Method for controlling stability of high-stage stope filling body

A filling body and high-level technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve problems such as loss of side support, threat to mine safety production, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

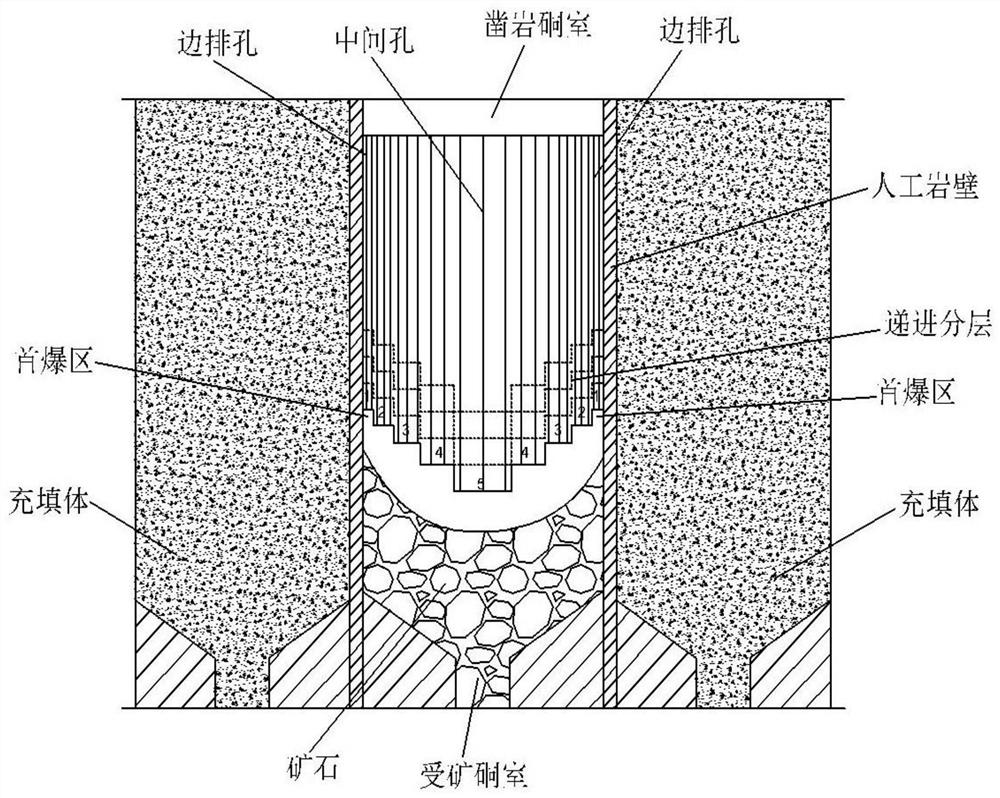

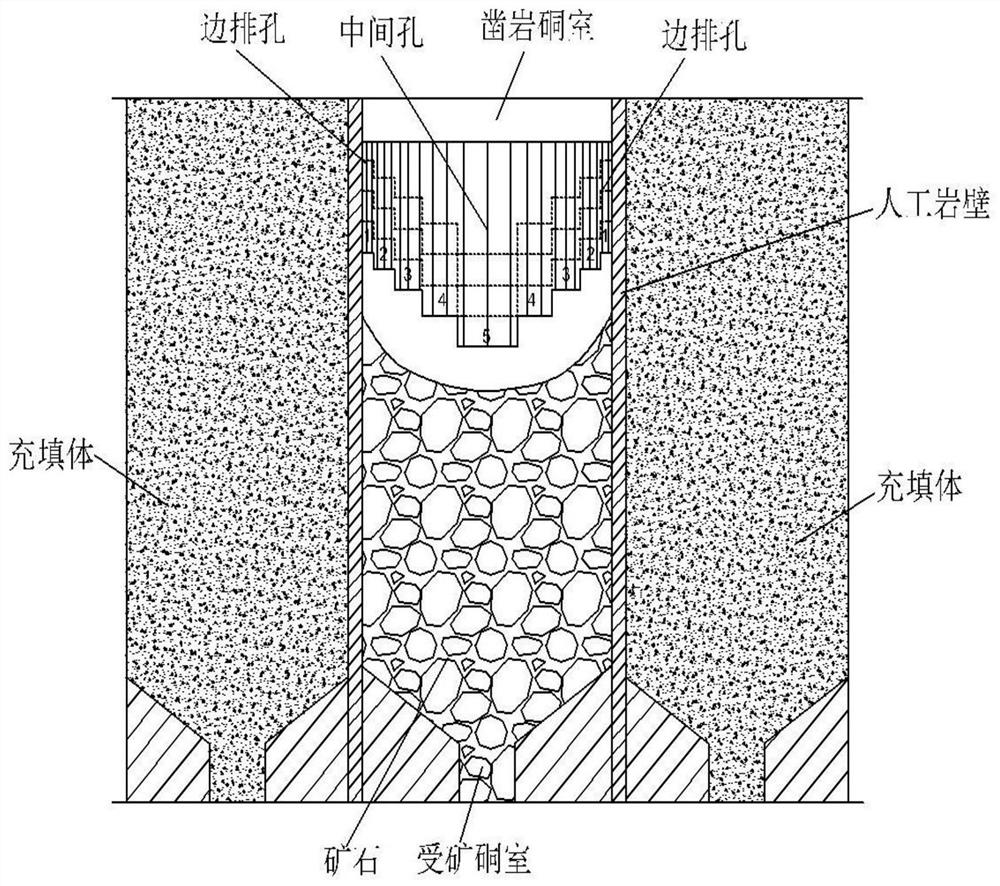

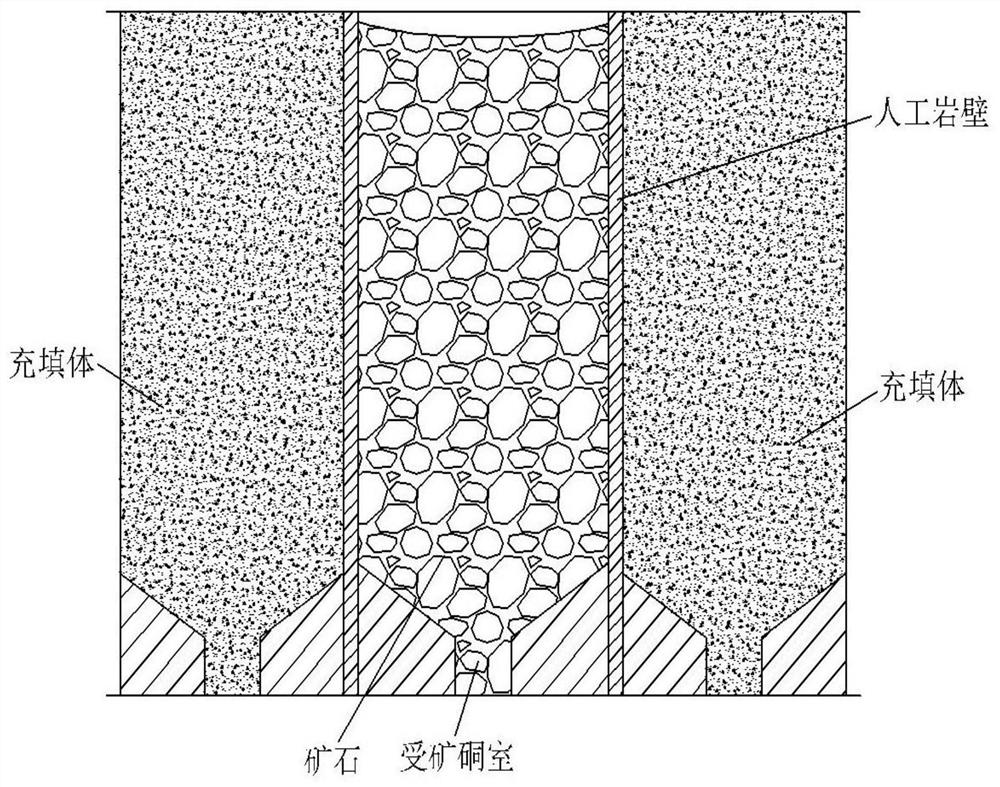

[0022] The invention discloses a method for controlling the stability of the stope filling body at a high stage, which includes two stages. The first stage is the stage of restricting the movement and deformation of the filling body by using the original rock and the blasted ore during the mining process; the second stage is the post-mining utilization Waste rock filling controls the stability stage of the filling body.

[0023] Such as Figure 1 to Figure 3 Shown:

[0024] In the first stage, the stope to be mined is divided into several progressive layers from bottom to top, and each progressive layer is divided into several mining units through precise design of blasthole positions, and only one or two of them are mined each time The unit is charged and blasted to reduce the amount of blasting charge and reduce the impact of blasting vibration on the filling body.

[0025] After the single progressive layer blasting is completed, a downward step extending from the stope bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com