Preparation method for ketoprofen

A technology of ketoprofen and benzoylphenyl, which is applied in the field of preparation of ketoprofen, can solve the problems of complex production process, low yield of finished product, high production cost, etc., and achieve simple production process and low production cost. Low, little pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

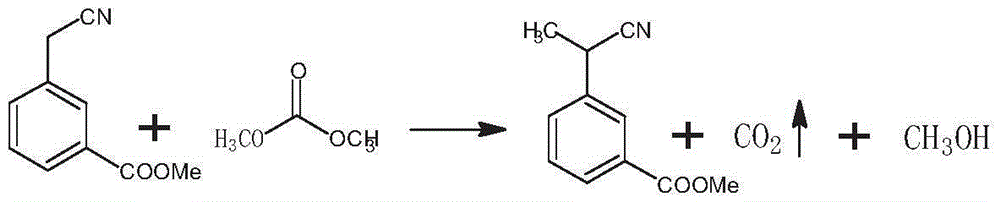

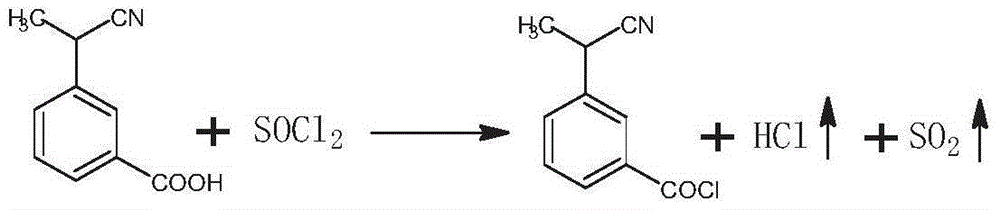

[0029] The preparation method of ketoprofen in this embodiment comprises 3-(1-cyanoethyl)methyl benzoate preparation stage, 3-(1-cyanoethyl)benzoic acid preparation stage, 3-(1-cyanoethyl) Base) benzoyl chloride preparation stage, 2-(3-benzoylphenyl) propionitrile preparation stage and ketoprofen stage, concrete steps are as follows:

[0030] 1) 3-(1-cyanoethyl) methyl benzoate preparation stage

[0031] Add methyl 3-cyanomethylbenzoate, dimethyl carbonate, and potassium carbonate with a molar ratio of 3:20:1 into a dry autoclave, and slowly heat up to 180°C under stirring, and control the pressure below 3MPa. After 30 hours of heat preservation, the reaction is completed; the reaction solution is filtered through pressure, washed with water to neutrality, and then excess dimethyl carbonate is removed by distillation, and high vacuum rectification is carried out to obtain methyl 3-(1-cyanoethyl)benzoate;

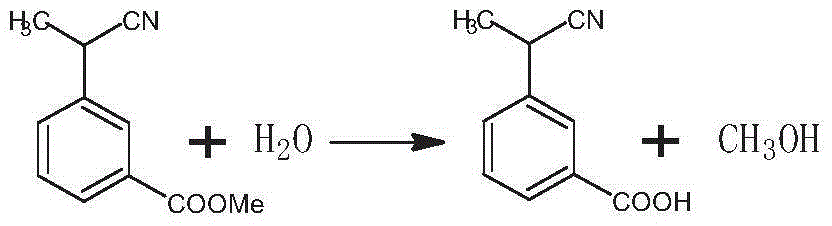

[0032] 2) 3-(1-cyanoethyl)benzoic acid preparation stage

[0033] Add...

Embodiment 2

[0041] The preparation method of ketoprofen in this embodiment comprises 3-(1-cyanoethyl)methyl benzoate preparation stage, 3-(1-cyanoethyl)benzoic acid preparation stage, 3-(1-cyanoethyl) Base) benzoyl chloride preparation stage, 2-(3-benzoylphenyl) propionitrile preparation stage and ketoprofen stage, concrete steps are as follows:

[0042] 1) 3-(1-cyanoethyl) methyl benzoate preparation stage

[0043] Add methyl 3-cyanomethylbenzoate, dimethyl carbonate, and potassium carbonate with a molar ratio of 1:10:1 into a dry autoclave, and slowly raise the temperature to 130°C under stirring, and control the pressure below 1.5MPa , and the reaction was completed after being incubated for 50 hours; the reaction solution was filtered through press, washed to neutrality, then distilled to remove excess dimethyl carbonate, and high vacuum rectification obtained 3-(1-cyanoethyl) methyl benzoate;

[0044] 2) 3-(1-cyanoethyl)benzoic acid preparation stage

[0045] Add water and 3-(1-cya...

Embodiment 3

[0053] The preparation method of ketoprofen in this embodiment comprises 3-(1-cyanoethyl)methyl benzoate preparation stage, 3-(1-cyanoethyl)benzoic acid preparation stage, 3-(1-cyanoethyl) Base) benzoyl chloride preparation stage, 2-(3-benzoylphenyl) propionitrile preparation stage and ketoprofen stage, concrete steps are as follows:

[0054] 1) 3-(1-cyanoethyl) methyl benzoate preparation stage

[0055] Add methyl 3-cyanomethylbenzoate, dimethyl carbonate, and potassium carbonate with a molar ratio of 2:8:0.01 into a dry autoclave, and slowly heat up to 300°C under stirring, and control the pressure below 6MPa. After 10 hours of heat preservation, the reaction is completed; the reaction solution is filtered through press, washed with water to neutrality, then the excess dimethyl carbonate is removed by distillation, and high vacuum rectification is carried out to obtain methyl 3-(1-cyanoethyl)benzoate;

[0056] 2) 3-(1-cyanoethyl)benzoic acid preparation stage

[0057] Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com