Method for preparing 1-bromopropane

A technology of bromopropane and propylene, which is applied in the field of preparing 1-bromopropane, can solve the problems of high production cost and difficult price of n-propanol, achieve low production cost, overcome high production cost, and reduce equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

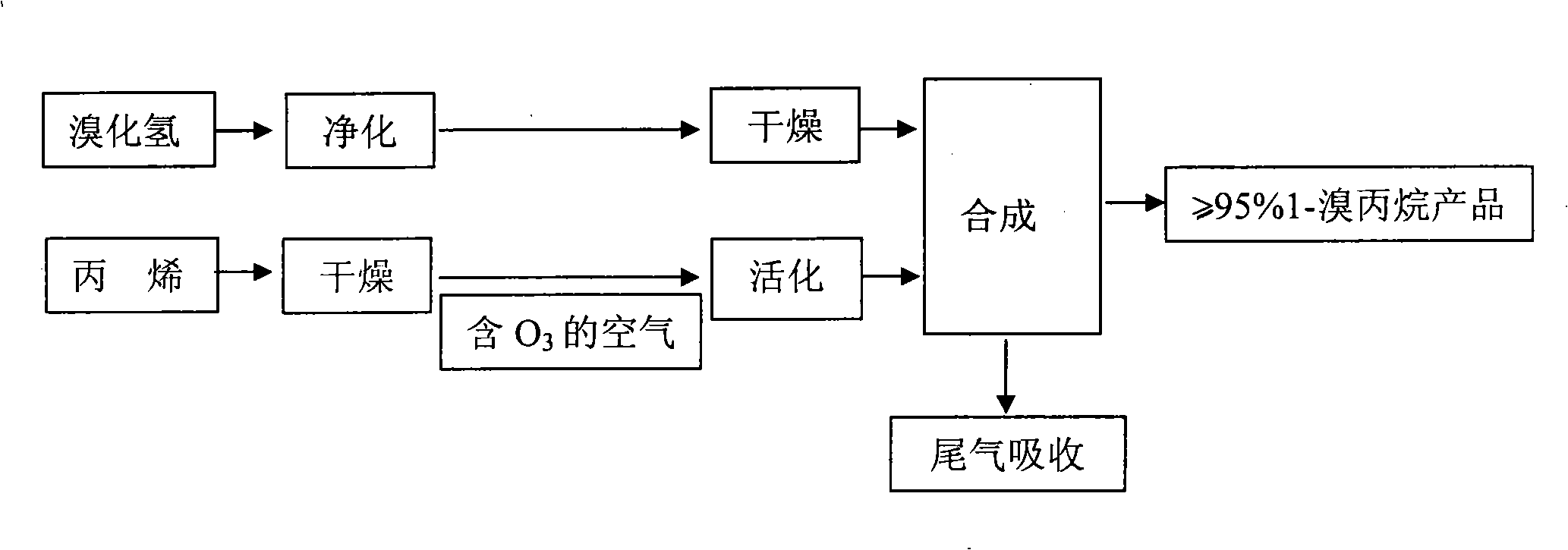

Method used

Image

Examples

Embodiment 1

[0023] Add 1 ton of 1-bromopropane base material containing 95% in the reaction equipment, open the propylene valve after 2 minutes of starting the circulation pump, the propylene amount is 274mol / h, and open the ozone machine at the same time, so that the gas output of the ozone machine is 0.6m 3 / h, the ozone content is 25ppm. After the ozone-containing gas and propylene are activated in the activation device, they enter the reaction equipment to dissolve the activated propylene in 1-bromopropane. Then open the hydrogen bromide valve after purification and drying, so that the flow rate of hydrogen bromide is 277mol / h into the reaction equipment, hydrogen bromide and activated propylene undergo free radical addition reaction, and the reaction temperature is strictly controlled by circulating water to be 35 ~38°C. After the tail gas passes through the tail gas absorption device, the unreacted hydrogen bromide gas is absorbed, and a small amount of non-condensable gas is discha...

Embodiment 2

[0025] Add 1.2 tons of 1-bromopropane bottom material containing 95% in the reaction equipment, open the propylene valve after 3 minutes of opening the circulation pump, the propylene amount is 365mol / h, open the ozone machine at the same time, make the gas output of the ozone machine be 0.6m 3 / h, the ozone content is 30ppm, after the ozone-containing gas and propylene are activated in the activation device, they enter the reaction equipment, so that the activated propylene is dissolved in 1-bromopropane. Then open the hydrogen bromide valve after purification and drying, so that the flow rate of hydrogen bromide is 372mol / h into the reaction equipment, hydrogen bromide and activated propylene undergo free radical addition reaction, and the reaction temperature is strictly controlled by circulating water to be 35 ~38°C. After the tail gas passes through the tail gas absorption device, the unreacted hydrogen bromide gas is absorbed, and a small amount of non-condensable gas is...

Embodiment 3

[0027] Add 1 ton of 1-bromopropane base material containing 95% in the reaction equipment, open the propylene valve after 2 minutes of starting the circulation pump, the propylene amount is 502mol / h, and open the ozone machine at the same time, so that the gas output of the ozone machine is 0.6m 3 / h, the ozone content is 40ppm, after the ozone-containing gas and propylene are activated in the activation device, they enter the reaction equipment, so that the activated propylene is dissolved in 1-bromopropane. Then open the hydrogen bromide valve after purification and drying, so that the flow rate of hydrogen bromide is 512mol / h into the reaction equipment, hydrogen bromide and activated propylene undergo free radical addition reaction, and the reaction temperature is strictly controlled by circulating water to be 35 ~38°C. After the tail gas passes through the tail gas absorption device, the unreacted hydrogen bromide gas is absorbed, and a small amount of non-condensable gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com