Method for recovering byproduct chloromethane in maltol production

A recovery method, the technology of methyl chloride, is applied in the field of recovery of by-product methyl chloride in the production of maltol, which can solve the problems of simple impurity removal process, large energy consumption, and insufficient purity of methyl chloride, so as to achieve simple operation process and increase the output of finished products , The effect of improving the purity of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

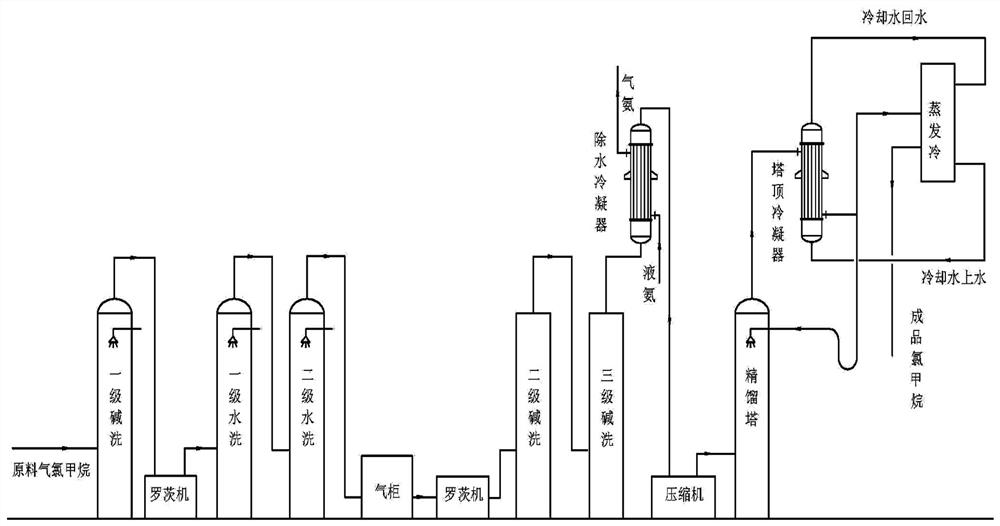

[0023] Such as figure 1 Shown, the recovery method of by-product methyl chloride in a kind of maltol production provided by the invention comprises the following steps:

[0024] 1) During the production process of maltol, the by-product methyl chloride raw material gas (including methyl chloride, hydrogen chloride, methanol, water, the proportions are 95%, 2%, 1%, 2% respectively) is produced at a pressure of 2KPa and a temperature of 20°C, enter the first-level alkali washing tower, and use 10% sodium hydroxide for alkali washing to remove part of the hydrogen chloride acid gas in the raw material gas of methyl chloride, and require the first-level alkali washing tower to have a pH ≥ 8;

[0025] 2) The methyl chloride gas after the primary alkali washing is pumped through the Roots machine (the outlet pressure of the Roots machine is controlled at about 0-30KPa), and then enters the primary and secondary water washing towers (the outlet flow of the primary water washing tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com