Steaming exhaust structure and electric steam box with same

A technology for steaming and exhausting steam, which is applied in the field of electric steamers and can solve problems such as the reduction of steam condensation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

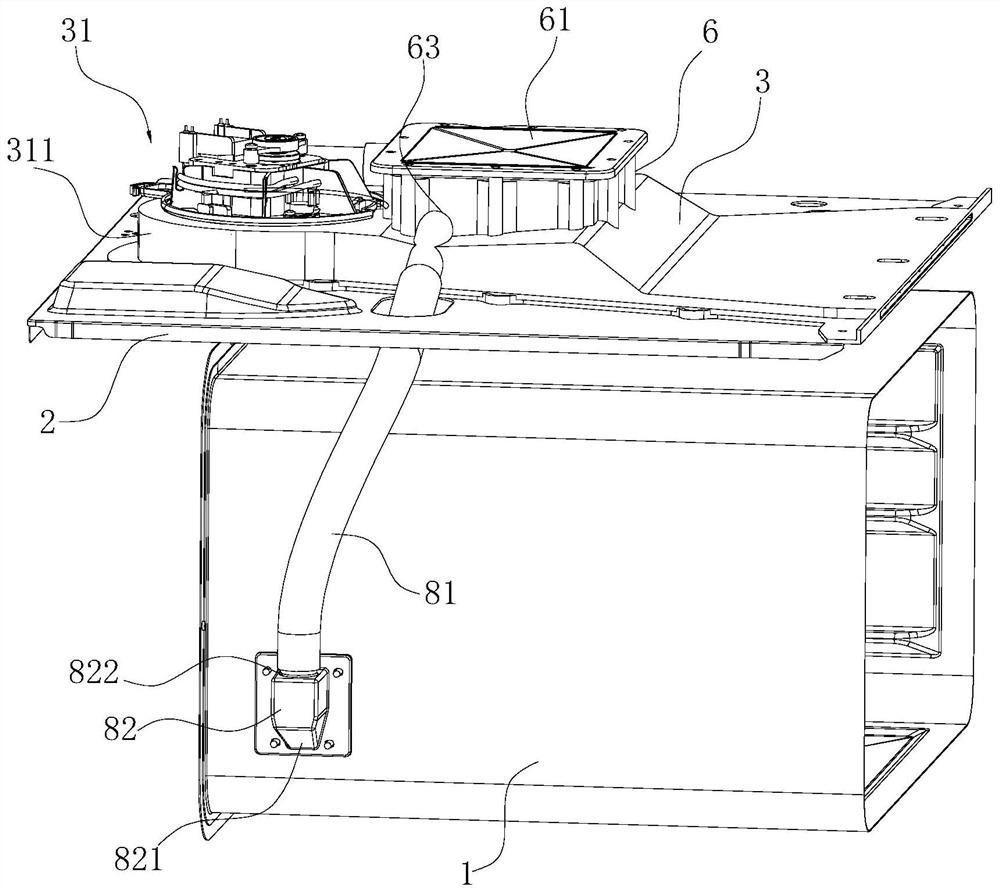

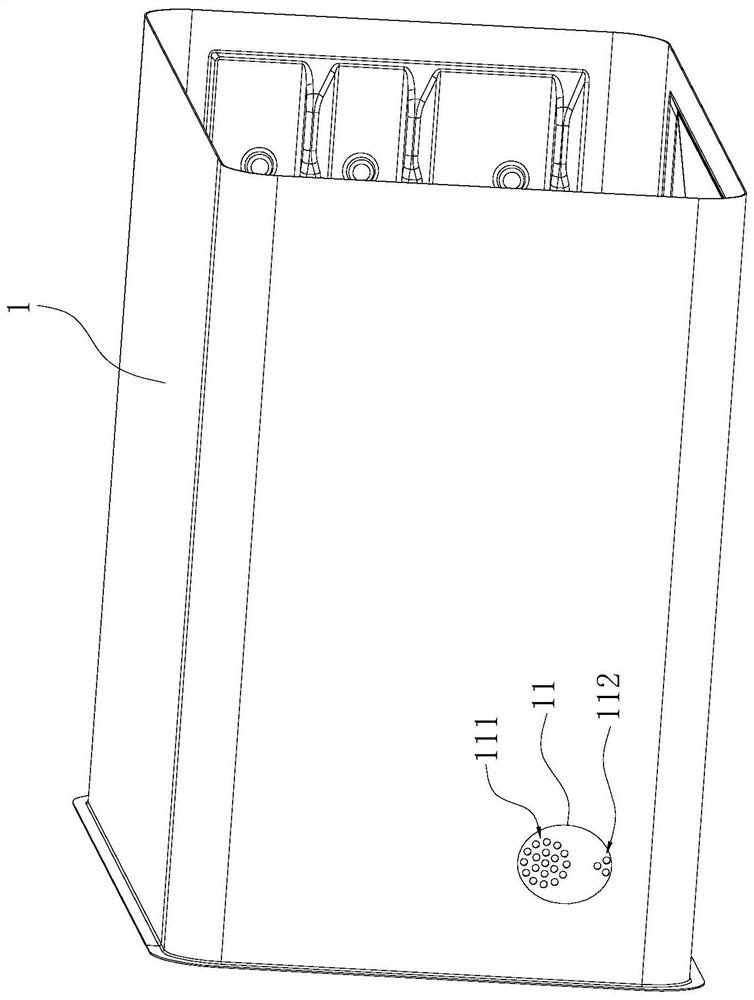

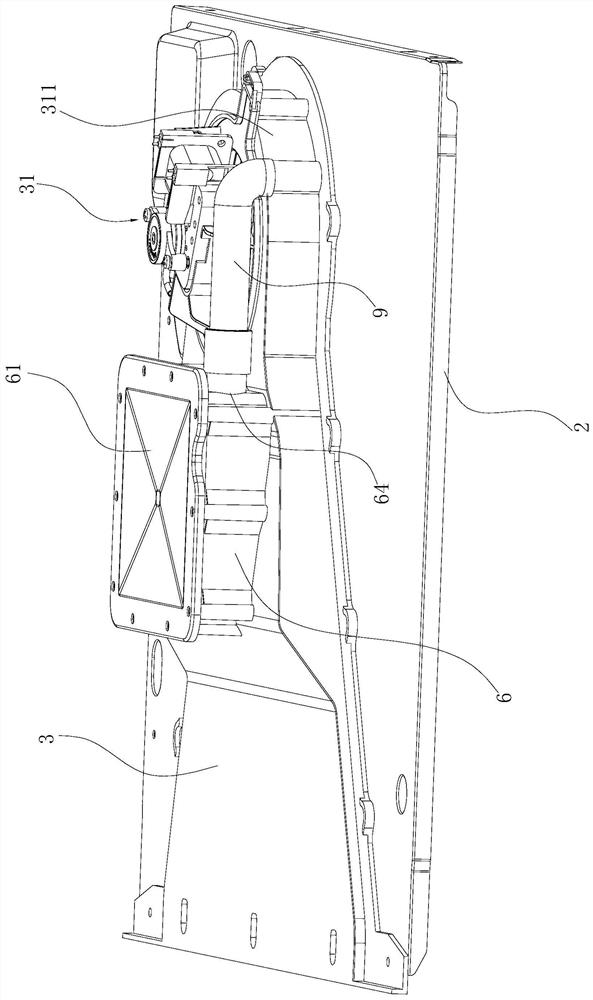

[0040] Such as Figure 1~6 As shown, an electric steamer includes a steaming exhaust structure, the steaming exhaust structure includes an inner tank 1, an upper mounting plate 2 is arranged above the inner tank 1, and the upper mounting plate 2 is covered with a The wind deflector 3, the heat dissipation channel 30 is surrounded between the wind deflector 3 and the upper surface of the upper mounting plate 2, and the upper cover of the wind deflector 3 is provided with a square condensation cover 6, and the condensation cover 6 and the wind deflector The upper surface of 3 encloses a condensation chamber 60, wherein, the steam inlet 63 of the above-mentioned condensation chamber 60 is in fluid communication with the steam exhaust port 11 of the above-mentioned liner 1 (the phase fluid communication here can have multiple realizations: when the condensation When the steam inlet 63 of the cavity 60 is adjacent to the steam exhaust port 11 of the inner bag 1, the two can be dire...

Embodiment 2

[0049] Such as Figure 7-9 As shown, different from Embodiment 1, the first air channel 30A can be opened and closed in this embodiment, and, when the temperature of the second cooling plate 62 is lower than the preset temperature (the preset temperature in this embodiment is When the second cooling plate 62 cannot condense the upper limit temperature of steam), the first air channel 30A is closed, and when the temperature of the second cooling plate 62 is higher than the preset temperature, the second air channel 30B is opened. Through the opening and closing of the first air passage 30A, on the one hand, when the temperature of the second cooling plate 62 is low, the exhaust gas entering the heat dissipation passage 30 can be concentrated through the second air passage through the closing of the first air passage 30A. 30B, thereby increasing the exhaust speed (by reducing the exhaust area to increase the air pressure inside the heat dissipation channel 30, thereby increasing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com