Equipment and method for rectifying and separating azeotrope of ethyl acetate and ethanol

A technology for the separation of ethyl acetate and rectification, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. Unsatisfactory effect and other problems, to achieve the effect of ensuring the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]ReferenceFigure 1 to Figure 6An embodiment of the present invention will be further described.

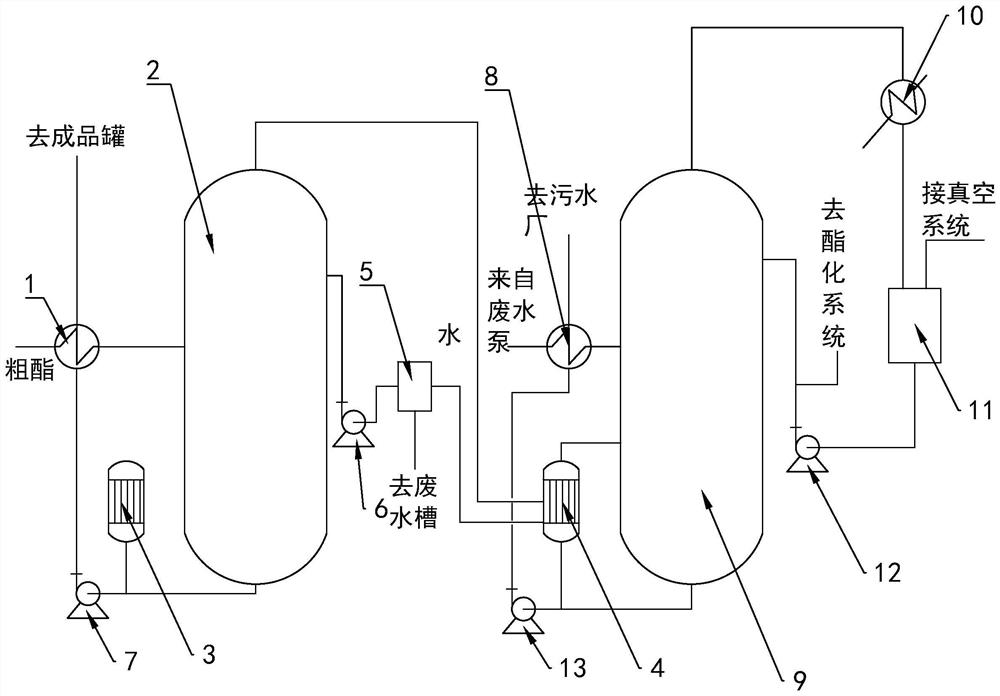

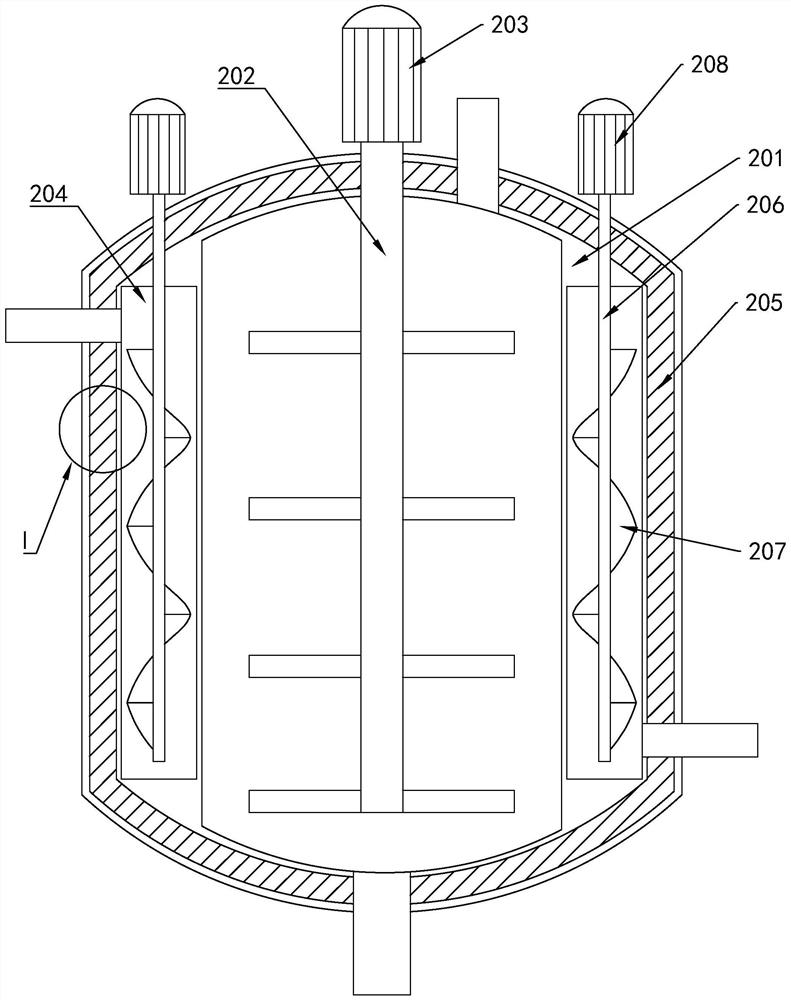

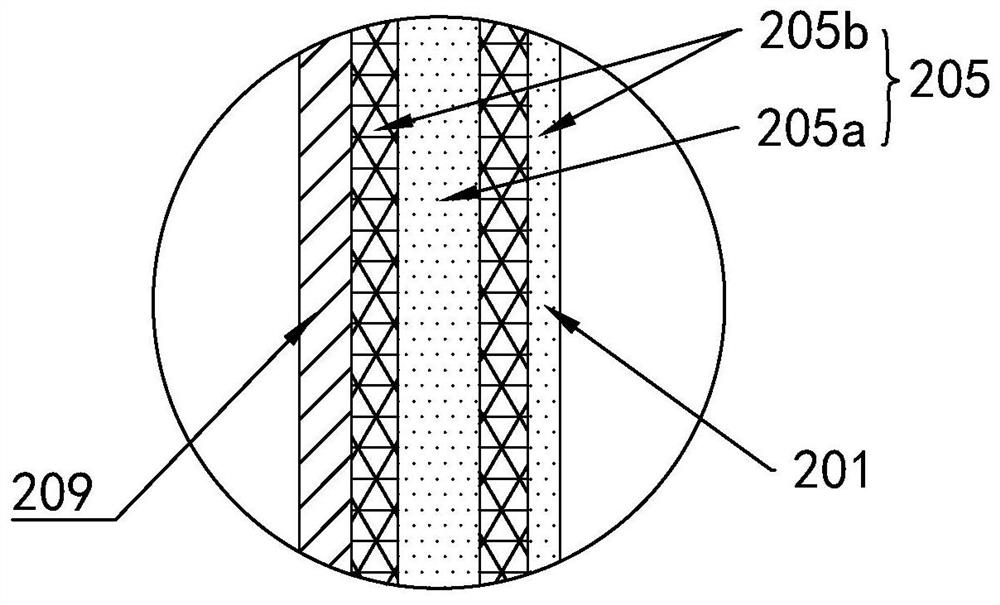

[0035]A device for rectifying and separating ethyl acetate and ethanol azeotrope, including condenser I1, distillation kettle 2, reboiler I3, reboiler II4, phase separator 5, pump I6, pump II7, condenser II8, Recovery tower 9, condenser III10, reflux tank 11 and pump III12 and pump IV13; the said condenser I1, condenser II8 and condenser III10 all include feed pipe 101, discharge pipe 102, water inlet pipe 103, and water outlet pipe 104. The condenser body 105 of the condensing chamber and the condenser tube. The condenser tube has a double-layer tube structure and includes an inner tube 106 and an outer support tube 107. The outer support tube 107 is sleeved on the outside of the inner tube 106. The outer side wall of the inner tube 106 is integrally formed with a number of condensing wings 108 evenly distributed along the circumference, and a wrapping part 109 that wraps the condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com