Washing and drying integrated machine with rolling drum

An all-in-one machine and drum technology, applied to other washing machines, household clothes dryers, washing devices, etc., can solve the problems of small water outlet, unstable path, large processing error, etc., to expand the area of the water outlet and increase the contact of water flow Surface, improve the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

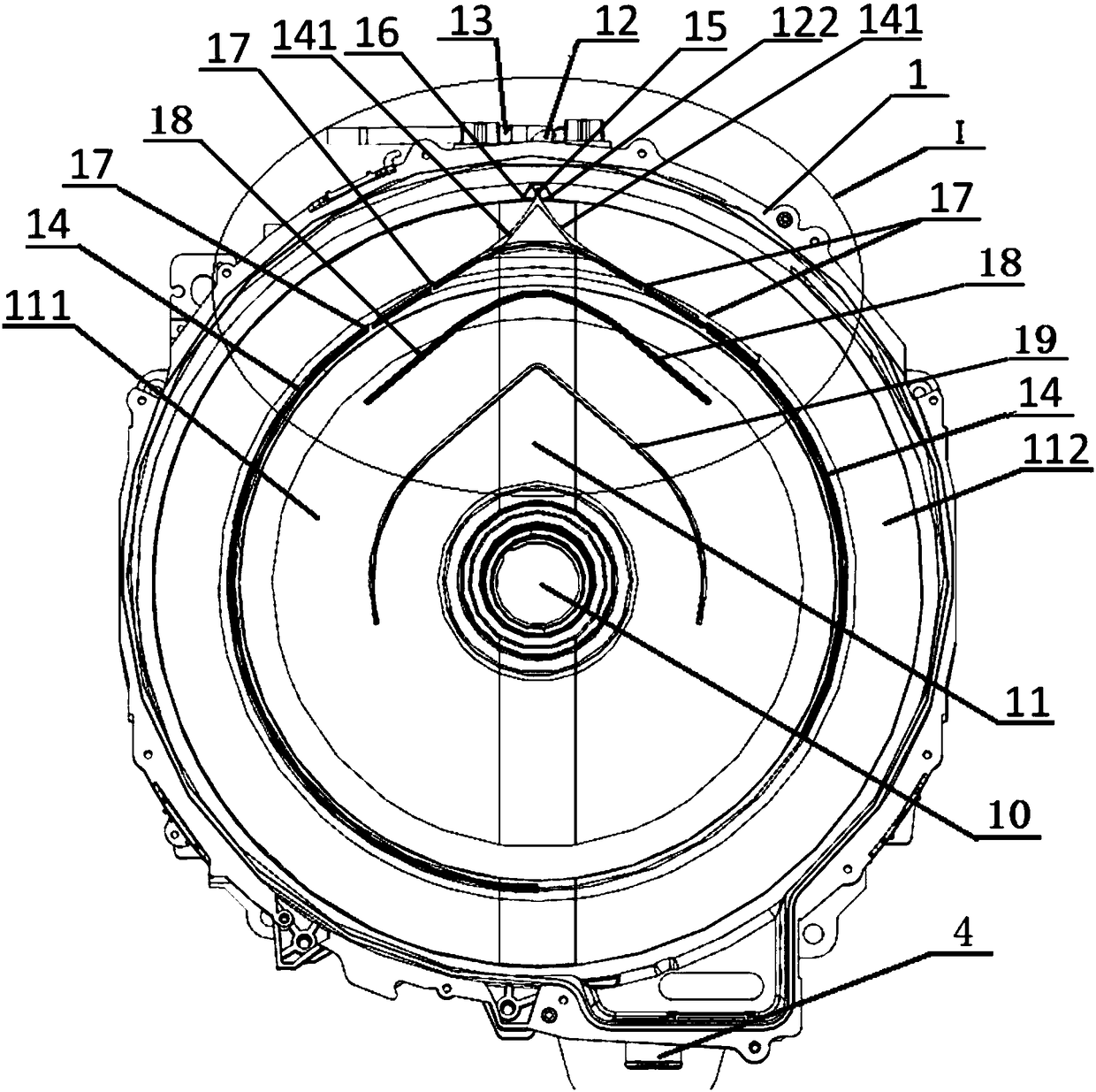

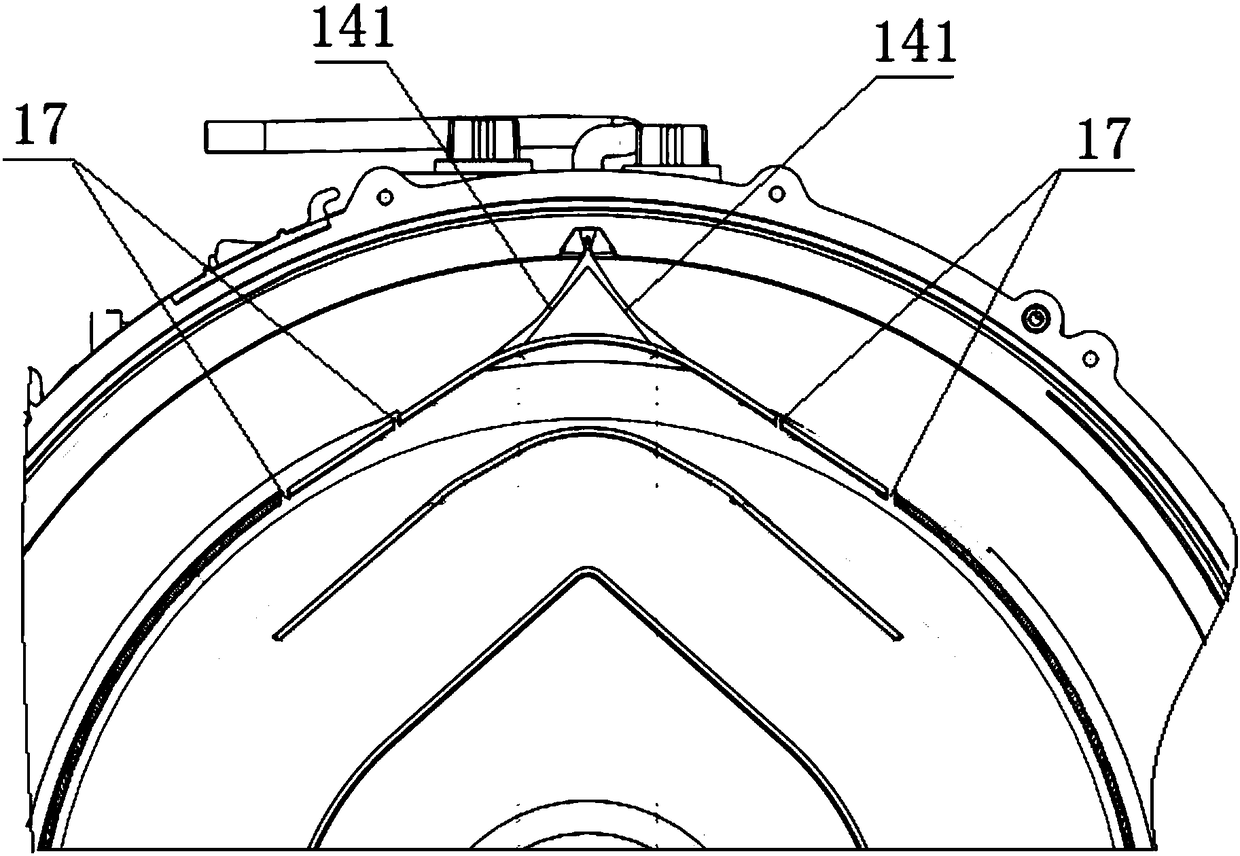

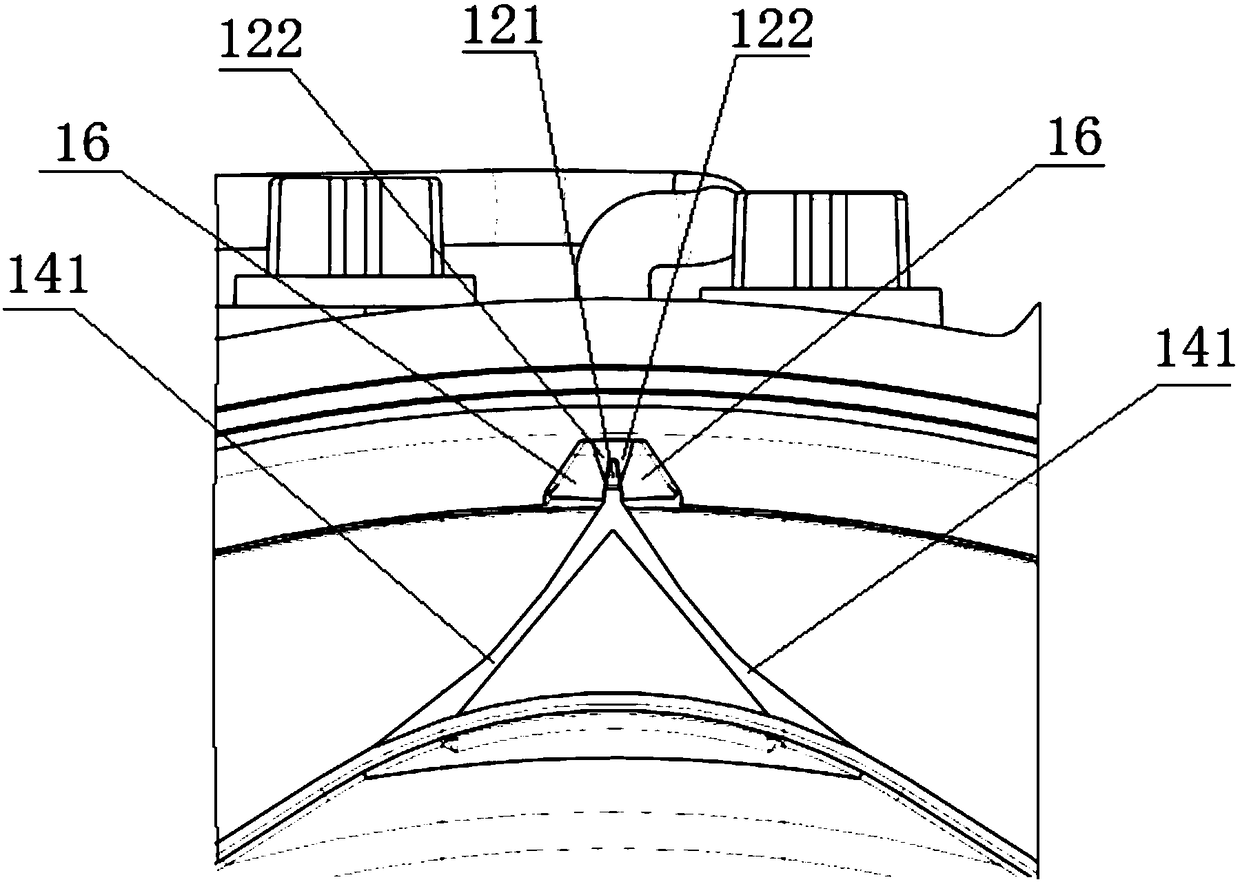

[0036] Such as figure 1 , diagram 2-1 , Figure 2-2 , image 3 and Figure 6 Shown is an embodiment of the integrated drum washer-dryer of the present invention. The drum washer-dryer includes a tub 1, a drum 2 and a cooling water supply device, the cooling water supply device supplies cooling water to the bottom wall 11 of the tub through a cooling water inlet channel 12, so that The bottom wall of the bucket forms a condensation surface. Since the condensation surface is directly formed on the bottom wall of the bucket, the space occupation is greatly reduced and the product shape is optimized. The outlet end 121 of the cooling water inlet channel 12 is arranged on the upper part of the bottom wall of the bucket, and a diverter component for diverting the cooling water inlet is provided at the outlet end 121 of the cooling water inlet channel. The outlet port 121 is separated by a flow dividing member to form a flow dividing outlet 122 . Through the diversion design o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com