Oil gas defrosting system and method for condensation method oil-gas recovery device

A recovery device and condensation method technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve problems such as increased oil-gas side resistance, blockage of oil-gas channels, affecting normal operation of oil-gas recovery devices, etc., to speed up defrosting speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

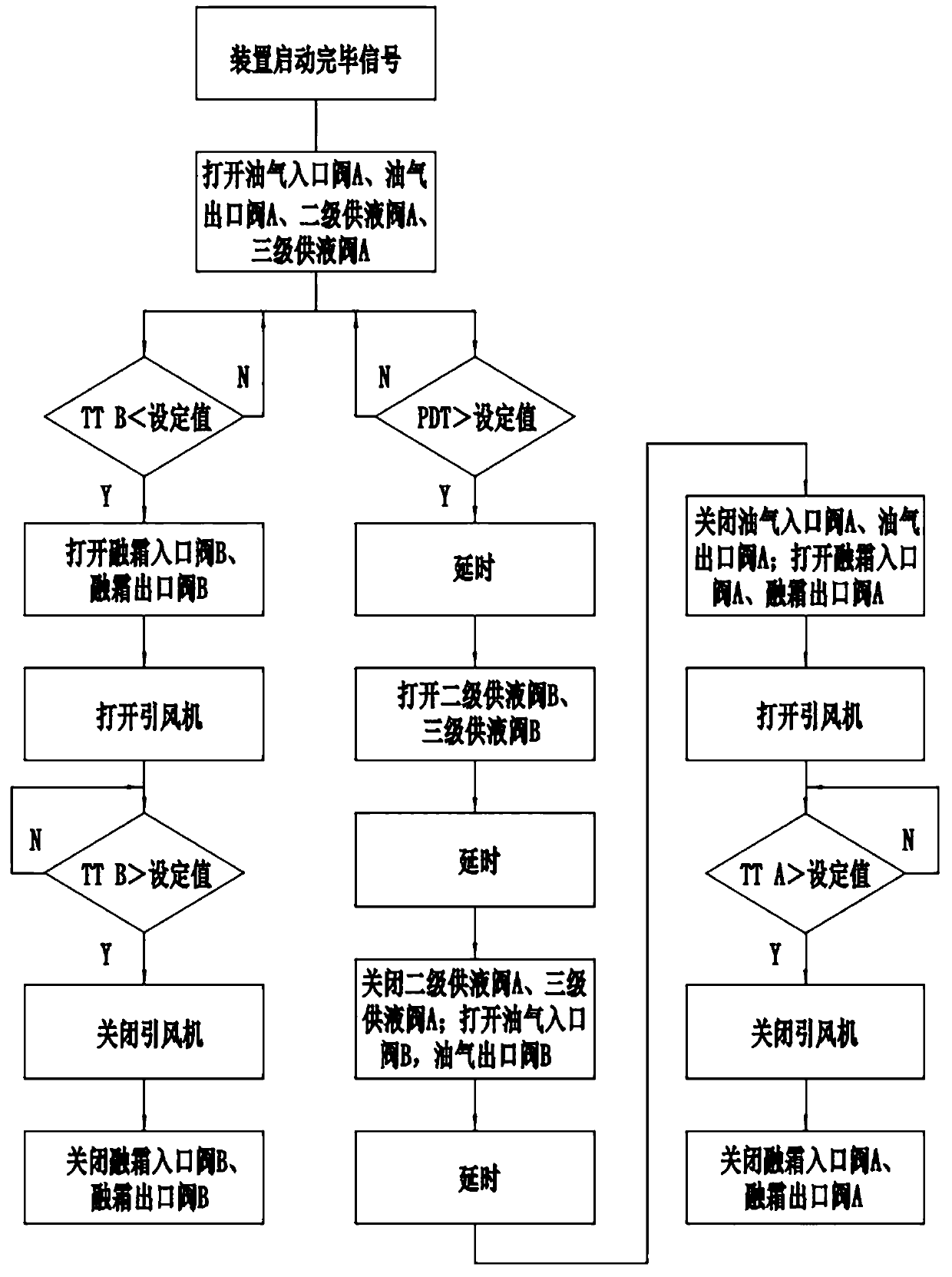

[0027] Describe the technical scheme of the present invention in detail below in conjunction with accompanying drawing:

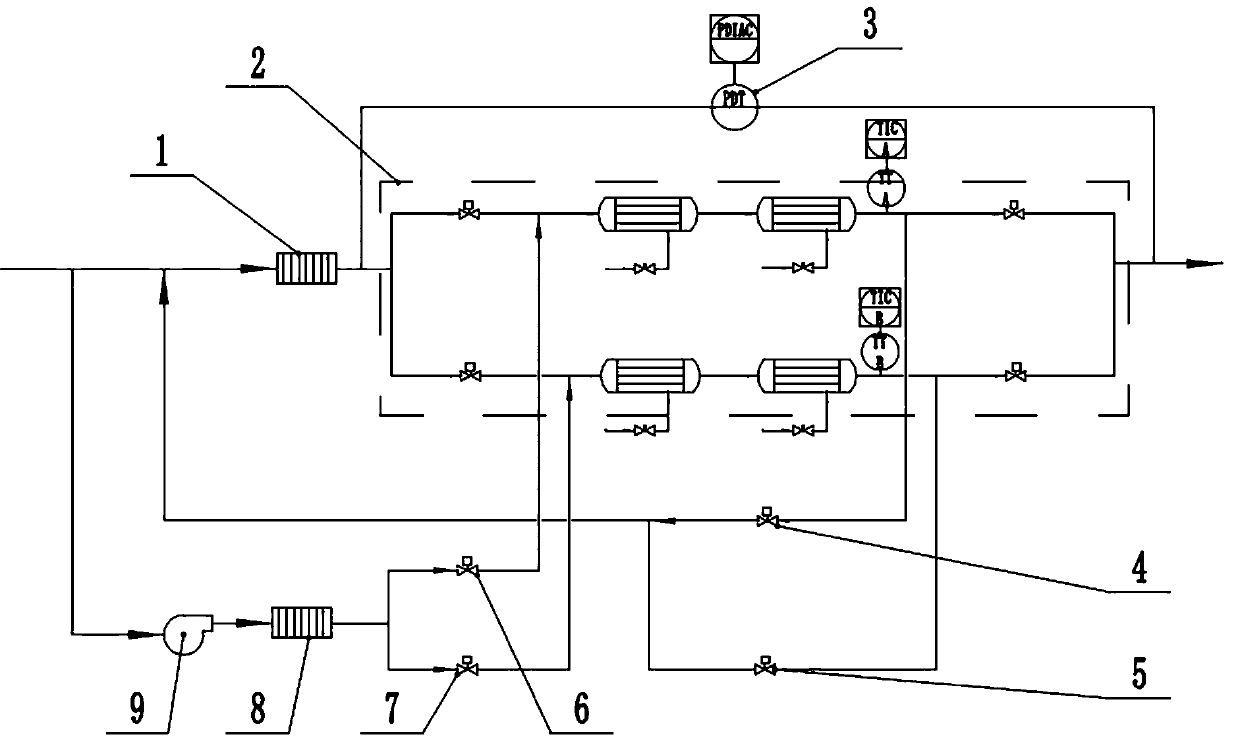

[0028] like figure 1 and 2 , An oil and gas defrosting system for a condensation method oil and gas recovery device, the oil and gas recovery device comprises an oil and gas inlet and an oil and gas outlet, and also includes a primary heat exchange installed between the oil and gas inlet and the oil and gas outlet in turn and used for condensing oil and gas 1 and post-stage heat exchange module 2.

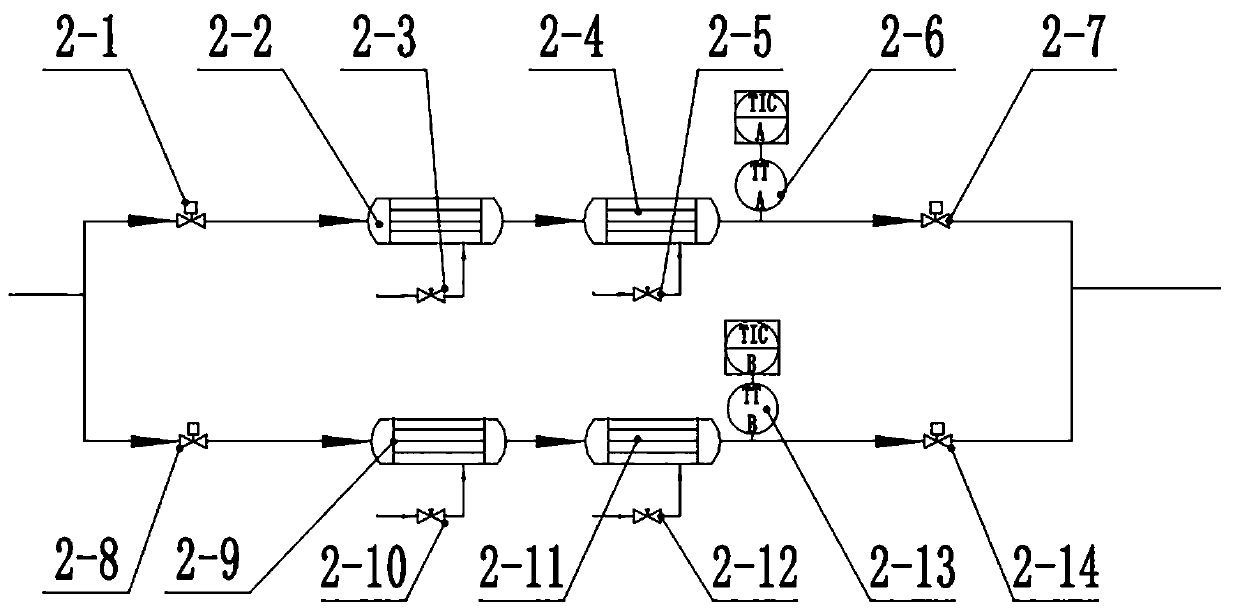

[0029] like figure 2 , the heat exchange module is provided with two parallel heat exchange branches A and B.

[0030] The heat exchange branch A is provided with oil and gas inlet valve A2-1, secondary heat exchanger A2-2, tertiary heat exchanger A2-4 and oil and gas outlet valve A2-7 in sequence along the oil and gas flow direction, and the secondary heat exchanger A2-2 is connected with the secondary liquid supply valve A2-3, and the tertiary heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com