Power transformer based on modular combination

A power transformer, modular technology, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve the problems of not being able to adapt to socialized production and repeated transportation , to achieve the effect of convenient disassembly, replacement and recycling, small size, and reasonable and compact body structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Figure 1-12 It is a figure which shows each embodiment of this invention. The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but this does not constitute any limitation to the present invention.

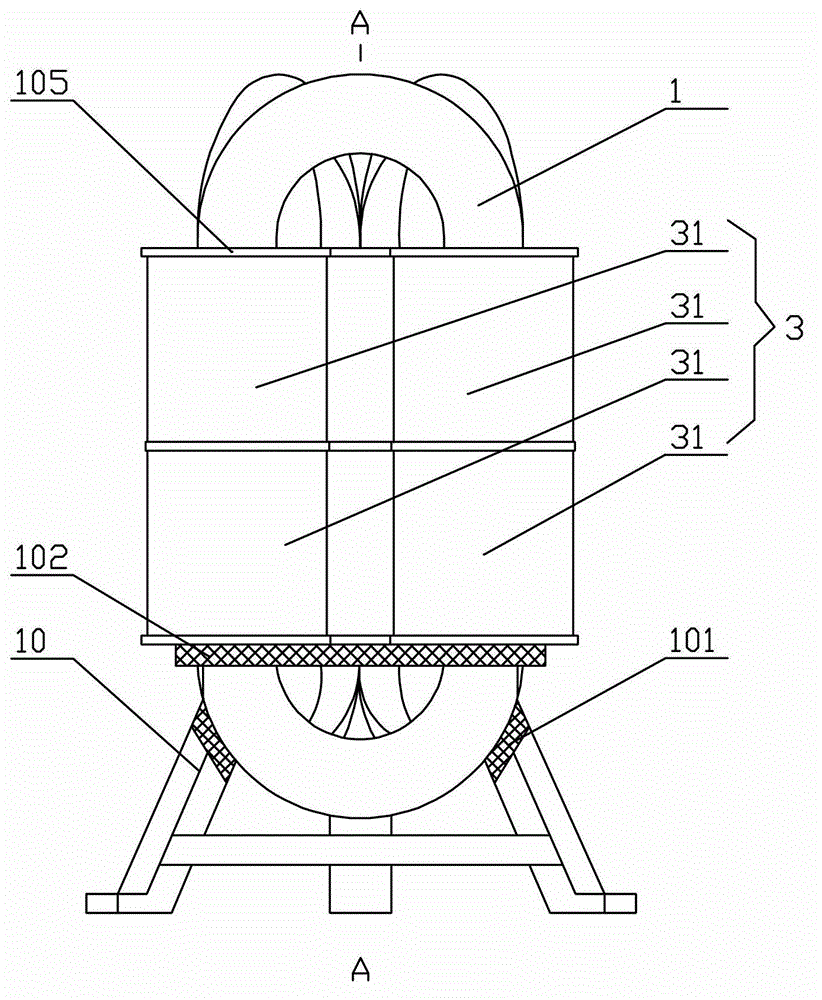

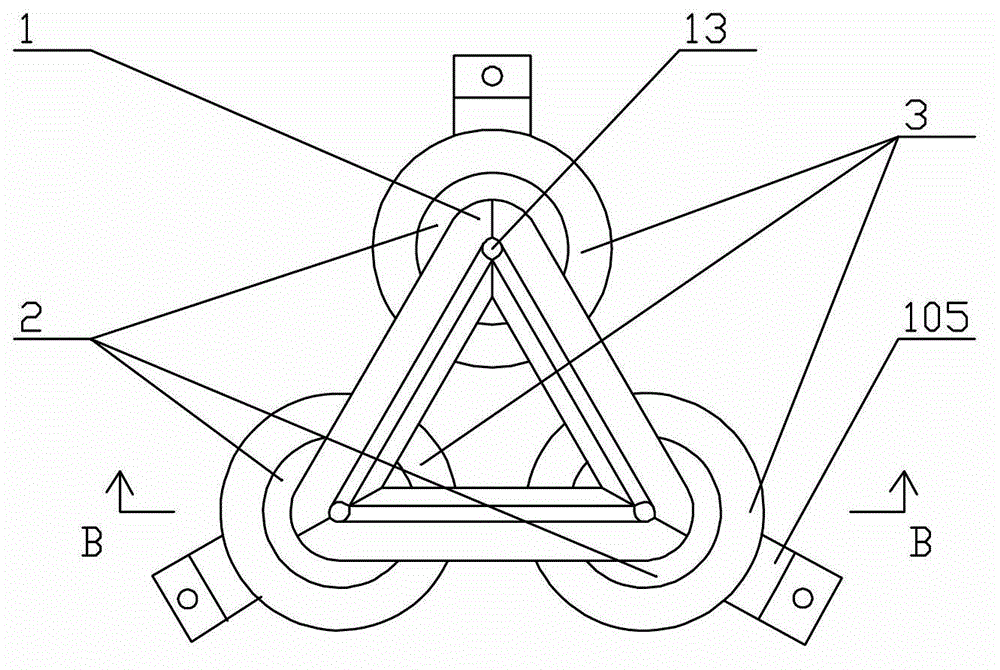

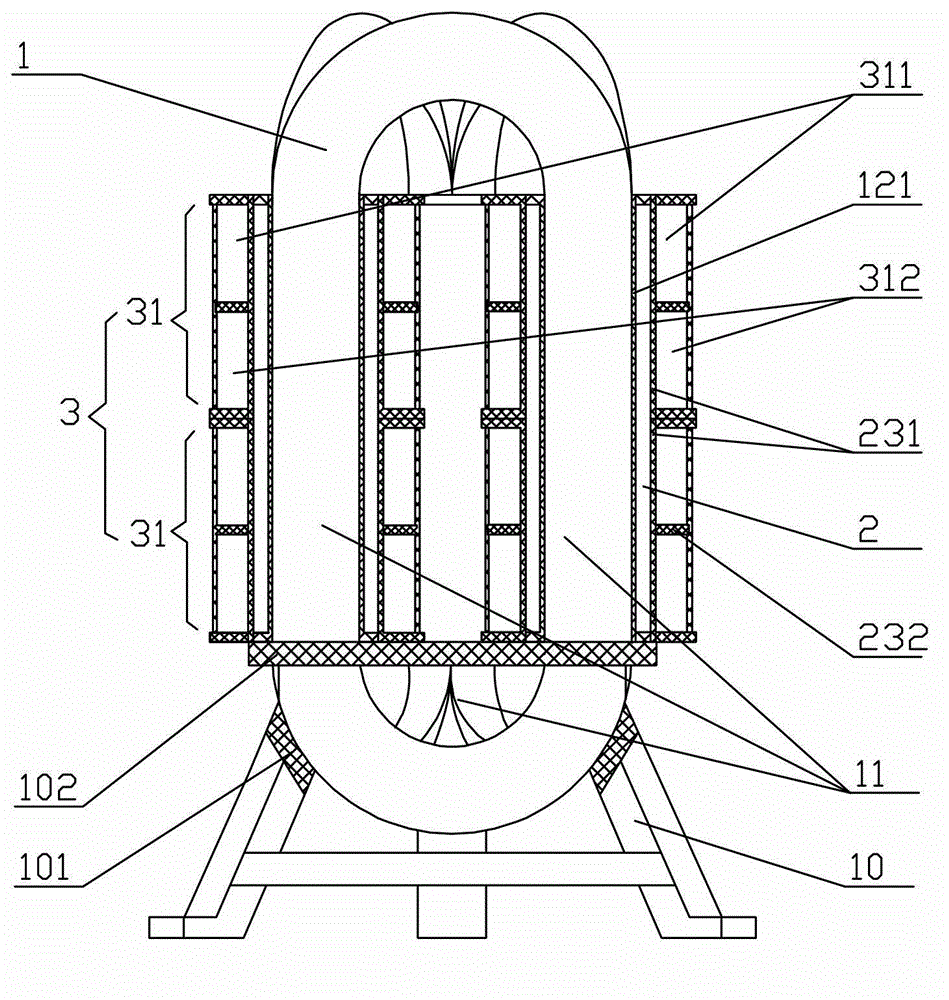

[0030] figure 1 , 2 , 4, 6 are overall or partial appearance schematic diagrams of the power transformer of the modular combination of the present invention, wherein Figure 4 Shown is a schematic view of the appearance structure of the three-dimensional wound core 1 of the transformer. The three-dimensional wound core is formed by combining the frames of three wound core elements 11 in pairs. and figure 1 shows the partial appearance structure of the combined three-phase iron core 1 and high-voltage foil winding 3, figure 2 yes figure 1 Example top view. image 3 yes figure 2 The BB sectional view of , which shows the internal structure of the transformer with the low-voltage wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com