Patents

Literature

39 results about "1-Bromopropane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1-Bromopropane (n-propylbromide or nPB) is an organobromine compound with the chemical formula CH₃CH₂CH₂Br. It is a colorless liquid that is used as a solvent. It has a characteristic hydrocarbon odor. Its industrial applications increased dramatically in the 21st century.

Azeotropic compositions comprising methyl perfluoropentene ethers for cleaning applications

The present disclosure provides azeotropic and azeotrope-like compositions comprised of methylperfluoropentene ethers and at least one of methanol, ethanol, 2-propanol, hexane, heptane, trans-1,2-dichloroethylene, ethyl formate, methyl formate, HFE-7100, HFE-7200 and 1-bromopropane or combinations thereof. The present disclosure also provides for methods of use for the azeotropic and azeotrope-like compositions.

Owner:EI DU PONT DE NEMOURS & CO

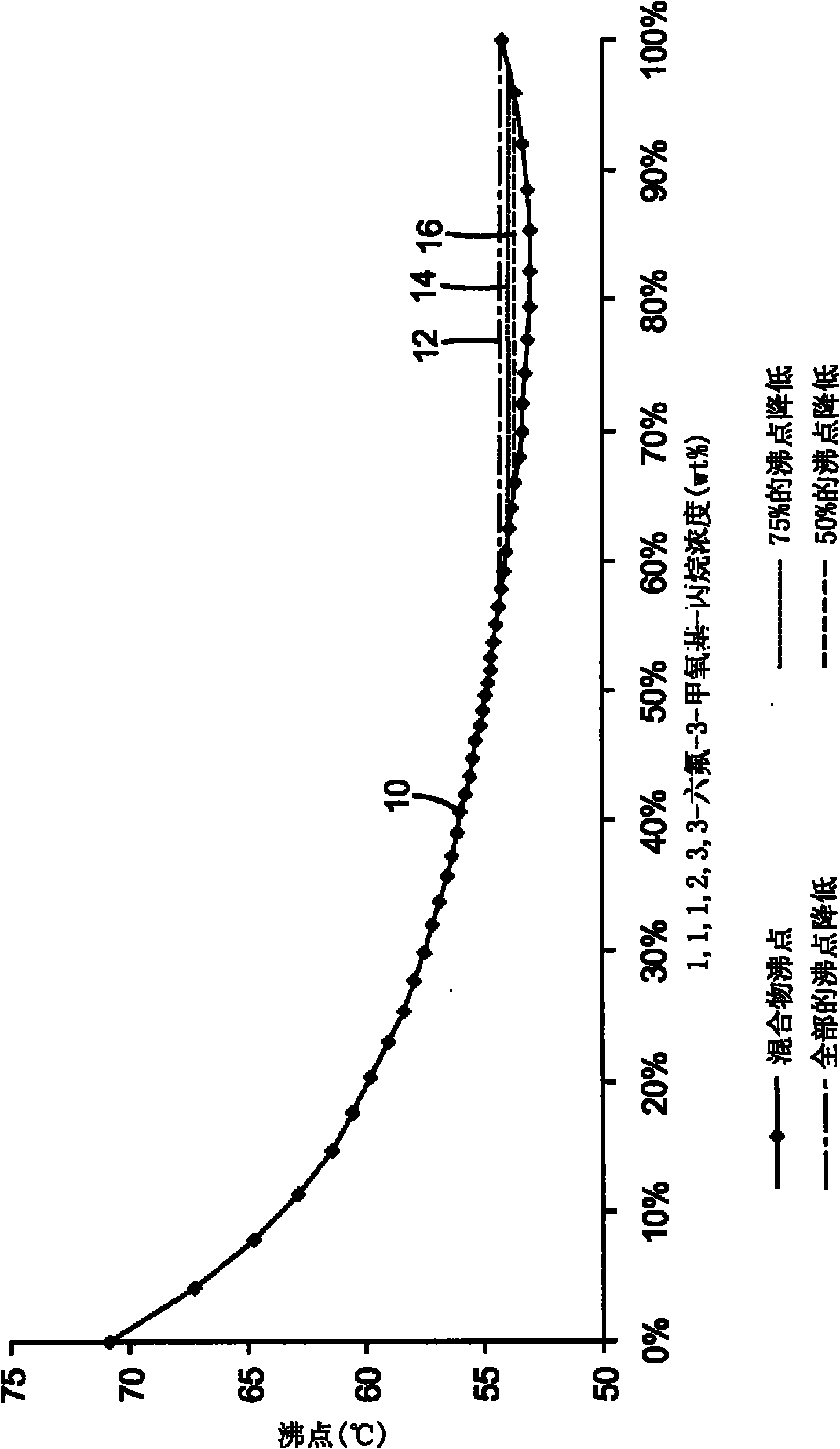

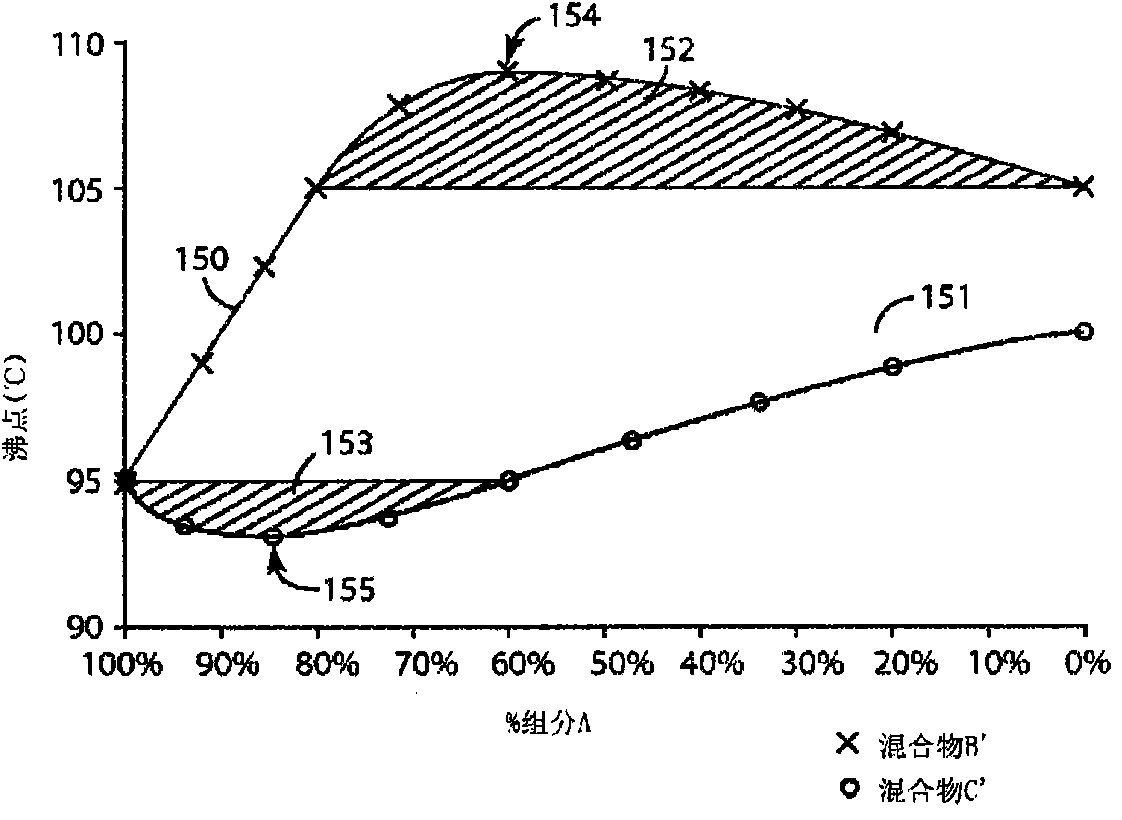

Azeotrope compositions containing a fluorocyclopentane

Novel azeotrope compositions comprised of a mixture of a fluorocyclopentane with a solvent selected from the group consisting of 1-bromopropane, t-dichloroethylene, and methylene chloride. Such compositions are useful as solvents in refrigeration flushing, oxygen system cleaning, foam blowing, and cleaning operations such as cold cleaning, vapor degreasing, and aerosol cleaners.

Owner:SHELLEF HLDG

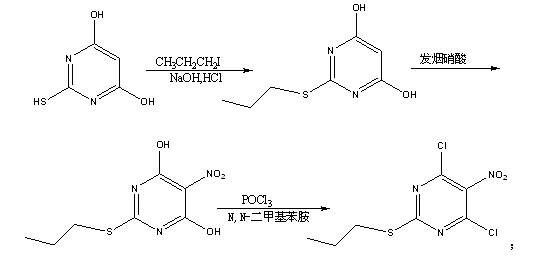

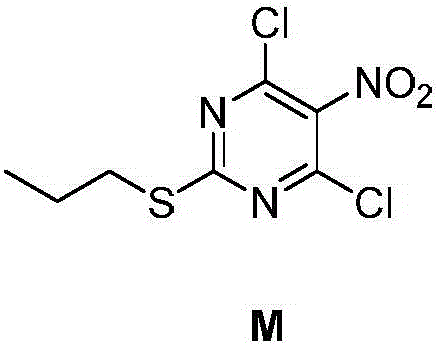

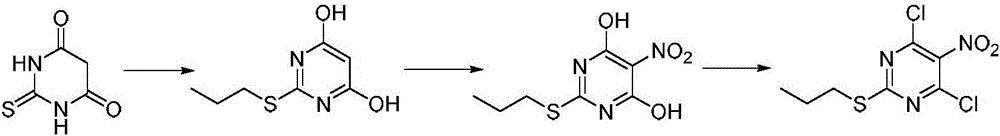

Method for preparing 4,6-dichloro-5-amino-2-(propylsulfanyl)pyrimidine

The invention provides a method for preparing 4,6-dichloro-5-amino-2-(propylsulfanyl)pyrimidine. The method comprises the following steps: 1, adding 4,6-dyhydroxy-2-mercaptopyrimidine into water, dripping a 10 percent sodium hydroxide solution, adding methanol and 1-bromopropane, reacting by keeping temperature, and acidifying to separate out crystals so as to obtain 4,6-dyhydroxy-2-(propylthio)pyrimidine; 2, adding fuming nitric acid into glacial acetic acid, adding the 4,6-dyhydroxy-2-(propylthio)pyrimidine, and adding water to separate out crystals so as to obtain 4,6-dyhydroxy-5-nitro-2-(propylthio)pyrimidine; 3, adding a chloro agent into dichloromethane, adding the 4,6-dyhydroxy-5-nitro-2-(propylthio)pyrimidine in batches, adding saturated brine, and postprocessing to obtain 4,6-dichloro-5-nitro-2-(propylthio)pyrimidine; and 4, adding iron powder into an organic solvent, adding the 4,6-dichloro-5-nitro-2-(propylthio)pyrimidine in batches, adding dichloromethane and water to dissolve residue, demixing, evaporating an organic layer to dryness under reduced pressure obtain an oily product, and adding a crystallizing solvent to obtain the 4,6-dichloro-5-amino-2-(propylsulfanyl)pyrimidine. The method overcomes defects of the prior art, so that production cost is reduced.

Owner:SHANDONG CHENGCHUANG PHARMA R&D

Chemical composition for a fire retardant textile

InactiveUS20060135386A1Improve performanceIncreased durabilityNon-surface-active detergent compositionsDry-cleaning apparatus for textilesWater basedChemical composition

The present invention relates to methods and chemical compositions utilizing NPB (n-propyl bromide) also called 1-bromopropane or propyl bromide or 1-BP or N-Bromopropane as non-aqueous carrier mediums to apply fire retardants, fluorocarbons and other chemicals to substrates, whereby the NPB is evaporated away leaving the remaining chemicals on the substrate. The present invention offers compositions and method for applying organic chemicals to substrates that perform superior to current water based technology. Additional, the invention offers a more economical and environmental friendly alternative to current chlorinated hydrocarbons carriers that are being phased out by mandate of the Environmental Protection Agency (EPA).

Owner:RISING LARRY

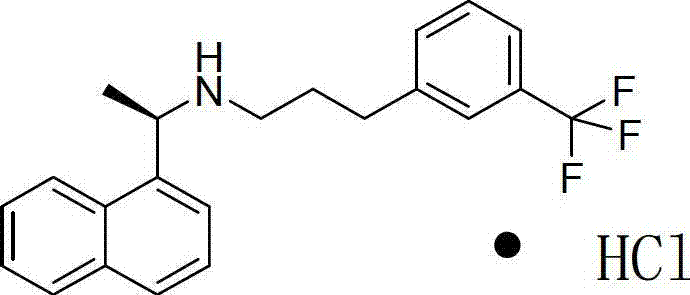

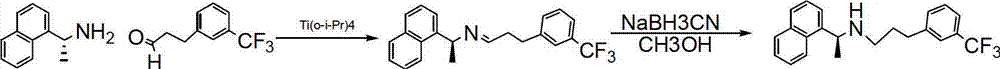

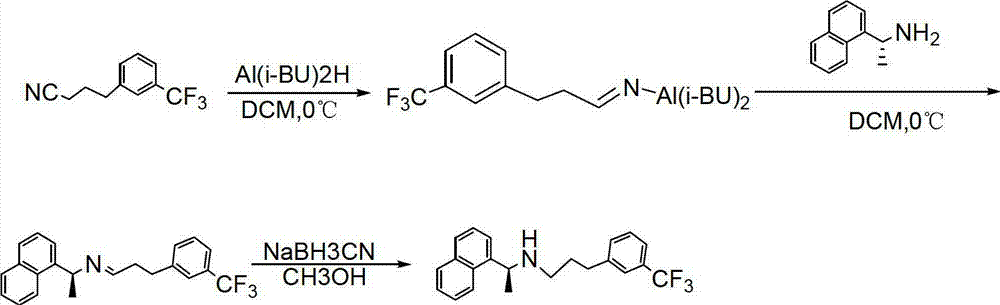

Preparation method of high-purity cinacalcet hydrochloride

InactiveCN103044267AReduce generationEasy to operateAmino compound purification/separationAmino preparation by functional substitutionAcetic acidEthyl ester

The invention relates to a preparation method of high-purity cinacalcet hydrochloride. The method comprises the following steps: using R(+)-1-naphthylethanamine and (3-(3-trifluoromethyl) phenyl)-1-bromopropane as starting materials, taking acetonitrile as a solvent, reacting under the action of alkali to get cinacalcet, acidifying a reaction solution in water with hydrochloric acid to get a cinacalcet hydrochloride crude product, and recrystallizing the crude product with ethyl acetate to get the high-purity cinacalcet hydrochloride. The method is simple to operate and suitable for industrialization.

Owner:CHINA RESOURCES SAIKE PHARMA

Electrical equipment cleaning agent and preparation method

InactiveCN101982544AStrong degreasing abilityGood decontamination effectOrganic non-surface-active detergent compositionsCleansing Agents1-Bromopropane

The invention discloses an electrical equipment cleaning agent and a preparation method. The preparation method comprises the following steps: placing 24.9-50.7 of 1-bromopropane, 7.3-14.8 of isopropanol and 34.5-67.9 of HCFC-141b into an enclosed reactor; and stirring under the normal pressure and at the temperature of 50-70 DEG C, and reacting for 30min to obtain the electrical equipment cleaning agent. The electrical equipment cleaning agent of the invention has low toxicity, low ODP value, small pungent odor, better dirt-removing capacity and permeability, can adjust the volatility of products, is not easy to burn, dose not burn when meeting naked flame, and has low price.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Green and environment-friendly live cleaning agent and preparation process thereof

InactiveCN108085178ALow toxicityNon-flammableOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsAlkaneOzone layer

The invention discloses a green and environment-friendly live cleaning agent and a preparation process thereof. The green and environment-friendly live cleaning agent is characterized by being prepared from components in percentage by mass as follows: 65%-85% of 1-bromopropane, 13%-33% of an alkane solvent, 0-15% of an alcohol solvent and 0-10% of ethyl acetate. The finished product is prepared after the components in the formula are weighed in percentage by mass and stirred and mixed uniformly. The raw materials are green and environment-friendly ingredients, and the green and environment-friendly live cleaning agent prepared with the formula and the process does not contain substances damaging ozone layers, is environmentally friendly and low in toxicity to human bodies and has the characteristics of being nonflammable, resistant to high pressure, easy to volatilize, free of residues and free from corrosion to metal, plastic and painting and the like.

Owner:山东泰丰清洗科技有限公司

Chemical formulations and methods utilizing NPB(n-propyl bromide) as non-aqueous carrier mediums to apply fluorocarbons and other organic chemicals to substrates

InactiveUS20040006827A1No ozone pollution propertiesGood choicePhysical treatmentSolvent treatment with solvent recoveryWater basedPropyl bromide

The present invention relates to methods and chemical formulations utilizing NPB(n-propyl bromide) also called 1-bromopropane or propyl bromide or 1-BP or N-Bromopropane as non-aqueous carrier mediums to apply fluorocarbons and other chemicals to substrates, whereby the NPB is evaporated away leaving the remaining chemicals on the substrate. The present invention offers formula and method for applying organic chemicals to substrates that perform superior to current water based technology. Additional, the invention offers a more economical and environmental friendly alternative to current chlorinated hydrocarbons carriers that are being phased out by mandate of the Environmental Protection Agency (EPA).

Owner:RISING LARRY ERVIN

Synthesis process for sodium valproate

InactiveCN105622390AIncrease conversion rate per passHigh yieldCarboxylic acid salt preparationGas phaseValproic Acid

The invention discloses a synthesis process for sodium valproate. The synthesis process comprises the following steps: mutually dissolving diethyl malonate and 1-bromopropane, slowly adding the obtained mixture into an ethanol solution of sodium ethoxide at a certain temperature, carrying out heating and reflux for 2 h, recovering ethanol until temperature is 110 DEG C, carrying out cooling to less than 80 DEG C, adding a certain amount of water to dissolve sodium bromide, carrying out layering to obtain a plurality of layers, then adding an aqueous sodium hydroxide solution with a concentration of 15 to 30%, carrying out hydrolysis at 60 to 70 DEG C for 3 h, then carrying out heating to recover ethanol until a gas phase temperature is 99 DEG C, carrying out cooling to less than 80 DEG C, adding hydrochloric acid for neutralization and acidifying, adding crude valproic acid to dissolve dipropylmalonic acid so as to obtain mixed acid and subjecting the mixed acid to slow heating and decarboxylation at 110 to 160 DEG C for production of crude valproic acid; and subjecting the crude valproic acid to rectification and refining, adding a certain amount of the aqueous sodium hydroxide solution for neutralization, adding toluene for reflux to bring out water, thereby allowing sodium valproate to dehydrate and crystallize and then successively carrying out filtering, washing with chloroform and drying so as to obtain finished sodium valproate. The process is safe and environment-friendly, produces good-quality sodium valproate, has low cost and is suitable for industrial production.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

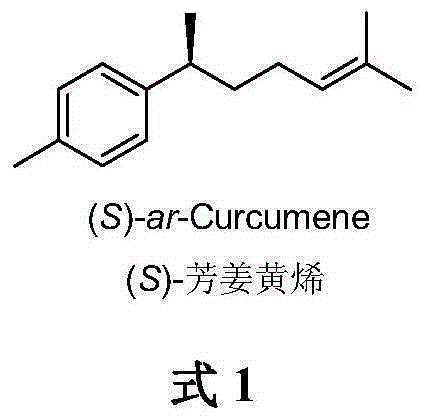

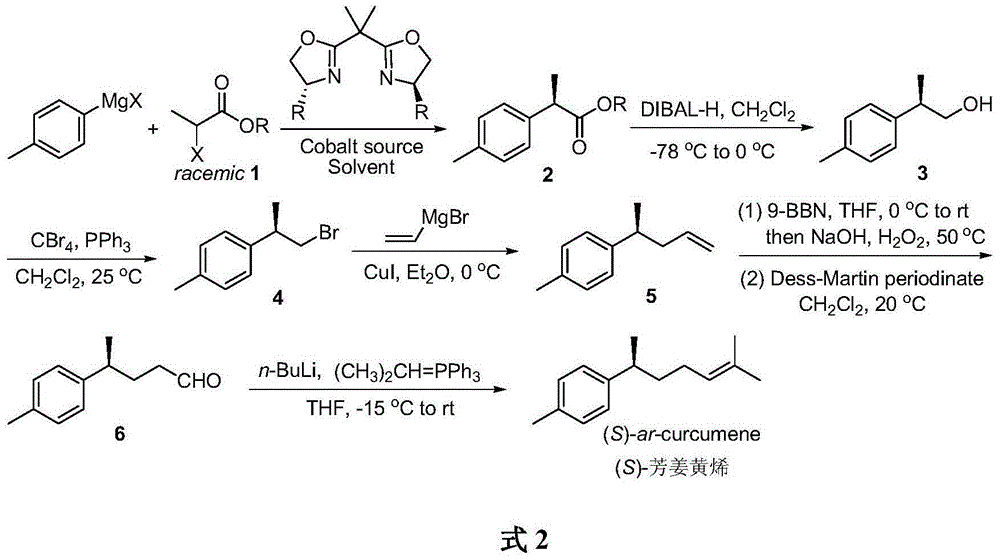

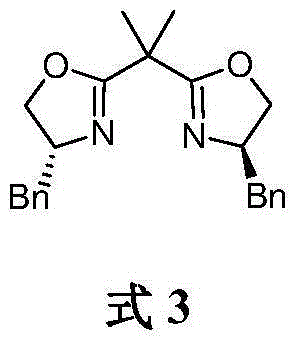

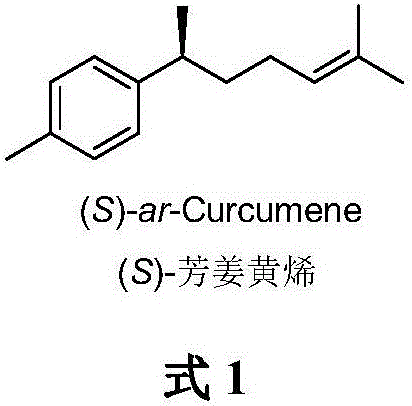

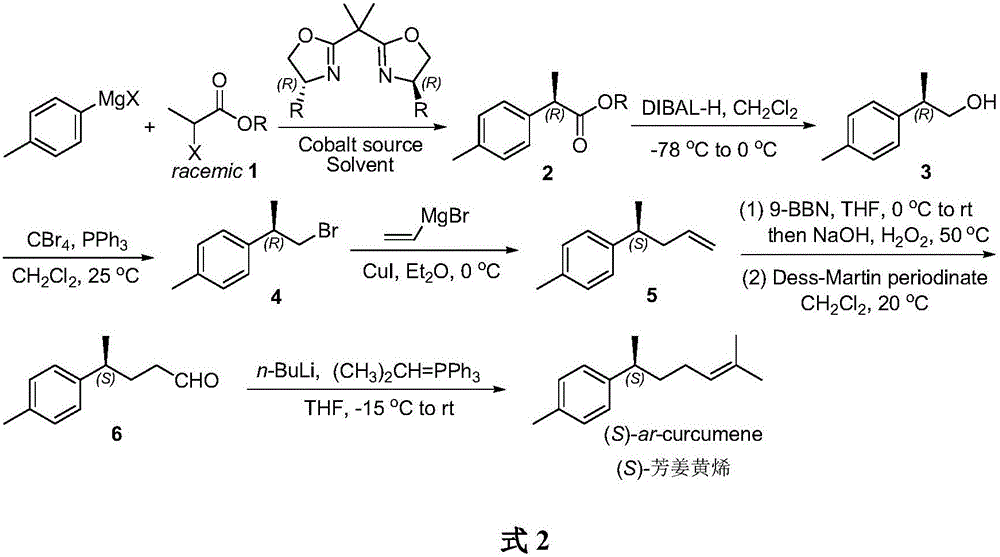

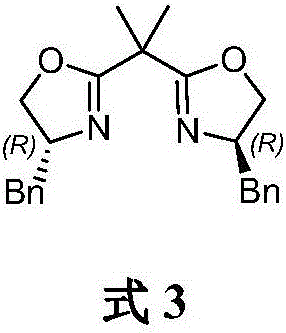

Method for asymmetrically catalyzing and synthesizing (S)-curcumene

The invention discloses a method for asymmetrically catalyzing and synthesizing (S)-curcumene. According to the method, racemization 2-halogenated propionate ester serves as a starting material, under the catalysis of bis oxazoline / cobalt, an asymmetrical Kumada cross coupling reaction is conducted, and (R)-2-p-methylphenyl propionate is obtained; then, (R)-2- p-methylphenyl-1-bromopropane is generated through reduction and bromine generation; next, coupling with vinyl Grignard reagent is conducted, borohydride-oxidation and Dess-Martin oxidation are conducted, and (S)-4-p-methylphenyl valeraldehyde is obtained; finally, a Wittig reaction is conducted, and (S)-curcumene is synthesized. The method is simple and concise in synthesis route, the total yield is 37%, and the optical purity of a product is 90%.

Owner:CHINA AGRI UNIV

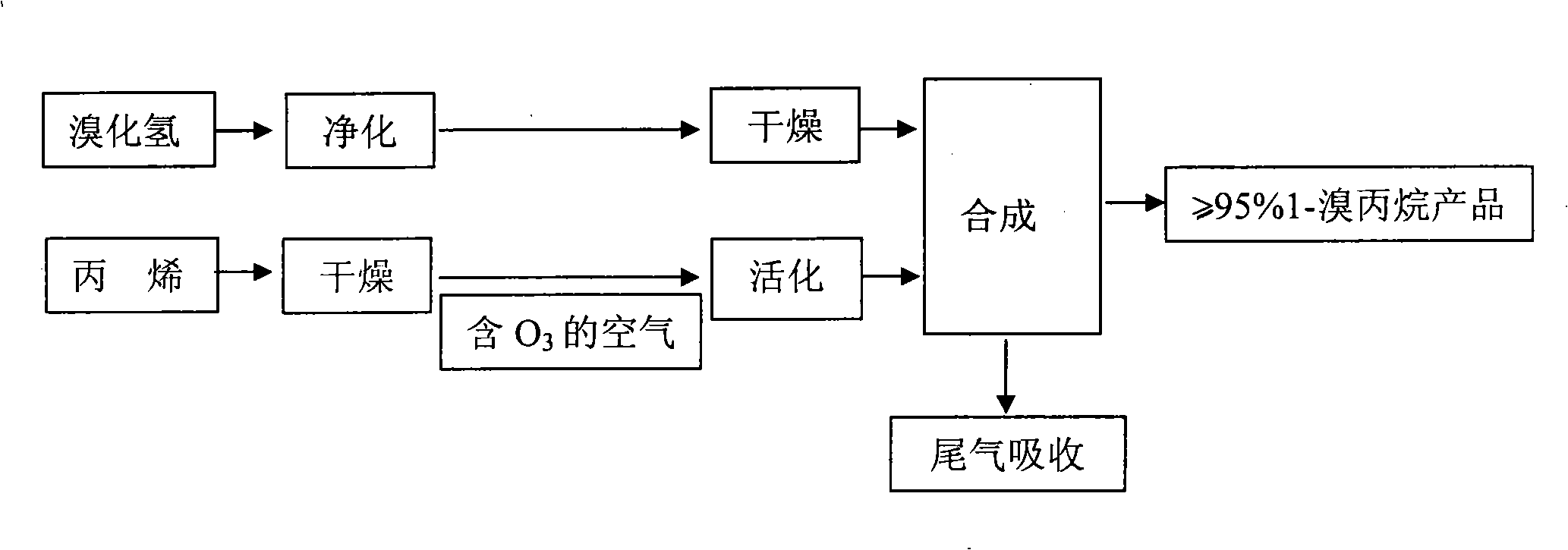

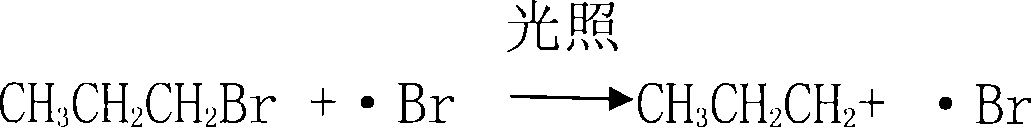

Method for preparing 1-bromopropane

ActiveCN101318876AOvercoming difficult problemsReduce manufacturing costPreparation by halogen halide additionPropyl bromide1-Bromopropane

The invention provides a method for making 1-propyl bromide, which comprises the preprocessing of hydrogen bromide, the drying of propylene, the activation of propylene and the synthesis of 1-propyl bromide. The method is to use high-purity gaseous hydrogen bromide and polymer-grade propylene as raw materials and carry out free radical reaction under the action of air containing 20 to 50 ppm ozone to obtain a product containing more than or equal to 95 percent of 1-propyl bromide. The reaction is carried out under the water-free condition in the presence of a reductive agent. The process has the advantages of low production cost, short route, simple and convenient operation, little corrosion to equipment, environmental protection, etc.

Owner:TIANJIN CHANGLU HAIJING GRP CO LTD

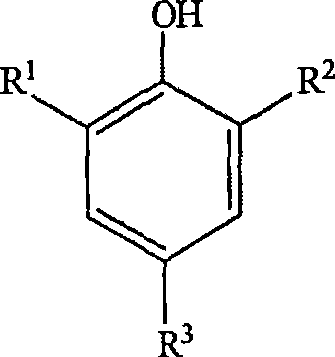

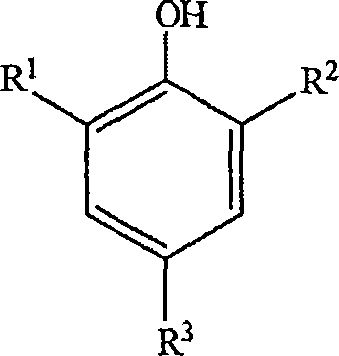

1-bromopropane having low acidity

The present invention provides a method comprising, mixing at least one phenol with a 1-bromopropane product mixture to form a phenol-containing 1-bromopropane product mixture, and obtaining the phenol-containing 1-bromopropane product mixture The purified 1-bromopropane product is recovered from the mixture. The present invention also provides a process for the preparation of a 1-bromopropane product mixture from 1-propanol and hydrogen bromide, characterized in that at least one phenol is mixed with the 1-bromopropane product mixture to form a A 1-bromopropane product mixture of phenol, and a purified 1-bromopropane product recovered from the phenol-containing 1-bromopropane product mixture.

Owner:ALBEMARLE CORP

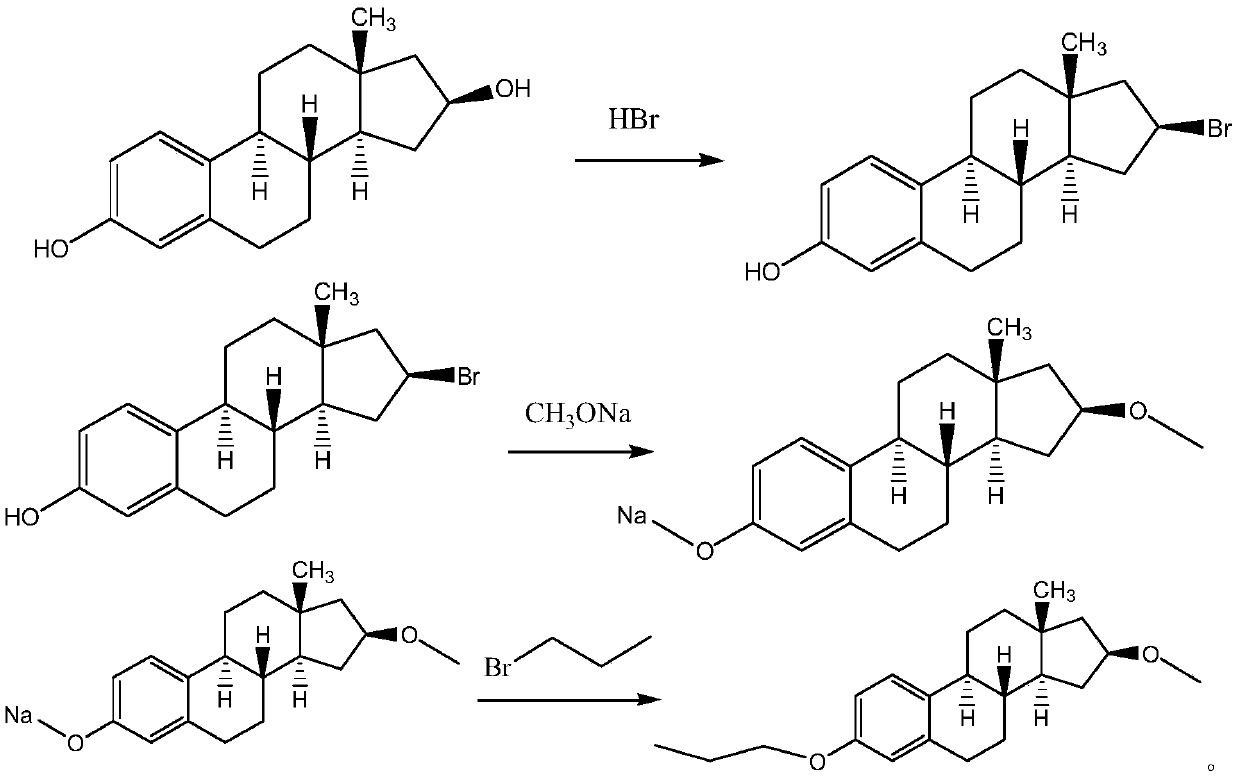

Synthesis process for promestriene

The invention relates to the technical field of medicine synthesis and in particular to a synthesis process for promestriene. The synthesis process comprises the following steps: by taking estradiol as a raw material, carrying out a halogenation reaction with a halogenation reagent under catalysis of a solid acid catalyst so as to generate 3-hydroxy-17beta-bromo-female steroid-1,3,5,(10)-triene, further carrying out a substitution reaction with a sodium methoxide methanol solution, and finally carrying out a synthesis reaction with 1-bromopropane by using Williamson so as to synthesize 3-hydroxy-17beta-methoxy-female steroid-1,3,5,(10)-triene, wherein the solid acid catalyst is a sulfonated carbon-based solid acid catalyst or a ZSM-5 molecular sieve catalyst. By adopting the synthesis process, hydrobromic acid and sodium methoxide are adopted to substitute sodium hydride of high danger and dimethyl sulphate of large toxicity, no combustible gas can be generated in the reaction, environment pollution and potential safety hazards can be reduced, the yield and the quality of a product can be ensured, the HPLC (high performance liquid) purity is greater than 99.8%, single impurities are less than 0.05%, and the synthesis process is applicable to industrial production.

Owner:BEIJING JINCHENG TAIER PHARMA CO LTD

Environment-friendly cleaning agent

InactiveCN105505624ALow damage indexLow global warming effectNon-surface-active detergent compositionsEpoxyDistillation

The invention relates to an environment-friendly cleaning agent, which comprises the following raw materials by dosage: 94%-95% of 1-bromopropane; 3%-4% of n-propanol; 0.2% of nitromethane; 0.8% of 1, 3-dioxolane; 0.7% of epoxy butane; and 0.3% of BHT. The environment-friendly cleaning agent provided by the invention has the advantages of low ozone depletion potential, low global warming effect, good environmental protection effect, high cleaning effect, high penetration, easy cleaning of microporous materials, fast drying speed, no flash point, low hydrolysis degree, stable gas-liquid phase change, and applicability to steam washing and distillation recovery, etc.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

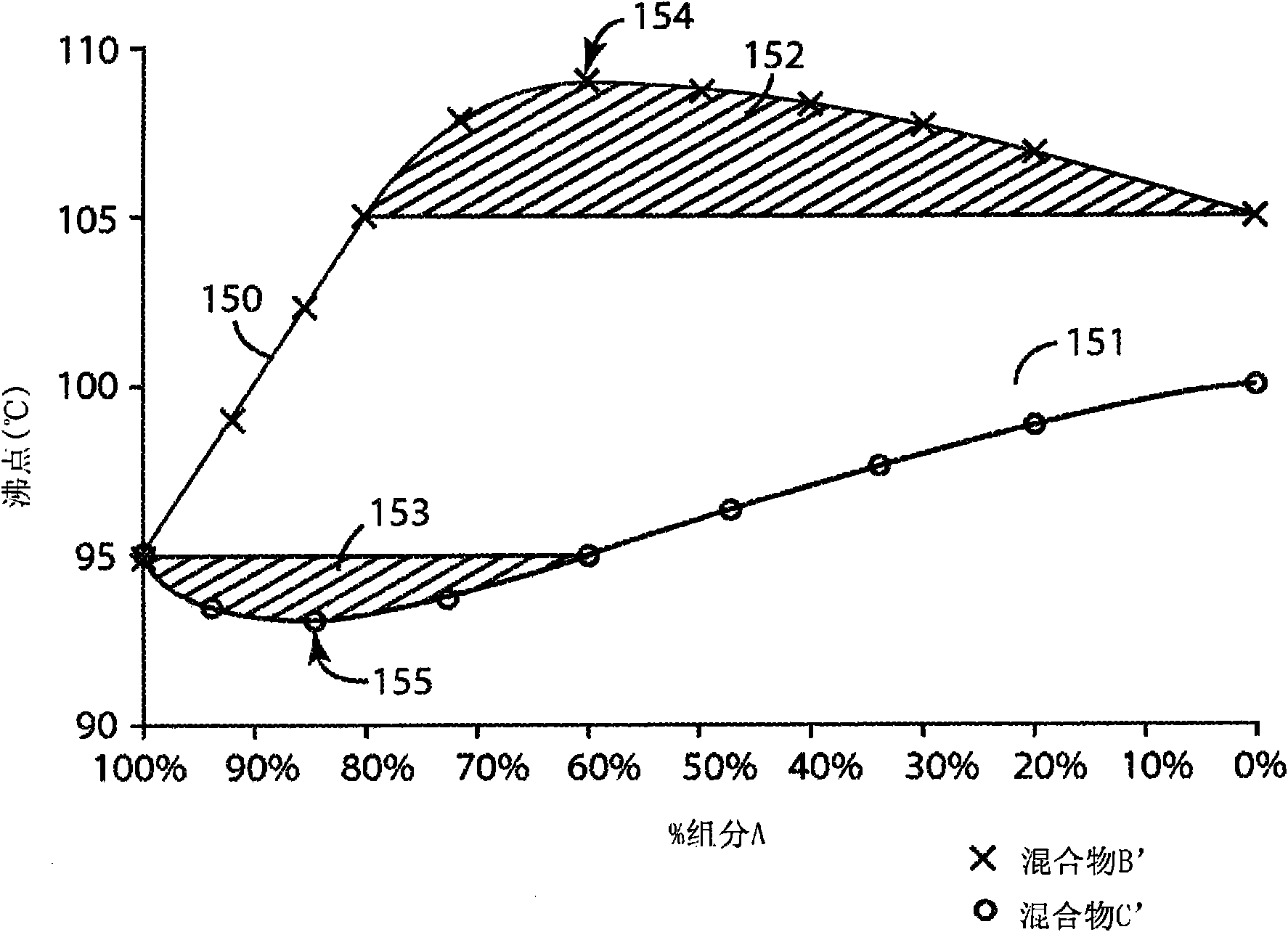

Azeotropic-like compositions with 1,1,1,2,3,3-hexafluoro-3-methoxy-propane and 1-bromopropane

InactiveCN101903488AHeat-exchange elementsNon-surface-active detergent solvents1-BromopropanePropane

Owner:3M INNOVATIVE PROPERTIES CO

Anti-corrosion and water-repellent substance and method

ActiveUS20170088955A1Improve adhesionAvoid Surface CorrosionLiquid surface applicatorsAnti-corrosive paintsParaffin waxNitromethane

An anti-corrosion and water-repellent substance configured for application to surfaces of materials to prevent corrosion and otherwise protect those materials. The substance consists of 1-bromopropane, nitromethane, ethyloxirane, and highly refined paraffin wax. In a preferred embodiment of a method of treating materials, the anti-corrosion and water-repellent substance is sprayed on a surface. In other embodiments, the substance may be applied with a brush or roller. In yet another embodiment, the substance may be applied by immersing the items being treated for optimal coverage of their exposed surfaces. The substance adheres to various materials and protects them by repelling water, acids, salt brines, and other substances and elements, including corrosives.

Owner:MICROCOR TECH INC

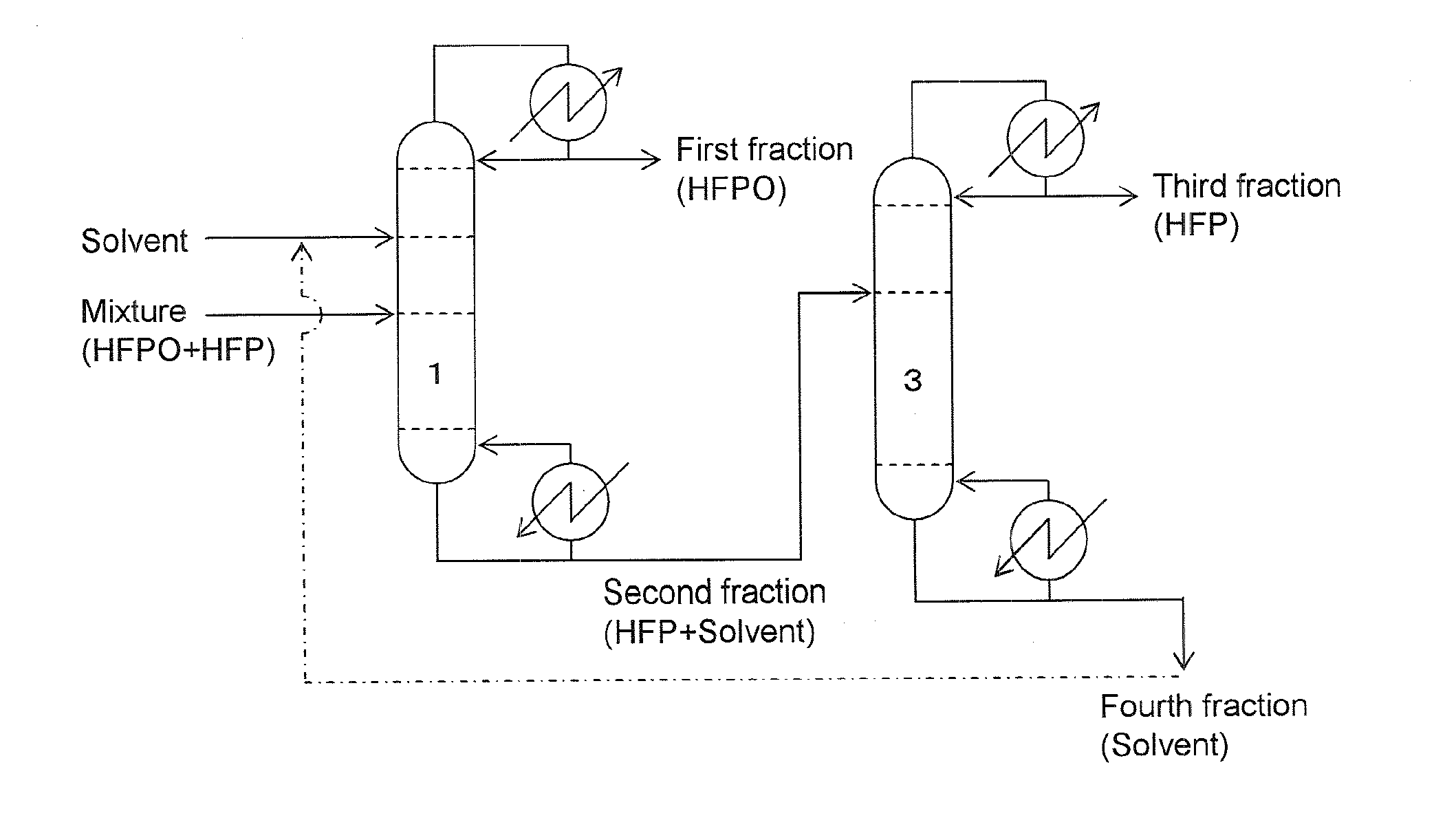

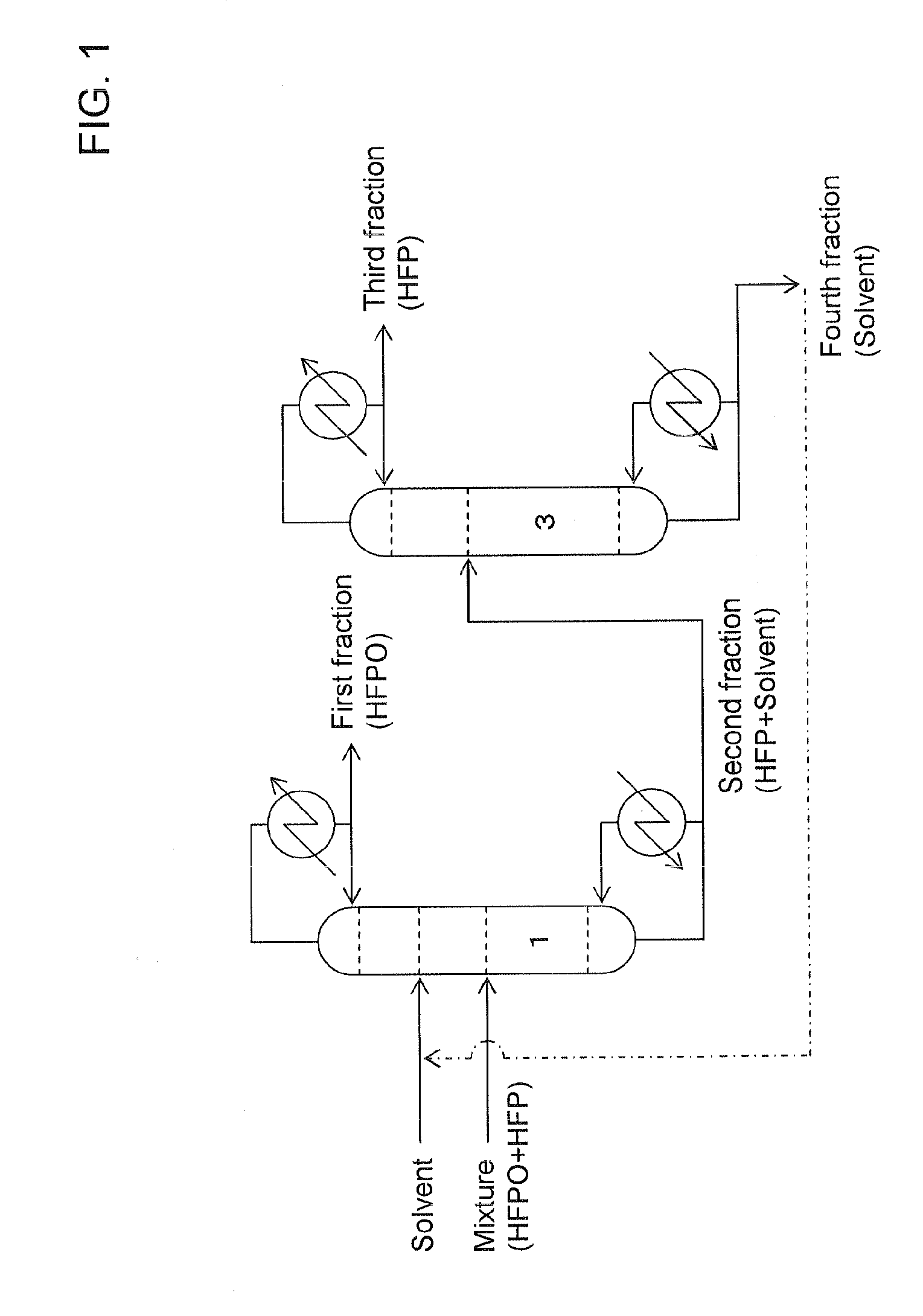

Method for separating hexafluoropropylene oxide from hexafluoropropylene

ActiveUS20120006672A1Reduce the burden onHalogenated hydrocarbon preparationExtractive distillationHexafluoropropyleneExtractive distillation

The present invention provides a novel method for separating hexafluoropropylene oxide (HFPO) from hexafluoropropylene (HFP), which is capable of reducing the burden on the environment. A mixture including HFPO and HFP is subjected to an extractive distillation operation using, as a solvent, at least one of a fluorine-containing saturated compound represented by the general formula CnHaFb (wherein n, a and b are integers which satisfy: n=3 to 8, 0≦a≦2n+1, and 1≦b≦2n+2) thereby separating into a first fraction including HFPO and a second fraction including HFP and the solvent. At least one of 1-bromopropane and 2-bromopropane may be u as the solvent in place of the fluorine-containing saturated compound.

Owner:DAIKIN IND LTD

Method for preparing tert-n-propyl ammonium bromide

InactiveCN109053459AHigh yieldIncrease reaction rateOrganic compound preparationAmino compound preparationGranularityAmmonium bromide

The invention discloses a method for preparing tert-n-propyl ammonium bromide. The method comprises the following steps: by taking 1-bromopropane and tri-n-propylamine as raw materials and ethanol asa solvent, synthesizing tert-n-propyl ammonium bromide in a reaction kettle, wherein the ethanol, the 1-bromopropane and the tri-n-propylamine are added in a mole ratio of 2.8 to 1.1 to 1, and a reaction yield is as high as 92%. By adopting the method, ethanol which is small in toxicity is adopted as the solvent, the reaction velocity can be increased, and the prepared tert-n-propyl ammonium bromide is uniform in crystal granularity, high in purity, high in yield, simple in operation step, low in production cost and good in industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

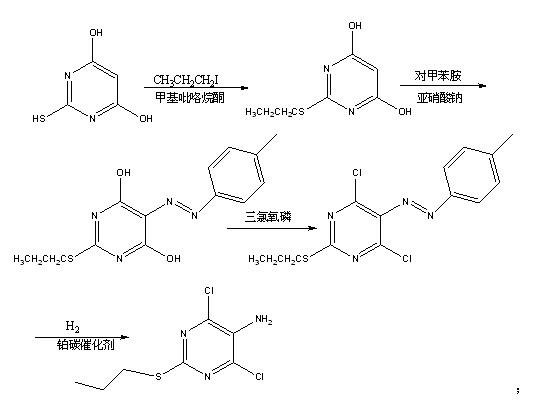

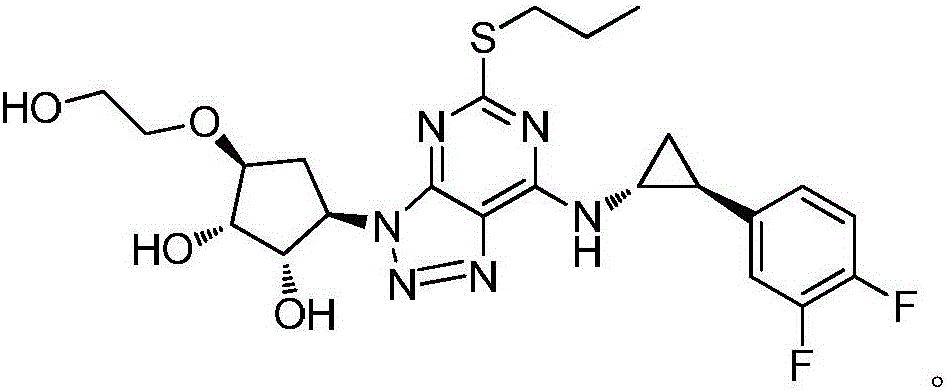

Preparation method for ticagrelor intermediate

The invention discloses a preparation method for a cagrelor intermediate. The preparation method comprises the following steps; step 1, reacting 2-nitro-1,3-malonic acid diester with sodium sulfocyanate and ammonium acetate in an aqueous solution of acetic acid so as to obtain a compound as shown in a formula II which is described in the specification; step 2, subjecting the compound as shown in the formula II to reflux in ethanol under the action of sodium alkoxide so as to obtain a compound as shown in a formula III which is described in the specification; step 3, subjecting the compound as shown in the formula III and 1-bromopropane to a contact reaction in 1,4-dioxane in the presence of alkali under the catalysis of zinc chloride; and step 4, subjecting a product of the step 3 and a chlorination reagent to a chlorination reaction in acetonitrile so as to obtain the ticagrelor intermediate 4,6-dichloro-5-nitro-2-(propylthio)pyridine. The preparation method provided by the invention has the advantages of few by-products, easy purification and high yield of the ticagrelor intermediate, usage of cheap and easily available raw materials and suitable for industrial production.

Owner:QINGDAO YUNTIAN BIOTECH

Household disinfection solution

The invention discloses a household disinfection solution, which is prepared from the following raw materials by mass: 7-11 parts of potassium iodide, 3-5 parts of triclosan, 5-7 parts of polyoxyethylene alkyl phenyl ether, 8-10 parts of chlorhexidine hydrochloride, 4-6 parts of alkyl amino acetate, 5-6 parts of 1-bromopropane, 3-4 parts of olea europaea fruit oil, 6-8 parts of ethoxyl lauryl ether, 8-9 parts of sodium dodecyl benzene sulfonate, 6-9 parts of sodium hypochlorite, 13-15 parts of potassium hydroxide, 5-7 parts of essence, and 30-40 parts of water. The household disinfection solution provided by the invention has the characteristics of long bactericidal and antibacterial duration, no irritating smell, safety and reliability, economic efficiency and environmental protection.

Owner:QINGDAO KELIKE INFORMATION TECH

Moisture retention and skin care perfumed soap

InactiveCN108060033APrevent drynessImprove decontamination abilitySoap detergents with organic compounding agentsDetergent compounding agentsTurpentineLanolin

The invention discloses a moisture retention and skin care perfumed soap. The perfumed soap is produced from, by weight, 8-11 parts of sodium citrate, 3-5 parts of 1-bromopropane, 5-8 parts of olive oil, 3-5 parts of ethanol, 9-13 parts of lanolin, 6-8 parts of sodium chloride, 7-9 parts of sorbitol, 10-14 parts of aloe powder, 5-7 parts of turpentine, 2-4 parts of Ziziphus jujuba Mill. extract, 5-9 parts of cucumber extract, 3-5 parts of skim milk, and the balance of a soap base. The perfumed soap has gentle skin care, moisture retention and moistening effects and a strong decontamination ability, and locks moisture to prevent skin dryness.

Owner:徐锋

Disinfectant

InactiveCN106577770AReduce health impactEffective disinfectionBiocideDead animal preservationTriclosanIodophor

The invention discloses a disinfectant which consists of the following mixed components in parts by weight: 10-15 parts of yeast cream, 6-15 parts of bamboo vinegar powder, 4-15 parts of sodium hexametaphosphate, 5-10 parts of 1-bromopropane, 6-10 parts of chlorhexidine hydrochloride, 6-15 parts of alkyl amino acetate, 10-15 parts of polyoxyethylene alkyl phenylate, 6-15 parts of triclosan, 5-10 parts of protamine, 10-15 parts of monoglyceride citrate, 5-10 parts of zinc acetate, 5-15 parts of iodophor and 60-70 parts of deionized water. When being used, the disinfectant disclosed by the invention has the minimum influence on health of users. The disinfectant is capable of effectively disinfecting air in the presence of people, and is an environmentally friendly and economic disinfectant.

Owner:林康

Environmental cleaning agent

InactiveCN106811341ALow damage indexLow global warming effectOrganic non-surface-active detergent compositionsEnvironmental resistanceDistillation

The invention relates to an environment-friendly cleaning agent. The environment-friendly cleaning agent comprises raw materials in terms of use amount: 94%-95% of 1-bromopropane, 3%-4% of n-propanol; 0.2% of nitromethane, 0.8% of 1,3-dioxolane, 0.7% of epoxybutane, and 0.3% of BHT. The environment-friendly cleaning agent has the advantages of being low in ozone destruction index, low in earth warming effect, good in environmental protection effect, high in the cleaning efficiency and the penetrating force, and the micro-porous material can be easily cleaned, the drying speed is high, the flash point is avoided, the hydrolysis degree is low, gas-liquid phase change is stable and the environment-friendly cleaning agent can be applied to steam cleaning, distillation recovery and the like.

Owner:周子童

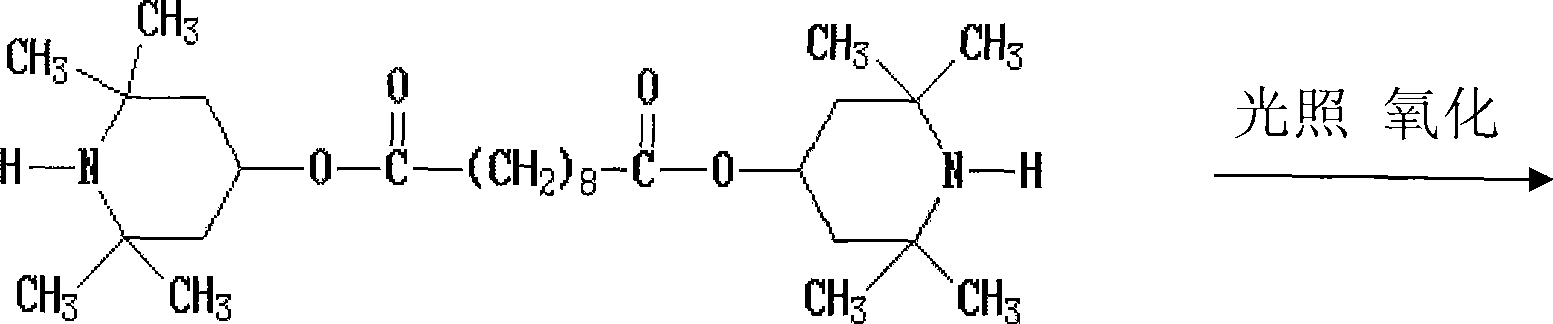

Method for improving stability of 1-methybrom

ActiveCN101367705APrevent oxidationAvoid decomposition and discolorationHalogenated hydrocarbon separation/purificationBiochemical engineeringDecomposition

The invention provides a method of improving the stability for 1-bromopropane. The method comprises: (1) filling the package vessel of the 1-bromopropane product with nitrogen; replacing air; preventing the 1-bromopropane product from oxygenation; (2) filling the vessel of step one with the 1-bromopropane product; (3) filling the 1-bromopropane product which is obtained from step two with ethylhexyl sebate (2,2,6,6-tetramethyl pyridyl) which is 1 to 5 thousandths of the quality thereof in order to prevent the 1-bromopropane product from decomposition and discoloration. The invention can isolate air and prevent the 1-bromopropane product from oxygenation. Alkyl radical can be captured effectively. The 1-bromopropane product is prevented from decomposition and discoloration. The stability of the 1-bromopropane product can be improved.

Owner:TIANJIN CHANGLU HAIJING GRP CO LTD

1-bromopropane having low acidity

This invention provides a process which comprises mixing permanganate with a 1-bromopropane product mixture to form a permanganate-containing 1-bromopropane product mixture, and recovering a purified 1-bromopropane product from said permanganate-containing 1-bromopropane product mixture. This invention also provides a process for preparing a 1-bromopropane product mixture from 1-propanol and hydrogen bromide, characterized by mixing permanganate with the 1-bromopropane product mixture to form a permanganate-containing 1-bromopropane product mixture and recovering a purified 1-bromopropane product from said permanganate-containing 1-bromopropane product mixture.

Owner:ALBEMARLE CORP

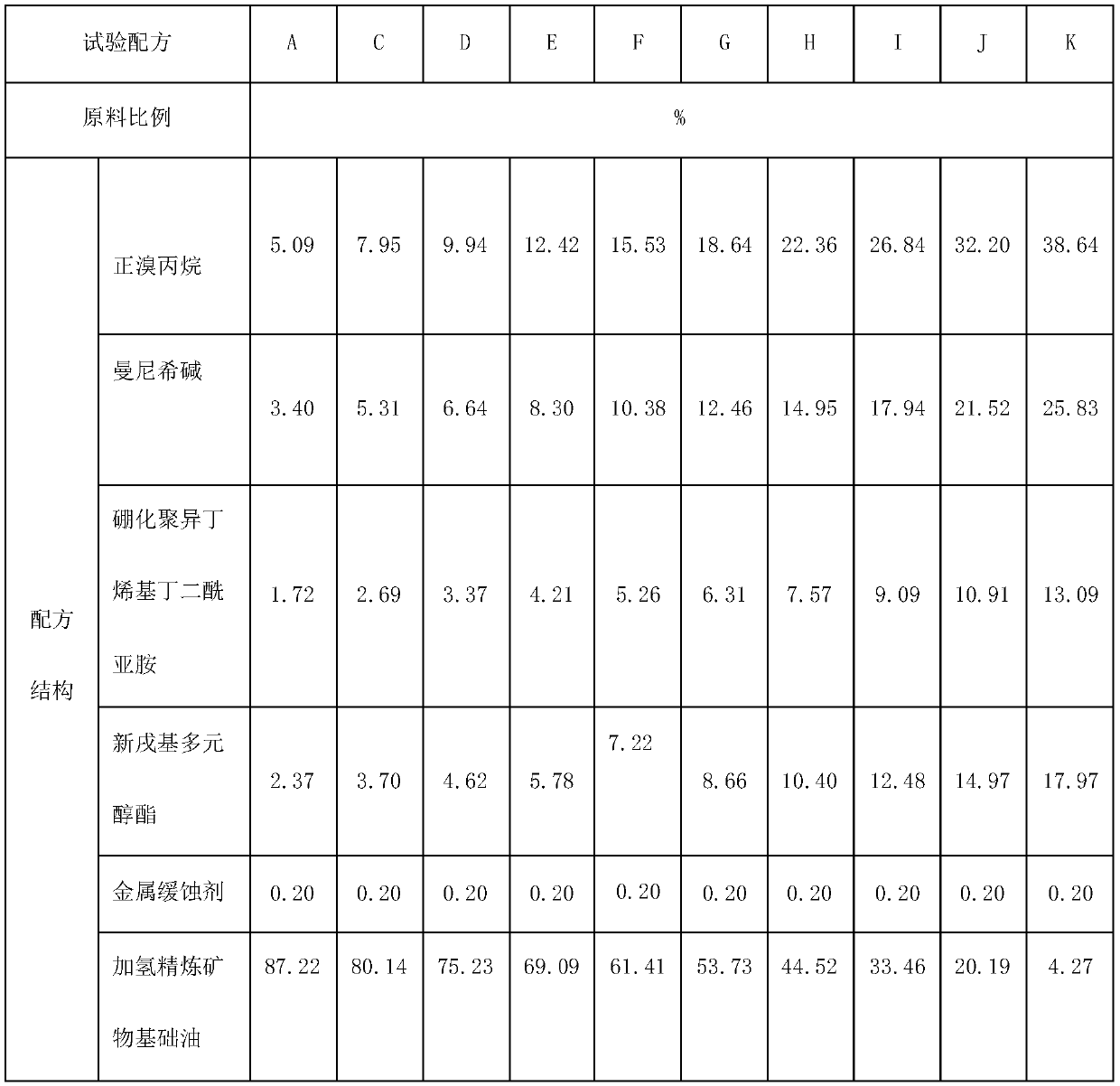

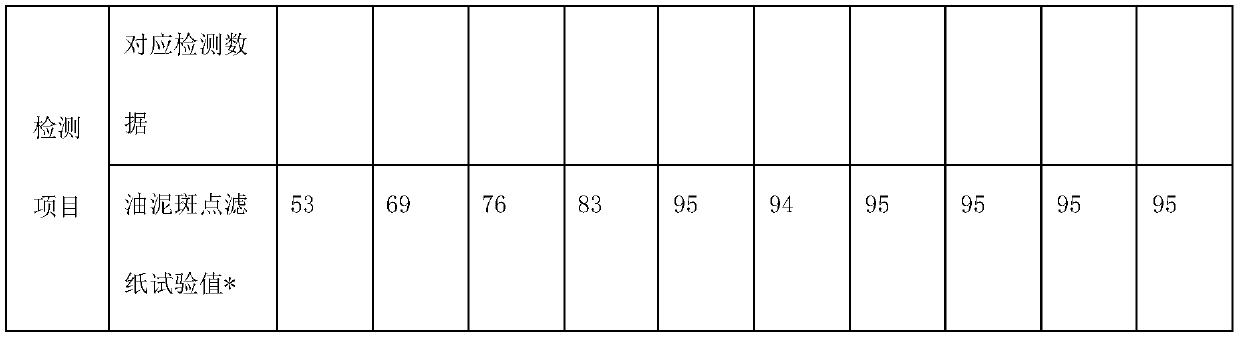

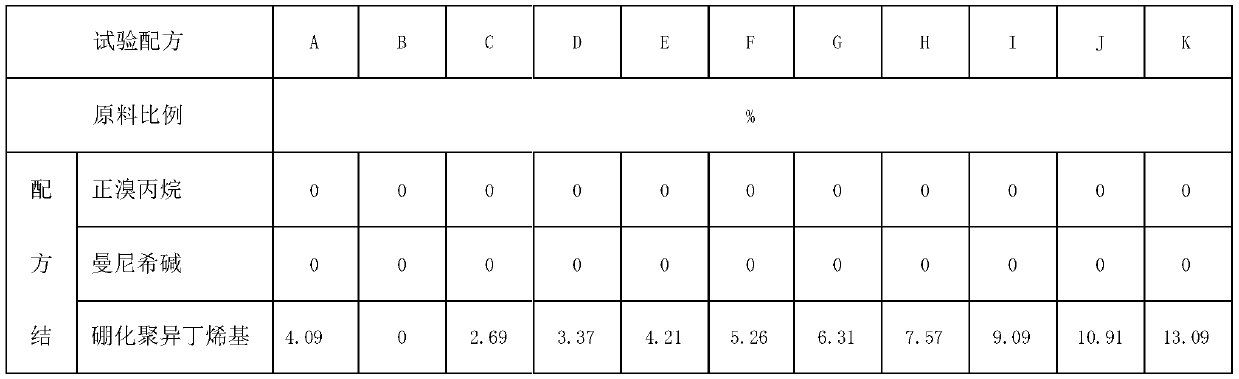

Dismantle-free cleaning composition for automotive engine lubricating system sludge and preparation method and application thereof

InactiveCN109825383AEfficient removalEffective dispersionOrganic non-surface-active detergent compositionsPolyolSludge

The invention belongs to the technical field of cleaning and discloses a dismantle-free cleaning composition for automotive engine lubricating system sludge and a preparation method and application thereof, wherein the dismantle-free cleaning composition comprises, by mass, 2-35% of 1-bromopropane, 2-35% of Mannich base, 2-35% of boronated polyisobutylene succinimide, 5-80% of neopentyl polyol ester, 0-0.2% of a metal corrosion inhibitor, and the balance of mineral base oil. The dismantle-free cleaning composition provided herein is effective in removing and dispersing carbon deposition and sludge in an engine lubricating system, has good antiwear and antifriction effects, and ensures that the parts of the engine lubricating system never wear.

Owner:江苏云瀚股份有限公司

Multifunctional powerful oil cleaning agent

InactiveCN108659970AEasy to cleanLow toxicityOrganic detergent compounding agentsSurface-active detergent compositionsCleansing Agents1-Bromopropane

The invention discloses a multifunctional powerful oil cleaning agent which comprises water, 1-bromopropane, fatty alcohol polyoxyethylene ether, pine oil, essence, trichloroethylene and p-chloro-m-xylenol. In the above manner, the multifunctional powerful oil cleaning agent provided by the invention not only can remove the newly generated oil, but also can remove the old oil, and has advantages of strong cleaning ability, low toxicity and better practicability.

Owner:SUZHOU RUINAIJIE ELECTRONICS SCI & TECH NEW MATERIAL

Anti-corrosion and water-repellent substance and method

ActiveUS9617645B1Improve adhesionAvoid Surface CorrosionLiquid surface applicatorsAnti-corrosive paintsParaffin waxNitromethane

An anti-corrosion and water-repellent substance configured for application to surfaces of materials to prevent corrosion and otherwise protect those materials. The substance consists of 1-bromopropane, nitromethane, ethyloxirane, and highly refined paraffin wax. In a preferred embodiment of a method of treating materials, the anti-corrosion and water-repellent substance is sprayed on a surface. In other embodiments, the substance may be applied with a brush or roller. In yet another embodiment, the substance may be applied by immersing the items being treated for optimal coverage of their exposed surfaces. The substance adheres to various materials and protects them by repelling water, acids, salt brines, and other substances and elements, including corrosives.

Owner:MICROCOR TECH INC

Solvent composition for dissolving plastics

The present invention provides a solvent composition comprises isopropyl bromide and / or normal propyl bromide and one or two or more kinds of nitroalkane in an amount of 15-40 wt.% based on the whole amount.

Owner:KANEKO KAGAKUKK

A method for asymmetric catalytic synthesis of (s) aromatic curcumene

The invention discloses a method for asymmetrically catalyzing and synthesizing (S)-curcumene. According to the method, racemization 2-halogenated propionate ester serves as a starting material, under the catalysis of bis oxazoline / cobalt, an asymmetrical Kumada cross coupling reaction is conducted, and (R)-2-p-methylphenyl propionate is obtained; then, (R)-2- p-methylphenyl-1-bromopropane is generated through reduction and bromine generation; next, coupling with vinyl Grignard reagent is conducted, borohydride-oxidation and Dess-Martin oxidation are conducted, and (S)-4-p-methylphenyl valeraldehyde is obtained; finally, a Wittig reaction is conducted, and (S)-curcumene is synthesized. The method is simple and concise in synthesis route, the total yield is 37%, and the optical purity of a product is 90%.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com