Method for preparing high-purity tetrapropylammonium bromide

A tetrapropylammonium bromide, high-purity technology, applied in the field of tetrapropylammonium bromide preparation, can solve the problems of low purity of tetrapropylammonium bromide, many impurities, etc., achieve good use prospects and high purity of finished products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

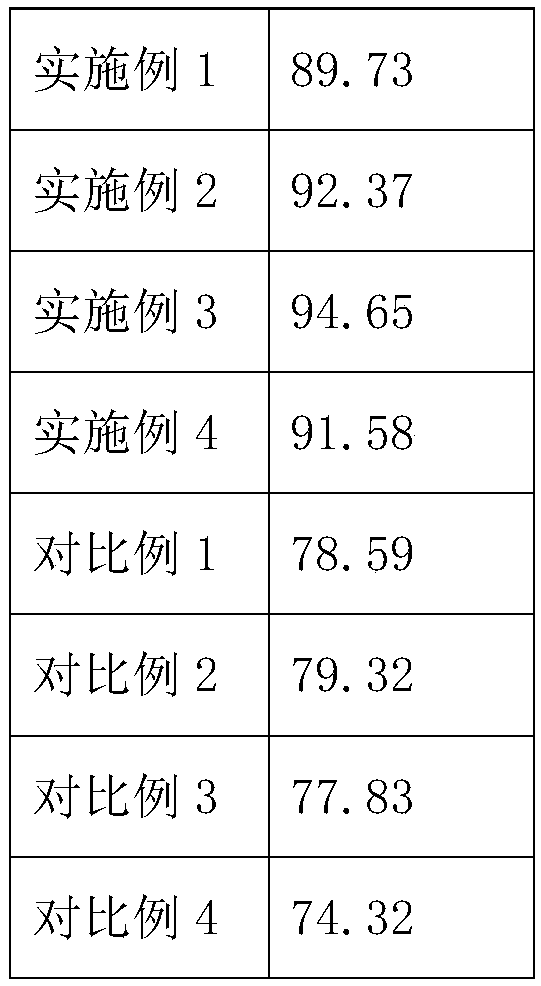

Embodiment 1

[0022] A method for preparing high-purity tetrapropylammonium bromide, the concrete steps are as follows:

[0023] Step 1, mix tri-n-propylamine, 1-bromopropane and butanone in an autoclave, the molar ratio of tri-n-propylamine and 1-bromopropane is 1:1.1, the temperature of the autoclave is 145 degrees Celsius, and the pressure is 0.68MPa, The temperature rise reaction is carried out under stirring. The system after the reaction is a solid-liquid two-phase, the solid phase is tetrapropylammonium bromide, and the liquid phase is unreacted raw materials. After the reaction is completed, an appropriate amount of water is added thereto, and the solid phase is dissolved in water to obtain Tetrapropylammonium bromide aqueous solution, tetrapropylammonium bromide aqueous solution is immiscible with unreacted raw material, separates and obtains tetrapropylammonium bromide aqueous solution;

[0024] Step 2: Distill the tetrapropylammonium bromide aqueous solution under reduced pressur...

Embodiment 2

[0028] A method for preparing high-purity tetrapropylammonium bromide, the concrete steps are as follows:

[0029] Step 1, mix tri-n-propylamine, 1-bromopropane and ethyl acetate in an autoclave, the molar ratio of tri-n-propylamine and 1-bromopropane is 1:1.2, heat up reaction under stirring, the system after reaction is solid Two phases of liquid, the solid phase is tetrapropylammonium bromide, the liquid phase is unreacted raw materials, after the reaction is completed, add an appropriate amount of water to it, and the solid phase is dissolved in water to obtain tetrapropylammonium bromide aqueous solution, tetrapropylammonium bromide Aqueous solution of ammonium chloride is immiscible with unreacted raw material, separates and obtains aqueous solution of tetrapropylammonium bromide;

[0030] Step 2, the tetrapropylammonium bromide aqueous solution is distilled under reduced pressure to recover ethyl acetate, and then the remaining products are dried to obtain the tetraprop...

Embodiment 3

[0034] A method for preparing high-purity tetrapropylammonium bromide, the concrete steps are as follows:

[0035] Step 1, mix tri-n-propylamine, 1-bromopropane and acetone in an autoclave, the molar ratio of tri-n-propylamine and 1-bromopropane is 1:1.3, the temperature of the autoclave is 152 degrees Celsius, the pressure is 0.65MPa, stir The temperature rise reaction is carried out under the following conditions. The system after the reaction is a solid-liquid two-phase, the solid phase is tetrapropylammonium bromide, and the liquid phase is unreacted raw materials. Propyl ammonium bromide aqueous solution, tetrapropyl ammonium bromide aqueous solution is immiscible with unreacted raw material, separates and obtains tetrapropyl ammonium bromide aqueous solution;

[0036] In step 2, tetrapropylammonium bromide aqueous solution is distilled under reduced pressure to recover acetone, and then the remaining products are dried, and rinsed with a modifier for 2 minutes. The modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com