A method for taking out a heat transfer tube of a steam generator

A steam generator and heat transfer tube technology, applied in the field of nuclear power maintenance, can solve problems such as vibration, radioactive leakage, and easy risk, and achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

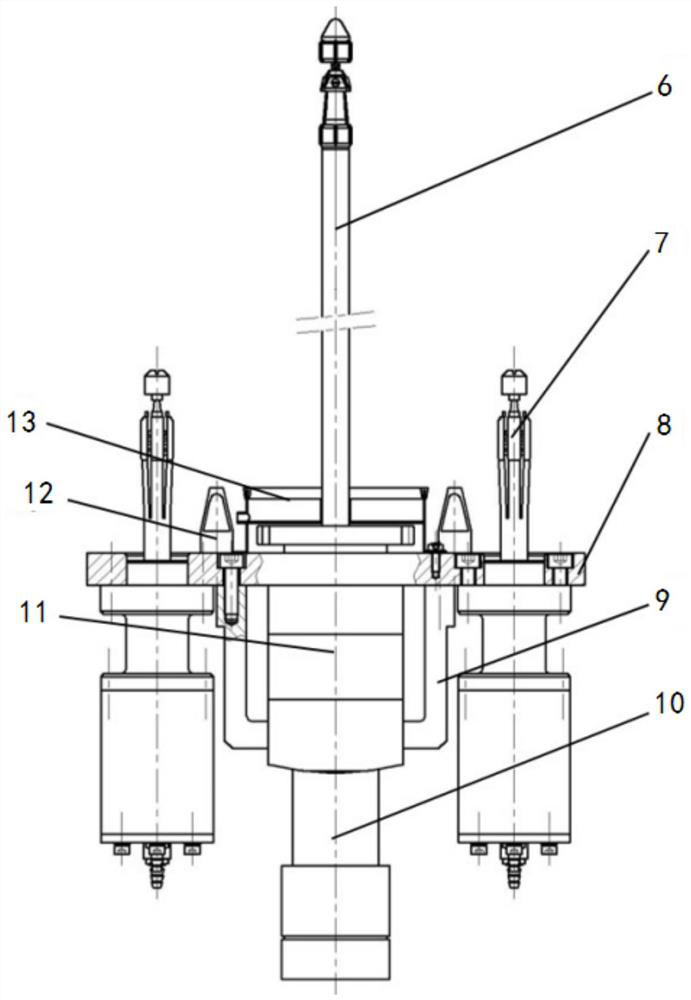

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

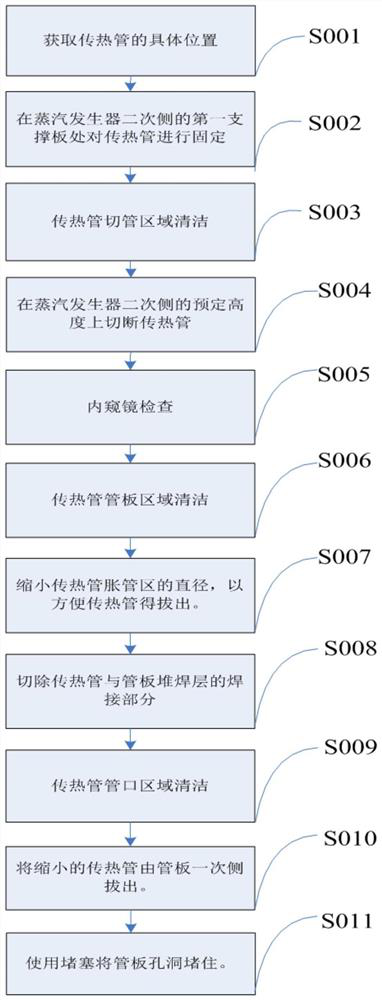

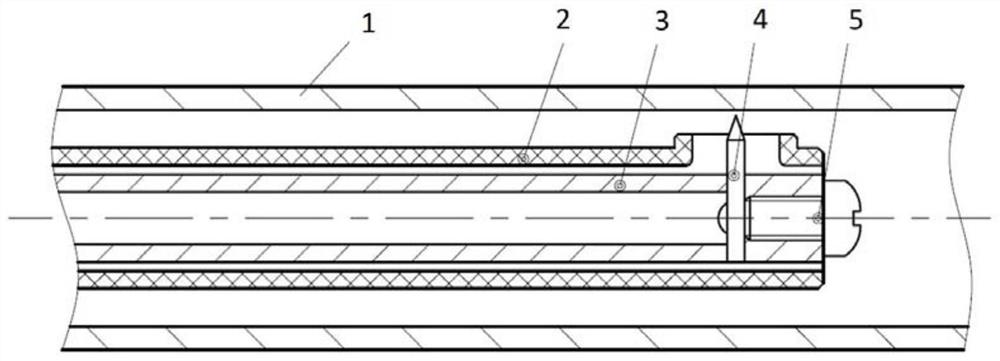

[0037] This embodiment provides a method for taking out the heat transfer tubes of a steam generator. The heat transfer tubes are taken out from the primary side of the tube hole of the steam generator tube sheet to overcome various difficulties and harsh conditions brought about by taking out the tubes from the secondary side. . Its process is as follows figure 1 As shown, the following steps are included in sequence:

[0038] S1. Obtain the specific position of the heat transfer tube

[0039] Since the heat transfer tube is taken out on the primary side, the specific position of the heat transfer tube to be taken out on the primary side of the steam generator needs to be obtained. The primary side of the tube hole of the steam generator tube sheet is densely covered with thousands of heat transfer tubes. The position can be obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com