and four supporting columns which are uniformly distributed are fixedly mounted on the side face of the main box body. Water in thewater storage box body can be pumped back into the mounting box body, so that underground water is recycled, and water resources are saved. Water is changed after the water temperature rises, so thatthe using amount of the underground water is controlled while the refrigeration effect of the water conditioner is guaranteed.

Owner:南京简诺生态农业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com