Energy-saving transformer with self-adaptation function

An energy-saving transformer and self-adaptive technology, applied in the direction of transformers, variable transformers, transformer/inductor cores, etc., can solve the problems of organic combination of energy-saving technologies, difficult processing, increased reactive power loss, etc., to improve the safety level and power supply quality, improve safety and service life, and reduce the effect of no-load loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

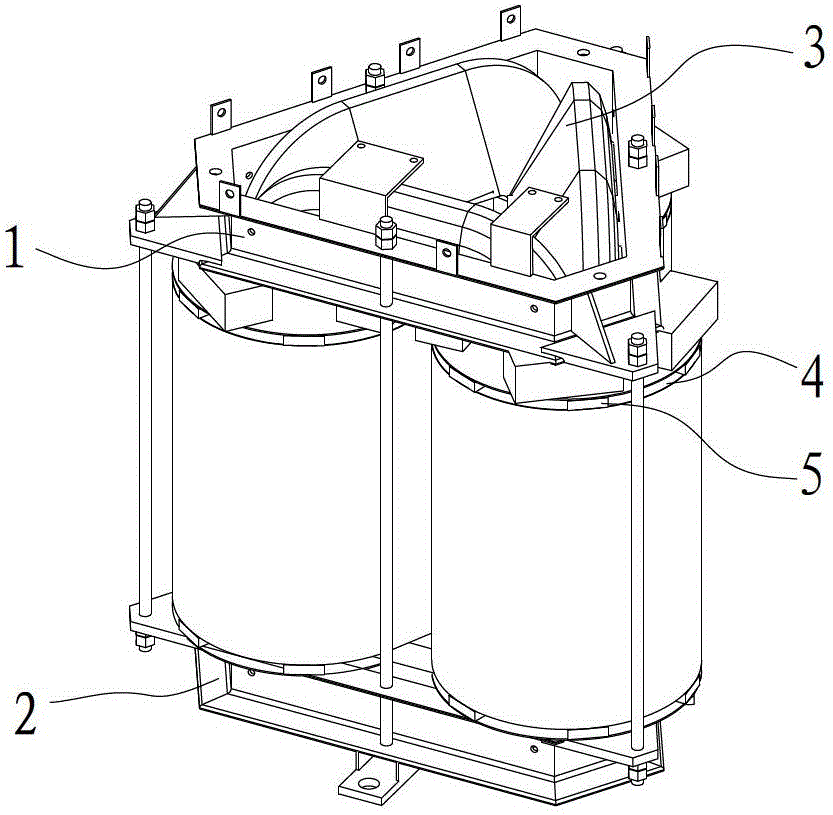

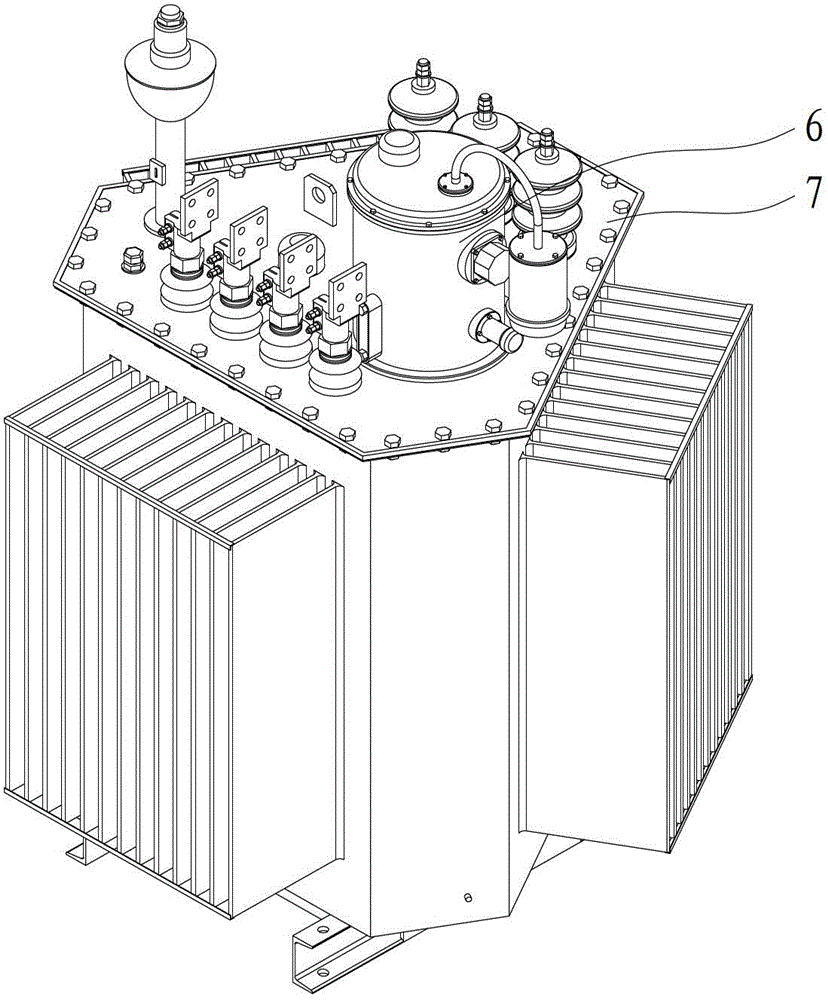

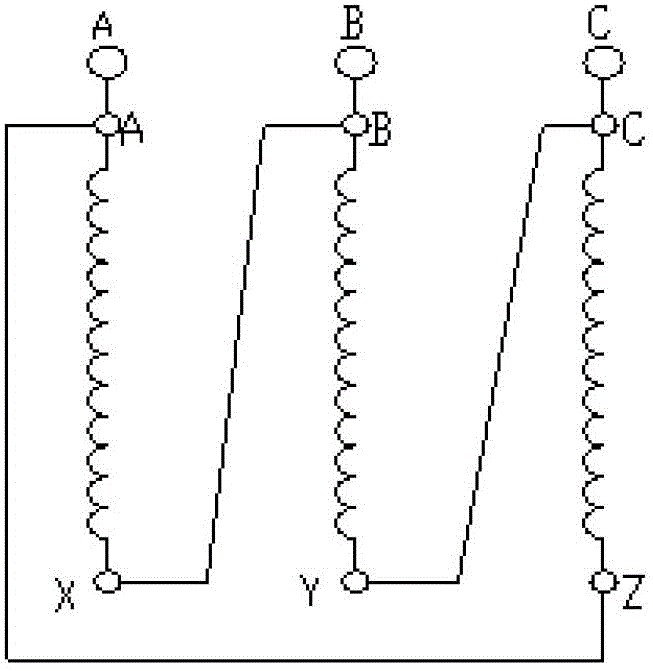

[0046] The present invention provides an energy-saving transformer with adaptive function, such as figure 1 as shown, figure 1 It is the internal structure diagram of the energy-saving transformer provided by the present invention, including: an upper clamp 1 and a lower clamp 2, a three-dimensional wound core 3 is arranged between the upper clamp 1 and the lower clamp 2, and a low-voltage winding is wound on the three-dimensional wound core 3 4 and the high-voltage winding 5, the low-voltage winding and the high-voltage winding taps are connected with a special on-load capacity adjustment switch 6, and the on-load capacity adjustment switch is installed on the fuel tank 7, such as figure 2 as shown, figure 2 It is the outline drawing of the energy-saving transformer provided by the present invention.

[0047] Through the use of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com