Ammonia and lithium bromide integrated absorption refrigeration device driven by heating medium water and method

An absorption refrigeration and lithium bromide technology, which is applied in refrigerators, refrigeration components, adsorption machines, etc., can solve the problems of high refrigeration cost and complicated refrigeration process, to ensure the condensation effect, reduce the temperature of the heat source, and solve the difficult recovery of waste heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

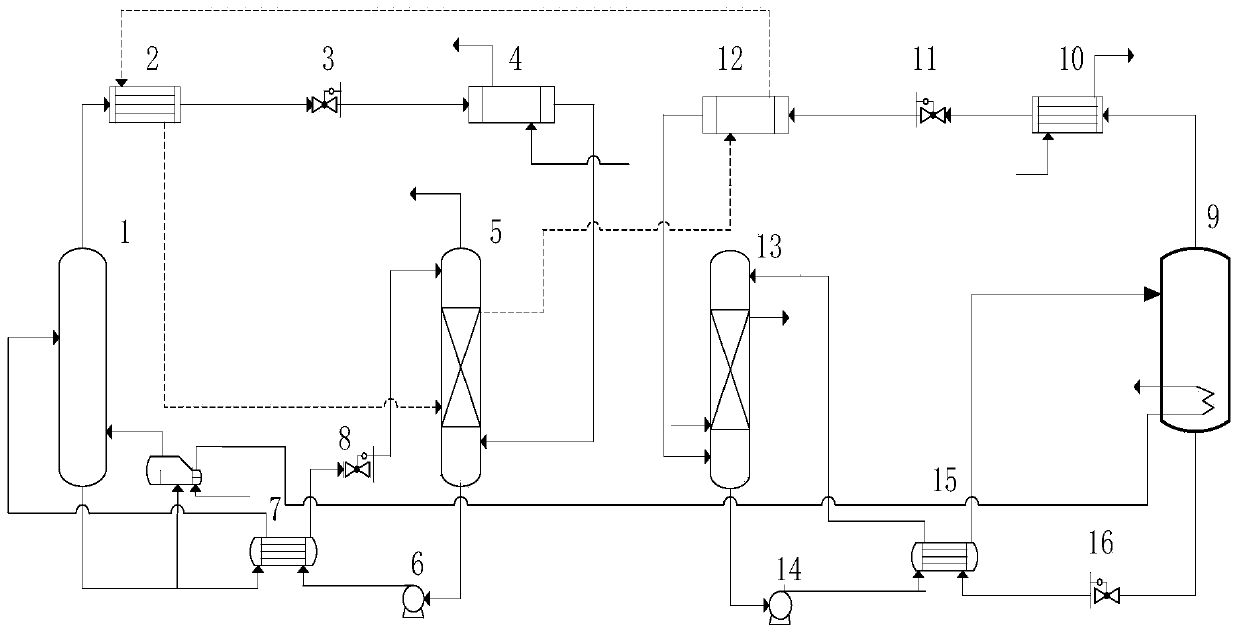

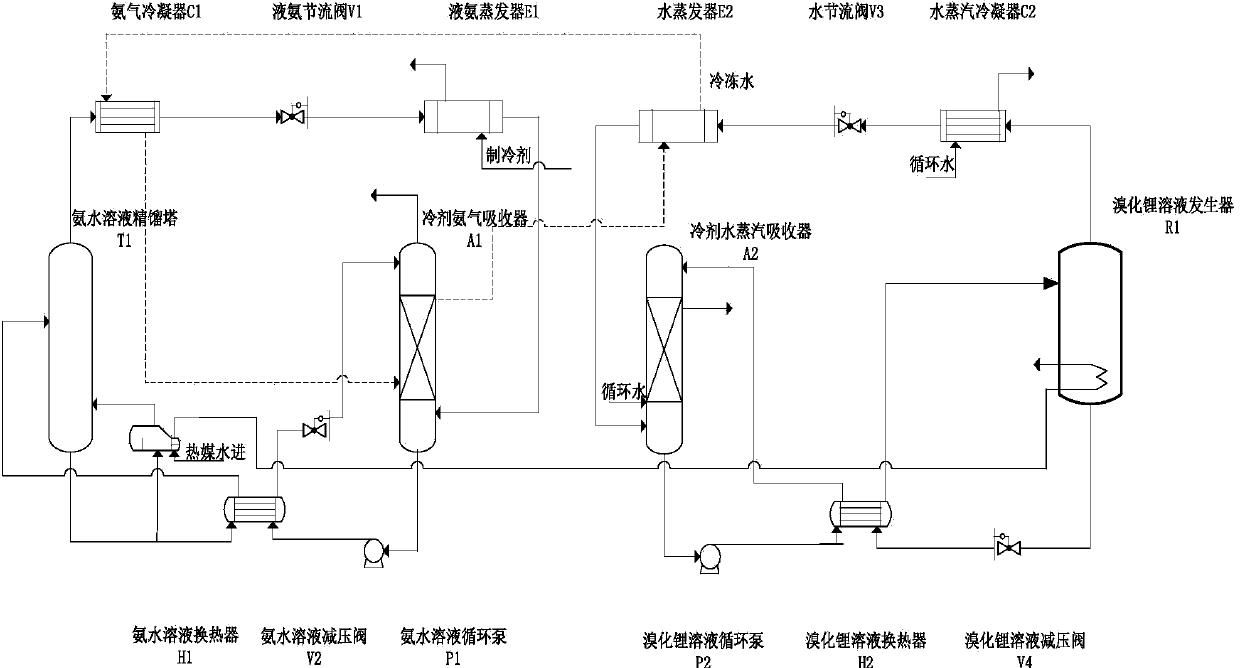

[0026] Such as figure 1As shown, the top of the ammonia solution rectifying tower 1 is connected to the ammonia condenser 2, and the ammonia enters the refrigerant ammonia absorber 5 after passing through the ammonia condenser 2, the liquid ammonia throttle valve 3, and the liquid ammonia evaporator 4 successively; The bottom of the ammonia solution rectification tower 1 is connected with the ammonia solution heat exchanger 7, and the dilute ammonia solution enters the refrigerant ammonia absorber 5 to absorb the refrigerant ammonia after passing through the ammonia solution heat exchanger 7 and the ammonia solution pressure reducing valve 8 successively, The concentrated ammonia solution at the outlet of the absorber 5 passes through the ammonia solution circulation pump 6 and the ammonia solution heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com