Photoelectric sensing hot gas bypass defrosting refrigerator and working method

A photoelectric sensor, photoelectric sensor technology, applied in household refrigerators, defrosting, using optical devices, etc., can solve the problems of low defrosting efficiency, incomplete defrosting, etc., achieve complete defrosting, save service life, and use convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

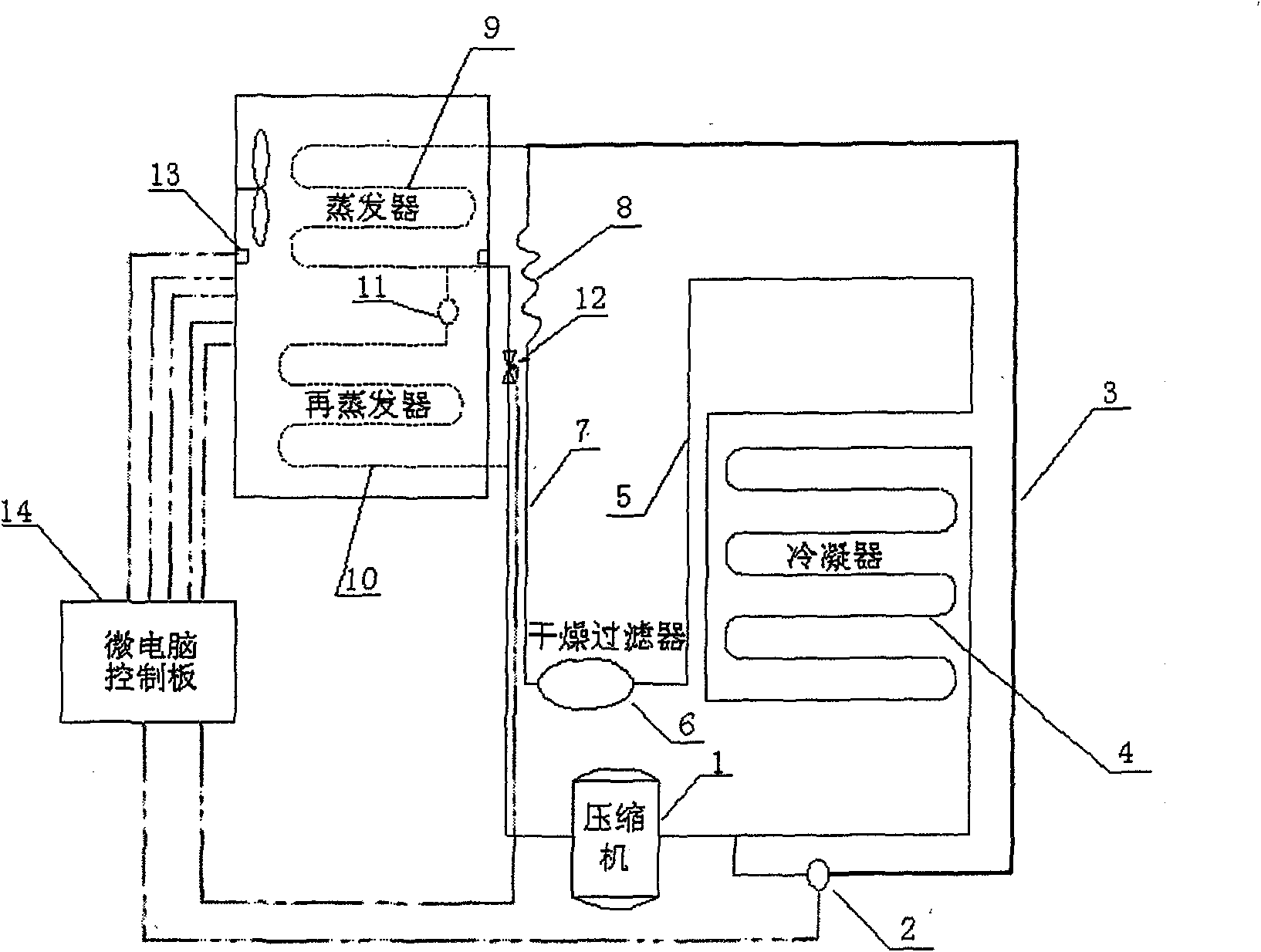

[0012] Such as figure 1 The structural diagram of the photoelectric sensor hot gas bypass defrosting refrigerator is shown. The photoelectric sensor hot gas bypass defrosting refrigerator includes a compressor 1, a solenoid valve 2, a hot gas bypass pipeline 3, a condenser 4, an anti-dew pipe 5, and a dry filter Device 6, heat recovery section 7, capillary tube 8, evaporator 9, re-evaporator 10, pressure reducing valve 11, stop valve 12, photoelectric sensor 13 and microcomputer control board 14. The output port of the compressor 1 is connected to the inlet of the evaporator 9 through the solenoid valve 2 and the hot gas bypass line 3, the output of the evaporator 9 is connected to the re-evaporator 10 through the pressure reducing valve 11, and the stop valve 12 is located between the output port of the evaporator 9 and the re-evaporator Between the output ports of the device 10, the photoelectric sensor 13 is placed on the side of the evaporator, the frost on the evaporator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com