Novel heat energy utilization system and novel heat energy utilization method for cyclohexanol production

A technology of cyclohexanol and thermal energy, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, separation/purification of hydroxyl compounds, etc., and can solve problems such as low heat utilization rate, failure to realize efficient recycling of heat, and waste of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

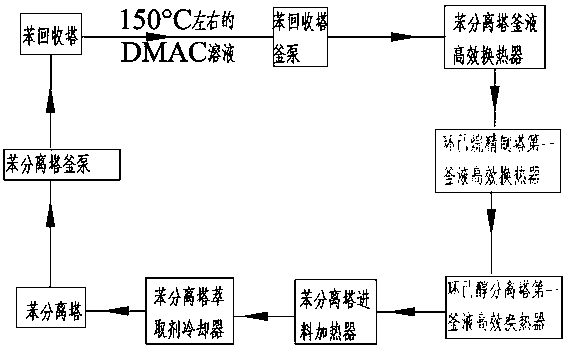

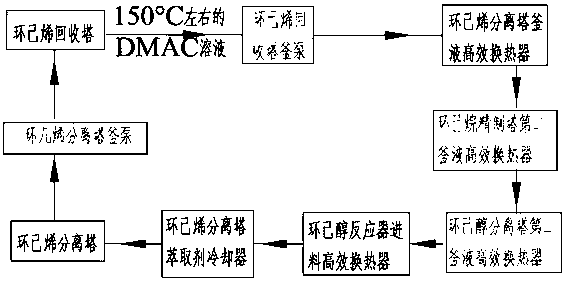

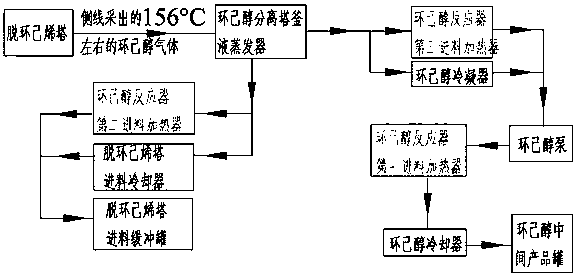

[0055] A new thermal energy utilization system in the production of cyclohexanol, comprising a benzene recovery tower thermal energy utilization unit (such as figure 1 shown), cyclohexene recovery tower heat utilization unit (such as figure 2 shown), decyclohexene tower heat utilization unit (such as image 3 shown) and cyclohexane refining tower thermal energy utilization unit (such as Figure 4 shown);

[0056] The heat energy utilization unit of the benzene recovery tower includes the benzene recovery tower, the benzene recovery tower tank pump, the high-efficiency heat exchanger for the tank liquid of the benzene separation tower, the high-efficiency heat exchanger for the first tank liquid of the cyclohexane refining tower, and the first tank of the cyclohexanol separation tower Liquid high-efficiency heat exchanger, benzene separation tower feed heater, benzene separation tower extractant cooler, benzene separation tower, benzene separation tower kettle pump;

[0057...

Embodiment 2

[0066] A new thermal energy utilization method in the production of cyclohexanol, the process equipment connection relationship is the same as that of Example 1, comprising the following steps:

[0067] ①The 140°C benzene recovery tower liquid DMAC is pumped out by the benzene recovery tower liquid pump, and first enters the benzene separation tower liquid high-efficiency heat exchanger to exchange heat for the benzene separation tower liquid at 120°C, reducing the temperature of DMAC to 125 ℃, followed by the high-efficiency heat exchanger for the first kettle liquid of the cyclohexane refining tower to exchange heat for the cyclohexane refining tower kettle liquid at 85°C, reducing the DMAC temperature to 105°C, and then entering the first kettle of the cyclohexanol separation tower The high-efficiency liquid heat exchanger exchanges heat for the 75°C cyclohexanol separation tower kettle liquid, and the DMAC temperature drops to 85°C, and then enters the benzene separation to...

Embodiment 3

[0073] A new thermal energy utilization method in the production of cyclohexanol, the process equipment connection relationship is the same as that of Example 1, comprising the following steps:

[0074] ① The 155°C benzene recovery tower liquid DMAC is pumped out by the benzene recovery tower liquid pump, and first enters the benzene separation tower liquid high-efficiency heat exchanger to exchange heat for the benzene separation tower liquid at 135°C, reducing the temperature of DMAC to 140 ℃, followed by the high-efficiency heat exchanger for the first kettle liquid of the cyclohexane refining tower to exchange heat for the 110℃ cyclohexane refining tower kettle liquid, and reduce the DMAC temperature to 115℃, and then enter the first kettle of the cyclohexanol separation tower The high-efficiency liquid heat exchanger exchanges heat for the 85°C cyclohexanol separation tower kettle liquid, and the DMAC temperature drops to 95°C, and then enters the benzene separation tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com